196:

121:

433:

460:

296:

24:

380:

The Soviet Union began its development of an analog in the 1940s, while negotiating with

Germany on building an IG Farben plant in Ukraine, basic scientific work was ongoing in 1942. The production only started in 1948 in Klin, after USSR got its hands on the 2000 volumes of IG Farben, and 10,000

472:

Nylon 6 fibres are tough, possessing high tensile strength, elasticity and lustre. They are wrinkleproof and highly resistant to abrasion and chemicals such as acids and alkalis. The fibres can absorb up to 2.4% of water, although this lowers tensile strength. The glass transition temperature of

376:

also succeeded in synthesizing nylon 6.) It was marketed as Perlon, and industrial production with a capacity of 3,500 tons per year was established in Nazi

Germany in 1943, using phenol as a feedstock. At first, the polymer was used to produce coarse fiber for artificial bristle, then the fiber

393:

Nylon 6 can be modified using comonomers or stabilizers during polymerization to introduce new chain end or functional groups, which changes the reactivity and chemical properties. It is often done to change its dyeability or flame retardance. Nylon 6 is synthesized by

530:

At present, polyamide 6 is a significant construction material used in many industries, for instance in the automotive industry, aircraft industry, electronic and electrotechnical industry, clothing industry and medicine. Annual demand for polyamides in

347:

industry. It is sold under numerous trade names including Perlon (Germany), Dederon (former East

Germany), Nylatron, Capron, Ultramid, Akulon, Kapron (former Soviet Union and satellite states), Rugopa (Turkey) and Durethan.

60:

Polycaprolactam, polyamide 6, PA6, poly-ε-caproamide, Perlon, Dederon, Capron, Ultramid, Akulon, Nylatron, Kapron, Alphalon, Tarnamid, Akromid, Frianyl, Schulamid, Durethan, Technyl, Nyorbits ,Winmark

Polymers

522:. Strong interchain interactions from hydrogen bonds between molecular nylon chains is said to be the cause by some sources. However, in 2023 a catalyst that rapidly breaks Nylon 6 down was reported.

622:

Soviet military administration in

Germany 1945-1949: Activities of the SMAG Directorate for studying the achievements of German science and technology in the Soviet zone of occupation of Germany

785:

618:Советская военная администрация в Германии 1945-1949: Деятельность Управления СВАГ по изучению достижений немецкой науки и техники в Советской зоне оккупации Германии

629:

456:

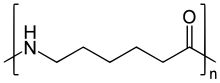

bond reverses at each bond, all nylon 6 amide bonds lie in the same direction (see figure: note the N to C orientation of each amide bond).

476:

As a synthetic fibre, Nylon 6 is generally white but can be dyed in a solution bath prior to production for different color results. Its

604:

722:

760:

518:

fungal strains can also degrade Nylon 6 through oxidation. Compared to aliphatic polyesters, Nylon 6 has been said to have poor

658:

283:

488:

153:

477:

395:

336:

303:

174:

377:

quality was improved, and

Germans started making parachutes, cord for aircraft tires and towing cables for gliders.

838:

833:

736:

809:

The

Promise of Nylon 6: A Case Study in Intelligent Product Design by William McDonough & Michael Braungart

262:

116:

46:

36:

426:

382:

332:

823:

191:

72:

828:

704:

625:

600:

343:. Its competition with nylon 6,6 and the example it set have also shaped the economics of the

546:

495:

g/cm. Its melting point is at 215 °C and can protect heat up to 150 °C on average.

694:

684:

576:

519:

432:

340:

213:

162:

82:

344:

321:

764:

295:

195:

120:

699:

672:

441:

422:

277:

808:

459:

452:

becomes part of the polymer backbone. Unlike nylon 6,6, in which the direction of the

817:

246:

109:

648:", NPTEL (National Programme On Technology Enhanced Learning), retrieved May 9, 2016

564:

357:

142:

786:"Grupa Azoty: Nowa wytwórnia pozwoli zająć pozycję 2. producenta poliamidu w UE"

597:

Synthetic

Socialism: Plastics and Dictatorship in the German Democratic Republic

399:

299:

448:

is broken, with the active groups on each side re-forming two new bonds as the

570:

484:

414:

93:

23:

515:

361:

324:

708:

723:"New Catalyst Completely Breaks Down Durable Plastic Pollution in Minutes"

645:

339:; this makes it a special case in the comparison between condensation and

689:

511:

445:

418:

365:

364:

in late 1930s (first synthesized in 1938) to reproduce the properties of

624:] (in Russian). Moscow: ROSSPEN, Russian State Archive. p. 65.

