163:

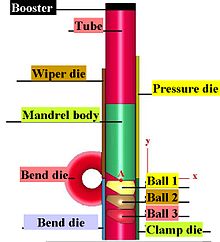

useful to prevent excessive thinning and collapse of the extrados of the tube. The mandrel, with or without ball with spherical links, is mostly used to prevent wrinkles and ovalization. For relatively easy bending processes (that is, as the difficulty factor BF decreases), the tooling can be progressively simplified, eliminating the need for the axial assist, the mandrel, and the wiper die (which mostly prevents wrinkling). Furthermore, in some particular cases, the standard tooling must be modified in order to meet specific requirements of the products.

140:

187:

68:. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry.

31:

336:

it easier to retrieve the spring from the pipe, it is a good idea to bend the pipe slightly more than required, and then slacken it off a little. Springs are less cumbersome than rotary benders, but are not suitable for bending short lengths of piping when it is difficult to get the required leverage on the pipe ends.

147:

Rotary draw bending (RDB) is a precise technology, since it bends using tooling or "die sets" which have a constant center line radius (CLR), alternatively indicated as mean bending radius (Rm). Rotary draw benders can be programmable to store multiple bend jobs with varying degrees of bending. Often

130:

Press bending is probably the first bending process used on cold pipes and tubing. In this process a die in the shape of the bend is pressed against the pipe forcing the pipe to fit the shape of the bend. Because the pipe is not supported internally there is some deformation of the shape of the pipe,

335:

The spring is pushed into the pipe until its center is roughly where the bend is to be. A length of flexible wire can be attached to the end of the spring to facilitate its removal. The pipe is generally held against the flexed knee, and the ends of the pipe are pulled up to create the bend. To make

331:

These are strong but flexible springs inserted into a pipe to support the pipe walls during manual bending. They have diameters only slightly less than the internal diameter of the pipe to be bent. They are only suitable for bending 15-and-22 mm (0.6-and-0.9 in) soft copper pipe (typically

71:

Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubricants needed by the pipe and tube bender to best shape the material, and

280:

In the sand packing process the pipe is filled with fine sand and the ends are capped. The filled pipe is heated in a furnace to 1,600 °F (870 °C) or higher. Then it is placed on a slab with pins set in it, and bent around the pins using a winch, crane, or some other mechanical force. The

220:

An induction coil is placed around a small section of the pipe at the bend point. It is then induction heated to between 800 and 2,200 degrees

Fahrenheit (430 and 1,200 C). While the pipe is hot, pressure is placed on the pipe to bend it. The pipe can then be quenched with either air or water spray

114:

Much of the tooling is made of hardened steel or tool steel to maintain and prolong the tool's life. However, when there is a concern of scratching or gouging the work piece, a softer material such as aluminum or bronze is utilized. For example, the clamping block, rotating form block and pressure

315:

In production of a product where the bend is not critical a plug mandrel can be used. A form type tapers the end of the mandrel to provide more support in the bend of the tube. When precise bending is needed a ball mandrel (or ball mandrel with steel cable) should be used. The conjoined ball-like

224:

Induction bending is used to produce bends for a wide range of applications, such as (thin walled) pipe lines for both the upstream and down stream and on- and off shore segments of the petrochemical industry, large radius structural parts for the construction industry, thick walled, short radius

80:

A tube can be bent in multiple directions and angles. Common simple bends consist of forming elbows, which are 90° bends, and U-bends, which are 180° bends. More complex geometries include multiple two-dimensional (2D) bends and three-dimensional (3D) bends. A 2D tube has the openings on the same

194:

Three-roll push bending (TRPB) is the most commonly used freeform-bending process to manufacture bending geometries consisting of several plane bending curves. Nevertheless, 3D-shaping is possible. The profile is guided between bending-roll and supporting-roll(s), while being pushed through the

177:

During the roll bending process the pipe, extrusion, or solid is passed through a series of rollers (typically three) that apply pressure to the pipe gradually changing the bend radius in the pipe. The pyramid style roll benders have one moving roll, usually the top roll. Double pinch type roll

162:

The complete tooling is required only for high-precision bending of difficult-to-bend tubes with relatively large OD/t (diameter/thickness) ratio and relatively small ratio between the mean bending radius Rm and OD. The use of axial boosting either on the tube free end or on the pressure die is

105:

The process of tube bending involves using mechanical force to push stock material pipe or tubing against a die, forcing the pipe or tube to conform to the shape of the die. Often, stock tubing is held firmly in place while the end is rotated and rolled around the die. Other forms of processing

195:

tools. The position of the forming-roll defines the bending radius. The bending point is the tangent-point between tube and bending-roll. To change the bending plane, the pusher rotates the tube around its longitudinal axis. Generally, a TRPB tool kit can be applied on a conventional

211:

Three roll bending of tubes and open profiles can also be performed with simpler machines, often semi-automatic and non CNC controlled, able to feed the tube into the bending zone by friction. These machines have often a vertical layout, i.e. the three rolls lie on a vertical plane.

