363:

2226:

3083:λ, abbreviation FIT (failures in time). This is the number of failures that can be expected in one billion (10) component-hours of operation (e.g. 1000 components for 1 million hours, or 1 million components for 1000 hours which is 1 ppm/1000 hours) at fixed working conditions during the period of constant random failures. These failure rate model implicitly assume the idea of "random failure". Individual components fail at random times but at a predictable rate. The standard operation conditions for the failure rate FIT are 40 °C and 0.5 U

491:. To achieve this, the "pellet" is submerged into a very weak solution of acid and DC voltage is applied. The total dielectric thickness is determined by the final voltage applied during the forming process. Initially the power supply is kept in a constant current mode until the correct voltage (i.e. dielectric thickness) has been reached; it then holds this voltage and the current decays to close to zero to provide a uniform thickness throughout the device and production lot. The chemical equations describing the dielectric formation process at the

351:

1782:

375:

2214:

1430:

606:

663:

467:/g powders, which have lower average particle sizes, are used for low voltage, high capacitance parts. By choosing the correct powder type and sintering temperature, a specific capacitance or voltage rating can be achieved. For example, a 220 μF 6 V capacitor will have a surface area close to 346 cm, or 80% of the size of a sheet of paper (US Letter, 8.5×11 inch paper has area ~413 cm), although the total volume of the pellet is only about 0.0016 cm.

3309:

1737:

3412:

1499:

3034:

3482:

2379:

1345:

form new oxide layer in weak areas of the dielectric), the dielectric thickness can be formed with much lower safety margins and consequently with much thinner dielectric than for solid types, resulting in a higher CV value per volume unit. Additionally, wet tantalum capacitors are able to operate at voltages in excess of 100 V up to 630 V, have a relatively low ESR, and have the lowest leakage current of all electrolytic capacitors.

253:

1337:

2725:

698:

2818:

manganese dioxide, due to moisture paths or due to cathode conductors (carbon, silver). This leakage current in solid electrolyte capacitors cannot be reduced by "healing" in the sense of generating new oxide because under normal conditions solid electrolytes are unable to deliver oxygen for forming processes. This statement should not be confused with the self-healing process during field crystallization, as described in

1404:. The solution R. L. Taylor and H. E. Haring from the Bell Labs found for the new miniaturized capacitor found in early 1950 was based on experience with ceramics. They ground metallic tantalum to a powder, pressed this powder into a cylindrical form and then sintered the powder particles at high temperature between 1,500 and 2,000 °C (2,730 and 3,630 °F) under vacuum conditions, into a pellet ("slug").

130:, which can form an insulating oxide layer. Applying a positive voltage to the tantalum anode material in an electrolytic bath forms an oxide barrier layer with a thickness proportional to the applied voltage. This oxide layer serves as the dielectric in an electrolytic capacitor. The properties of this oxide layer are compared with those of a niobium electrolytic capacitor oxide layer in the following table:

651:

28:

3919:

3473:

inverse of the individual capacitor's leakage current. Since every capacitor differs a little bit in individual leakage current the capacitors with a higher leakage current will get less voltage. The voltage balance over the series connected capacitors is not symmetrically. Passive or active voltage balance has to be provided in order to stabilize the voltage over each individual capacitor.

20:

119:

1641:

5343:

3576:, which defer to the standards of other industry organizations for particular application characteristics, e.g. the EIA size standards, IPC solderability standards, etc. The quality and reliability standards and methods of the US MIL-STD specifications are used for components requiring a higher reliability or a less benign operating environment are required.

686:-535-BAAC standard. The different sizes can also be identified by case code letters. For some case sizes (A to E), which have been manufactured for many decades, the dimensions and case coding over all manufactures are still largely the same. However, new developments in tantalum electrolytic capacitors such as the multi-anode technique to reduce the

590:

3109:, for other temperature and voltage applied, for current load, capacitance value, circuit resistance, mechanical influences and humidity, the FIT figure can recalculated with acceleration factors standardized for industrial or military contexts. For example, higher temperature and applied voltage cause the failure rate to increase.

1485:

manganese dioxide electrolyte, which have been available since 2002. The materials and processes used to produce niobium-dielectric capacitors are essentially the same as for existing tantalum-dielectric capacitors. The characteristics of niobium electrolytic capacitors and tantalum electrolytic capacitors are roughly comparable.

1418:, Sprague's Director of Research, is considered to be the actual inventor of tantalum capacitors in 1954. His invention was supported by R. J. Millard, who introduced the "reform" step in 1955, a significant improvement in which the dielectric of the capacitor was repaired after each dip-and-convert cycle of MnO

419:

3504:

For

Tantalum capacitors from the early 1970s the polarity is indicated by a dot. Positive lead is the lead on the right when the side with the dot is facing you. The positive lead may also be very slightly longer. Furthermore the polarity is marked on PCBs by differently-shaped solder points if there

3493:

Tantalum electrolytic capacitors with solid electrolyte are marked at their positive terminal with a bar or a "+". Tantalum electrolytic capacitors with non-solid electrolyte (axial leaded style) are marked on the negative terminal with a bar or a "-" (minus). The polarity better can be identified on

3489:

All tantalum capacitors are polarized components, with distinctly marked positive or negative terminals. When subjected to reversed polarity (even briefly), the capacitor depolarizes and the dielectric oxide layer breaks down, which can cause it to fail even when later operated with correct polarity.

2817:

in parallel with the capacitor in the series-equivalent circuit of electrolytic capacitors. The main causes of leakage current for solid tantalum capacitors are electrical breakdown of the dielectric, conductive paths due to impurities or due to poor anodization, bypassing of dielectric due to excess

1585:

and is the value for which the capacitor has been designed. Standardized measuring condition for electrolytic capacitors is an AC measuring method with a frequency of 100 to 120 Hz. Electrolytic capacitors differ from other capacitor types, whose capacitances are typically measured at 1 kHz

1569:

The electrical characteristics of tantalum electrolytic capacitors depend on the structure of the anode and the electrolyte used. This influences the capacitance value of tantalum capacitors, which depend on operating frequency and temperature. The basic unit of electrolytic capacitors capacitance is

3295:

The extremely thin oxide film of a tantalum electrolytic capacitor, the dielectric layer, must be formed in an amorphous structure. Changing the amorphous structure into a crystallized structure is reported to increase the conductivity by 1000 times, combined with an enlargement of the oxide volume.

3112:

The most often cited source for recalculation the failure rate is the MIL-HDBK-217F, the "bible" of failure rate calculations for electronic components. SQC Online, the online statistical calculators for acceptance sampling and quality control gives an online tool for short examination to calculate

2715:

Solid tantalum electrolytic capacitors can be damaged by surge, peak or pulse currents. Tantalum capacitors, which are exposed to surge, peak or pulse currents should be used with a voltage derating up to 70% in highly inductive circuits. If possible, the voltage profile should be a ramp turn-on, as

459:

at high temperature (typically 1200 to 1800 °C) which produces a mechanically strong pellet and drives off many impurities within the powder. During sintering, the powder takes on a sponge-like structure, with all the particles interconnected into a monolithic spatial lattice. This structure is

3513:

Tantalum capacitors, like most other electronic components and if enough space is available, have imprinted markings to indicate manufacturer, type, electrical and thermal characteristics, and date of manufacture. But most tantalum capacitors are chip types so the reduced space limits the imprinted

3335:

Surge currents after soldering-induced stresses may start crystallization, leading to insulation breakdown. The only way to avoid catastrophic failures is to limit the current which can flow from the source in order to reduce the breakdown to a limited area. Current flowing through the crystallized

2978:

Dielectric absorption occurs when a capacitor that has remained charged for a long time retains some charge when briefly discharged. Although an ideal capacitor would reach zero volts after discharge, real capacitors develop a small voltage from time-delayed dipole discharging, a phenomenon that is

1710:

With a reverse voltage applied, a reverse leakage current flows in very small areas of microcracks or other defects across the dielectric layer to the anode of the electrolytic capacitor. Although the current may only be a few microamps, it represents a very high localized current density which can

1371:

Due to their relatively high price, wet tantalum electrolytic capacitors have few consumer applications. They are used in ruggedized industrial applications, such as in probes for oil exploration. Types with military approvals can provide the extended capacitance and voltage ratings, along with the

3174:

The polymer electrolyte have a small deterioration of conductivity by a thermal degradation mechanism of the conductive polymer. The electrical conductivity decreased, as a function of time, in agreement with a granular metal type structure, in which aging is due to the shrinking of the conductive

