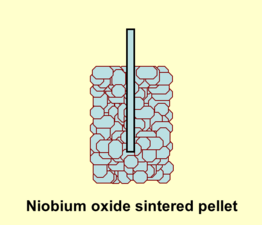

832:. The solution found by R. L. Taylor and H. E. Haring of the Bell Labs was based on experience with ceramics. They ground down tantalum to a powder, pressed this powder into a cylindrical form and then sintered the powder particles into a pellet ("slug") at high temperatures, between 1500 and 2000 °C, under vacuum conditions. These first sintered tantalum capacitors used a non-solid electrolyte not consistent with the concept of solid state electronics. 1952 a targeted search in the Bell Labs for a solid electrolyte by D. A. McLean and F. S. Power led to the invention of manganese dioxide as a solid electrolyte for a sintered tantalum capacitor.

390:

378:

1061:, load life or useful life of electrolytic capacitors is a special characteristic of non-solid electrolytic capacitors, especially non-solid aluminum electrolytic capacitors. Their liquid electrolyte can evaporate over time, leading to wear-out failures. Solid niobium capacitors with manganese dioxide electrolyte have no wear-out mechanism, so the constant failure rate lasts up to the point when all capacitors have failed. They don't have a life time specification like non-solid aluminum electrolytic capacitors.

402:

846:

22:

1329:

1184:

194:

190:

in the West, with major capacitor manufacturers taking interest in the late 1990s. The materials and processes used to produce niobium capacitors are essentially the same as for tantalum capacitors. Rising tantalum prices in 2000 and 2001 encouraged the development of niobium electrolytic capacitors with manganese dioxide and polymer electrolytes, which have been available since 2002.

155:

969:

825:) used this phenomenon for an idea of a polarized "Electric liquid capacitor with aluminum electrodes". In 1896 Pollak obtained a patent for the first electrolytic capacitor. The first tantalum electrolytic capacitors with wound tantalum foils and non-solid electrolyte were developed in 1930 by Tansitor Electronics Inc., USA, and used for military purposes.

130:(NbO) as anode material. Niobium oxide is a hard ceramic material characterized by high metallic conductivity. Niobium oxide powder can be prepared in a similar structure to that of tantalum powder and can be processed in a similar way to produce capacitors. It also can be oxidized by anodic oxidation (

1064:

However, solid polymer niobium electrolytic capacitors do have a life time specification. The electrolyte deteriorates by a thermal degradation mechanism of the conductive polymer. The electrical conductivity decreases, as a function of time, in agreement with a granular structure, in which aging is

1018:

The surge voltage indicates the maximum peak voltage value that may be applied to electrolytic capacitors during their application for a limited number of cycles. The surge voltage is standardized in IEC/EN 60384-1. For niobium electrolytic capacitors the surge voltage shall be not higher than

995:

The voltage proof of electrolytic capacitors decreases with increasing temperature. For some applications it is important to use a higher temperature range. Lowering the voltage applied at a higher temperature maintains safety margins. For some capacitor types therefore the IEC standard specifies a

189:

In the 1960s, the higher availability of niobium ore compared with tantalum ore prompted research into niobium electrolytic capacitors in the Soviet Union. Here they served the same purpose as tantalum capacitors in the West. With the collapse of the Iron

Curtain, the technology became better-known

107:

Niobium is a sister metal to tantalum. Niobium has a similar melting point (2744 °C) to tantalum and exhibits similar chemical properties. The materials and processes used to produce niobium-dielectric capacitors are essentially the same as for existing tantalum-dielectric capacitors. However,

1336:

Niobium capacitors are in general polarized components, with distinctly marked positive terminals. When subjected to reversed polarity (even briefly), the capacitor depolarizes and the dielectric oxide layer breaks down, which can cause it to fail even when later operated with correct polarity. If

916:

The electrical characteristics of niobium electrolytic capacitors depend on structure of the anode and the type of electrolyte. The capacitance value of the capacitor depends on measuring frequency and temperature. The rated capacitance value or nominal value is specified in the data sheets of the

270:

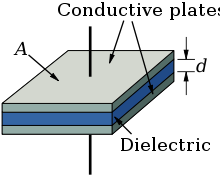

The niobium anode material is manufactured from a powder sintered into a pellet with a rough surface structure intended to increase the electrode surface area A compared to a smooth surface with the same footprint. This increase in surface area can increase the capacitance by a factor of up to 200

1246:

dielectric breaks down and the capacitor exhibits a thermal runaway failure. In comparison to solid tantalum capacitors the thermal runaway of niobium anodes will occur at about three times higher power than of tantalum anodes. This gives a significant reduction (95%) of the ignition failure mode

853:

Niobium electrolytic capacitors as discrete components are not ideal capacitors, they have losses and parasitic inductive parts. All properties can be defined and specified by a series equivalent circuit composed out of an idealized capacitance and additional electrical components which model all

555:

Tantalum and niobium electrolytic capacitors with solid electrolyte as surface-mountable chip capacitors are mainly used in electronic devices in which little space is available or a low profile is required. They operate reliably over a wide temperature range without large parameter deviations.

