17:

217:

483:

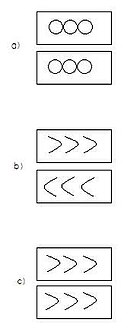

will result elongated dimples, which are parabolic depressions that coalesce in planes of maximum shear stress. The depressions point back to the crack origin, and shear influenced failure will produce depressions that point in opposite directions on opposing fracture surfaces. Combined tension and

66:

and the matrix. Additionally, microvoids often form at grain boundaries or inclusions within the material. Microvoids grow during plastic flow of the matrix, and microvoids coalesce when adjacent microvoids link together or the material between microvoids experiences

76:

50:

466:

62:

MVC proceeds in three stages: nucleation, growth, and coalescence of microvoids. The nucleation of microvoids can be caused by particle cracking or interfacial failure between

331:

269:

300:

387:

358:

538:

212:{\displaystyle \ln \left({\frac {\bar {R}}{R_{0}}}\right)=\int \limits _{0}^{\epsilon _{q}}A\left({\frac {3\sigma _{m}}{2\sigma _{ys}}}\right)d\epsilon _{v}^{p}}

239:

488:

will also produce the elongated dimple morphology, but the directions of the depressions will be in the same direction on both fracture surfaces.

611:

514:

71:. Microvoid coalescence leads to fracture. Void growth rates can be predicted assuming continuum plasticity using the Rice-Tracey model:

479:

results in equiaxed dimples, which are spherical depressions a few micrometres in diameter that coalesce normal to the loading axis.

564:

394:

660:

20:

655:

606:. Milne, I., Ritchie, R. O., Karihaloo, B. L. (1st ed.). Amsterdam: Elsevier/Pergamon. 2003. pp. 186–192.

635:

16:

63:

68:

309:

244:

629:

532:

475:

MVC can result in three distinct fracture morphologies based on the type of loading at failure.

303:

278:

363:

617:

607:

570:

560:

520:

510:

476:

336:

224:

649:

241:

is a constant typically equal to 0.283 (but dependent upon the stress triaxiality),

480:

272:

53:

MVC fracture surface morphologies for a) tension, b) shear, and c) bending failures

23:

image of microvoid coalescence seen on a ductile fracture surface of 6061-T6 Al

621:

524:

574:

589:

Deformation and

Fracture Mechanics of Engineering Materials, Fourth Edition

601:

43:

35:

509:. Wright, Wendelin J. (Seventh ed.). Boston, MA. pp. 236–237.

485:

49:

48:

39:

15:

461:{\displaystyle {\bar {R}}={\frac {R_{1}+R_{2}+R_{3}}{3}}}

397:

366:

339:

312:

281:

247:

227:

79:

460:

381:

352:

325:

294:

263:

233:

211:

591:. John Wiley and Sons, Inc, Hoboken, NJ: 1996.

557:Mechanical properties of engineered materials

8:

333:is the equivalent Von Mises plastic strain,

537:: CS1 maint: location missing publisher (

446:

433:

420:

413:

399:

398:

396:

368:

367:

365:

344:

338:

317:

311:

286:

280:

252:

246:

226:

203:

198:

175:

160:

150:

135:

130:

125:

106:

92:

90:

78:

507:The science and engineering of materials

497:

627:

530:

38:mechanism observed in the majority of

7:

550:

548:

505:Askeland, Donald R. (January 2015).

559:. Marcel Dekker. pp. 393–394.

389:produced by the stress triaxality:

603:Comprehensive structural integrity

14:

34:) is a high energy microscopic

404:

373:

97:

1:

471:Fracture surface morphologies

326:{\displaystyle \epsilon _{q}}

264:{\displaystyle \sigma _{ys}}

295:{\displaystyle \sigma _{m}}

677:

382:{\displaystyle {\bar {R}}}

360:is the particle size, and

42:and in some engineering

587:Hertzberg, Richard W.

634:: CS1 maint: others (

555:Soboyejo, W.O (2003).