1667:

The voltage rating of electrolytic capacitors decreases with increasing temperature. For some applications it is important to use a higher temperature range. Lowering the voltage applied at a higher temperature maintains safety margins. For some capacitor types therefore the IEC standard specify a

1484:

This development to low ESR capacitors with high CV-volumes in chip style for the rapid growing SMD technology in the 1990s increased the demand on tantalum chips dramatically. However, another price explosion for tantalum in 2000/2001 forced the development of niobium electrolytic capacitors with

1344:

The main feature of modern non-solid (wet) tantalum electrolytic capacitors is their energy density compared with that of solid tantalum and wet aluminum electrolytic capacitors within the same temperature range. Due to their self-healing properties (the non-solid electrolyte can deliver oxygen to

3356:

Solid tantalum capacitors with crystallization are most likely to fail at power-on. It is believed that the voltage across the dielectric layer is the trigger mechanism for the breakdown and that the switch-on current pushes the collapse to a catastrophic failure. To prevent such sudden failures,

1506:

Tantalum electrolytic capacitors as discrete components are not ideal capacitors, as they have losses and parasitic inductive parts. All properties can be defined and specified by a series equivalent circuit composed of an idealized capacitance and additional electrical components which model all

442:

of powders is expressed in capacitance (C, usually in μF) times volts (V) per gram (g). Since the mid-1980s, manufactured tantalum powders have exhibited around a ten-fold improvement in CV/g values (from approximately 20k to 200k). The typical particle size is between 2 and 10 μm. Figure 1 shows

1690:

The surge voltage indicates the maximum peak voltage value that may be applied to electrolytic capacitors during their application for a limited number of cycles. The surge voltage is standardized in IEC/EN 60384-1. For tantalum electrolytic capacitors the surge voltage shall be 1.3 times of the

522:

The dielectric layer thickness generated by the forming voltage is directly proportional to the voltage proof of electrolytic capacitors. Electrolytic capacitors are manufactured with a safety margin in oxide layer thickness, which is the ratio between voltage used for electrolytical creation of

518:

The oxide forms on the surface of the tantalum, but it also grows into the material. For each unit thickness of oxide growth, one third grows out and two thirds grows in. Due to the limits of oxide growth, there is a limit on the maximum voltage rating of tantalum oxide for each of the presently

3472:

need higher voltages than aluminum electrolytic capacitors usually offer. For such applications electrolytic capacitors can be connected in series for increased voltage withstanding capability. During charging, the voltage across each of the capacitors connected in series is proportional to the

1348:

The original wet tantalum capacitors developed in the 1930s were axial capacitors, having a wound cell consisting of a tantalum anode and foil cathode separated by a paper stripe soaked with an electrolyte, mounted in a silver case and non-hermetic elastomer sealed. Because of the inertness and

526:

The safety margin for solid tantalum capacitors with manganese dioxide electrolyte is typically between 2 and 4. That means that for a 25 V tantalum capacitor with a safety margin of 4 the dielectric voltage proof can withstand 100 V to provide a more robust dielectric. This very high

3119:

Tantalum capacitors are reliable components. Continuous improvement in tantalum powder and capacitor technologies have resulted in a significant reduction in the amount of impurities present, which formerly have caused most of the field crystallization failures. Commercially available tantalum

1448:

Although solid tantalum capacitors offered lower ESR and leakage current values than the aluminum electrolytics, in 1980 a price shock for tantalum in the industry dramatically reduced the usability of tantalum capacitors, especially in consumer entertainment electronics. In search of cheaper

336:. However, in comparing the permittivities of different oxide materials, it is seen that tantalum pentoxide has an approximately 3 times higher permittivity than aluminum oxide. Tantalum electrolytic capacitors of a given CV value can therefore be smaller than aluminum electrolytic capacitors.

3543:

Version 2: coding with year code/month code. The year codes are: "R" = 2003, "S"= 2004, "T" = 2005, "U" = 2006, "V" = 2007, "W" = 2008, "X" = 2009, "A" = 2010, "B" = 2011, "C" = 2012, "D" = 2013, "E" = 2014 etc. Month codes are: "1" to "9" = Jan. to Sept., "O" = October, "N" = November, "D" =

3291:

Tantalum capacitors are reliable on the same very high level as other electronic components with very low failure rates. However, they have a single unique failure mode called "field crystallization". Field crystallization is the major reason for degradation and catastrophic failures of solid

3899:

at high frequency. Tantalum capacitors can replace aluminum electrolytic capacitors in situations where the external environment or dense component packing results in a sustained hot internal environment and where high reliability is important. Equipment such as medical electronics and space

3300:

is characterized by a sudden rise in leakage current within a few milliseconds, from nanoamp magnitude to amp magnitude in low-impedance circuits. Increasing current flow can accelerate in an "avalanche effect" and rapidly spread through the metal/oxide. This can result in various degrees of

3331:

Impurities, tiny mechanical damages, or imperfections in the dielectric can affect the structure, changing it from amorphous to crystalline structure and thus lowering the dielectric strength. The purity of the tantalum powder is one of the most important parameters for defining its risk of

328:

All etched or sintered anodes have a much larger total surface area compared to a smooth surface of the same overall dimensions. This surface area increase boosts the capacitance value by a factor of up to 200 (depending on the rated voltage) for solid tantalum electrolytic capacitors.

2958:

2963:

The value of the leakage current depends on the voltage applied, on temperature of the capacitor, on measuring time, and on influence of moisture caused by case sealing conditions. They normally have a very low leakage current, most much lower than the specified worst-case.

3517:

Smaller capacitors use a shorthand notation. The most commonly used format is: XYZ J/K/M "V", where XYZ represents the capacitance (calculated as XY × 10 pF), the letters K or M indicate the tolerance (±10% and ±20% respectively) and "V" represents the working voltage.

3071:

and is divided into three areas: Early failures or infant mortality failures, constant random failures and wear out failures. Failure types included in the total failure rate are short circuit, open circuit, and degradation failures (exceeding electrical parameters).

1476:

are better by a factor of 1000 than that of manganese dioxide, and are close to the conductivity of metals. In 1993 NEC introduced their SMD polymer tantalum electrolytic capacitors, called "NeoCap". In 1997 Sanyo followed with their "POSCAP" polymer tantalum chips.

232:

After forming a dielectric oxide on the rough anode structures, a cathode is needed. An electrolyte acts as the cathode of electrolytic capacitors. There are many different electrolytes in use. Generally, the electrolytes will be distinguished into two species,

81:

Tantalum capacitors are inherently polarized components. Reverse voltage can destroy the capacitor. Non-polar or bipolar tantalum capacitors are made by effectively connecting two polarized capacitors in series, with the anodes oriented in opposite directions.

1480:

A new conductive polymer for tantalum polymer capacitors was presented by Kemet at the "1999 Carts" conference. This capacitor used the newly developed organic conductive polymer PEDT Poly(3,4-ethylenedioxythiophene), also known as PEDOT (trade name

Baytron).

4756:

3455:

Small or low voltage electrolytic capacitors may be safely connected in parallel. Large sizes capacitors, especially large sizes and high voltage types should be individually protected against sudden discharge of the whole bank due to a failed capacitor.

1586:

or higher. For tantalum capacitors a DC bias voltage of 1.1 to 1.5 V for types with a rated voltage of ≤2.5 V or 2.1 to 2.5 V for types with a rated voltage of >2.5 V may be applied during the measurement to avoid reverse voltage.

2576:

The ripple current is specified as an effective (RMS) value at 100 or 120 Hz or at 10 kHz at upper category temperature. Non-sinusoidal ripple currents have to be analyzed and separated into their component sinusoidal frequencies by means of

362:

1891:

1589:

The percentage of allowed deviation of the measured capacitance from the rated value is called capacitance tolerance. Electrolytic capacitors are available in different tolerance series classifications, whose values are specified in the

4564:

Y. K. ZHANG, J. LIN,Y. CHEN, Polymer

Aluminum Electrolytic Capacitors with Chemically-Polymerized Polypyrrole (PPy) as Cathode Materials Part I. Effect of Monomer Concentration and Oxidant on Electrical Properties of the Capacitors,

3301:

destruction from rather small, burned areas on the oxide to zigzag burned streaks covering large areas of the pellet or complete oxidation of the metal. If the current source is unlimited a field crystallization may cause a capacitor

1425:

This first solid electrolyte manganese dioxide had 10 times better conductivity than all other types of non-solid electrolyte capacitors. In the style of tantalum pearls, they soon found wide use in radio and new television devices.