1266:

in tantalum capacitors and therefore grows thicker per applied volt and so operates at lower field strength for a given voltage rating with the lower electrical stress the dielectric. In combination with niobium oxide anodes, which are more stable against oxygen diffusion that results in lower

564:

In order to compare the different characteristics of the different electrolytic chip capacitor types, specimens with the same dimensions and of comparable capacitance and voltage are compared in the following table. In such a comparison the values for ESR and ripple current load are the most

1073:

The different types of electrolytic capacitors show different behaviors in long-term stability, inherent failure modes and their self-healing mechanisms. Application rules for types with an inherent failure mode are specified to ensure capacitors high reliability and long life.

451:

The combination of anode materials for niobium and tantalum electrolytic capacitors and the electrolytes used has formed a wide variety of capacitor types with different properties. An outline of the main characteristics of the different types is shown in the table below.

119:) into the niobium anode metal is very high, resulting in leakage current instability or even capacitor failures. There are two possible ways to reduce oxygen diffusion and improve leakage current stability – either by doping metallic niobium powders with nitride into

185:

This property of niobium was known since the beginning of the 20th century. Although niobium is more abundant in nature and less expensive than tantalum, its high melting point of 2744 °C hindered the development of niobium electrolytic capacitors.

1065:

due to the shrinking of the conductive polymer grains. The life time of polymer electrolytic capacitors is specified in similar terms like non-solid e-caps but its life time calculation follows other rules leading to much longer operational life times.

816:

The phenomenon that can electrochemically form an oxide layer on aluminum and metals like tantalum or niobium, blocking an electric current in one direction but allowing it to flow in the other direction, was discovered in 1875 by the French researcher

389:

1707:

E. Vitoratos, S. Sakkopoulos, E. Dalas, N. Paliatsas, D. Karageorgopoulos, F. Petraki, S. Kennou, S. A. Choulis, Thermal degradation mechanisms of PEDOT:PSS, Organic

Electronics, Volume 10, Issue 1, February 2009, Pages 61–66,

932:

The percentage of allowed deviation of the measured capacitance from the rated value is called capacitance tolerance. Electrolytic capacitors are available in different tolerance series, whose values are specified in the

565:

important parameters for the use of electrolytic capacitors in modern electronic equipment. The lower the ESR the higher the ripple current per volume, thus the better the functionality of the capacitor in the circuit.

87:

Like most electrolytic capacitors, niobium capacitors are polarized components. Reverse voltages or ripple currents higher than specified tolerances can destroy the dielectric and thus the capacitor; the resulting

266:

per volt. This very thin dielectric layer, combined with a sufficiently high dielectric strength, allows niobium electrolytic capacitors to achieve a high volumetric capacitance comparable to tantalum capacitors.

134:, forming) to generate the insulating dielectric layer. Thus two types of niobium electrolytic capacitors are marketed, those using a passivated niobium anode and those using a niobium oxide anode. Both types use

108:

niobium as a raw material is much more abundant in nature than tantalum and is less expensive. The characteristics of niobium electrolytic capacitors and tantalum electrolytic capacitors are roughly comparable.

377:

362:

The higher permittivity and lower breakdown voltage of niobium pentoxide relative to tantalum pentoxide results in niobium capacitors and tantalum capacitors having similar sizes for a given capacitance.

1007:

Lower voltage applied may have positive influences for tantalum (and niobium) electrolytic capacitors. Lowering the voltage applied increases the reliability and reduces the expected failure rate.

1219:

but much lower than a short. In case of faults or impurities in the dielectric which evokes a partial dielectric breakdown the conducting channel would be effectively isolated by reduction of Nb

925:. The standardized measuring condition for electrolytic capacitors is an AC measuring method with a frequency of 100/120 Hz. The AC measuring voltage shall not exceed 0,5 V AC-

257:

1191:

A rare failure in solid electrolytic capacitors is breakdown of the dielectric caused by faults or impurities. In niobium electrolytic capacitors the dielectric is niobium pentoxide (Nb

1000:". The category voltage is the maximum DC voltage or peak pulse voltage that may be applied continuously to a capacitor at any temperature within the category temperature range T

828:

The development of solid electrolyte tantalum capacitors began in the early 1950s as a miniaturized, more reliable low-voltage support capacitor to complement the newly invented

401:

1027:

Like other electrolytic capacitors, niobium electrolytic capacitors are polarized and require the anode electrode voltage to be positive relative to the cathode voltage.

99:

in the 1960s. Since 2002 they have been commercially available in the West, taking advantage of the lower cost and better availability of niobium relative to tantalum.

1365:. The definition of the characteristics and the procedure of the test methods for capacitors for use in electronic equipment are set out in the generic specification:

1669:

1019:

round 1.3 times of the rated voltage, rounded off to the nearest volt. The surge voltage applied to niobium capacitors may influence the capacitors failure rate.

1354:

905:

1650:

D. F. Tailor, Tantalum and

Tantalum Compounds, Fansteel Inc., Encyclopedia of Chemical Technology, Vol. 19, 2nd ed. 1969 John Wiley & sons, Inc.

1304:

1297:

1466:

158:

Diagram illustrating anodic oxidation, in which a metallic anode in an electrolyte forms an oxide layer in response to the application of voltage.

