782:. Their primary conclusion was that while the rams succeeded in partly shearing through the drill pipe they failed to seal the bore because the drill pipe had buckled out of the intended line of action of the rams (because the drill string was caught at a tool joint in the upper annular BOP valve), jamming the shears and leaving the drill string shear actuator unable to deliver enough force to complete its stroke and fold the cut pipe over and seal the well. They did not suggest any failure of actuation as would be caused by faulty batteries. The upper section of the blow out preventer failed to separate as designed due to numerous oil leaks compromising hydraulic actuator operation, and this had to be cut free during recovery.

536:. Drill pipe including the larger-diameter tool joints (threaded connectors) can be "stripped" (i.e., moved vertically while pressure is contained below) through an annular preventer by careful control of the hydraulic closing pressure. Annular blowout preventers are also effective at maintaining a seal around the drillpipe even as it rotates during drilling. Regulations typically require that an annular preventer be able to completely close a wellbore, but annular preventers are generally not as effective as ram preventers in maintaining a seal on an open hole. Annular BOPs are typically located at the top of a BOP stack, with one or two annular preventers positioned above a series of several ram preventers.

164:. BOP stacks frequently utilize both types, typically with at least one annular BOP stacked above several ram BOPs. Blowout preventers are used on land wells, offshore rigs, and subsea wells. Land and subsea BOPs are secured to the top of the wellbore, known as the wellhead. BOPs on offshore rigs are mounted below the rig deck. Subsea BOPs are connected to the offshore rig above by a drilling riser that provides a continuous pathway for the drill string and fluids emanating from the wellbore. In effect, a riser extends the wellbore to the rig. Blowout preventers do not always function correctly. An example of this is the

305:) occurs, rig operators or automatic systems close the blowout preventer units, sealing the annulus to stop the flow of fluids out of the wellbore. Denser mud is then circulated into the wellbore down the drill string, up the annulus and out through the choke line at the base of the BOP stack through chokes (flow restrictors) until downhole pressure is overcome. Once “kill weight” mud extends from the bottom of the well to the top, the well has been “killed”. If the integrity of the well is intact drilling may be resumed. Alternatively, if circulation is not feasible it may be possible to kill the well by "

357:

510:

55:

650:

426:

47:

390:, but uses a pair of opposing steel plungers, rams. The rams extend toward the center of the wellbore to restrict flow or retract open in order to permit flow. The inner and top faces of the rams are fitted with packers (elastomeric seals) that press against each other, against the wellbore, and around tubing running through the wellbore. Outlets at the sides of the BOP housing (body) are used for connection to choke and kill lines or valves.

681:

434:

754:'s equipment for the Macondo site (including incorrectly routing hydraulic pressure to a stack test valve instead of a pipe ram BOP) which increased the risk of BOP failure, in spite of warnings from their contractor to that effect. Another hypothesis was that a junction in the drilling pipe may have been positioned in the BOP stack in such a way that its shear rams had an insurmountable thickness of material to cut through.

39:

569:

368:

31:

450:(also known as shear seal rams, or sealing shear rams) are intended to seal a wellbore, even when the bore is occupied by a drill string, by cutting through the drill string as the rams close off the well. The upper portion of the severed drill string is freed from the ram, while the lower portion may be crimped and the “fish tail” captured to hang the drill string off the BOP.

518:

458:

rods) in the manner of a screw jack. Torque from turning the ram shafts by wrench or hand wheel was converted to linear motion and the rams, coupled to the inner ends of the ram shafts, opened and closed the well bore. Such screw jack type operation provided enough mechanical advantage for rams to overcome downhole pressures and seal the wellbore annulus.

309:", forcibly pumping in the heavier mud from the top through the kill line connection at the base of the stack. This is less desirable because of the higher surface pressures likely needed and the fact that much of the mud originally in the annulus must be forced into receptive formations in the open hole section beneath the deepest casing shoe.

179:

328:

unit can weigh in excess of 30,000 pounds), while the space allotted for BOP stacks on existing offshore rigs has not grown commensurately. Thus a key focus in the technological development of BOPs over the last two decades has been limiting their footprint and weight while simultaneously increasing safe operating capacity.