178:

benders have two adjustable rolls, usually the bottom rolls, and a fixed top roll. This method of bending causes very little deformation in the cross section of the pipe. This process is suited to producing coils of pipe as well as long gentle bends like those used in truss systems.

316:

disks are inserted into the tubing to allow for bending while maintaining the same diameter throughout. Other styles include using sand, cerrobend, or frozen water. These allow for a somewhat constant diameter while providing an inexpensive alternative to the aforementioned styles.

159:, handles, lines and much more. Rotary draw benders create aesthetically pleasing bends when the right tooling is matched to the application. CNC rotary draw bending machines can be very complex and use sophisticated tooling to produce severe bends with high quality requirements.

110:

is placed inside the tube to prevent collapsing. The tube is held in tension by a wiper die to prevent any creasing during stress. A wiper die is usually made of a softer alloy such as aluminum or brass to avoid scratching or damaging the material being bent.

88:

One side effect of bending the workpiece is the wall thickness changes; the wall along the inner radius of the tube becomes thicker and the outer wall becomes thinner. To reduce this the tube may be supported internally and or externally to preserve the

101:

Tube bending as a process starts with loading a tube into a tube or pipe bender and clamping it into place between two dies, the clamping block and the forming die. The tube is also loosely held by two other dies, the wiper die and the pressure die.

115:

die are often formed from hardened steel because the tubing is not moving past these parts of the machine. The pressure die and the wiping die are formed from aluminum or bronze to maintain the shape and surface of the work piece as it slides by.

39:

294:

A mandrel is a steel rod or linked ball inserted into the tube while it is being bent to give the tube extra support to reduce wrinkling and breaking the tube during this process. The different types of mandrels are as follows.

84:

A two plane bend or compound bend is defined as a compound bend that has a bend in the plan view and a bend in the elevation. When calculating a two plane bend, one must know the bend angle and rotation (dihedral angle).

131:

resulting in an oval cross section. This process is used where a consistent cross section of the pipe is not required. Although a single die can produce various shapes, it only works for one size tube and radius.

199:

machine. The process is very flexible since with a unique tool set, several bending radii values Rm can be obtained, although the geometrical precision of the process is not comparable to

605:

264:

The pipe is filled with a water solution, frozen, and bent while cold. The solute (soap can be used) makes the ice flexible. This technique is used to make trombones.

567:

148:

a positioning index table (IDX) is attached to the bender allowing the operator to reproduce complex bends which can have multiple bends and differing planes.

497:

Engel, B.; Kersten, S.; Anders, D. (2011), "Spline-Interpolation and

Calculation of Machine Parameters for the Three-Roll-Pushbending of Spline-Contours",

598:

466:

Strano, Matteo; B.M. Colosimo; E. Del

Castillo (2011). "Improved design of a three roll tube bending process under geometrical uncertainties".

431:

Mentella, A.; Strano, M. (10 October 2011). "Rotary draw bending of small diameter copper tubes: predicting the quality of the cross-section".

393:

535:

272:

A similar techniques using pitch was formerly used, but discontinued because the pitch was hard to clean out without excessive heat.

591:

560:

64:

Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a

354:

61:. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures.

913:

619:

553:

918:

359:

923:

151:

Rotary draw benders are the most popular machines for use in bending tube, pipe and solids for applications like:

835:

676:

364:

305:

Ball mandrel without cable: unlinked steel ball bearings inserted into tube, used on critical and precise bends

90:

106:

including pushing stock through rollers that bend it into a simple curve. For some tube bending processing, a

887:

706:

681:

671:

339:

Bending springs for smaller diameter pipes (10 mm copper pipe) slide over the pipe instead of inside.

54:

731:

726:

666:

661:

615:

139:

308:

Ball mandrel with cable: linked ball bearings inserted into tube, used on critical bend and precise bends

93:. Depending on the bend angle, wall thickness, and bending process the inside of the wall may wrinkle.

716:

471:

186:

65:

433:

Proceedings of the

Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture

514:

448:

862:

857:

792:

686:

635:

389:

58:

409:

506:

479:

440:

928:

767:

711:

475:

815:

736:

907:

810:

805:

518:

452:

50:

203:. Bending contours defined as spline- or polynomial-functions can be manufactured.