1939:

D. Bach, Dissertation, 2009-06-05, Universität

Karlsruhe (TH), EELS investigations of stoichiometric niobium oxides and niobium-based capacitors

1337:

the failure is a short circuit (the most common occurrence), and current is not limited to a safe value, catastrophic thermal runaway may occur.

1290:

213:

Every electrolytic capacitor can be thought of as a "plate capacitor" whose capacitance increases with the electrode area (A) and the dielectric

1616:

1445:

395:

Schematic representation of the structure of a sintered niobium electrolytic capacitor with solid electrolyte and the cathode contacting layers

1078:

Long-term electrical behavior, failure modes, self-healing mechanism, and application rules of the different types of electrolytic capacitors

1945:

988:

is the maximum DC voltage or peak pulse voltage that may be applied continuously at any temperature within the rated temperature range T

1934:

937:

specified in IEC 60063. For abbreviated marking in tight spaces, a letter code for each tolerance is specified in IEC 60062.

1627:

1575:

1562:

Ch. Schnitter, A. Michaelis, U. Merker, H. C. Starck, Bayer, New

Niobium Based Materials for Solid Electrolyte Capacitors, Carts 2002

170:

bath and applying a positive voltage to it forms a layer of electrically insulating oxide whose thickness corresponds to the applied

111:

Niobium electrolytic capacitors can be made with high purity niobium as the anode but the diffusion of oxygen from the dielectric (Nb

1735:

1931:

854:

losses and inductive parameters of a capacitor. In this series-equivalent circuit the electrical characteristics are defined by:

1615:

Y. Pozdeev-Freeman, P. Maden, Vishay, Solid-Electrolyte

Niobium Capacitors Exhibit Similar Performance to Tantalum, 2002-02-01,

1377:

1909:

1397:

Niobium capacitors are available in SMD style, that makes them suitable for all portable electronic systems with flat design

1804:

1547:

1499:

1668:

E. K. Reed, Jet

Propulsion Laboratory, Characterization of Tantalum Polymer Capacitors, NEPP Task 1.21.5, Phase 1, FY05]

1659:

R. L. Taylor and H. E. Haring, "A metal semi-conductor capacitor," J. Electrochem. Soc., vol. 103, p. 611, November, 1956.

949:

942:

934:

1692:

897:

884:

223:

1639:

1454:

976:

Referring to IEC/EN 60384-1 standard the allowed operating voltage for niobium capacitors is called "rated voltage U

1004:. The relation between both voltages and temperatures is given in the picture right (or above, on mobile devices).

1771:

T. Zednicek, AVX, A Study of Field

Crystallization in Tantalum Capacitors and its effect on DCL and Reliability,

1403:

Niobium capacitors are available with solid electrolyte for low ESR applications and stable electrical parameters

73:

1753:

1543:

T. Zednicek, S. Sita, C. McCracken, W. A. Millman, J. Gill, AVX, Niobium Oxide

Technology Roadmap, CARTS 2002

1035:

General information to impedance, ESR, dissipation factor tan δ, ripple current, and leakage current see

383:

The capacitor cell of a niobium electrolytic capacitor consists of sintered niobium or niobium monoxide powder

1358:

811:

120:

1604:

1720:

1362:

1047:

1036:

179:

38:

871:

1437:

1369:

IEC 60384-1, Fixed capacitors for use in electronic equipment – Part 1: Generic specification

1843:

Radovan Faltus, AVX, Advanced capacitors ensure long-term control-circuit stability, 2012-02-07, EDT

1709:

1525:

569:

Comparison of the most important characteristics of different types of electrolytic chip capacitors

1972:

1951:

1587:

1495:

21:

1416:

275:

77:

1603:

T. Kárník, AVX, Niobium oxide for capacitor manufacturing, Metal 2008, 2008-05-13 – 2008-05-15,

1328:

1113:

Thermally induced insulating of faults in the dielectric by decomposition of the electrolyte MnO

818:

1373:

Until now (2014) no IEC detail specification for niobium electrolytic capacitors is available.

1303:

1296:

845:

1927:

1183:

433:

425:

135:

81:

54:

1142:

Insulating of faults in the dielectric by oxidation or evaporation of the polymer electrolyte

1772:

1458:

1289:

926:

413:

80:

chip capacitors in certain voltage and capacitance ratings. They are available with a solid

50:

904:

Using a series equivalent circuit instead of a parallel equivalent circuit is specified by

1757:

1739:

1696:

1551:

1529:

1200:

262:

The dielectric thickness of niobium electrolytic capacitors is very thin, in the range of

193:

123:

1688:

Ch. Reynolds, AVX, Technical

Information, Reliability Management of Tantalum Capacitors,

1332:

Niobium electrolytic chip capacitors are marked with a bar at the positive component side

197:

A dielectric material is placed between two conducting plates (electrodes), each of area

1732:

1234:

As more energy is applied to a faulty solid niobium eventually either the high ohmic NbO

407:

Construction of a typical SMD niobium electrolytic chip capacitor with solid electrolyte

1944:

Ch. Schnitter: The taming of niobium. In: Bayer research, Bayer AG, 2004 (2007-02-11),

900:

which is the effective self-inductance of the capacitor, usually abbreviated as "ESL".