3490:

If the failure is a short circuit (the most common occurrence), and current is not limited to a safe value, catastrophic thermal runaway may occur. This failure can even result in the capacitor forcefully ejecting its burning core.

3175:

polymer grains. The life time of polymer electrolytic capacitors is specified in similar terms to the non-solid electrolytic caps, but its life time calculation follows other rules which lead to much longer operational life times.

1711:

cause a tiny hot-spot. This can cause some conversion of amorphous tantalum pentoxide to the more conductive crystalline form. When a high current is available, this effect can avalanche and the capacitor may become a total short.

3505:

are no "+" or "-" signs printed on the PCB. For example a square-shaped solder point is used for positive polarity (needs to be verified on particular case measuring connection against ground, negative or positive voltage pins)

690:

or the "face down" technique to reduce the inductance have led to a much wider range of chip sizes and their case codes. These departures from EIA standards mean devices from different manufacturers are no longer always uniform.

5012:

E. Vitoratos, S. Sakkopoulos, E. Dalas, N. Paliatsas, D. Karageorgopoulos, F. Petraki, S. Kennou, S.A. Choulis, Thermal degradation mechanisms of PEDOT:PSS, Organic

Electronics, Volume 10, Issue 1, February 2009, Pages 61–66,

2706:

In solid tantalum electrolytic capacitors the heat generated by the ripple current influences the reliability of the capacitors. Exceeding the limit tends to result in catastrophic failures with shorts and burning components.

2156:

2701:

2225:

527:

safety factor is substantiated by the failure mechanism of solid tantalum capacitors, "field crystallization". For tantalum capacitors with solid polymer electrolyte the safety margin is much lower, typically around 2.

454:

The powder is compressed around a tantalum wire (known as the riser wire) to form a "pellet". The riser wire ultimately becomes the anode connection to the capacitor. This pellet/wire combination is subsequently vacuum

1904:. Regarding to the IEC/EN 60384-1 standard, the impedance values of tantalum electrolytic capacitors are measured and specified at 10 kHz or 100 kHz depending on the capacitance and voltage of the capacitor.

3532:

Capacitance, tolerance and date of manufacture can be indicated with a short code specified in IEC/EN 60062. Examples of short-marking of the rated capacitance (microfarads): μ47 = 0,47 μF, 4μ7 = 4.7 μF, 47μ = 47 μF

3101:

as reference conditions and expressed as per cent failed components per thousand hours (n %/1000 h). That is "n" number of failed components per 10 hours or in FIT the ten-thousand-fold value per 10 hours.

543:

The next stage for solid tantalum capacitors is the application of the cathode plate (wet tantalum capacitors use a liquid electrolyte as a cathode in conjunction with their casing). This is achieved by pyrolysis of

3183:

Tantalum capacitors show different electrical long-term behaviors depending on the electrolyte used. Application rules for types with an inherent failure mode are specified to ensure high reliability and long life.

2244:) summarizes all resistive losses of the capacitor. These are the terminal resistances, the contact resistance of the electrode contact, the line resistance of the electrodes, the electrolyte resistance, and the

97:, and where reliability is crucial. Due to its reliability, durability and performance under extreme conditions, it is used in medical equipment, aerospace and military applications. Other applications include

2845:

476:

536:

3887:

circuits to achieve long hold duration, and some long duration timing circuits where precise timing is not critical. They are also often used for power supply rail decoupling in parallel with film or

1699:

Transient voltage or a current spike applied to tantalum electrolytic capacitors with solid manganese dioxide electrolyte can cause some tantalum capacitors to fail and may directly lead to a short.

575:

This process is repeated several times through varying specific gravities of nitrate solution, to build up a thick coat over all internal and external surfaces of the "pellet", as shown in Figure 4.

2345:

447:

2556:

1407:

These first sintered tantalum capacitors used a liquid electrolyte. In 1952 Bell Labs researchers discovered the use manganese dioxide as a solid electrolyte for a sintered tantalum capacitor.

316:

3336:

area causes heating in the manganese dioxide cathode near the fault. At increased temperatures a chemical reaction then reduces the surrounding conductive manganese dioxide to the insulating

1896:

The impedance is a frequency dependent AC resistance and possesses both magnitude and phase at a particular frequency. In data sheets of electrolytic capacitors, only the impedance magnitude

1714:

Nevertheless, tantalum electrolytic capacitors can withstand for short instants a reverse voltage for a limited number of cycles. The most common guidelines for tantalum reverse voltage are:

350:

2049:

325:

per volt. Despite this, the dielectric strengths of these oxide layers are quite high. Thus, tantalum capacitors can achieve a high volumetric capacitance compared to other capacitor types.

1393:

The first tantalum electrolytic capacitors with wound tantalum foils and non-solid electrolyte were developed in 1930 by

Tansitor Electronic Inc. (US), and were used for military purposes.

3292:

tantalum capacitors. More than 90% of the today's rare failures in tantalum solid-state electrolytic capacitors are caused by shorts or increased leakage current due to this failure mode.

374:

1982:

3548:

For very small capacitors no marking is possible, only the component's packaging or the assembly manufacturer's records of the components used can be used to identify a component fully.

639:

2485:

This internal generated heat, in addition to the ambient temperature and possibly other external heat sources, leads to a capacitor body temperature having a temperature difference of

1410:

Although the fundamental inventions came from the Bell Labs, the innovations for manufacturing commercially viable tantalum electrolytic capacitors were done by the researchers of the

2480:

1679:

Lower voltage applied may have positive influences for tantalum electrolytic capacitors. Lowering the voltage applied increases the reliability and reduces the expected failure rate.

3595:

The tests and requirements to be met by aluminum and tantalum electrolytic capacitors for use in electronic equipment for approval as standardized types are set out in the following

4203:

650:

1672:". The category voltage is the maximum DC voltage or peak pulse voltage that may be applied continuously to a capacitor at any temperature within the category temperature range T

3497:

A particular cause of confusion is that on surface mount tantalum capacitors the positive terminal is marked with a bar. Whereas on aluminium surface mount capacitors it is the

1797:

at a particular frequency in an AC circuit. In this sense impedance is a measure of the ability of the capacitor to attenuate alternating currents and can be used like Ohms law

3052:

and can be described qualitatively and quantitatively; it is not directly measurable. The reliability of electrolytic capacitors are empirically determined by identifying the

2573:. The temperature of the capacitor, which is established on the balance between heat produced and distributed, should not exceed the capacitors maximum specified temperature.

3305:. In this circumstance, the failure can be catastrophic if there is nothing to limit the available current, as the series resistance of the capacitor can become very low.

1803:

552:. The "pellet" is dipped into an aqueous solution of nitrate and then baked in an oven at approximately 250 °C to produce the dioxide coat. The chemical equation is:

2762:

4569:

1907:

Besides measuring, the impedance can also be calculated using the idealized components out of a capacitor's series-equivalent circuit, including an ideal capacitor

4743:

P. Vasina, T. Zednicek, Z. Sita, J. Sikula, J. Pavelka, AVX, Thermal and

Electrical Breakdown Versus Reliability of Ta2O5 Under Both – Bipolar Biasing Conditions

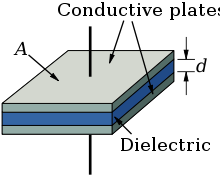

4379:

2782:

4153:

4044:

Tantalum electrolytic fixed capacitors from Japan : determination of no injury in investigation no. AA1921-159 under the

Antidumping Act, 1921, as amended

4530:

4485:

4289:

1728:

These guidelines apply for short excursion and should never be used to determine the maximum reverse voltage under which a capacitor can be used permanently.

443:

powders of successively finer grain, resulting in greater surface area per unit volume. Note the very great difference in particle size between the powders.

2213:

5265:

3020:

circuits. However, in most applications where tantalum electrolytic capacitors are supporting power supply lines, dielectric absorption is not a problem.

4981:

4516:

4104:

I. Horacek, T. Zednicek, S. Zednicek, T. Karnik, J. Petrzilek, P. Jacisko, P. Gregorova, AVX, "High CV Tantalum

Capacitors: Challenges and Limitations"

682:

style as tantalum chip capacitors. It has contact surfaces on the end faces of the case and is manufactured in different sizes, typically following the

3188:

Long-term electrical behavior, failure modes, self-healing mechanism, and application rules of the different types of tantalum electrolytic capacitors

1390:

patented a capacitor using aluminum electrodes and a liquid electrolyte. Aluminum electrolytic capacitors were commercially manufactured in the 1930s.