701:

576:

320:

172:

302:

Form mandrel: a solid rod with curved end used on bend when more support is needed

645:

882:

877:

640:

247:

wide range of pipe sizes can be accommodated in one machine (1” OD thru 80”OD)

30:

17:

444:

872:

867:

800:

777:

691:

156:

119:

510:

468:

The 14th

International ESAFORM Conference on Material Forming: ESAFORM 2011

38:

721:

152:

892:

852:

830:

825:

782:

762:

741:

696:

348:

107:

483:

118:

Pipe bending machines are typically human powered, pneumatic powered,

820:

772:

225:

bends for the power generating industry and city heating systems.

185:

138:

37:

29:

281:

sand in the pipe minimizes distortion in the pipe cross section.

587:

549:

545:

470:. AIP Conference Proceedings. Vol. 1353. pp. 35–40.

72:

the different ways the tube may be used (tube, pipe wires).

536:"Brass instrument manufacturing: How metal makes music"

235:

bend radii and angles (1°-180°) can be freely selected

384:

Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994),

122:

assisted, hydraulic driven, or electric servomotor.

791:

755:

654:

628:

244:significant savings can be obtained on field welds

299:Plug mandrel: a solid rod used on normal bends

81:plane; a 3D has openings on different planes.

599:

561:

8:

241:accurate pipe spools can easily be produced

606:

592:

584:

568:

554:

546:

250:excellent wall thinning and ovality values

332:used in household plumbing) or PVC pipe.

228:Big advantages of induction bending are:

200:

196:

388:(1st ed.), Industrial Press Inc.,

386:Manufacturing Processes Reference Guide

376:

323:is a common application for a mandrel.

530:

528:

319:Performance automotive or motorcycle

238:highly accurate bend radii and angles

7:

143:Full tooling for rotary draw bending

53:processes used to permanently form

221:or be cooled against ambient air.

25:

355:Bending machine (manufacturing)

190:Three-roll push bending process

1:

276:Sand-packing/hot-slab forming

499:Steel Research International

42:A trombone with some U-bends

360:Brake (sheet metal bending)

311:Sand: sand packed into tube

945:

170:

848:

583:

207:Simple three-roll bending

677:Electrohydraulic forming

445:10.1177/0954405411416306

365:Spring Back Compensation

155:, frames, motor vehicle

682:Electromagnetic forming

182:Three-roll push bending

667:Casting (metalworking)

511:10.1002/srin.201100077

191:

144:

43:

35:

888:Tools and terminology

189:

142:

41:

33:

27:Metal forming process

717:Progressive stamping

232:no need for mandrels

914:Fabrication (metal)

793:Finishing processes

476:2011AIPC.1353...35S

201:rotary draw bending

197:rotary draw bending

135:Rotary draw bending

919:Metalworking tools

411:Pipe Bending Guide

192:

145:

44:

36:

924:Tubing (material)

901:

900:

844:

843:

756:Joining processes

687:Explosive forming

655:Forming processes

505:(10): 1180–1186,

484:10.1063/1.3589488

395:978-0-8311-3049-7

216:Induction bending

16:(Redirected from

936:

623:

608:

601:

594:

585:

570:

563:

556:

547:

540:

539:

532:

523:

522:

494:

488:

487:

463:

457:

456:

428:

422:

420:

419:

418:

406:

400:

398:

381:

289:

288:

21:

944:

943:

939:

938:

937:

935:

934:

933:

904:

903:

902:

897:

840:

787:

751:

712:Press hardening

650:

624:

622:, and finishing

614:

612:

579:

574:

544:

543:

534:

533:

526:

496:

495:

491:

465:

464:

460:

430:

429:

425:

416:

414:

408:

407:

403:

396:

383:

382:

378:

373:

345:

329:

327:Bending springs

292:

286:

285:

278:

270:

262:

257:

218:

209:

184:

175:

169:

137:

128:

99:

78:

28:

23:

22:

15:

12:

11:

5:

942:

940:

932:

931:

926:

921:

916:

906:

905:

899:

898:

896:

895:

890:

885:

880:

875:

870:

865:

860:

855:

849:

846:

845:

842:

841:

839:

838:

833:

828:

823:

818:

816:Mass finishing

813:

808:

803:

797:

795:

789:

788:

786:

785:

780:

775:

770:

765:

759:

757:

753:

752:

750:

749:

744:

739:

734:

729:

724:

719:

714:

709:

704:

699:

694:

689:

684:

679:

674:

669:

664:

658:

656:

652:

651:

649:

648:

643:

638:

632:

630:

626:

625:

613:

611:

610:

603:

596:

588:

581:

580:

575:

573:

572:

565:

558:

550:

542:

541:

524:

489:

458:

439:(2): 267–278.