485:

Single ram and double ram BOPs are commonly available. The names refer to the quantity of ram cavities (equivalent to the effective quantity of valves) contained in the unit. A double ram BOP is more compact and lighter than a stack of two single ram BOPs while providing the same functionality, and

469:

Ram BOPs for use in deepwater applications universally employ hydraulic actuation. Threaded shafts are often still incorporated into hydraulic ram BOPs as lock rods that hold the ram in position after hydraulic actuation. By using a mechanical ram locking mechanism, constant hydraulic pressure need

415:

close around a drill pipe, restricting flow in the annulus (ring-shaped space between concentric objects) between the outside of the drill pipe and the wellbore, but do not obstruct flow within the drill pipe. Variable-bore pipe rams can accommodate tubing in a wider range of outside diameters than

770:

failed blowout preventer was removed from the well and began being slowly lifted to the surface. Later that day a replacement blowout preventer was placed on the well. On

September 4 at 6:54 p.m. CDT the failed blowout preventer reached the surface of the water and at 9:16 p.m. CDT it was

761:

On July 10, 2010, BP began operations to install a sealing cap, also known as a capping stack, atop the failed blowout preventer stack. Based on BP's video feeds of the operation the sealing cap assembly, called Top Hat 10, included a stack of three blind shear ram BOPs manufactured by Hydril (a GE

757:

It was later discovered that a second piece of tubing got into the BOP stack at some point during the

Macondo incident, potentially explaining the failure of the BOP shearing mechanism. As of July 2010 it was unknown whether the tubing might have been casing that shot up through the well or perhaps

465:

Because BOPs are depended on for safety and reliability, efforts to minimize the complexity of the devices are still employed to ensure longevity. As a result, despite the ever-increasing demands placed on them, state of the art ram BOPs are conceptually the same as the first effective models, and

703:

incident on April 20, 2010, the blowout preventer should have been activated automatically, cutting the drillstring and sealing the well to preclude a blowout and subsequent oil spill in the Gulf of Mexico, but it failed to fully engage. Underwater robots (ROVs) later were used to manually trigger

477:

Shear-type ram BOPs require the greatest closing force in order to cut through tubing occupying the wellbore. Boosters (auxiliary hydraulic actuators) are frequently mounted to the outer ends of a BOP's hydraulic actuators to provide additional shearing force for shear rams. If a situation arises

621:

Pumps on the rig normally deliver pressure to the blowout preventer stack through hydraulic lines. Hydraulic accumulators are on the BOP stack enable closure of blowout preventers even if the BOP stack is disconnected from the rig. It is also possible to trigger the closing of BOPs automatically

559:

In 1972, Ado N. Vujasinovic was awarded a patent for a variation on the annular preventer known as a spherical blowout preventer, so-named because of its spherical-faced head. As the piston rises the packing unit is thrust upward against the curved head, which constricts the packing unit inward.

481:

Ram BOPs are typically designed so that well pressure will help maintain the rams in their closed, sealing position. That is achieved by allowing fluid to pass through a channel in the ram and exert pressure at the ram's rear and toward the center of the wellbore. Providing a channel in the ram

457:

The original ram BOPs of the 1920s were simple and rugged manual devices with minimal parts. The BOP housing (body) had a vertical well bore and horizontal ram cavity (ram guide chamber). Opposing rams (plungers) in the ram cavity translated horizontally, actuated by threaded ram shafts (piston

327:

Exploitable reservoirs of oil and gas are increasingly rare and remote, leading to increased subsea deepwater well exploration and requiring BOPs to remain submerged for as long as a year in extreme conditions. As a result, BOP assemblies have grown larger and heavier (e.g. a single ram-type BOP

577:

When wells are drilled on land or in very shallow water where the wellhead is above the water line, BOPs are activated by hydraulic pressure from a remote accumulator. Several control stations will be mounted around the rig. They also can be closed manually by turning large wheel-like handles.

461:

Hydraulic rams BOPs were in use by the 1940s. Hydraulically actuated blowout preventers had many potential advantages. The pressure could be equalized in the opposing hydraulic cylinders causing the rams to operate in unison. Relatively rapid actuation and remote control were facilitated, and

719:

investigating the causes of the explosion that his agency last inspected the rig's blowout preventer in 2005. BP representatives suggested that the preventer could have suffered a hydraulic leak. Gamma-ray imaging of the preventer conducted on May 12 and May 13, 2010 showed that the preventer's

617:

An emergency disconnect system/sequence (EDS) disconnects the rig from the well in case of an emergency. The EDS is also intended to automatically trigger the deadman switch, which closes the BOP, kill and choke valves. The EDS may be a subsystem of the BOP stack's control pods or separate.