3565:

2064:

1558:

2587:

3132:

is this failure rate for a 100 μF/25 V tantalum chip capacitor used with a series resistance of 0.1 Ω the failure rate is 0.02 FIT.

1364:

which led to increasing leakage currents and short circuits, new styles of wet tantalum capacitors use a sintered tantalum pellet cell and a gelled

4455:

4017:

3405:

3398:

4603:

3767:

602:

The picture below shows the production flow of tantalum electrolytic chip capacitors with sintered anode and solid manganese dioxide electrolyte.

3391:

4645:

3789:

368:

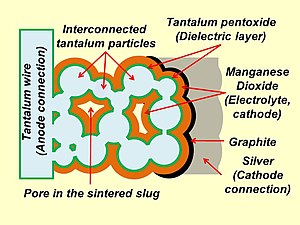

Schematic representation of the structure of a sintered tantalum electrolytic capacitor with solid electrolyte and the cathode contacting layers

4717:

4698:

4676:

4588:

3643:

The market of tantalum electrolytic capacitors in 2008 was approximately US$ 2.2 billion, which was roughly 12% of the total capacitor market.

2810:

is a special characteristic for electrolytic capacitors other conventional capacitors don't have. This current is represented by the resistor

4326:

4271:

P. Vasina, T. Zednicek, AVX, J. Sikula, J. Pavelka, AVX, Failure Modes of

Tantalum Capacitors made by Different Technologies, CARTS US 2001

5187:

5124:

A. Teverovsky, Derating of Surge

Currents for Tantalum Capacitors, Dell Services Federal Government, Inc. NASA/GSFC Greenbelt, MD 20771, US

2255:

behind smoothing and may influence the circuit functionality. Related to the capacitor ESR is accountable for internal heat generation if a

1691:

rated voltage, rounded off to the nearest volt. The surge voltage applied to tantalum capacitors may influence the capacitors failure rate.

122:

Basic principle of the anodic oxidation, in which, by applying a voltage with a current source, an oxide layer is formed on a metallic anode

4849:

3040:

with times of "early failures", "random failures", and wear-out failures". The time of random failures is the time of constant failure rate

2953:{\displaystyle I_{\mathrm {Leak} }=0{.}01\,\mathrm {{A} \over {V\cdot F}} \cdot U_{\mathrm {R} }\cdot C_{\mathrm {R} }+3\,\mathrm {\mu A} }

4950:

1660:

is the maximum DC voltage or peak pulse voltage that may be applied continuously at any temperature within the rated temperature range T

638:

4874:

4316:

1437:

In 1971, Intel launched its first microcomputer (the MCS 4) and 1972 Hewlett Packard launched one of the first pocket calculators (the

5135:

D. Liu, MEI Technologies, Inc. NASA Goddard Space Flight Center, Failure Modes in Capacitors When Tested Under a Time-Varying Stress

4782:

4623:

Ch. Schnitter, A. Michaelis, U. Merker, H.C. Starck, Bayer, New Niobium Based Materials for Solid Electrolyte Capacitors, Carts 2002

3745:

1785:

Typical impedance curves for different capacitance values over frequency. As higher the capacitance as lower the resonance frequency.

694:

An overview of the dimensions of conventional tantalum rectangular chip capacitors and their coding is shown in the following table:

609:

Representation of the production flow of tantalum electrolytic capacitors with sintered anode and solid manganese dioxide electrolyte

5303:

4000:

5040:

4733:

4554:

460:

of predictable mechanical strength and density, but is also highly porous, producing a large internal surface area (see Figure 2).

4644:

Y. Pozdeev-Freeman, P. Maden, Vishay, Solid-Electrolyte Niobium Capacitors Exhibit Similar Performance to Tantalum, Feb 1, 2002,

1707:

Tantalum electrolytic are polarized and generally require anode electrode voltage to be positive relative to the cathode voltage.

1620:

The required capacitance tolerance is determined by the particular application. Electrolytic capacitors, which are often used for

4821:

4767:

4468:

1756:

or similar applications, capacitors are seen as a storage component to store electrical energy. But for smoothing, bypassing, or

1507:

losses and inductive parameters of a capacitor. In this series-equivalent circuit the electrical characteristics are defined by:

628:

Axial-leaded tantalum capacitors, with solid and non-solid electrolyte, mostly used for military, medical and space applications.

63:

dielectric layer, the tantalum capacitor distinguishes itself from other conventional and electrolytic capacitors in having high

662:

4713:

A. Teverovsky, Perot Systems Code 562, NASA GSFCE, Effect of Surge Current Testing on Reliability of Solid Tantalum Capacitors

3947:

3932:

1740:

Simplified series-equivalent circuit of a capacitor for higher frequencies (above); vector diagram with electrical reactances X

1628:

capacitors don't have the need for narrow tolerances because they are mostly not used for accurate frequency applications like

75:

3048:

of a component is a property that indicates how well a component performs its function in a time interval. It is subject to a

3962:

2305:

1594:

specified in IEC 60063. For abbreviated marking in tight spaces, a letter code for each tolerance is specified in IEC 60062.

683:

2825:

The specification of the leakage current in datasheets often will be given by multiplication of the rated capacitance value

5347:

4584:

U. Merker, K. Wussow, W. Lövenich, H. C. Starck GmbH, New Conducting Polymer Dispersions for Solid Electrolyte Capacitors,

4566:

4378:

E. K. Reed, Jet Propulsion Laboratory, Characterization of Tantalum Polymer Capacitors, NEPP Task 1.21.5, Phase 1, FY05]

1771:

to filter undesired AC components from voltage rails. For this (biased) AC function the frequency dependent AC resistance (

4369:

R. L. Taylor and H. E. Haring, "A metal semi-conductor capacitor," J. Electrochem. Soc., vol. 103, p. 611, November, 1956.

3632:

3494:

the shaped side of the case, which has the positive terminal. The different marking styles can cause dangerous confusion.

2401:) after rectifying an AC voltage and flows as charge and discharge current through the decoupling or smoothing capacitor.

2367:

1606:

1599:

1591:

4305:

3120:

capacitors now have reached as standard products the high MIL standard "C" level which is 0.01%/1000h at 85 °C and U

2277:. The dissipation factor is determined by the tangent of the phase angle between the subtraction of capacitive reactance

586:

to provide a good connection from the manganese dioxide cathode plate to the external cathode termination(see Figure 5).

5146:

3892:

2510:

2237:

1550:

1537:

1442:

1400:

in the early 1950s as a miniaturized and more reliable low-voltage support capacitor to complement their newly invented

687:

282:

4910:

IEC/EN 61709, Electric components. Reliability. Reference conditions for failure rates and stress models for conversion

3635:

are working together to raise awareness of the relationship between consumer electronic devices and conflict minerals.

2581:

and the equivalent ripple current calculated as the square root of the sum of the squares of the individual currents.

242:

4418:

A. Fraioli, Recent Advances in the Solid-State Electrolytic Capacitor, IRE Transactions on Component Parts, June 1958

2397:

value of a superimposed AC current of any frequency upon a DC current. It arises mainly in power supplies (including

2003:

1648:

Referring to IEC/EN 60384-1 standard the allowed operating voltage for tantalum capacitors is called "rated voltage U

5278:

Conference Record of 1998 IEEE Industry Applications Conference. Thirty-Third IAS Annual Meeting (Cat. No.98CH36242)

5136:

4938:

4272:

4537:

4492:

4342:

4341:

Manufacturer's Cross Reference and Tantalum Chip Capacitor Part Numbering Systems; F3075D; Kemet; November 2004>

4286:

4065:

3469:

3091:

2398:

5125:

5058:

4833:

4285:

Y. Pozdeev-Freeman, Vishay, How Far Can We Go with High CV Tantalum Capacitors, PCI, January/February 2005, p. 6,

1939:

5158:

4920:

4089:

Tomáš Kárník, AVX, NIOBIUM OXIDE FOR CAPACITOR MANUFACTURING, METAL 2008, 13. –15. 5. 2008, Hradec nad Moravicí

3833:

55:, covered by an insulating oxide layer that forms the dielectric, surrounded by liquid or solid electrolyte as a

4257:

T.Zednicek, AVX, A Study of Field Crystallization in Tantalum Capacitors and its effect on DCL and Reliability,

3811:

2259:

flows over the capacitor. This internal heat may influence the reliability of tantalum electrolytic capacitors.