462:

383:

354:

327:

296:

265:

235:

213:

142:

54:

24:

661:Materials degradation

463:

384:

355:

353:{\displaystyle R_{o}}

328:

297:

266:

236:

214:

121:

64:precipitate particles

52:

28:Microvoid coalescence

19:

395:

364:

337:

310:

279:

245:

225:

77:

208:

656:Fracture mechanics

458:

379:

350:

323:

292:

261:

231:

209:

194:

55:

25:

613:978-0-08-049073-1

516:978-1-305-07676-1

456:

407:

376:

234:{\displaystyle A}

185:

112:

100:

668:

640:

639:

633:

625:

598:

592:

585:

579:

578:

552:

543:

542:

536:

528:

502:

467:

465:

464:

459:

457:

452:

451:

450:

438:

437:

425:

424:

414:

409:

408:

400:

388:

386:

385:

380:

378:

377:

369:

359:

357:

356:

351:

349:

348:

332:

330:

329:

324:

322:

321:

301:

299:

298:

293:

291:

290:

270:

268:

267:

262:

260:

259:

240:

238:

237:

232:

218:

216:

215:

210:

207:

202:

190:

186:

184:

183:

182:

166:

165:

164:

151:

141:

140:

139:

129:

117:

113:

111:

110:

101:

93:

91:

58:Fracture process

676:

675:

671:

670:

669:

667:

666:

665:

646:

645:

644:

643:

626:

614:

600:

599:

595:

586:

582:

567:

554:

553:

546:

529:

517:

504:

503:

499:

494:

477:Tensile loading

473:

442:

429:

416:

415:

393:

392:

362:

361:

340:

335:

334:

313:

308:

307:

282:

277:

276:

248:

243:

242:

223:

222:

171:

167:

156:

152:

146:

131:

102:

86:

75:

74:

60:

40:metallic alloys

12:

11:

5:

674:

672:

664:

663:

658:

648:

647:

642:

641:

612:

593:

580:

565:

544:

515:

496:

495:

493:

490:

481:Shear stresses

472:

469:

455:

449:

445:

441:

436:

432:

428:

423:

419:

412:

406:

403:

375:

372:

347:

343:

320:

316:

289:

285:

258:

255:

251:

230:

206:

201:

197:

193:

189:

181:

178:

174:

170:

163:

159:

155:

149:

145:

138:

134:

128:

124:

120:

116:

109:

105:

99:

96:

89:

85:

82:

59:

56:

13:

10:

9:

6:

4:

3:

2:

673:

662:

659:

657:

654:

653:

651:

637:

631:

623:

619:

615:

609:

605:

604:

597:

594:

590:

584:

581:

576:

572:

568:

566:0-203-91039-7

562:

558:

551:

549:

545:

540:

534:

526:

522:

518:

512:

508:

501:

498:

491:

489:

487:

482:

478:

470:

468:

453:

447:

443:

439:

434:

430:

426:

421:

417:

410:

401:

390:

370:

345:

341:

318:

314:

305:

287:

283:

274:

256:

253:

249:

228:

219:

204:

199:

195:

191:

187:

179:

176:

172:

168:

161:

157:

153:

147:

143:

136:

132:

126:

122:

118:

114:

107:

103:

94:

87:

83:

80:

72:

70:

65:

57:

51:

47:

45:

41:

37:

33:

29:

22:

18:

602:

596:

588:

583:

556:

506:

500:

474:

391:

273:yield stress

220:

73:

61:

31:

27:

26:

304:mean stress

650:Categories

492:References

630:cite book

622:190802556

533:cite book

525:903959750

405:¯

374:¯

315:ϵ

284:σ

250:σ

196:ϵ

173:σ

158:σ

133:ϵ

123:∫

98:¯

84:

575:54091550

44:plastics

36:fracture

486:bending

302:is the

271:is the

69:necking

620:

610:

573:

563:

523:

513:

221:where

636:link

618:OCLC

608:ISBN

571:OCLC

561:ISBN

539:link

521:OCLC

511:ISBN

32:MVC

21:SEM

652::

632:}}

628:{{

616:.

569:.

547:^

535:}}

531:{{

519:.

306:,

275:,

81:ln

46:.

638:)

624:.

577:.

541:)

527:.

454:3

448:3

444:R

440:+

435:2

431:R

427:+

422:1

418:R

411:=

402:R

371:R

346:o

342:R

319:q

288:m

257:s

254:y

229:A

205:p

200:v

192:d

188:)

180:s

177:y

169:2

162:m

154:3

148:(

144:A

137:q

127:0

119:=

115:)

108:0

104:R

95:R

88:(

30:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.