81:(mMTs), for example a miniaturized milling machine, is an expansion of using traditional macroscale techniques to manufacture mesoscale products. With the limitation of self-excited vibration of machine tools and fatigue, microassembly and micro- and mesoscale milling are created to improve the maximum stiffness and dynamic operation of the milling process, which improves the overall performance of manufacturing. The development of mMTs has revealed many challenges that are specific to machining at the small scales. These challenges stem from the large influence of grain size at small scales and the necessity of extremely small tolerances for both the machine tools and the measuring tools.

17:

68:, and extremely small motors and bearings; lenses for cameras and other micro parts for mobile telephones; micro-batteries, mesoscale fuel cells, microscale pumps, valves, and mixing devices for microchemical reactors; biomedical implants, microholes for fiber optics; medical devices such as stents and valves; mini nozzles for high-temperature jets; mesoscale molds; desktop- or micro-factories, and many others.

27:

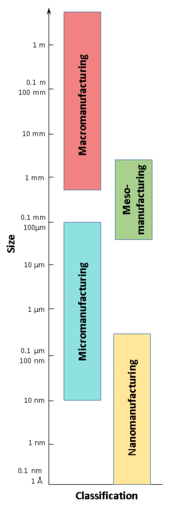

is the process of creating components and products in a range of approximately from 0.1mm to 5mm with high accuracy and precision using a wide variety of engineering materials. Mesomanufacturing processes are filling the gap between macro- and micromanufacturing processes and overlaps both of them

87:

is a traditional technique that uses nanosecond pulses of ultraviolet light to create mesoscale features like holes, fillets, etc. The removal of material during laser machining is proportional to exposure time and therefore this process can be used to create three dimensional features.

76:

Manufacturing in the mesoscale can be accomplished by scaling down macroscale manufacturing processes or scaling up nanomanufacturing processes. Macroscale techniques like mill and lathe machining have been successful used to create features in the range of 25 μm. Meso

109:

and the work piece and therefore it can only be used to manufacture materials that conduct electricity. One advantage of EDM is that it can be used on hard materials that do not work well in traditional machining processes, such as titanium.

99:, to the work piece, causing material to be removed. FIB sputtering has a relatively low rate of material removal and therefore has limited application.

105:(EDM) is another subtractive manufacturing process used in the mesoscale. This process requires that electricity be transferred between the tool

191:

102:

272:

32:(< 100 nm), microscale (100 nm to 100 μm) and macroscale manufacturing (> 0.5 mm).

150:

216:

132:"Mesoscale and Microscale Manufacturing Processes: Challenges for Materials, Fabrication and Metrology"

249:

209:"Adaptively tuned micromanipulator and fixturing mechanism for micro and mesoscale manufacturing"

95:

sputtering (FIB) to remove material. This process involves focusing a beam of ions, for example

16:

187:

162:

92:

65:

29:

229:

266:

84:

61:

45:

78:

41:

208:

106:

57:

53:

96:

167:

49:

248:

Benavides, Gilbert L.; Adams, David P. (June 2001).

28:(see picture). Other manufacturing technologies are

131:

64:, and other areas. Specific applications include

155:Journal of Manufacturing Science and Engineering

182:Kalpakjian, Serope; Schmid, Steven R. (2006).

130:Dow, T. A.; Scattergood, R. O. (Winter 2003).

8:

184:Manufacturing, Engineering & Technology

136:American Society for Precision Engineering

166:

149:Dohda, Kuniaki; Ni, Jun (November 2004).

40:Application of mesomanufacturing include

15:

119:

91:A less traditional technique is to use

225:

214:

7:

243:

241:

239:

125:

123:

207:Moore, Paul Michael (2014-01-01).

186:. Pearson Education. p. 858.

14:

151:"Micro/Meso-scale Manufacturing"

255:. Sandia National Laboratories.

103:Electrical discharge machining

1:

250:"Meso-Machining Capabilities"

20:Manufacturing Classification

289:

211:. UNIVERSITY OF FLORIDA.

25:Mesoscale manufacturing

224:Cite journal requires

21:

19:

273:Industrial processes

66:mechanical watches

22:

168:10.1115/1.1814125

280:

257:

256:

254:

245:

234:

233:

227:

222:

220:

212:

204:

198:

197:

179:

173:

172:

170:

146:

140:

139:

127:

93:focused ion beam

288:

287:

283:

282:

281:

279:

278:

277:

263:

262:

261:

260:

252:

247:

246:

237:

223:

213:

206:

205:

201:

194:

181:

180:

176:

148:

147:

143:

129:

128:

121:

116:

85:Laser machining

74:

38:

12:

11:

5:

286:

284:

276:

275:

265:

264:

259:

258:

235:

226:|journal=

199:

192:

174:

141:

118:

117:

115:

112:

73:

70:

62:communications

37:

34:

13:

10:

9:

6:

4:

3:

2:

285:

274:

271:

270:

268:

251:

244:

242:

240:

236:

231:

218:

210:

203:

200:

195:

193:0-13-148965-8

189:

185:

178:

175:

169:

164:

160:

156:

152:

145:

142:

137:

133:

126:

124:

120:

113:

111:

108:

104:

100:

98:

94:

89:

86:

82:

80:

79:Machine tools

71:

69:

67:

63:

59:

55:

51:

47:

46:biotechnology

43:

35:

33:

31:

26:

18:

217:cite journal

202:

183:

177:

158:

154:

144:

135:

101:

90:

83:

75:

39:

36:Applications

24:

23:

42:electronics

161:(4): 641.

114:References

107:electrode

72:Processes

30:nanoscale

267:Category

58:avionics

54:medicine

97:gallium

190:

50:optics

253:(PDF)

230:help

188:ISBN

163:doi

159:126

269::

238:^

221::

219:}}

215:{{

157:.

153:.

134:.

122:^

60:,

56:,

52:,

48:,

44:,

232:)

228:(

196:.

171:.

165::

138:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.