5327:

3967:

3937:

1781:

1752:

Tantalum electrolytic capacitors, as well as other conventional capacitors, have two electrical functions. For

1411:

2428:

2231:

Typical impedance and ESR curves over frequency for different electrolytic capacitor styles compared with MLCC

4105:

1349:

stability of the tantalum dielectric oxide layer against strong acids, the wet tantalum capacitors could use

3569:

3076:

3061:

3045:

2383:

332:

The volume of an electrolytic capacitor is defined by the product of capacitance and voltage, the so-called

5081:

4810:

4798:

4744:

4656:

4633:

23:

Tantalum capacitors in different styles: axial, radial and SMD-chip versions (size comparison with a match)

5281:

5025:

4861:

4465:

Larry E. Mosley, Intel Corporation, Capacitor Impedance Needs For Future Microprocessors, CARTS USA 2006,

4304:

R. Faltus, AVX Corp.EET Asia, Choosing the right capacitors to ensure long-term control-circuit stability

4149:

4090:

3942:

3573:

3332:

crystallization. Since the mid-1980s, manufactured tantalum powders have exhibited an increase in purity.

3128:. Recalculated in FIT with the acceleration factors coming from MIL HDKB 217F at 40 °C and 0.5 U

1429:

1381:

679:

40:

3148:, load life or useful life of tantalum electrolytic capacitors depends entirely on the electrolyte used:

2980:

2973:

2807:

1524:

1386:

The group of "valve metals" capable of forming an insulating oxide film was discovered in 1875. In 1896

439:

102:

4755:

A. Berduque, Kemet, Low ESR Aluminium Electrolytic Capacitors for Medium to High Voltage Applications,

4408:

3009:

Dielectric absorption can cause a problem in circuits where very small currents are used, such as long-

1445:(ESR) for bypass and decoupling capacitors of standard electrolytic capacitors needed to be decreased.

605:

1886:{\displaystyle Z={\frac {\hat {u}}{\hat {\imath }}}={\frac {U_{\mathrm {eff} }}{I_{\mathrm {eff} }}}.}

1415:

5014:

4778:

Vishay BCcomponents, Introduction Aluminum Capacitors, Revision: 10-Sep-13 1 Document Number: 28356,

3896:

3337:

3297:

1772:

1757:

1625:

1577:

The capacitance value specified in the data sheets of the manufacturers is called rated capacitance C

1468:

in 1975 was a break-through in point of lower ESR. The conductivities of conductive polymers such as

1361:

5286:

5264:

Electronic Capacitors, SIC 3675, NAICS 334414: Electronic Capacitor Manufacturing, Industry report:

4714:

4695:

4673:

4585:

4131:

5363:

4237:

H. W. Holland, Kemet, Solid Tantalum Capacitor Failure Mechanism and Determination of Failure Rates

3411:

3308:

2252:

1765:

4483:

W. Serjak, H. Seyeda, Ch. Cymorek, Tantalum Availability: 2000 and Beyond, PCI, March/April 2002,

4454:

K. Lischka, Spiegel 27.09.2007, 40 Jahre Elektro-Addierer: Der erste Taschenrechner wog 1,5 Kilo,

4130:

H. Haas, H. C. Starck GmbH, Magnesium Vapour Reduced Tantalum Powders with Very High Capacitances

2839:

together with an addendum figure, measured after a measuring time of 2 or 5 minutes, for example:

622:

Tantalum chip capacitors: SMD style for surface mounting, 80% of all tantalum capacitors are SMDs

5309:

4694:

A. Teverovsky, NASA, Effect of Surge Current Testing on Reliability of Solid Tantalum Capacitors

3972:

3924:

3528:

476M 100V implies a capacitance of 47 × 10 pF = 47 μF (M = ±20%) with a working voltage of 100 V.

3348:) and insulates the crystallized oxide in the tantalum oxide layer, stopping local current flow.

3049:

2570:

2266:

1453:

394:

86:

44:

3907:

on computer motherboards and in peripherals, due to their small size and long-term reliability.

3525:

105K 330V implies a capacitance of 10 × 10 pF = 1 μF (K = ±10%) with a working voltage of 330 V.

1736:

3404:

3397:

3033:

1498:

589:

5299:

5095:

R. Faltus, AVX, Advanced capacitors ensure long-term control-circuit stability, 7/2/2012, EDT

4975:

4957:

4510:

4322:

4187:

4047:

3996:

3957:

3952:

3888:

3628:

3617:

Surface mount fixed tantalum electrolytic capacitors with conductive polymer solid electrolyte

3097:

For tantalum capacitors, often the failure rate is specified at 85 °C and rated voltage U

2731:

2562:

2245:

1621:

1397:

549:

545:

134:

Characteristics of the different oxide layers in tantalum and niobium electrolytic capacitors

98:

71:

4222:

B. Goudswaard, F. J. J. Driesens, "Failure Mechanism of Solid Tantalum Capacitors", Philips,

3605:

Surface mount fixed tantalum electrolytic capacitors with manganese dioxide solid electrolyte

385:

A typical tantalum capacitor is a chip capacitor and consists of tantalum powder pressed and

5291:

5080:

J.Gill, T. Zednicek, AVX, VOLTAGE DERATING RULES FOR SOLID TANTALUM AND NIOBIUM CAPACITORS,

4878:

4258:

3904:

3679:

3481:

3390:

2578:

2394:

2378:

2355:

2199:

of the capacitor. At this point, the capacitor begins to behave primarily as an inductance.

1557:

Using a series equivalent circuit rather than a parallel equivalent circuit is specified by

1465:

1357:

356:

The capacitor cell of a tantalum electrolytic capacitor consists of sintered tantalum powder

4779:

1336:

475:

126:

Electrolytic capacitors use a chemical feature of some special metals, historically called

5062:

5044:

4786:

4721:

4702:

4680:

4614:

F. Jonas, H.C.Starck, Baytron, Basic chemical and physical properties, Präsentation 2003,

4592:

4573:

4472:

4293:

3884:

3701:

3465:

3017:

1461:

1441:). The requirements for capacitors increased, especially the demand for lower losses. The

535:

435:

252:

94:

4937:

SQC online table calculator, Capacitor Failure Rate Model, MIL-HDBK-217, Rev. F—Notice 2

4655:

Ch. Reynolds, AVX, Technical Information, Reliability Management of Tantalum Capacitors,

3627:

Tantalum capacitors are the main use of the element tantalum. Tantalum ore is one of the

487:

is then formed over all the tantalum particle surfaces by the electrochemical process of

380:

Construction of a typical SMD tantalum electrolytic chip capacitor with solid electrolyte

256:

A dielectric material is placed between two conducting plates (electrodes), each of area

5107:

5037:

4948:

Hitachi, Precautions in using Tantalum Capacitors, 4.2 Failure Rate Calculation Formula

4632:

T. Zednicek, W. A. Millman, Ch. Reynolds, AVX, Tantalum and Niobium Technology Roadmap

697:

446:

3057:

2767:

2724:

1790:

1682:

Applying a higher voltage than specified may destroy tantalum electrolytic capacitors.

1457:

249:. The oxide layer may be destroyed if the polarity of the applied voltage is reversed.

31:

10 μF 30 VDC-rated tantalum capacitors, solid electrolyte epoxy-dipped style.

4466:

3900:

equipment that require high quality and reliability makes use of tantalum capacitors.

1553:

which is the effective self-inductance of the capacitor, usually abbreviated as "ESL".

1422:

deposition. This dramatically reduced the leakage current of the finished capacitors.

5357:

5096:

3903:

An especially common application for low-voltage tantalum capacitors is power supply

3536:

The date of manufacture is often printed in accordance with international standards.

3302:

3116:

Some manufacturers of tantalum capacitors may have their own FIT calculation tables.

3105:

For conditions other than the standard operation conditions 40 °C and 0.5 U

3068:

3037:

3010:

2404:

Ripple currents generate heat inside the capacitor body. This dissipation power loss

1676:. The relation between both voltages and temperatures is given in the picture right.

1365:

1350:

5313:

4732:

I. Bishop, J. Gill, AVX Ltd., Reverse Voltage Behavior of Solid Tantalum Capacitors

4117:

1748:

and resistance ESR and for illustration the impedance Z and dissipation factor tan δ

1449:

alternatives, the industry switched back to using aluminum electrolytic capacitors.