558:

449:

317:

236:

129:

532:

410:

385:

technical documentation, as a result of victory in the World War II.

369:

276:

Except where otherwise noted, data are given for materials in their

536:

458:

453:

431:

373:

328:

294:

552:

463:

Nylon 6 (above) has a structure similar to Nylon 6,6 (below).

179:

659:

Polyamide Fiber

Physical and Chemical Properties of Nylon 6

372:

on its production. (Around the same time, Kohei

Hoshino at

671:

Tokiwa, Y.; Calabia, B. P.; Ugwu, C. U.; Aiba, S. (2009).

539:. They are produced by all leading chemical companies.

421:for about 4–5 hours, the ring breaks and undergoes

661:”, textilefashionstudy.com, retrieved May 9, 2016.

542:The largest producers of polyamide 6 in Europe:

141:

763:(in Polish). att.grupaazoty.com. Archived from

81:

8:

677:International Journal of Molecular Sciences

646:Synthesis of Modified Polyamides (Nylon 6)

599:. The University of North Carolina Press.

194:

119:

15:

698:

688:

444:, the amide bond within each caprolactam

436:Polymerization of caprolactam to Nylon 6.

425:. Then the molten mass is passed through

406:. When caprolactam is heated at about 533

161:

40:Poly(azepan-2-one); poly(hexano-6-lactam)

588:

514:of Nylon 6, but not polymers. Certain

302:molecule used to synthesize Nylon 6 by

190:

110:

270:434 °C; 813 °F; 707 K

7:

402:. Caprolactam has 6 carbons, hence

132:

742:(in Polish). static.grupaazoty.com

14:

356:Polycaprolactam was developed by

22:

280:(at 25 °C , 100 kPa).

673:"Biodegradability of Plastics"

1:

429:to form fibres of nylon 6.

396:ring-opening polymerization

337:ring-opening polymerization

335:, but instead is formed by

304:ring opening polymerization

855:

788:(in Polish). wyborcza.biz

579:, 100,000 tonnes per year

573:, 100,000 tonnes per year

567:, 125,000 tonnes per year

561:, 170,000 tonnes per year

555:, 240,000 tonnes per year

549:, 260,000 tonnes per year

274:

255:

206:

65:

57:

45:

35:

30:

21:

737:"Segment Tworzywa 2015"

473:Nylon 6 is 47 °C.

616:Zaharov, V.V. (2007).

491:with a density of 1.14

464:

437:

368:without violating the

306:

535:amounts to a million

462:

435:

298:

47:Systematic IUPAC name

690:10.3390/ijms10093722

526:Production in Europe

333:condensation polymer

327:. Unlike most other

510:sp. (NK87) degrade

331:, nylon 6 is not a

18:

725:. 3 December 2023.

595:Rubin, E. (2014),

465:

438:

307:

284:Infobox references

16:

839:German inventions

761:"Alphalon™ (PA6)"

631:978-5-8243-0882-2

341:addition polymers

292:Chemical compound

290:

289:

251:218.3 °C (493 K)

175:CompTox Dashboard

846:

834:Synthetic fibers

797:

796:

794:

793:

782:

776:

775:

773:

772:

757:

751:

750:

748:

747:

741:

733:

727:

726:

719:

713:

712:

702:

692:

668:

662:

655:

649:

642:

636:

635:

613:

607:

593:

520:biodegradability

494:

483:

409:

320:, in particular

214:Chemical formula

199:

198:

183:

181:

165:

145:

134:

123:

112:

85:

26:

19:

854:

853:

849:

848:

847:

845:

844:

843:

814:

813:

805:

800:

791:

789:

784:

783:

779:

770:

768:

759:

758:

754:

745:

743:

739:

735:

734:

730:

721:

720:

716:

670:

669:

665:

656:

652:

643:

639:

632:

615:

614:

610:

594:

590:

586:

528:

501:

492:

481:

470:

407:

391:

354:

345:synthetic fibre

322:semicrystalline

314:polycaprolactam

293:

286:

281:

267:

264:

230:

226:

222:

216:

202:

184:

177:

168:

148:

135:

104:

88:

75:

61:

53:

52:

41:

12:

11:

5:

852:

850:

842:

841:

836:

831:

826:

816:

815:

812:

811:

804:

803:External links

801:

799:

798:

777:

752:

728:

714:

683:(9): 3722–42.