473:

Typical ram actuator assemblies (operator systems) are secured to the BOP housing by removable bonnets. Unbolting the bonnets from the housing allows BOP maintenance and facilitates the substitution of rams. In that way, for example, a pipe ram BOP can be converted to a blind shear ram BOP.

453:

In addition to the standard ram functions, variable-bore pipe rams are frequently used as test rams in a modified blowout preventer device known as a stack test valve. Stack test valves are positioned at the bottom of a BOP stack and resist downward pressure (unlike BOPs, which resist upward

555:

The original type of annular blowout preventer used a “wedge-faced” (conical-faced) piston. As the piston rises, vertical movement of the packing unit is restricted by the head and the sloped face of the piston squeezes the packing unit inward, toward the center of the wellbore.

140:

are commonly used interchangeably and in a general manner to describe an assembly of several stacked blowout preventers of varying type and function, as well as auxiliary components. A typical subsea deepwater blowout preventer system includes components such as electrical and

323:

and the wellbore itself, authorities recommend, and regulations require, that BOPs be regularly inspected, tested and refurbished. Tests vary from daily test of functions on critical wells to monthly or less frequent testing on wells with low likelihood of control problems.

904:

923:

194:

Blowout preventers come in a variety of styles, sizes and pressure ratings. Several individual units serving various functions are combined to compose a blowout preventer stack. Multiple blowout preventers of the same type are frequently provided for

500:

The highest-capacity large-bore ram blowout preventer on the market, as of July 2010, was

Cameron's EVO 20K BOP, with a hold-pressure rating of 20,000 psi, ram force in excess of 1,000,000 pounds, and a well–bore diameter of up to 18.75 inches.

625:

Individual wells along the U.S. coastline may also be required to have BOPs with backup acoustic control. General requirements of other nations, including Brazil, were drawn to require this method. BOPs featuring this method may cost as much as

478:

whereby the shear rams are to be activated, it is best practice for the

Driller to have the string spaced as to ensure the rams will shear the body of the drillpipe as opposed to having a tooljoint (much thicker metal) across the shear rams.

724:

work is unknown. A statement released by

Congressman Bart Stupak revealed that, among other issues, the emergency disconnect system (EDS) did not function as intended and may have malfunctioned due to the explosion on the Deepwater Horizon.

547:

packing unit, reinforced with steel ribs. The packing unit is situated in the BOP housing between the head and hydraulic piston. When the piston is actuated, its upward thrust forces the packing unit to constrict, like a

765:

The U.S. government wanted the failed blowout preventer to be replaced in case of any pressure change that occurs when the relief well intersected with the well. On

September 3, 2010, at 1:20 p.m. CDT the 300

101:), tools, and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole leading to the reservoir) when a blowout threatens. Blowout preventers are critical to the safety of crew,

758:

broken drill pipe that dropped into the well. The DNV final report indicated that the second tube was the segment of the drill string that was ejected after being cut by the blow out preventer shears.

497:

consumption, and improved connectors, packers, seals, locks and rams. In addition, limiting BOP weight and footprint are significant concerns to account for the limitations of existing rigs.

938:

489:

Technological development of ram BOPs has been directed towards deeper and higher pressure wells, greater reliability, reduced maintenance, facilitated replacement of components, facilitated

117:

312:

If the blowout preventers and mud do not restrict the upward pressures of a kick, a blowout results, potentially shooting tubing, oil and gas up the wellbore, damaging the rig, and leaving

97:. In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing (e.g. drill pipe and

521:

Diagram of an annular blowout preventer in open and fully closed configurations. The flexible annulus (donut) in blue is forced into the drillpipe cavity by the hydraulic pistons.

762:

Oil & Gas company), one of

Cameron's chief competitors. By July 15 the 3 ram capping stack had sealed the Macondo well, if only temporarily, for the first time in 87 days.

552:, sealing the annulus or openhole. Annular preventers have only two moving parts, piston and packing unit, making them simple and easy to maintain relative to ram preventers.

614:

Two control pods are provided on the BOP for redundancy. Electrical signal control of the pods is primary. Acoustical, ROV intervention and dead-man controls are secondary.