1966:

1950:

Niobium Powder for Electrolytic Capacitor, JFE Technical Report No. 6 (October 2005)

1844:

1811:

1586:

Niobium Powder for Electrolytic Capacitor, JFE Technical Report No. 6 (October 2005)

127:

89:

1258:

of solid niobium electrolytic capacitors has a lower breakdown voltage proof than Ta

1935:

9781259007316 – Capacitors : Technology and Trends by R P Deshpande - AbeBooks

1574:

J. Moore, Kemet, Nb capacitors compared to Ta capacitors a less costly alternative

1058:

1054:

822:

214:

96:

1519:

Tantalum-Niobium International Study Center, Tantalum and Niobium – Early History

1384:

EIA-717-A Surface Mount Niobium and Tantalum Capacitor Qualification Specification

1815:

1544:

1491:

1350:

887:

which summarizes all ohmic losses of the capacitor, usually abbreviated as "ESR"

436:

167:

163:

62:

996:"temperature derated voltage" for a higher temperature, the "category voltage U

154:

1892:"Beuth Verlag – Normen, Standards & Fachliteratur kaufen | seit 1924"

1786:

1689:

1626:

Rutronik, Tantalum & Niobium Capacitors, Technical Standards and Benefits

1346:

1177:

niobium anode: voltage derating 50% niobium oxide anode: voltage derating 20%

1010:

Applying a higher voltage than specified may destroy electrolytic capacitors.

972:

Relation between rated and category voltage and rated and category temperature

956:

829:

429:

175:

58:

456:

Overview of the key features of niobium and tantalum electrolytic capacitors

1267:

voltage derating rules compared with passivated niobium or tantalum anodes.

968:

417:

263:

131:

1187:

Self-healing in solid niobium capacitors with manganese dioxide electrolyte

1163:

Thermally induced insulation of faults in the dielectric by reduction of Nb

560:

Comparison of electrical parameters of niobium and tantalum capacitor types

412:

A typical niobium capacitor is a chip capacitor and consists of niobium or

271:

for solid niobium electrolytic capacitors, depending on the rated voltage.

1406:

Niobium capacitors have a limited number of manufacturers (AVX and Vishay)

274:

The properties of the niobium pentoxide dielectric layer, compared with a

821:. He coined the term "valve metal" for such metals. Charles Pollak (born

1750:

1453:(4). Fansteel Metallurgical Corporation, North Chicago, Illinois, USA:

440:

171:

66:

46:

1462:

1031:

Impedance, ESR and dissipation factor, ripple current, leakage current

1910:"G. Roos, Digi-Key, Niobium Capacitors Slow to Take Hold, 2012-11-20"

1873:

1638:

Charles Pollack: D.R.P. 92564, filed 1896-01-14, granted 1897-05-19

1353:

components and related technologies follows the rules given by the

1199:). Besides this pentoxide there is an additional niobium suboxide,

282:

Characteristics of the different tantalum and niobium oxide layers

1805:"Voltage derating rules for solid Tantalum and Niobium capacitors"

1438:"An Investigation of Columbium as an Electrolytic Capacitor Metal"

1327:

1182:

967:

844:

421:

192:

153:

42:

20:

1940:

1679:

D. A. McLean, F. S. Power, Proc. Inst. Radio Engrs. 44 (1956) 872

1394:

Niobium capacitors serve as a replacement for tantalum capacitors

1211:

is a semi-conducting material with a higher conductivity than Nb

447:

Comparison of niobium and tantalum electrolytic capacitor types

95:

Niobium capacitors were developed in the United States and the

1957:

1855:

1380:

publish a standard for niobium and tantalum chip capacitors:

1490:

Folster, J. H. D.; Holley, E. E.; Whitman, A. (1964-06-26).

1046:

For general information on reliability and failure rate see

162:

Niobium, similarly to tantalum and aluminum, is a so-called

65:

on the surface of the oxide layer serves as the capacitor's

1719:

Nichicon, Technical Guide, Calculation Formula of Lifetime

1069:

Failure modes, self-healing mechanism and application rules

367:

Basic construction of solid niobium electrolytic capacitors

1891:

1523:

1520:

1492:"Production engineering measure for Columbium capacitors"

1376:

For electronics manufacturers in the United States the

849:

Series-equivalent circuit model of a tantalum capacitor

799:(1) 100 μF/10 V, unless otherwise specified,

802:(2) calculated for a capacitor 100 μF/10 V,

217:(ε), and decreases with the dielectric thickness (d).

1798:

1796:

1794:

1731:

Estimating of Lifetime Fujitsu Media Devices Limited

226:

1926:

R. P. Deshpande, Capacitors: Technology and Trends,

1751:

NIC Technical Guide, Calculation Formula of Lifetime

1400:

Niobium capacitors have no inrush current limitation

523:

Niobium oxide electrolytic capacitor, sintered anode

1128:Voltage derating 50% Series resistance 3 Ω/V

252:{\displaystyle C=\varepsilon \cdot {\frac {A}{d}}}

251:

25:SMD chip style of niobium electrolytic capacitors

478:Tantalum electrolytic capacitor, sintered anode

92:can cause a fire or explosion in larger units.