663:

650:

637:

630:

608:

605:978-1469615103

587:

585:

582:

581:

580:

574:

568:

562:

556:

550:

527:

524:

504:Flavobacterium

500:

499:Biodegradation

497:

469:

466:

442:polymerization

423:polymerization

390:

387:

353:

350:

291:

288:

287:

282:

278:standard state

275:

272:

271:

268:

261:

258:

257:

253:

252:

249:

243:

242:

239:

233:

232:

228:

224:

220:

217:

212:

209:

208:

204:

203:

201:

200:

187:

185:

173:

170:

169:

167:

166:

158:

156:

150:

149:

147:

146:

138:

136:

128:

125:

124:

114:

106:

105:

103:

102:

98:

96:

90:

89:

87:

86:

78:

76:

71:

68:

67:

63:

62:

59:

55:

54:

50:

49:

43:

42:

39:

33:

32:

28:

27:

13:

10:

9:

6:

4:

3:

2:

851:

840:

837:

835:

832:

830:

827:

825:

822:

821:

819:

810:

807:

806:

802:

787:

781:

778:

767:on 2016-04-26

766:

762:

756:

753:

738:

732:

729:

724:

718:

715:

710:

706:

701:

696:

691:

686:

682:

678:

674:

667:

664:

660:

654:

651:

647:

641:

638:

633:

627:

623:

619:

612:

609:

606:

602:

598:

592:

589:

583:

578:

575:

572:

569:

566:

563:

560:

557:

554:

551:

548:

545:

544:

543:

540:

538:

534:

525:

523:

521:

517:

513:

509:

505:

498:

496:

490:

486:

479:

474:

467:

461:

457:

455:

451:

447:

443:

434:

430:

428:

424:

420:

416:

412:

405:

401:

397:

388:

386:

384:

378:

375:

371:

367:

363:

359:

351:

349:

346:

342:

338:

334:

330:

326:

323:

319:

315:

311:

305:

301:

297:

285:

279:

273:

269:

266:

260:

259:

254:

250:

248:

247:Melting point

245:

244:

240:

238:

235:

234:

218:

215:

211:

210:

205:

197:

193:

192:DTXSID6049694

189:

188:

186:

176:

172:

171:

164:

160:

159:

157:

155:

152:

151:

144:

140:

139:

137:

131:

127:

126:

122:

118:

115:

113:

111:ECHA InfoCard

108:

107:

100:

99:

97:

95:

92:

91:

84:

80:

79:

77:

74:

70:

69:

64:

56:

48:

44:

38:

34:

29:

25:

20:

790:. Retrieved

780:

769:. Retrieved

765:the original

755:

744:. Retrieved

731:

717:

680:

676:

666:

653:

640:

621:

617:

611:

596:

591:

541:

529:

507:

503:

502:

475:

471:

439:

413:in an inert

403:

392:

379:

358:Paul Schlack

355:

313:

309:

308:

263:Autoignition

241:1.084 g/mL

66:Identifiers

58:Other names

577:Grupa Azoty

508:Pseudomonas

400:caprolactam

381:volumes of

300:Caprolactam

265:temperature

207:Properties

117:100.124.824

824:Polyamides

818:Categories

792:2016-04-12

771:2016-04-12

746:2016-04-12

584:References

468:Properties

427:spinnerets

415:atmosphere

163:14GUK8I73Z

94:ChemSpider

83:25038-54-4

73:CAS Number

37:IUPAC name

516:white rot

512:oligomers

506:sp. and

389:Synthesis

362:IG Farben

325:polyamide

829:Plastics

709:19865515

480:is 6–8.5

478:tenacity

446:molecule

419:nitrogen

366:Nylon 66

256:Hazards

17:Nylon 6

700:2769161

559:Lanxess

547:Fibrant

450:monomer

440:During

404:Nylon 6

352:History

318:polymer

310:Nylon 6

237:Density

231:

130:PubChem

707:

697:

628:

603:

565:Radici

537:tonnes

533:Europe

493:

482:

408:

370:patent

329:nylons

31:Names

740:(PDF)

620:[

454:amide

374:Toray

316:is a

143:32775

705:PMID

626:ISBN

601:ISBN

571:DOMO

553:BASF

154:UNII

101:None

51:Poly

695:PMC

685:doi

417:of

398:of

383:AEG

360:at

312:or

227:NO)

180:EPA

133:CID

820::

703:.

693:.

681:10

679:.

675:.

485:gf

225:11

219:(C

795:.

774:.

749:.

711:.

687::

657:”

644:"

634:.

489:D

487:/

411:K

229:n

223:H

221:6

182:)

178:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.