581:

In deeper offshore operations with the wellhead just above the mudline on the sea floor, there are five primary ways by which a BOP can be controlled. The possible means are:

444:

are designed to shear the pipe in the well and seal the wellbore simultaneously. It has steel blades to shear the pipe and seals to seal the annulus after shearing the pipe.

105:(the equipment system used to drill a wellbore) and environment, and to the monitoring and maintenance of well integrity; thus blowout preventers are intended to provide

422:(also known as sealing rams), which have no openings for tubing, can close off the well when the well does not contain a drill string or other tubing, and seal it.

720:

internal valves were partially closed and were restricting the flow of oil. Whether the valves closed automatically during the explosion or were shut manually by

529:

in 1946; a U.S. patent for it was awarded in 1952. Often around the rig it is called the "Hydril", after the name of the original manufacturer of such devices.

1037:

470:

not be maintained. Lock rods may be coupled to ram shafts or not, depending on manufacturer. Other types of ram locks, such as wedge locks, are also used.

1261:

817:

771:

placed in a special container on board the vessel Helix Q4000. The failed blowout preventer was taken to a NASA facility in

Louisiana for examination by

746:

Documents discussed during congressional hearings June 17, 2010, suggested that a battery in the device's control pod was flat and that the rig's owner,

454:

pressures). By closing the test ram and a BOP ram around the drill string and pressurizing the annulus, the BOP is pressure-tested for proper function.

1235:

850:

1153:

416:

standard pipe rams, but typically with some loss of pressure capacity and longevity. A pipe ram should not be closed if there is no pipe in the hole.

376:

361:

946:

1179:

128:), is used to refer to a single blowout preventer unit. A blowout preventer may also simply be referred to by its type (e.g. ram). The terms

737:

736:

in 2009 did not require redundant acoustic control means. Insofar as the BOPs could not be closed successfully by underwater manipulation (

721:

685:

598:

490:

610:/ Auto Shear: fail-safe activation of selected BOPs during an emergency, and if the control, power and hydraulic lines have been severed.

1315:

1201:

751:

604:: remotely operated vehicles (ROVs) mechanically control valves and provide hydraulic pressure to the stack (via “hot stab” panels);

380:

1270:

989:

282:, "mud", is fed through the drill string down to the drill bit, "blade", and returns up the wellbore in the ring-shaped void,

902:, Knox, Granville S., "Control head and blow-out preventer", published 1952-09-09, assigned to Hydril Corp.

82:, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves.

1310:

1290:

591:

Acoustical

Control Signal: sent from the surface based on a modulated/encoded pulse of sound transmitted by an underwater

1245:

1202:"Forensic Examination of Deepwater Horizon Blowout Preventer (Final Report for United States Department of the Interior)"

1102:

1300:

1285:

429:

Patent

Drawing of a Varco Shaffer Ram BOP Stack. A shear ram BOP has cut the drillstring and a pipe ram has hung it off.

1262:

https://web.archive.org/web/20061005223639/http://www.asmenews.org/archives/backissues/july03/features/703oilwell.html

968:

733:

712:

708:

697:

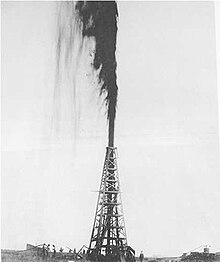

639:

1266:

1246:

Blowout preventer: Definition from the US department of Labor, Occupational Safety & Health Administration (OSHA)

532:

An annular-type blowout preventer can close around the drill string, casing or a non-cylindrical object, such as the

1044:

743:), pending results of a complete investigation, it is uncertain whether this omission was a factor in the blowout.

807:

540:

356:

274:

In drilling a typical high-pressure well, drill strings are routed through a blowout preventer stack toward the

345:

196:

875:

921:, Vujasinovic, Ado N., "Blowout preventer", published 1972-06-06, assigned to The Rucker Co.

379:

was invented by James Smither Abercrombie and Harry S. Cameron in 1922, and was brought to market in 1924 by

1232:

854:

796:

779:

509:

298:

94:

86:

79:

1088:

1043:. U.S. House Committee on Commerce and Energy, Subcommittee on Oversight and Investigations. Archived from

1305:

526:

1128:

707:

As of May 2010 it was unknown why the blowout preventer failed. Chief surveyor John David Forsyth of the

170:

blowout, where the pipe line going through the BOP was slightly bent and the BOP failed to cut the pipe.