423:

401:

394:

375:

374:

372:

369:

368:

367:

362:

357:

352:

344:

341:

328:

325:

313:

312:

309:

306:

303:

300:

291:

283:

277:

274:

269:

266:

261:

258:

256:

253:

252:

251:

248:

245:

242:

239:

236:

233:

217:

214:

208:

205:

183:

180:

171:Main article:

168:

165:

136:

133:

127:

124:

98:

95:

77:

74:

26:

24:

18:Conduit bender

14:

13:

10:

9:

6:

4:

3:

2:

941:

930:

927:

925:

922:

920:

917:

915:

912:

911:

909:

894:

891:

889:

886:

884:

881:

879:

876:

874:

871:

869:

866:

864:

861:

859:

856:

854:

851:

850:

847:

837:

834:

832:

829:

827:

824:

822:

819:

817:

814:

812:

811:Heat treating

809:

807:

804:

802:

799:

798:

796:

794:

790:

784:

781:

779:

776:

774:

771:

769:

766:

764:

761:

760:

758:

754:

748:

745:

743:

740:

738:

735:

733:

730:

728:

725:

723:

720:

718:

715:

713:

710:

708:

705:

703:

700:

698:

695:

693:

690:

688:

685:

683:

680:

678:

675:

673:

670:

668:

665:

663:

660:

659:

657:

653:

647:

644:

642:

639:

637:

634:

633:

631:

627:

621:

617:

609:

604:

602:

597:

595:

590:

589:

586:

582:

578:

571:

566:

564:

559:

557:

552:

551:

548:

537:

531:

529:

525:

520:

516:

512:

508:

504:

500:

493:

490:

485:

481:

477:

473:

469:

462:

459:

454:

450:

446:

442:

438:

434:

427:

424:

413:

412:

405:

402:

397:

391:

387:

380:

377:

370:

366:

363:

361:

358:

356:

353:

350:

347:

346:

342:

340:

337:

333:

326:

324:

322:

317:

310:

307:

304:

301:

298:

297:

296:

284:

282:

275:

273:

268:Pitch packing

267:

265:

259:

254:

249:

246:

243:

240:

237:

234:

231:

230:

229:

226:

222:

215:

213:

206:

204:

202:

198:

188:

181:

179:

174:

166:

164:

160:

158:

154:

149:

141:

134:

132:

126:Press bending

125:

123:

121:

116:

112:

109:

103:

96:

94:

92:

91:cross section

86:

82:

75:

73:

69:

67:

62:

60:

56:

52:

51:metal forming

48:

40:

32:

19:

747:Tube bending

746:

702:Hydroforming

577:Metalworking

502:

498:

492:

467:

461:

436:

432:

426:

415:, retrieved

410:

404:

385:

379:

338:

334:

330:

321:exhaust pipe

318:

314:

293:

279:

271:

263:

227:

223:

219:

210:

193:

176:

173:Roll bending

167:Roll bending

161:

150:

146:

129:

117:

113:

104:

100:

87:

83:

79:

70:

63:

47:Tube bending

46:

45:

858:Fabrication

806:Galvanizing

646:Sheet metal

636:Fabrication

620:fabrication

351:(mechanics)

260:Ice packing

34:Bent tubing

908:Categories

878:Metallurgy

821:Patination

641:Piece work

417:2018-07-24

371:References

157:roll cages

873:Machining

868:Jewellery

836:Polishing

801:Anodizing

778:Soldering

692:Extrusion

519:136452513

453:110467253

153:handrails

120:hydraulic

97:Processes

883:Smithing

773:Riveting

768:Crimping

737:Spinning

722:Punching

707:Stamping

343:See also

76:Geometry

893:Welding

863:Forming

853:Casting

831:Plating

826:Peening

783:Welding

763:Brazing

742:Swaging

732:Sinking

727:Rolling

697:Forging

672:Drawing

662:Coining

629:General

616:Forming

472:Bibcode

349:Bending

287:Mandrel

255:Packing

108:mandrel

49:is any

929:Piping

517:

451:

392:

59:tubing

515:S2CID

449:S2CID

55:pipes

390:ISBN

507:doi

480:doi

441:doi

437:226

66:die

57:or

910::

618:,

527:^

513:,

503:82

501:,

478:.

447:.

435:.

607:e

600:t

593:v

569:e

562:t

555:v

538:.

521:.

509::

486:.

482::

474::

455:.

443::

421:.

399:.

290:s

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.