5170:

3145:

3141:

3080:

3053:

1761:

1387:

273:

74:. Tantalum electrolytic capacitors are considerably more expensive than comparable

60:

27:

3657:

418:

345:

Construction of a solid tantalum chip capacitor with manganese dioxide electrolyte

321:

The dielectric thickness of electrolytic capacitors is very thin, in the range of

4899:

4407:

Sprague, Dr. Preston Robinson Granted 103rd Patent Since Joining Company In 1929

2382:

The high ripple current across the smoothing capacitor C1 in a power supply with

2354:

is used for capacitors with very low losses in frequency determining circuits or

1340:

Cross section of a non-solid all tantalum electrolytic capacitor, hermetic sealed

523:

dielectric and rated voltage of the capacitor, to ensure reliable functionality.

4553:

About the Nobel Prize in Chemistry 2000, Advanced Information, October 10, 2000,

3579:

The definition of the characteristics and the procedure of the test methods for

3561:

2195:. With frequencies above the resonance the impedance increases again due to the

2151:{\displaystyle Z={\sqrt {{ESR}^{2}+(X_{\mathrm {C} }+(-X_{\mathrm {L} }))^{2}}}}

1540:

which summarizes all ohmic losses of the capacitor, usually abbreviated as "ESR"

1469:

430:

Tantalum capacitors are manufactured from a powder of relatively pure elemental

90:

64:

3918:

3540:

Version 1: coding with year/week numeral code, "1208" is "2012, week number 8".

2696:{\displaystyle I_{R}={\sqrt {{i_{1}}^{2}+{i_{2}}^{2}+{i_{3}}^{2}+{i_{n}}^{2}}}}

1668:"temperature derated voltage" for a higher temperature, the "category voltage U

118:

19:

5248:"Beuth Verlag – Normen, Standards & Fachliteratur kaufen | seit 1924"

4171:

3914:

3557:

3013:

2566:

1995:

1644:

Relation between rated and category voltage and rated and category temperature

1629:

1613:

1401:

484:

398:

5276:

Prymak, J.D. (1998). "New tantalum capacitors in power supply applications".

4797:

I. Salisbury, AVX, Thermal Management of Surface Mounted Tantalum Capacitors

3855:

3647:

Product programs of larger manufacturers of tantalum electrolytic capacitors

2386:

causes significant internal heat generation corresponding to the capacitor's

1372:

high quality levels required for avionics, military, and space applications.

5295:

4872:"Understand Capacitor Soakage to Optimize Analog Systems" by Bob Pease 1982

4318:

Tantalum and Niobium-Based Capacitors: Science, Technology, and Applications

3883:

The low leakage and high capacity of tantalum capacitors favor their use in

3580:

3312:

If the current is limited in tantalum electrolytic capacitors with solid MnO

2163:

1640:

488:

456:

386:

189:

4427:

R. J. Millard, Sprague, US Patent 2936514, October 24, 1955 – May 17, 1960

4051:

3991:

Dhanasekharan Natarajan (2015). "Selection and Application of Components".

2265:

Discussions of electrolytic capacitors historically sometimes refer to the

2208:

Typical impedance and ESR curves as a function of frequency and temperature

5342:

4860:

R. W. Franklin, AVX, ANALYSIS OF SOLID TANTALUM CAPACITOR LEAKAGE CURRENT

4191:

678:

More than 90% of all tantalum electrolytic capacitors are manufactured in

4398:

Preston Robinson, Sprague, US Patent 3066247, 25 Aug. 1954 – 27 Nov. 1962

2359:

1768:

579:

431:

48:

5157:

Epcos, Aluminum electrolytic capacitors, General technical informations

4204:"J. Qazi, Kemet, An Overview of Failure Analysis of Tantalum Capacitors"

2262:

Generally, the ESR decreases with increasing frequency and temperature.

5055:

4227:

2489:

against the ambient. This heat has to be distributed as thermal losses

402:

272:

whose capacitance is greater the larger the electrode area, A, and the

56:

578:

In traditional construction, the "pellet" is successively dipped into

3723:

2728:

general leakage behavior of electrolytic capacitors: leakage current

1794:

706:

Standard dimensions for surface-mount (SMD) tantalum chip capacitors

618:

Tantalum electrolytic capacitors are made in three different styles:

583:

5229:

2561:

The internal generated heat has to be distributed to the ambient by

625:

Tantalum "pearls", resin-dipped, single-ended style for PCB mounting

4995:

2358:

where the reciprocal value of the dissipation factor is called the

3480:

3307:

3032:

2723:

1780:

1753:

1735:

1639:

1571:

1497:

1473:

1438:

1428:

1353:

as an electrolyte, thus providing them with a relatively low ESR.

1335:

1327:

Note: EIA 3528 metric is also known as EIA 1411 imperial (inches).

696:

604:

588:

534:

492:

474:

445:

417:

390:

322:

251:

117:

52:

26:

18:

4768:

Joelle Arnold, Uprating of Electrolytic Capacitors, DfR Solutions

4437:

4389:

D. A. McLean, F. S. Power, Proc. Inst. Radio Engrs. 44 (1956) 872

4118:"H.C. Starck GmbH, Product Information Tantalum capacitor powder"

3367:

using of circuits with slow power-up modes (soft-start circuits).

276:, ε, are and the thinner the thickness, d, of the dielectric is.

3591:

IEC/EN 60384-1: Fixed capacitors for use in electronic equipment

3316:

electrolyte, a self-healing process can take place, reducing MnO

2415:

and is the squared value of the effective (RMS) ripple current

241:

electrolytes. Non-solid electrolytes are a liquid medium whose

5211:

4900:"Modeling Dielectric Absorption in Capacitors", by Ken Kundert

4809:

R.W. Franklin, AVX, Ripple Rating of Tantalum Chip Capacitors

4356:

D. F. Tailor, Tantalum and Tantalum Compounds, Fansteel Inc.,

3611:

fixed tantalum capacitors with non-solid and solid electrolyte

1724:

1% of rated voltage to a maximum of 0.1 V at 125 °C.

246:

3556:

Standard definitions of characteristics and test methods for

1721:

3% of rated voltage to a maximum of 0.5 V at 85 °C,

5024:

Nichicon, Technical Guide, Calculation Formula of Lifetime

4604:

John Prymak, Kemet, Replacing MnO2 with Polymers, 1999 CARTS

1793:

ratio of the voltage to the current with both magnitude and

1718:

10% of rated voltage to a maximum of 1 V at 25 °C,

340:

Basic construction of solid tantalum electrolytic capacitors

4921:"MIL-HDBK-217 F NOTICE-2 RELIABILITY PREDICTION ELECTRONIC"

4046:. United States International Trade Commission. p. 1.

463:

Larger surface areas produce higher capacitance; thus high

5247:

5188:"1uF 35V Radial Dipped Tantalum Dip Capacitor Color Coded"

3156:

have a life time specification. (When hermetically sealed)

1923:

therefore is given by the geometric (complex) addition of

105:, telecommunications equipment, and computer peripherals.

67:

per volume (high volumetric efficiency) and lower weight.

4875:"Understand Capacitor Soakage to Optimize Analog Systems"

4822:

KEMET, Ripple Current Capabilities, Technical Update 2004

3564:

components and related technologies are published by the

2299:

is small, the dissipation factor can be approximated as:

85:

Tantalum electrolytic capacitors are extensively used in

2987:

Values of dielectric absorption for tantalum capacitors

5171:"REVERSE VOLTAGE BEHAVIOR OF SOLID TANTALUM CAPACITORS"

4834:"R.W. Franklin, AVX, AN EXPLORATION OF LEAKAGE CURRENT"

3514:

signs to capacitance, tolerance, voltage and polarity.

3000:

Tantalum electrolytic capacitors with solid electrolyte

2340:{\displaystyle \tan \delta ={\mbox{ESR}}\cdot \omega C}

1502:

Series-equivalent circuit model of a tantalum capacitor

1396:

Solid electrolyte tantalum capacitors were invented by

3361:

50% application voltage derating against rated voltage

2322:

1919:. In this case the impedance at the angular frequency

1356:

Because in the past, silver casings had problems with

5036:

Estimating of Lifetime FUJITSU MEDIA DEVICES LIMITED

4066:"Tantalum Capacitor Characteristics And Applications"

3113:

given failure rate values to application conditions.

2848:

2770:

2734:

2716:

this reduces the peak current seen by the capacitor.

2590:

2513:

2431:

2308:

2067:

2006:

1942:

1806:

1433:

Conductivity of non-solid and solid used electrolytes

285:

5056:

NIC Technical Guide, Calculation Formula of Lifetime

4148:

J. Gill, AVX, Basic Tantalum Capacitor Technology,

3485:

Polarity marking of tantalum electrolytic capacitors

2219:

Typical impedance and ESR as a function of frequency

4360:, Vol. 19, 2nd ed. 1969 John Wiley & sons, Inc.