1062:

371:

Blowout preventer diagram showing different types of rams. (a) blind ram (b) pipe ram and (c) shear ram.

1256:

918:

899:

627:

607:

802:

486:

is thus desirable in many applications. Triple ram BOPs are also manufactured, but not as common.

275:

90:

1251:

54:

1295:

1022:

772:

283:

239:

224:

Additionally, and in performing those primary functions, blowout preventer systems are used to:

85:

Blowout preventers were developed to cope with extreme erratic pressures and uncontrolled flow (

46:

425:

740:

601:

287:

263:

166:

98:

294:

to counter opposing pressure from the formation being drilled, allowing drilling to proceed.

964:

729:

716:

319:

Since BOPs are important for the safety of the crew and natural environment, as well as the

1180:"Failed blowout preventer, a key piece of evidence in Gulf oil spill probe, secure on boat"

680:

1239:

1075:

494:

433:

302:

249:

348:

BOP stacks, typically with at least one annular BOP capping a stack of several ram BOPs.

17:

663:

Please help update this article to reflect recent events or newly available information.

362:

Patent Drawing of the Original Ram-type Blowout Preventer, by Cameron Iron Works (1922)

313:

279:

146:

38:

572:

A accumulator unit that stores pressure ready to activate the BOPs on a land based BOP

1279:

1209:

Deepwater Horizon Joint Investigation (Official Site of the Joint Investigation Team)

1154:"BP: Blowout preventer that failed to stop Gulf of Mexico oil leak removed from well"

1017:

291:

145:, control pods, hydraulic accumulators, test valve, kill and choke lines and valves,

568:

320:

232:

102:

30:

1129:"Discovery of second pipe in Deepwater Horizon riser stirs debate among experts"

791:

533:

367:

93:

during drilling. Kicks can lead to a potentially catastrophic event known as a

1038:"Opening Statement, "Inquiry into the Deepwater Horizon Gulf Coast Oil Spill""

837:

747:

592:

387:

290:(piping that lines the wellbore). The column of drilling mud exerts downward

267:

183:

142:

549:

544:

306:

245:

200:

106:

42:

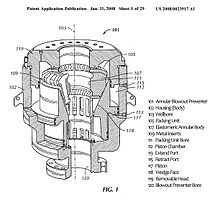

Cameron International Corporation's EVO Ram BOP Patent Drawing (with legend)

585:

Hydraulic Control Signal: sent from surface through a hydraulic umbilical;

513:

Patent Drawing of Original Shaffer Spherical-type Blowout Preventer (1972)

178:

960:

812:

588:

Electrical Control Signal: sent from the surface through a control cable;

256:

211:

75:

517:

543:

to shut in the wellbore. It has a donut-like rubber seal, known as an

1257:

https://www.osha.gov/SLTC/etools/oilandgas/drilling/wellcontrol.html

220:

Allow controlled volumes of fluid to be withdrawn from the wellbore.

1148:

1146:

679:

567:

516:

508:

432:

424:

366:

355:

187:

177:

71:

53:

45:

37:

1174:

1172:

1170:

1200:

Gary D. Kenney; Bryce A. Levett; Neil G. Thompson (2011-03-20).

482:

also limits the thrust required to overcome well bore pressure.

74:

or similar mechanical device, used to seal, control and monitor

1252:

https://www.osha.gov/SLTC/etools/oilandgas/images/bop_stack.jpg

840:", video content produced by Transocean. Accessed 26 June 2020.

961:"Deepwater Horizon Joint Investigation Team official Web site"

767:

643:

1233:

Blowout preventer: Definition from the Schlumberger glossary

711:

testified in hearings before the Joint Investigation of the

206:

The primary functions of a blowout preventer system are to:

1091:

Wall Street Journal, 28 April 2010. Retrieved 3 June 2010.

990:"Hearings: Rig's blowout preventer last inspected in 2005"

876:"First Ram-Type Blowout Preventer (Engineering Landmark)"

462:

hydraulic rams were well-suited to high pressure wells.

152:

Two categories of blowout preventer are most prevalent:

778:

On March 20, 2011, DNV presented their report to the

539:

An annular blowout preventer uses the principle of a

120:

to refer to blowout preventers. The abbreviated term

1103:"BP oil disaster puts spotlight on small Texan firm"

939:"Oil Spill Points to Rig Fail-Safe as Utter Failure"

560:Both types of annular preventer are in common use.

692:Blowout Preventer (BOP), Thursday, April 22, 2010.

58:Patent Drawing of a Subsea BOP Stack (with legend)

50:Patent Drawing of Hydril Annular BOP (with legend)

286:, between the outside of the drill pipe and the

252:, influx, from the reservoir into the wellbore);

630:500,000 more than those that omit the feature.

393:Rams, or ram blocks, are of four common types:

1016:Henry Fountain, Matthew L. Wald (2010-05-12),

622:based on too high pressure or excessive flow.

525:The annular blowout preventer was invented by

199:, an important factor in the effectiveness of

160:

799:with a list of notable offshore well blowouts

149:, hydraulic connectors, and a support frame.

8:

704:the blind shear ram preventer, to no avail.

386:A ram-type BOP is similar in operation to a

1182:. FoxNews.com. Associated Press. 2010-09-04

1156:. FoxNews.com. Associated Press. 2010-09-03

217:Provide means to add fluid to the wellbore;

1018:"BP Says Leak May Be Closer to a Solution"

1011:

1009:

818:Offshore oil spill prevention and response

154:

125:

278:of oil and gas. As the well is drilled,

1089:Leaking Oil Well Lacked Safeguard Device

29:

829:

228:Regulate and monitor wellbore pressure;

1071:

1060:

437:Schematic view of closing shear blades

238:Shut in the well (e.g. seal the void,

70:) (pronounced B-O-P) is a specialized

7:

1036:Bart Stupak, Chairman (2010-05-12).

466:resemble those units in many ways.

124:, usually prefaced by a type (e.g.

344:. Both are often used together in

109:to the systems that include them.

25:

242:, between drillpipe and casing);

851:"Schlumberger Oilfield Glossary"

648:

688:(ROV) attempts to activate the

1267:Photograph of subsea BOP stack

336:BOPs come in two basic types,

1:

1127:Hammer, David (9 July 2010).

1271:Oil states Offshore Products

1101:Clark, Andrew (2010-06-18).

988:David Hammer (2010-05-26).

969:Minerals Management Service

734:Minerals Management Service

713:Minerals Management Service

709:American Bureau of Shipping

640:Deepwater Horizon oil spill

1332:

637:

210:Confine well fluid to the

1316:Industrial safety devices

808:Christmas tree (oil well)

722:remotely operated vehicle

686:Remotely Operated Vehicle

657:This section needs to be

634:Deepwater Horizon blowout

505:Annular blowout preventer

270:(in case of emergencies).

259:(close off the wellbore);

78:and gas wells to prevent

18:Annular blowout preventer

838:Blow Out Preventer (BOP)

231:Center and hang off the

138:blowout preventer system

797:Blowout (well drilling)

780:US Department of Energy

134:blowout preventer stack

1070:Cite journal requires

750:, may have "modified"

701:drilling rig explosion

693:

573:

522:

514:

493:intervention, reduced

438:

430:

372:

364:

191:

59:

51:

43:

35:

683:

571:

520:

512:

436:

428:

370:

359:

352:Ram blowout preventer

248:(prevent the flow of

181:

57:

49:

41:

33:

1311:Industrial equipment

1291:Petroleum production

527:Granville Sloan Knox

292:hydrostatic pressure

182:The Lucas Gusher at

1301:Drilling technology

1286:American inventions

728:The permit for the

684:A robotic arm of a

118:oilfield vernacular

89:) emanating from a

1238:2010-06-24 at the

1023:The New York Times

773:Det Norske Veritas

694:

574:

523:

515:

439:

431:

381:Cameron Iron Works

373:

365:

192:

60:

52:

44:

36:

803:Subsea technology

699:Deepwater Horizon

690:Deepwater Horizon

678:

677:

167:Deepwater Horizon

130:blowout preventer

64:blowout preventer

34:Blowout preventer

27:Specialized valve

16:(Redirected from

1323:

1220:

1219:

1217:

1216:

1206:

1197:

1191:

1190:

1188:

1187:

1176:

1165:

1164:

1162:

1161:

1150:

1141:

1140:

1138:

1136:

1124:

1118:

1117:

1115:

1113:

1098:

1092:

1086:

1080:

1079:

1073:

1068:

1066:

1058:

1056:

1055:

1049:

1042:

1033:

1027:

1026:

1013:

1004:

1003:

1001:

1000:

985:

979:

978:

976:

975:

965:U.S. Coast Guard

957:

951:

950:

945:, archived from

934:

928:

927:

926:

922:

915:

909:

908:

907:

903:

896:

890:

889:

887:

886:

872:

866:

865:

863:

862:

853:. Archived from

847:

841:

834:

730:Macondo Prospect

717:U.S. Coast Guard

673:

670:

664:

652:

651:

644:

448:Blind shear rams

235:in the wellbore;

21:

1331:

1330:

1326:

1325:

1324:

1322:

1321:

1320:

1276:

1275:

1240:Wayback Machine

1229:

1224:

1223:

1214:

1212:

1204:

1199:

1198:

1194:

1185:

1183:

1178:

1177:

1168:

1159:

1157:

1152:

1151:

1144:

1134:

1132:

1126:

1125:

1121:

1111:

1109:

1100:

1099:

1095:

1087:

1083:

1069:

1059:

1053:

1051:

1047:

1040:

1035:

1034:

1030:

1015:

1014:

1007:

998:

996:

987:

986:

982:

973:

971:

959:

958:

954:

936:

935:

931:

924:

917:

916:

912:

905:

898:

897:

893:

884:

882:

874:

873:

869:

860:

858:

849:

848:

844:

835:

831:

826:

788:

674:

668:

665:

662:

653:

649:

642:

636:

576:

566:

564:Control methods

507:

495:hydraulic fluid

354:

334:

303:formation fluid

250:formation fluid

246:“Kill” the well

176:

143:hydraulic lines

28:

23:

22:

15:

12:

11:

5:

1329:

1327:

1319:

1318:

1313:

1308:

1303:

1298:

1293:

1288:

1278:

1277:

1274:

1273:

1264:

1259:

1254:

1249:

1243:

1228:

1227:External links

1225:

1222:

1221:

1205:(PDF (9.4 Mb))

1192:

1166:

1142:

1119:

1093:

1081:

1072:|journal=

1028:

1005:

994:Times-Picayune

980:

952:

937:Carl Franzen,

929:

910:

891:

867:

842:

828:

827:

825:

822:

821:

820:

815:

810:

805:

800:

794:

787:

784:

676:

675:

656:

654:

647:

638:Main article:

635:

632:

612:

611:

608:Deadman Switch

605:

596:

589:

586:

565:

562:

506:

503:

353:

350:

333:

330:

314:well integrity

280:drilling fluid

272:

271:

260:

253:

243:

236:

229:

222:

221:

218:

215:

175:

172:

91:well reservoir

87:formation kick

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1328:

1317:

1314:

1312:

1309:

1307:

1306:Safety valves

1304:

1302:

1299:

1297:

1294:

1292:

1289:

1287:

1284:

1283:

1281:

1272:

1268:

1265:

1263:

1260:

1258:

1255:

1253:

1250:

1247:

1244:

1241:

1237:

1234:

1231:

1230:

1226:

1210:

1203:

1196:

1193:

1181:

1175:

1173:

1171:

1167:

1155:

1149:

1147:

1143:

1130:

1123:

1120:

1108:

1104:

1097:

1094:

1090:

1085:

1082:

1077:

1064:

1050:on 2010-05-20

1046:

1039:

1032:

1029:

1025:

1024:

1019:

1012:

1010:

1006:

995:

991:

984:

981:

970:

966:

962:

956:

953:

949:on 2010-05-04

948:

944:

940:

933:

930:

920:

914:

911:

901:

895:

892:

881:

877:

871:

868:

857:on 2010-06-24

856:

852:

846:

843:

839:

833:

830:

823:

819:

816:

814:

811:

809:

806:

804:

801:

798:

795:

793:

790:

789:

785:

783:

781:

776:

774:

769:

763:

759:

755:

753:

749:

744:

742:

739:

735:

731:

726:

723:

718:

714:

710:

705:

702:

700:

691:

687:

682:

672:

660:

655:

646:

645:

641:

633:

631:

629:

623:

619:

615:

609:

606:

603:

600:

597:

594:

590:

587:

584:

583:

582:

579:

570:

563:

561:

557:

553:

551:

546:

542:

537:

535:

530:

528:

519:

511:

504:

502:

498:

496:

492:

487:

483:

479:

475:

471:

467:

463:

459:

455:

451:

449:

445:

443:

435:

427:

423:

421:

417:

414:

410:

408:

404:

400:

396:

391:

389:

384:

382:

378:

369:

363:

358:

351:

349:

347:

343:

339:

331:

329:

325:

322:

317:

316:in question.

315:

310:

308:

304:

300:

295:

293:

289:

285:

281:

277:

269:

265:

261:

258:

254:

251:

247:

244:

241:

237:

234:

230:

227:

226:

225:

219:

216:

213:

209:

208:

207:

204:

202:

198:

189:

185:

180:

173:

171:

169:

168:

163:

162:

157:

156:

150:

148:

144:

139:

135:

131:

127:

126:ram preventer

123:

119:

115:

110:

108:

104:

100:

96:

92:

88:

83:

81:

77:

73:

69:

65:

56:

48:

40:

32:

19:

1269:linked from

1213:. Retrieved

1208:

1195:

1184:. Retrieved

1158:. Retrieved

1133:. Retrieved

1122:

1110:. Retrieved

1107:The Guardian

1106:

1096:

1084:

1063:cite journal

1052:. Retrieved

1045:the original

1031:

1021:

997:. Retrieved

993:

983:

972:. Retrieved

955:

947:the original

942:

932:

913:

894:

883:. Retrieved

879:

870:

859:. Retrieved

855:the original

845:

832:

777:

764:

760:

756:

745:

741:Intervention

727:

706:

698:

695:

689:

669:January 2021

666:

658:

624:

620:

616:

613:

602:Intervention

580:

575:

558:

554:

538:

531:

524:

499:

488:

484:

480:

476:

472:

468:

464:

460:

456:

452:

447:

446:

441:

440:

419:

418:

412:

411:

406:

402:

398:

394:

392:

385:

374:

346:drilling rig

341:

337:

335:

326:

321:drilling rig

318:

311:

296:

273:

233:drill string

223:

205:

193:

165:

159:

153:

151:

137:

133:

129:

121:

113:

111:

84:

67:

63:

61:

792:Bell nipple

696:During the

545:elastomeric

407:blind shear

307:bullheading

301:(influx of

147:riser joint

116:is used in

107:fail-safety

99:well casing

1280:Categories

1215:2011-04-20

1211:. EP030842

1186:2010-09-05

1160:2010-09-03

1131:. nola.com

1054:2010-05-12

999:2010-05-26

974:2010-05-26

919:US 3667721

900:US 2609836

885:2007-01-18

861:2007-01-18

824:References

748:Transocean

593:transducer

442:Shear rams

420:Blind rams

388:gate valve

268:drill pipe

262:Sever the

197:redundancy

184:Spindletop

1296:Oil wells

550:sphincter

413:Pipe rams

276:reservoir

255:Seal the

203:devices.

201:fail-safe

122:preventer

112:The term

1248:May 2010

1242:May 2010

1236:Archived

943:AOL news

880:ASME.org

813:Oil well

786:See also

715:and the

257:wellhead

212:wellbore

80:blowouts

1135:13 July

1112:19 June

775:(DNV).

752:Cameron

732:by the

659:updated

377:ram BOP

342:annular

297:When a

284:annulus

240:annulus

161:annular

95:blowout

925:

906:

405:, and

288:casing

264:casing

190:(1901)

1048:(PDF)

1041:(PDF)

541:wedge

534:kelly

403:shear

399:blind

332:Types

188:Texas

72:valve

1137:2010

1114:2010

1076:help

967:and

628:US$

395:pipe

375:The

340:and

299:kick

158:and

136:and

768:ton

738:ROV

599:ROV

491:ROV

338:ram

266:or

174:Use

155:ram

114:BOP

103:rig

76:oil

68:BOP

1282::

1207:.

1169:^

1145:^

1105:.

1067::

1065:}}

1061:{{

1020:,

1008:^

992:.

963:.

941:,

878:.

409:.

401:,

397:,

383:.

360:A

186:,

132:,

62:A

1218:.

1189:.

1163:.

1139:.

1116:.

1078:)

1074:(

1057:.

1002:.

977:.

888:.

864:.

836:"

671:)

667:(

661:.

595:;

214:;

66:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.