372:Construction of a solid niobium chip capacitor

8:

1136:Deterioration of conductivity, ESR increases

1767:

1765:

1494:(report). North Adams, Massachusetts, USA:

1076:

912:Capacitance standard values and tolerances

454:

424:of the capacitor, with the oxide layer of

166:. Placing such a metal in contact with an

1839:

1837:

1835:

1781:

1779:

1539:

1537:

1355:International Electrotechnical Commission

1133:Tantalum e-caps solid polymer electrolyte

278:layer, are given in the following table:

239:

225:

1599:

1597:

1595:

778:Aluminum capacitors, Polymer electrolyte

758:Aluminum capacitors, Polymer electrolyte

662:Tantalum capacitors, Multianode, polymer

642:Tantalum capacitors, Polymer electrolyte

589:Max. Leakage current after 2 Min. (μA)

586:Max. Ripple current 85/105 °C (mA)

567:

280:

1570:

1568:

1428:

1247:compared to solid tantalum capacitors.

1081:

583:Max. ESR 100 kHz, 20 °C (mΩ)

459:

370:

1446:Journal of the Electrochemical Society

959:, tolerance ±10%, letter code "K"

952:, tolerance ±20%, letter code "M"

945:, tolerance ±20%, letter code "M"

812:Electrolytic capacitors § History

7:

1803:Zedníček, Tomáš; Gill, John (2003).

1436:Shtasel, A.; Knight, H. T. (1961) .

618:Tantalum capacitors, Multianode, MnO

72:Niobium capacitors are available in

710:Niobium capacitors, Multianode, MnO

1125:if current availability is limited

917:manufacturers and is symbolized C

870:, the resistance representing the

861:, the capacitance of the capacitor

302:Dielectric layer thickness (nm/V)

14:

1785:Vishay, DC Leakage Failure Mode,

1361:, non-governmental international

1302:

1295:

1288:

1083:Type of electrolytic capacitors

734:Niobium-caps Polymer electrolyte

400:

388:

376:

1502:from the original on 2022-06-21

1472:from the original on 2022-06-21

1086:Long-term electrical behavior

174:. This oxide layer acts as the

1281:Electrolytic capacitor symbols

574:Electrolytic capacitor family

461:Electrolytic capacitor family

31:niobium electrolytic capacitor

1:

1874:"Welcome to the IEC Webstore"

1522:and Applications for Niobium

1345:The standardization for all

898:equivalent series inductance

885:equivalent series resistance

1956:Introduction to capacitors

1455:The Electrochemical Society

146:) as the dielectric layer.

76:packaging and compete with

1989:

964:Rated and category voltage

836:Electrical characteristics

809:

580:Dimension DxL, WxHxL (mm)

45:(+) is made of passivated

1150:Niobium e-caps, solid MnO

1100:Tantalum e-caps solid MnO

1042:Reliability and life time

841:Series-equivalent circuit

522:

477:

299:Breakdown voltage (V/μm)

203:and with a separation of

53:, on which an insulating

594:Tantalum capacitors, MnO

526:Solid, manganese dioxide

495:Solid, manganese dioxide

481:Non-solid, sulfuric acid

334:Niobium or Niobium oxide

1317:Electrolytic capacitor

1250:The dielectric layer Nb

1092:Self-healing mechanism

992:(IEC/EN 60384-1).

980:" or "nominal voltage U

761:Panasonic SP-UE 180/6.3

686:Niobium capacitors, MnO

470:Max. rated voltage (V)

467:Capacitance range (μF)

1363:standards organization

1333:

1314:Electrolytic capacitor

1311:Electrolytic capacitor

1271:Additional information

1231:if energy is limited.

1188:

1160:no unique determinable

1048:electrolytic capacitor

1037:electrolytic capacitor

984:". The rated voltage U

973:

850:

473:Max. temperature (°C)

293:Relative permittivity

253:

210:

180:electrolytic capacitor

159:

39:electrolytic capacitor

26:

16:Electrolytic capacitor

1331:

1186:

1145:Voltage derating 20%

1139:Field crystallization

1110:Field crystallization

971:

848:

420:into a pellet as the

310:Tantalum pentoxide Ta

254:

196:

157:

24:

337:Niobium pentoxide Nb

224:

1496:Sprague Electric Co

1227:into high ohmic NbO

1171:into insulating NbO

1079:

955:rated capacitance,

948:rated capacitance,

941:rated capacitance,

570:

457:

416:powder pressed and

283:

35:Columbium capacitor

33:(historically also

1756:2013-09-15 at the

1738:2013-12-24 at the

1695:2013-08-06 at the

1550:2014-02-24 at the

1528:2016-02-13 at the

1417:Types of capacitor

1334:

1189:

1117:into insulating Mn

1095:Application rules

1077:

974:

851:

568:

455:

281:

276:tantalum pentoxide

249:

211:

160:

27:

1463:10.1149/1.2428084

1321:

1320:

1276:Capacitor symbols

1238:channel or the Nb

1181:

1180:

797:

796:

793:40 (0.04CV)

781:Kemet A700 100/10

773:100 (0.1CV)

749:20 (0.02CV)

729:20 (0.02CV)

705:20 (0.02CV)

677:100 (0.1CV)

665:Kemet T530 150/10

657:100 (0.1CV)

645:Kemet T543 330/10

637:10 (0.01CV)

625:Kemet T510 330/10

613:10 (0.01CV)

601:Kemet T494 330/10

553:

552:

434:manganese dioxide

426:niobium pentoxide

360:

359:

247:

136:niobium pentoxide

103:Basic information

82:manganese dioxide

55:niobium pentoxide

1980:

1914:

1913:

1906:

1900:

1899:

1888:

1882:

1881:

1870:

1864:

1863:

1852:

1846:

1841:

1830:

1829:

1827:

1826:

1820:

1814:. Archived from

1809:

1800:

1789:

1783:

1774:

1769:

1760:

1748:

1742:

1729:

1723:

1717:

1711:

1705:

1699:

1686:

1680:

1677:

1671:

1666:

1660:

1657:

1651:

1648:

1642:

1636:

1630:

1624:

1618:

1613:

1607:

1601:

1590:

1584:

1578:

1572:

1563:

1560:

1554:

1541:

1532:

1517:

1511:

1510:

1508:

1507:

1487:

1481:

1480:

1478:

1477:

1471:

1457:(ECS): 343–347.

1442:

1433:

1324:Polarity marking

1306:

1299:

1292:

1285:

1284:

1080:

874:of the capacitor

717:AVX, NBM 220/6.3

693:AVX, NOS 220/6,3

571:

458:

404:

392:

380:

296:Oxide structure

284:

258:

256:

255:

250:

248:

240:

150:Anodic oxidation

57:layer acts as a

51:niobium monoxide

1988:

1987:

1983:

1982:

1981:

1979:

1978:

1977:

1963:

1962:

1946:Wayback Machine

1923:

1921:Further reading

1918:

1917:

1908:

1907:

1903:

1890:

1889:

1885:

1878:webstore.iec.ch

1872:

1871:

1867:

1854:

1853:

1849:

1842:

1833:

1824:

1822:

1818:

1807:

1802:

1801:

1792:

1784:

1777:

1770:

1763:

1758:Wayback Machine

1749:

1745:

1740:Wayback Machine

1730:

1726:

1718:

1714:

1706:

1702:

1697:Wayback Machine

1687:

1683:

1678:

1674:

1667:

1663:

1658:

1654:

1649:

1645:

1637:

1633:

1625:

1621:

1614:

1610:

1602:

1593:

1585:

1581:

1573:

1566:

1561:

1557:

1552:Wayback Machine

1542:

1535:

1530:Wayback Machine

1518:

1514:

1505:

1503:

1489:

1488:

1484:

1475:

1473:

1469:

1440:

1435:

1434:

1430:

1425:

1413:

1391:

1343:

1341:Standardization

1326:

1278:

1273:

1265:

1261:

1257:

1253:

1245:

1241:

1237:

1230:

1226:

1222:

1218:

1214:

1210:

1206:

1201:niobium dioxide

1198:

1194:

1174:

1170:

1166:

1153:

1124:

1120:

1116:

1103:

1071:

1044:

1033:

1025:

1023:Reverse voltage

1016:

1003:

999:

991:

987:

983:

979:

966:

924:

920:

914:

895:

882:

872:leakage current

869:

843:

838:

819:Eugène Ducretet

814:

808:

737:NEC, NMC 100/10

713:

689:

621:

597:

562:

449:

408:

405:

396:

393:

384:

381:

369:

344:

340:

317:

313:

287:Anode material

222:

221:

152:

145:

141:

124:niobium nitride

118:

114:

105:

17:

12:

11:

5:

1986:

1984:

1976:

1975:

1965:

1964:

1961:

1960:

1954:

1948:

1942:

1937:

1922:

1919:

1916:

1915:

1901:

1883:

1865:

1847:

1831:

1790:

1775:

1761:

1743:

1724:

1712:

1700:

1681:

1672:

1661:

1652:

1643:

1631:

1619:

1608:

1591:

1579:

1564:

1555:

1533:

1512:

1482:

1427:

1426:

1424:

1421:

1420:

1419:

1412:

1409:

1408:

1407:

1404:

1401:

1398:

1395:

1390:

1387:

1386:

1385:

1371:

1370:

1342:

1339:

1325:

1322:

1319:

1318:

1315:

1312:

1308:

1307:

1300:

1293:

1277:

1274:

1272:

1269:

1263:

1259:

1255:

1251:

1243:

1239:

1235:

1228:

1224:

1220:

1216:

1212:

1208:

1204:

1196:

1192:

1179:

1178:

1175:

1172:

1168:

1164:

1161:

1158:

1155:

1151:

1147:

1146:

1143:

1140:

1137:

1134:

1130:

1129:

1126:

1122:

1118:

1114:

1111:

1108:

1105:

1101:

1097:

1096:

1093:

1090:

1089:Failure modes

1087:

1084:

1070:

1067:

1043:

1040:

1032:

1029:

1024:

1021:

1015:

1012:

1001:

997:

989:

985:

981:

977:

965:

962:

961:

960:

953:

946:

922:

918:

913:

910:

902:

901:

893:

888:

880:

875:

867:

862:

842:

839:

837:

834:

807:

804:

795:

794:

791:

788:

785:

782:

779:

775:

774:

771:

768:

765:

762:

759:

755:

754:

751:

750:

747:

744:

741:

738:

735:

731:

730:

727:

724:

721:

718:

715:

711:

707:

706:

703:

700:

697:

694:

691:

687:

683:

682:

679:

678:

675:

672:

669:

666:

663:

659:

658:

655:

652:

649:

646:

643:

639:

638:

635:

632:

629:

626:

623:

619:

615:

614:

611:

608:

605:

602:

599:

595:

591:

590:

587:

584:

581:

578:

575:

561:

558:

551:

550:

547:

544:

541:

540:Solid, polymer

537:

536:

533:

530:

527:

524:

520:

519:

516:

513:

510:

509:Solid, polymer

506:

505:

502:

499:

496:

492:

491:

488:

485:

482:

479:

475:

474:

471:

468:

465:

462:

448:

445:

432:, and a solid

410:

409:

406:

399:

397:

394:

387:

385:

382:

375:

373:

368:

365:

358:

357:

354:

351:

348:

345:

342:

338:

335:

331:

330:

327:

324:

321:

318:

315:

311:

308:

304:

303:

300:

297:

294:

291:

288:

260:

259:

246:

243:

238:

235:

232:

229:

151:

148:

143:

139:

116:

112:

104:

101:

15:

13:

10:

9:

6:

4:

3:

2:

1985:

1974:

1971:

1970:

1968:

1959:

1955:

1953:

1949:

1947:

1943:

1941:

1938:

1936:

1933:

1929:

1925:

1924:

1920:

1911:

1905:

1902:

1897:

1893:

1887:

1884:

1879:

1875:

1869:

1866:

1861:

1857:

1851:

1848:

1845:

1840:

1838:

1836:

1832:

1821:on 2013-08-06

1817:

1813:

1806:

1799:

1797:

1795:

1791:

1788:

1782:

1780:

1776:

1773:

1768:

1766:

1762:

1759:

1755:

1752:

1747:

1744:

1741:

1737:

1734:

1728:

1725:

1722:

1716:

1713:

1710:

1704:

1701:

1698:

1694:

1691:

1685:

1682:

1676:

1673:

1670:

1665:

1662:

1656:

1653:

1647:

1644:

1641:

1635:

1632:

1629:

1623:

1620:

1617:

1612:

1609:

1606:

1600:

1598:

1596:

1592:

1589:

1583:

1580:

1577:

1571:

1569:

1565:

1559:

1556:

1553:

1549:

1546:

1540:

1538:

1534:

1531:

1527:

1524:

1521:

1516:

1513:

1501:

1497:

1493:

1486:

1483:

1468:

1464:

1460:

1456:

1452:

1448:

1447:

1439:

1432:

1429:

1422:

1418:

1415:

1414:

1410:

1405:

1402:

1399:

1396:

1393:

1392:

1388:

1383:

1382:

1381:

1379:

1374:

1368:

1367:

1366:

1364:

1360:

1356:

1352:

1348:

1340:

1338:

1330:

1323:

1316:

1313:

1310:

1309:

1305:

1301:

1298:

1294:

1291:

1287:

1286:

1283:

1282:

1275:

1270:

1268:

1248:

1232:

1202:

1185:

1176:

1162:

1159:

1156:

1149:

1148:

1144:

1141:

1138:

1135:

1132:

1131:

1127:

1112:

1109:

1106:

1099:

1098:

1094:

1091:

1088:

1085:

1082:

1075:

1068:

1066:

1062:

1060:

1056:

1051:

1049:

1041:

1039:

1038:

1030:

1028:

1022:

1020:

1014:Surge Voltage

1013:

1011:

1008:

1005:

993:

970:

963:

958:

954:

951:

947:

944:

940:

939:

938:

936:

930:

928:

911:

909:

908:/EN 60384-1.

907:

899:

892:

889:

886:

879:

876:

873:

866:

863:

860:

857:

856:

855:

847:

840:

835:

833:

831:

826:

824:

820:

813:

805:

803:

800:

792:

789:

786:

783:

780:

777:

776:

772:

769:

766:

763:

760:

757:

756:

753:

752:

748:

745:

742:

739:

736:

733:

732:

728:

725:

722:

719:

716:

709:

708:

704:

701:

698:

695:

692:

685:

684:

681:

680:

676:

673:

670:

667:

664:

661:

660:

656:

653:

650:

647:

644:

641:

640:

636:

633:

630:

627:

624:

617:

616:

612:

609:

606:

603:

600:

593:

592:

588:

585:

582:

579:

576:

573:

572:

566:

559:

557:

548:

545:

542:

539:

538:

534:

531:

528:

525:

521:

517:

514:

511:

508:

507:

503:

500:

497:

494:

493:

489:

486:

483:

480:

476:

472:

469:

466:

463:

460:

453:

446:

444:

442:

438:

435:

431:

427:

423:

419:

415:

414:niobium oxide

403:

398:

391:

386:

379:

374:

371:

366:

364:

355:

352:

349:

346:

336:

333:

332:

328:

325:

322:

319:

309:

306:

305:

301:

298:

295:

292:

289:

286:

285:

279:

277:

272:

268:

265:

244:

241:

236:

233:

230:

227:

220:

219:

218:

216:

208:

207:

202:

201:

195:

191:

187:

183:

181:

177:

173:

169:

165:

156:

149:

147:

137:

133:

129:

128:niobium oxide

125:

122:

109:

102:

100:

98:

93:

91:

90:short circuit

85:

84:electrolyte.

83:

79:

75:

70:

68:

64:

60:

56:

52:

48:

44:

40:

36:

32:

23:

19:

1958:CapSite 2023

1932:1-25900731-6

1904:

1896:www.beuth.de

1895:

1886:

1877:

1868:

1859:

1850:

1823:. Retrieved

1816:the original

1746:

1727:

1715:

1703:

1684:

1675:

1664:

1655:

1646:

1640:D.R.P. 92564

1634:

1622:

1611:

1582:

1558:

1515:

1504:. Retrieved

1485:

1474:. Retrieved

1450:

1444:

1431:

1375:

1372:

1344:

1335:

1280:

1279:

1249:

1233:

1190:

1072:

1063:

1059:service life

1052:

1045:

1034:

1026:

1017:

1009:

1006:

994:

975:

931:

915:

903:

890:

877:

864:

858:

852:

827:

823:Karol Pollak

815:

801:

798:

563:

554:

484:0.1...18,000

464:Electrolyte

450:

411:

361:

273:

269:

261:

215:permittivity

212:

205:

204:

199:

198:

188:

184:

168:electrolytic

161:

110:

106:

97:Soviet Union

94:

86:

71:

34:

30:

28:

18:

1154:electrolyte

1104:electrolyte

784:7.3x4.3x4.0

764:7.3x4.3x4.2

740:7.3x4.3x2.8

720:7.3x4.3x4.1

714:electrolyte

696:7.3x4.3x4.1

690:electrolyte

668:7.3x4.3x4.0

648:7.3x4.3x4.0

628:7.3x4.3x4.0

622:electrolyte

604:7.3x4.3x4.0

598:electrolyte

498:0.1...3,300

437:electrolyte

290:Dielectric

164:valve metal

63:electrolyte

1973:Capacitors

1860:www.iec.ch

1856:"Homepage"

1825:2015-01-02

1506:2022-06-21

1476:2022-06-21

1423:References

1359:non-profit

1351:electronic

1347:electrical

1207:). The NbO

957:E12 series

830:transistor

810:See also:

512:10...1,500

430:dielectric

264:nanometers

176:dielectric

121:passivated

61:. A solid

59:dielectric

1357:(IEC), a

1055:life time

950:E6 series

943:E3 series

543:4.7...470

529:1...1,500

350:amorphous

323:amorphous

237:⋅

234:ε

132:anodizing

126:or using

49:metal or

1967:Category

1754:Archived

1736:Archived

1693:Archived

1548:Archived

1526:Archived

1500:Archived

1467:Archived

1411:See also

1389:Features

935:E series

504:125/150

490:125/200

418:sintered

307:Tantalum

78:tantalum

37:) is an

868:leakage

806:History

441:cathode

439:as the

172:voltage

67:cathode

47:niobium

1930:

1157:stable

1107:stable

896:, the

883:, the

577:Type

178:in an

41:whose

1819:(PDF)

1808:(PDF)

1470:(PDF)

1441:(PDF)

422:anode

69:(−).

43:anode

1928:ISBN

1203:(NbO

1053:The

790:4700

770:3700

726:2561

702:1461

674:4970

654:4900

634:2500

610:1285

549:105

535:105

518:105

356:2.5

329:1.6

1952:PDF

1812:AVX

1787:PDF

1733:PDF

1721:PDF

1690:PDF

1628:PDF

1605:PDF

1588:PDF

1576:PDF

1545:PDF

1459:doi

1451:108

1378:EIA

927:RMS

906:IEC

894:ESL

881:ESR

607:100

501:125

487:630

428:as

353:400

326:625

138:(Nb

74:SMD

1969::

1894:.

1876:.

1858:.

1834:^

1810:.

1793:^

1778:^

1764:^

1594:^

1567:^

1536:^

1498:.

1465:.

1449:.

1443:.

1349:,

1057:,

1050:.

929:.

787:10

723:40

699:80

651:10

631:35

546:16

532:10

515:25

443:.

347:41

320:27

182:.

29:A

1912:.

1898:.

1880:.

1862:.

1828:.

1509:.

1479:.

1461::

1264:5

1262:O

1260:2

1256:5

1254:O

1252:2

1244:5

1242:O

1240:2

1236:2

1229:2

1225:5

1223:O

1221:2

1217:5

1215:O

1213:2

1209:2

1205:2

1197:5

1195:O

1193:2

1173:2

1169:5

1167:O

1165:2

1152:2

1123:3

1121:O

1119:2

1115:2

1102:2

1002:C

998:C

990:R

986:R

982:N

978:R

923:N

921:C

919:R

891:L

878:R

865:R

859:C

767:7

746:-

743:-

712:2

688:2

671:5

620:2

596:2

343:5

341:O

339:2

316:5

314:O

312:2

245:d

242:A

231:=

228:C

209:.

206:d

200:A

144:5

142:O

140:2

117:5

115:O

113:2

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.