3583:for use in electronic equipment are set out in the

401:, and a solid manganese dioxide electrolyte as the

5147:Jim Keith, What a cap-astrophe!, EDN, May 27, 2010

2952:

2776:

2756:

2695:

2551:{\displaystyle P_{th}=\Delta T\cdot A\cdot \beta }

2550:

2474:

2339:

2150:

2043:

1976:

1885:

311:{\displaystyle C=\varepsilon \cdot {\frac {A}{d}}}

310:

268:Every electrolytic capacitor in principle forms a

4672:J. Gill, AVX, Surge in Solid Tantalum Capacitors,

2191:), then the impedance will only be determined by

5076:

5074:

5072:

5070:

2819:

2044:{\displaystyle X_{L}=\omega L_{\mathrm {ESL} }}

593:Figure 5: Solid tantalum cathode cross section.

59:. Because of its very thin and relatively high

4018:"Tantalum Capacitors for Medical Applications"

3279:in the dielectric by oxidation or evaporation

4218:

4216:

4042:Harold M. Graves, Susan Daniel Tripp (1980).

3124:or 1 failure per 10 hours at 85 °C and U

2251:ESR influences the remaining superimposed AC

1368:electrolyte mounted in a pure tantalum case.

8:

1977:{\displaystyle X_{C}=-{\frac {1}{\omega C}}}

1778:) is as important as the capacitance value.

4690:

4688:

4668:

4666:

4664:

4253:

4251:

4249:

4247:

4245:

4243:

4144:

4142:

4140:

4138:

3159:Those using manganese dioxide electrolytes

3062:Reliability engineering#Reliability testing

519:available tantalum powders (see Figure 3).

4281:

4279:

4186:. 4. Auflage. Roederstein, Landshut 1991,

3645:

3364:using a series resistance of 3 Ω/V or

3186:

1565:Capacitance standard values and tolerances

704:

393:of the capacitor, with the oxide layer of

5285:

5091:

5089:

4352:

4350:

4267:

4265:

4166:

4164:

4162:

4160:

4100:

4098:

3566:International Electrotechnical Commission

2942:

2941:

2928:

2927:

2913:

2912:

2892:

2887:

2885:

2884:

2876:

2854:

2853:

2847:

2769:

2739:

2733:

2685:

2678:

2673:

2663:

2656:

2651:

2641:

2634:

2629:

2619:

2612:

2607:

2604:

2595:

2589:

2518:

2512:

2454:

2449:

2436:

2430:

2321:

2307:

2273:, in the relevant data sheets instead of

2166:, in which the both reactive resistances

2140:

2126:

2125:

2105:

2104:

2088:

2077:

2074:

2066:

2028:

2027:

2011:

2005:

1959:

1947:

1941:

1865:

1864:

1847:

1846:

1840:

1825:

1815:

1813:

1805:

701:Dimensioning of a tantalum chip capacitor

298:

284:

3296:The field crystallization followed by a

3179:Failure modes and self-healing mechanism

2985:

2475:{\displaystyle P_{L}=I_{R}^{2}\cdot ESR}

2377:

132:

4850:Kemet, Polymer Tantalum Chip Capacitors

4224:Electrocomponent Science and Technology

3993:Reliable Design of Electronic Equipment

3983:

3468:with DC-link for frequency controls in

3191:

3079:prediction is generally expressed in a

3067:The reliability normally is shown in a

2206:

709:

633:Different styles of tantalum capacitors

631:

343:

4980:: CS1 maint: archived copy as title (

4973:

4515:: CS1 maint: archived copy as title (

4508:

1764:, the capacitors work additionally as

1382:Electrolytic capacitor § History

7:

5328:Choosing and Using Bypass Capacitors

2832:with the value of the rated voltage

2784:for different kinds of electrolytes

2711:Current surge, peak or pulse current

1900:is specified, and simply written as

47:. It consists of a pellet of porous

5280:. Vol. 2. pp. 1129–1137.

4358:Encyclopedia of Chemical Technology

3238:by reduction of the electrolyte MnO

2789: non solid, high water content

2256:

3544:December. "X5" is then "2009, May"

3252:if current availability is limited

2946:

2929:

2914:

2899:

2893:

2888:

2864:

2861:

2858:

2855:

2530:

2127:

2106:

2035:

2032:

2029:

1872:

1869:

1866:

1854:

1851:

1848:

1523:, the resistance representing the

1514:, the capacitance of the capacitor

656:Tantalum "pearls" for PCB mounting

14:

4170:VISHAY, DC Leakage Failure Mode,

3572:, non-governmental international

3166:Those using polymer electrolytes

2983:, "soakage" or "battery action".

2366:) which represents a resonator's

1616:, tolerance ±10%, letter code "K"

1609:, tolerance ±20%, letter code "M"

1602:, tolerance ±20%, letter code "M"

539:Figure 4: Manganese dioxide layer

5341:

3917:

3410:

3403:

3396:

3389:

3152:Those using liquid electrolytes

2295:. If the capacitor's inductance

2224:

2212:

2203:ESR and dissipation factor tan δ

661:

649:

637:

409:Materials, production and styles

373:

361:

349:

76:aluminum electrolytic capacitors

4016:Geismar, Lizzie (Sep 1, 2017).

3948:List of capacitor manufacturers

3933:Aluminum electrolytic capacitor

3170:have a life time specification.

3163:have a life time specification.

3090:The reciprocal value of FIT is

2968:Dielectric absorption (soakage)

2248:in the dielectric oxide layer.

37:tantalum electrolytic capacitor

4321:. Springer. 13 December 2021.

3963:Solid aluminum capacitor (SAL)

3650:

3633:non-governmental organizations

3382:Electrolytic capacitor symbols

3268:Deterioration of conductivity,

2137:

2133:

2115:

2097:

1987:and by an inductive reactance

1830:

1820:

16:Type of electrolytic capacitor

1:

5326:Tamara Schmitz and Mike Wong

5230:"Welcome to the IEC Webstore"

3234:Thermally induced insulating

614:Styles of tantalum capacitors

4226:, 1976, Vol. 3. pp. 171–179

3501:terminal that is so marked.

3257:Series resistance 3 Ω/V

3236:of faults in the dielectric

2496:over the capacitors surface

2399:switched-mode power supplies

2238:equivalent series resistance

1927:, by a capacitive reactance

1551:equivalent series inductance

1538:equivalent series resistance

1443:equivalent series resistance

3056:in production-accompanying

2500:and the thermal resistance

674:Chip capacitors (case size)

479:Figure 3: Dielectric layer.

5382:

4184:Der Elektrolyt-Kondensator

4070:Advanced Refractory Metals

3281:of the polymer electrolyte

3092:mean time between failures

3029:Reliability (failure rate)

2971:

2820:Reliability (failure rate)

2393:A "ripple current" is the

1636:Rated and category voltage

1489:Electrical characteristics

1379:

422:Figure 1: Tantalum powder

4996:"KEMET – A YAGEO Company"

3834:Samsung Electro-Mechanics

3653:

3357:manufacturers recommend:

3265:solid polymer electrolyte

3024:Reliability and life time

2284:from inductive reactance

1494:Series-equivalent circuit

668:Axial tantalum capacitors

450:Figure 2: Sintered anode.

260:and with a separation of

43:, a passive component of

3995:. Springer. p. 21.

3968:Surface-mount technology

3938:Coltan mining and ethics

3597:sectional specifications

3195:electrolytic capacitors

2795: non solid, organic

2757:{\displaystyle I_{leak}}

1581:or nominal capacitance C

1412:Sprague Electric Company

644:Tantalum chip capacitors

5296:10.1109/IAS.1998.730289

5192:West Florida Components

3464:Some applications like

2384:half-wave rectification

2350:The dissipation factor

2162:In the special case of

1652:" or "nominal voltage U

1332:Wet tantalum capacitors

3943:Electrolytic capacitor

3574:standards organization

3486:

3372:Additional information

3328:

3041:

2995:Dielectric Absorption

2954:

2803:

2778:

2764:as a function of time

2758:

2697:

2552:

2476:

2390:

2341:

2152:

2045:

1978:

1887:

1786:

1749:

1656:". The rated voltage U

1645:

1503:

1434:

1341:

702:

610:

594:

540:

480:

451:

427:

312:

265:

176:Tantalum pentoxide, Ta

123:

41:electrolytic capacitor

32:

24:

4442:www.computerposter.ch

4022:Medical Design Briefs

3585:Generic specification

3484:

3311:

3277:Insulating of faults

3273:Field crystallization

3255:Voltage derating 50%

3230:Field crystallization

3036:

2981:dielectric relaxation

2974:Dielectric absorption

2955:

2779:

2759:

2727:

2698:

2553:

2477:

2381:

2342:

2180:have the same value (

2153:

2046:

1979:

1888:

1789:The impedance is the

1784:

1760:applications like in

1739:

1643:

1501:

1432:

1339:

700:

608:

592:

538:

478:

449:

440:volumetric efficiency

421:

389:into a pellet as the

313:

255:

207:Niobium pentoxide, Nb

121:

103:measuring instruments

30:

22:

5350:at Wikimedia Commons

5112:www.elna-america.com

3338:manganese(III) oxide

3298:dielectric breakdown

3284:Voltage derating 20%

3200:electrical behavior

2846:

2801: solid, polymer

2768:

2732:

2588:

2511:

2429:

2306:

2065:

2004:

1940:

1915:, and an inductance

1804:

283:

89:that require stable

5348:Tantalum capacitors

5108:"ELNA AMERICA, INC"

3654:Available versions

3648:

3451:Parallel connection

3189:

2988:

2459:

1612:rated capacitance,

1605:rated capacitance,

1598:rated capacitance,

1454:conducting polymers

1452:The development of

707:

135:

45:electronic circuits

5061:2013-09-15 at the

5043:2013-12-24 at the

4785:2016-01-26 at the

4720:2014-12-14 at the

4701:2014-12-14 at the

4679:2015-01-09 at the

4591:2016-03-04 at the

4572:2014-12-14 at the

4543:on August 8, 2014.

4471:2014-12-14 at the

4292:2016-01-24 at the

4182:K. H. Thiesbürger:

3973:Types of capacitor

3925:Electronics portal

3891:which provide low

3889:ceramic capacitors

3646:

3509:Imprinted markings

3487:

3329:

3320:into insulating Mn

3243:into insulating Mn

3187:

3050:stochastic process

3042:

2992:Type of capacitor

2986:

2950:

2808:DC leakage current

2804:

2774:

2754:

2693:

2571:thermal conduction

2548:

2472:

2445:

2391:

2337:

2326:

2267:dissipation factor

2148:

2041:

1974:

1883:

1787:

1750:

1664:(IEC/EN 60384-1).

1646:

1504:

1435:

1342:

705:

703:

611:

595:

541:

499:2 Ta → 2 Ta + 10 e

481:

452:

428:

395:tantalum pentoxide

308:

266:

133:

124:

99:power supply units

87:electronic devices

33:

25:

5346:Media related to

4328:978-3-030-89514-3

3958:Polymer capacitor

3953:Niobium capacitor

3876:

3875:

3680:Cornell-Dubillier

3629:conflict minerals

3470:three-phase grids

3460:Series connection

3448:

3447:

3377:Capacitor symbols

3352:Failure avoidance

3289:

3288:

3007:

3006:

2903:

2777:{\displaystyle t}

2691:

2563:thermal radiation

2356:resonant circuits

2325:

2246:dielectric losses

2146:

1972:

1878:

1835:

1833:

1823:

1695:Transient voltage

1398:Bell Laboratories

1324:

1323:

550:manganese dioxide

546:manganese nitrate

502:2 Ta + 10 OH → Ta

306:

230:

229:

109:Basic information

72:conflict resource

5371:

5345:

5330:

5324:

5318:

5317:

5289:

5273:

5267:

5262:

5256:

5255:

5244:

5238:

5237:

5226:

5220:

5219:

5208:

5202:

5201:

5199:

5198:

5184:

5178:

5177:

5175:

5167:

5161:

5155:

5149:

5144:

5138:

5133:

5127:

5122:

5116:

5115:

5104:

5098:

5093:

5084:

5078:

5065:

5053:

5047:

5034:

5028:

5022:

5016:

5010:

5004:

5003:

4992:

4986:

4985:

4979:

4971:

4969:

4968:

4962:

4956:. Archived from

4955:

4946:

4940:

4935:

4929:

4928:

4917:

4911:

4908:

4902:

4896:

4890:

4889:

4887:

4886:

4877:. Archived from

4870:

4864:

4858:

4852:

4847:

4841:

4840:

4838:

4830:

4824:

4819:

4813:

4807:

4801:

4795:

4789:

4776:

4770:

4765:

4759:

4753:

4747:

4741:

4735:

4730:

4724:

4711:

4705:

4692:

4683:

4670:

4659:

4653:

4647:

4642:

4636:

4630:

4624:

4621:

4615:

4612:

4606:

4601:

4595:

4582:

4576:

4562:

4556:

4551:

4545:

4544:

4542:

4536:. Archived from

4535:

4527:

4521:

4520:

4514:

4506:

4504:

4503:

4497:

4491:. Archived from

4490:

4481:

4475:

4463:

4457:

4452:

4446:

4445:

4434:

4428:

4425:

4419:

4416:

4410:

4405:

4399:

4396:

4390:

4387:

4381:

4376:

4370:

4367:

4361:

4354:

4345:

4339:

4333:

4332:

4313:

4307:

4302:

4296:

4283:

4274:

4269:

4260:

4255:

4238:

4235:

4229:

4220:

4211:

4210:

4208:

4200:

4194:

4180:

4174:

4168:

4155:

4146:

4133:

4128:

4122:

4121:

4114:

4108:

4102:

4093:

4087:

4081:

4080:

4078:

4076:

4062:

4056:

4055:

4039:

4033:

4032:

4030:

4028:

4013:

4007:

4006:

3988:

3927:

3922:

3921:

3649:

3615:IEC/EN 60384-24—

3609:IEC/EN 60384-15—

3477:Polarity marking

3466:AC/AC converters

3414:

3407:

3400:

3393:

3386:

3385:

3263:Tantalum e-caps

3218:Tantalum e-caps

3190:

2989:

2959:

2957:

2956:

2951:

2949:

2934:

2933:

2932:

2919:

2918:

2917:

2904:

2902:

2891:

2886:

2880:

2869:

2868:

2867:

2800:

2794:

2788:

2783:

2781:

2780:

2775:

2763:

2761:

2760:

2755:

2753:

2752:

2702:

2700:

2699:

2694:

2692:

2690:

2689:

2684:

2683:

2682:

2668:

2667:

2662:

2661:

2660:

2646:

2645:

2640:

2639:

2638:

2624:

2623:

2618:

2617:

2616:

2605:

2600:

2599:

2579:Fourier analysis

2557:

2555:

2554:

2549:

2526:

2525:

2504:to the ambient.

2481:

2479:

2478:

2473:

2458:

2453:

2441:

2440:

2346:

2344:

2343:

2338:

2327:

2323:

2228:

2216:

2157:

2155:

2154:

2149:

2147:

2145:

2144:

2132:

2131:

2130:

2111:

2110:

2109:

2093:

2092:

2087:

2075:

2050:

2048:

2047:

2042:

2040:

2039:

2038:

2016:

2015:

1983:

1981:

1980:

1975:

1973:

1971:

1960:

1952:

1951:

1892:

1890:

1889:

1884:

1879:

1877:

1876:

1875:

1859:

1858:

1857:

1841:

1836:

1834:

1826:

1824:

1816:

1814:

1527:of the capacitor

1466:Hideki Shirakawa

1416:Preston Robinson

1358:silver migration

708:

665:

653:

641:

495:are as follows:

434:metal. A common

377:

365:

353:

317:

315:

314:

309:

307:

299:

164:Dielectric layer

136:

5381:

5380:

5374:

5373:

5372:

5370:

5369:

5368:

5354:

5353:

5338:

5333:

5325:

5321:

5306:

5287:10.1.1.369.4789

5275:

5274:

5270:

5263:

5259:

5246:

5245:

5241:

5234:webstore.iec.ch

5228:

5227:

5223:

5210:

5209:

5205:

5196:

5194:

5186:

5185:

5181:

5173:

5169:

5168:

5164:

5156:

5152:

5145:

5141:

5134:

5130:

5123:

5119:

5106:

5105:

5101:

5094:

5087:

5079:

5068:

5063:Wayback Machine

5054:

5050:

5045:Wayback Machine

5035:

5031:

5023:

5019:

5011:

5007:

4994:

4993:

4989:

4972:

4966:

4964: