262:

containing copper. Titanium condenser tubes are usually the best technical choice, however the use of titanium condenser tubes has been virtually eliminated by the sharp increases in the costs for this material. The tube lengths range to about 85 ft (26 m) for modern power plants, depending on the size of the condenser. The size chosen is based on transportability from the manufacturers’ site and ease of erection at the installation site. The outer diameter of condenser tubes typically ranges from 3/4 inch to 1-1/4 inch, based on condenser cooling water friction considerations and overall condenser size.

31:

185:

386:(being cheapest) plates are mounted at suitable places inside the water boxes. These zinc plates will get corroded first being in the lowest range of anodes. Hence these zinc anodes require periodic inspection and replacement. This involves comparatively less down time. The water boxes made of steel plates are also protected inside by epoxy paint.

235:

at the inlet of each tube giving rise to erosion, and to reduce flow friction. Some makers also recommend plastic inserts at the entry of tubes to avoid eddies eroding the inlet end. In smaller units some manufacturers use ferrules to seal the tube ends instead of rolling. To take care of length wise

354:

The concentration of undissolved gases is high over air zone tubes. Therefore, these tubes are exposed to higher corrosion rates. Some times these tubes are affected by stress corrosion cracking, if original stress is not fully relieved during manufacture. To overcome these effects of corrosion some

410:

Depending on the extent of the fouling, the impact can be quite severe on the condenser's ability to condense the exhaust steam coming from the turbine. As fouling builds up within the tubing, an insulating effect is created and the heat-transfer characteristics of the tubes are diminished, often

270:

The tube sheet at each end with tube ends rolled, for each end of the condenser is closed by a fabricated box cover known as a waterbox, with flanged connection to the tube sheet or condenser shell. The waterbox is usually provided with man holes on hinged covers to allow inspection and cleaning.

157:

plates and is stiffened as needed to provide rigidity for the shell. When required by the selected design, intermediate plates are installed to serve as baffle plates that provide the desired flow path of the condensing steam. The plates also provide support that help prevent sagging of long tube

394:

As one might expect, with millions of gallons of circulating water flowing through the condenser tubing from seawater or fresh water, anything that is contained within the water flowing through the tubes can ultimately end up on either the condenser tubesheet (discussed previously) or within the

116:

of steam to mechanical power in the turbine, the better is its efficiency. By condensing the exhaust steam of a turbine at a pressure below atmospheric pressure, the steam pressure drop between the inlet and exhaust of the turbine is increased, which increases the amount of heat available for

261:

depending on several selection criteria. The use of copper bearing alloys such as brass or cupro nickel is rare in new plants, due to environmental concerns of toxic copper alloys. Also depending on the steam cycle water treatment for the boiler, it may be desirable to avoid tube materials

70:. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure (and temperature) as a water-cooled surface condenser.

108:. The difference between the heat of steam per unit mass at the inlet to the turbine and the heat of steam per unit mass at the outlet from the turbine represents the heat which is converted to mechanical power. Therefore, the more the conversion of heat per

240:

of tubes some designs have expansion joint between the shell and the tube sheet allowing the latter to move longitudinally. In smaller units some sag is given to the tubes to take care of tube expansion with both end water boxes fixed rigidly to the shell.

411:

requiring the turbine to be slowed to a point where the condenser can handle the exhaust steam produced. Typically, this can be quite costly to power plants in the form of reduced output, increase fuel consumption and increased CO

312:

The tubes, the tube sheets and the water boxes may be made up of materials having different compositions and are always in contact with circulating water. This water, depending on its chemical composition, will act as an

348:, to ensure there is no marine growth on the pipes or the tubes. This practice must be strictly regulated to make sure the circulating water returning to the sea or river source is not affected.

415:

emissions. This "derating" of the turbine to accommodate the condenser's fouled or blocked tubing is an indication that the plant needs to clean the tubing in order to return to the turbine's

460:

publishes several performance test codes on condensers and heat exchangers. These include ASME PTC 12.2-2010, Steam

Surface Condensers, and PTC 30.1-2007, Air cooled Steam Condensers.

686:

145:

as well in other applications. There are many fabrication design variations depending on the manufacturer, the size of the steam turbine, and other site-specific conditions.

620:

363:

As the tube ends get corroded there is the possibility of cooling water leakage to the steam side contaminating the condensed steam or condensate, which is harmful to

231:

is provided, with holes for the tubes to be inserted and rolled. The inlet end of each tube is also bellmouthed for streamlined entry of water. This is to avoid

679:

200:

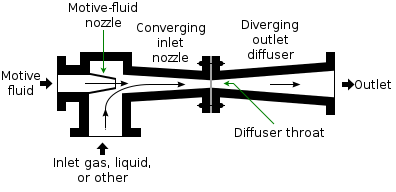

system. Such an ejector system uses steam as the motive fluid to remove any non-condensible gases that may be present in the surface condenser. The

1561:

367:. The other parts of water boxes may also get affected in the long run requiring repairs or replacements involving long duration shut-downs.

456:

National and international test codes are used to standardize the procedures and definitions used in testing large condensers. In the U.S.,

419:. A variety of methods for cleaning are available, including online and offline options, depending on the plant's site-specific conditions.

672:

648:

130:

1136:

407:

that can grow on the tubesheet, to wood or other debris that blocks the tubing, and finally, corrosion products (discussed previously).

286:

at bottom to drain the waterbox for maintenance. Similarly on the outlet waterbox the cooling water connection will have large flanges,

395:

tubing itself. Tube-side fouling for surface condensers falls into five main categories; particulate fouling like silt and sediment,

137:

The adjacent diagram depicts a typical water-cooled surface condenser as used in power stations to condense the exhaust steam from a

1636:

1131:

604:

576:

73:

Surface condensers are also used in applications and industries other than the condensing of steam turbine exhaust in power plants.

89:, and also to convert the turbine exhaust steam into pure water (referred to as steam condensate) so that it may be reused in the

1595:

1507:

340:

The corrosive effect of sea or river water has to be tolerated and remedial methods have to be adopted. One method is the use of

436:

1566:

1401:

1210:

196:

For water-cooled surface condensers, the shell's internal vacuum is most commonly supplied by and maintained by an external

854:

43:

1240:

1230:

1434:

1298:

1279:

1270:

1154:

766:

709:

475:

1646:

1048:

1600:

1589:

1146:

165:(often referred to as the hotwell) is provided. Condensate is pumped from the outlet or the hotwell for reuse as

59:

153:

The shell is the condenser's outermost body and contains the heat exchanger tubes. The shell is fabricated from

1641:

1374:

1306:

364:

205:

1610:

1605:

1526:

1250:

1195:

917:

873:

490:

1615:

1513:

1354:

1235:

886:

824:

121:

of the exhaust steam is carried away by the cooling medium (water or air) used by the surface condenser.

1571:

1480:

1205:

1126:

1099:

829:

814:

724:

505:

232:

55:

1540:

30:

403:, scaling and crystallization such as calcium carbonate, macrofouling which can include anything from

161:

At the bottom of the shell, where the condensate collects, an outlet is installed. In some designs, a

1651:

1225:

1164:

1025:

891:

839:

776:

729:

533:(Eleventh edition (Two volumes) ed.). John Wiley & Sons (Wiley Engineering Handbook Series).

526:

142:

67:

1534:

1068:

942:

859:

849:

375:

341:

294:

pockets are located at inlet and outlet pipes for local measurements of cooling water temperature.

1467:

1461:

1455:

1447:

1442:

1030:

614:

538:

428:

416:

86:

645:

317:

between the metallic composition of tubes and water boxes. This will give rise to electrolytic

1331:

1169:

1118:

1073:

1053:

1040:

1020:

1002:

947:

901:

771:

714:

600:

572:

379:

237:

90:

1407:

1395:

1368:

1094:

1012:

982:

834:

485:

166:

1580:

1313:

1255:

1174:

1063:

1058:

972:

927:

652:

550:

287:

275:

274:

These waterboxes on inlet side will also have flanged connections for cooling water inlet

250:

228:

105:

63:

17:

633:

1499:

1348:

1320:

997:

896:

819:

809:

719:

297:

In smaller units, some manufacturers make the condenser shell as well as waterboxes of

290:, vent connection also at higher level and drain connections at lower level. Similarly

201:

1630:

1287:

1260:

1159:

1078:

914:

500:

495:

138:

51:

1488:

1245:

992:

977:

932:

786:

781:

695:

404:

254:

184:

154:

118:

109:

82:

1413:

1387:

1340:

937:

911:

881:

759:

754:

314:

291:

216:

212:

129:

1419:

1362:

987:

922:

906:

844:

801:

791:

396:

334:

330:

66:

which convert steam from its gaseous to its liquid state at a pressure below

1215:

1200:

480:

470:

318:

298:

227:

At each end of the shell, a sheet of sufficient thickness usually made of

1104:

345:

258:

197:

189:

113:

400:

1220:

957:

355:

manufacturers provide higher corrosive resistant tubes in this area.

173:

94:

739:

595:

Thomas C. Elliott, Kao Chen, Robert

Swanekamp (coauthors) (1997).

283:

279:

183:

128:

117:

conversion to mechanical power. Most of the heat liberated due to

81:

In thermal power plants, the purpose of a surface condenser is to

47:

29:

664:

457:

383:

162:

101:

668:

441:

Replacing barometric condensers in steam-driven ejector systems

172:

For most water-cooled surface condensers, the shell is under

34:

Surface condenser with end plate extended to reveal tube banks

333:, have the worst corrosion characteristics. River water with

282:

for air venting at higher level, and hand-operated drain

85:

the exhaust steam from a steam turbine to obtain maximum

188:

Diagram of a typical modern injector or ejector. For a

636:

from website of the Air

Pollution Training Institute

100:

The steam turbine itself is a device to convert the

1554:

1525:

1498:

1479:

1433:

1386:

1339:

1330:

1297:

1278:

1269:

1188:

1145:

1117:

1087:

1039:

1011:

965:

956:

872:

800:

747:

738:

702:

321:which will start from more anodic materials first.

133:

Diagram of a typical water-cooled surface condenser

337:are also undesirable for condenser cooling water.

329:, in particular when sea water has added chemical

208:, applies to the operation of steam jet ejectors.

378:is typically employed to overcome this problem.

680:

8:

619:: CS1 maint: multiple names: authors list (

351:On the steam (shell) side of the condenser:

309:On the cooling water side of the condenser:

597:Standard Handbook of Powerplant Engineering

1336:

1275:

962:

744:

687:

673:

665:

599:(2nd ed.). McGraw-Hill Professional.

590:

588:

562:

560:

253:, copper alloys such as brass or bronze,

219:type, are also popular for this service.

125:Diagram of water-cooled surface condenser

634:Air Pollution Control Orientation Course

423:Other applications of surface condensers

1562:Glossary of steam locomotive components

518:

656:Figure 3a, Layout of surface condenser

612:

546:

536:

531:Kents' Mechanical Engineers' Handbook

7:

176:during normal operating conditions.

658:(scroll to page 11 of 34 pdf pages)

1414:National Museum of Scotland engine

25:

567:Babcock & Wilcox Co. (2005).

1596:List of steam technology patents

249:Generally the tubes are made of

204:, which is a particular case of

646:Energy savings in steam systems

1581:Murdoch's model steam carriage

1567:History of steam road vehicles

46:installed to condense exhaust

1:

1508:Murray's Hypocycloidal Engine

569:Steam: Its Generation and Use

44:shell and tube heat exchanger

1231:Return connecting rod engine

390:Effects of tube side fouling

278:, small vent pipe with hand

192:, the motive fluid is steam.

1155:Condensing steam locomotive

476:Condensing steam locomotive

437:Ocean Thermal Energy (OTEC)

1668:

1462:"Coalbrookdale Locomotive"

529:(Editor in Chief) (1936).

444:Geothermal energy recovery

326:Sea water based condensers

1468:"Pen-y-Darren" locomotive

1137:Single- and double-acting

371:Protection from corrosion

18:Condenser (steam turbine)

1637:Power station technology

1307:Newcomen Memorial Engine

211:Motor driven mechanical

1611:Timeline of steam power

1606:Stationary steam engine

1489:Woolf's compound engine

1396:Soho Manufactory engine

1251:Steeple compound engine

918:straight line mechanism

491:Fossil fuel power plant

104:in steam to mechanical

1616:Water-returning engine

1590:Lean's Engine Reporter

1363:Chacewater Mine engine

1236:Six-column beam engine

193:

134:

97:as boiler feed water.

56:thermal power stations

35:

27:Steam engine component

1456:London Steam Carriage

506:Thermal power station

206:Bernoulli's principle

187:

132:

33:

1402:Bradley Works engine

1226:Reciprocating engine

1049:Babcock & Wilcox

892:Centrifugal governor

527:Robert Thurston Kent

447:Desalination systems

433:Vacuum refrigeration

359:Effects of corrosion

143:electrical generator

68:atmospheric pressure

943:Sun and planet gear

376:Cathodic protection

342:sodium hypochlorite

1443:Richard Trevithick

1041:Water-tube boilers

855:Gresley conjugated

651:2007-09-27 at the

549:has generic name (

429:Vacuum evaporation

417:nameplate capacity

380:Sacrificial anodes

194:

135:

42:is a water-cooled

36:

1647:Energy conversion

1624:

1623:

1550:

1549:

1429:

1428:

1113:

1112:

1013:Fire-tube boilers

868:

867:

571:(41st ed.).

198:steam jet ejector

40:surface condenser

16:(Redirected from

1659:

1574:fardier à vapeur

1408:Whitbread Engine

1369:Smethwick Engine

1337:

1276:

1095:Feedwater heater

963:

745:

689:

682:

675:

666:

659:

643:

637:

631:

625:

624:

618:

610:

592:

583:

582:

564:

555:

554:

548:

544:

542:

534:

523:

486:Feedwater heater

365:steam generators

288:butterfly valves

276:butterfly valves

167:boiler feedwater

21:

1667:

1666:

1662:

1661:

1660:

1658:

1657:

1656:

1642:Heat exchangers

1627:

1626:

1625:

1620:

1546:

1521:

1494:

1475:

1425:

1382:

1326:

1314:Fairbottom Bobs

1299:Newcomen engine

1293:

1265:

1211:Expansion valve

1184:

1170:Watt's separate

1141:

1109:

1083:

1035:

1007:

952:

928:Parallel motion

864:

815:Stephenson link

796:

734:

703:Operating cycle

698:

693:

663:

662:

653:Wayback Machine

644:

640:

632:

628:

611:

607:

594:

593:

586:

579:

566:

565:

558:

545:

535:

525:

524:

520:

515:

510:

466:

454:

425:

414:

399:like slime and

392:

373:

361:

307:

268:

251:stainless steel

247:

229:stainless steel

225:

182:

151:

127:

91:steam generator

79:

64:heat exchangers

28:

23:

22:

15:

12:

11:

5:

1665:

1663:

1655:

1654:

1649:

1644:

1639:

1629:

1628:

1622:

1621:

1619:

1618:

1613:

1608:

1603:

1598:

1593:

1586:

1585:

1584:

1578:

1564:

1558:

1556:

1552:

1551:

1548:

1547:

1545:

1544:

1538:

1531:

1529:

1523:

1522:

1520:

1519:

1511:

1504:

1502:

1496:

1495:

1493:

1492:

1485:

1483:

1477:

1476:

1474:

1473:

1472:

1471:

1465:

1459:

1453:

1439:

1437:

1431:

1430:

1427:

1426:

1424:

1423:

1417:

1411:

1405:

1399:

1392:

1390:

1384:

1383:

1381:

1380:

1372:

1366:

1360:

1352:

1349:Kinneil Engine

1345:

1343:

1334:

1328:

1327:

1325:

1324:

1321:Elsecar Engine

1318:

1310:

1303:

1301:

1295:

1294:

1292:

1291:

1284:

1282:

1273:

1267:

1266:

1264:

1263:

1258:

1253:

1248:

1243:

1241:Steeple engine

1238:

1233:

1228:

1223:

1218:

1213:

1208:

1203:

1198:

1192:

1190:

1186:

1185:

1183:

1182:

1177:

1172:

1167:

1162:

1157:

1151:

1149:

1143:

1142:

1140:

1139:

1134:

1129:

1123:

1121:

1115:

1114:

1111:

1110:

1108:

1107:

1102:

1100:Feedwater pump

1097:

1091:

1089:

1085:

1084:

1082:

1081:

1076:

1071:

1066:

1061:

1056:

1051:

1045:

1043:

1037:

1036:

1034:

1033:

1028:

1023:

1017:

1015:

1009:

1008:

1006:

1005:

1000:

995:

990:

985:

980:

975:

969:

967:

966:Simple boilers

960:

954:

953:

951:

950:

948:Watt's linkage

945:

940:

935:

930:

925:

920:

909:

904:

899:

897:Connecting rod

894:

889:

884:

878:

876:

870:

869:

866:

865:

863:

862:

857:

852:

847:

842:

837:

832:

827:

822:

817:

812:

806:

804:

798:

797:

795:

794:

789:

784:

779:

774:

769:

764:

763:

762:

751:

749:

742:

736:

735:

733:

732:

727:

722:

717:

712:

706:

704:

700:

699:

694:

692:

691:

684:

677:

669:

661:

660:

638:

626:

605:

584:

577:

556:

517:

516:

514:

511:

509:

508:

503:

498:

493:

488:

483:

478:

473:

467:

465:

462:

453:

450:

449:

448:

445:

442:

439:

434:

431:

424:

421:

412:

391:

388:

372:

369:

360:

357:

306:

303:

267:

264:

246:

243:

224:

221:

215:, such as the

202:Venturi effect

181:

178:

150:

147:

126:

123:

78:

75:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

1664:

1653:

1650:

1648:

1645:

1643:

1640:

1638:

1635:

1634:

1632:

1617:

1614:

1612:

1609:

1607:

1604:

1602:

1599:

1597:

1594:

1592:

1591:

1587:

1582:

1579:

1576:

1575:

1570:

1569:

1568:

1565:

1563:

1560:

1559:

1557:

1553:

1542:

1539:

1536:

1533:

1532:

1530:

1528:

1524:

1517:

1516:

1512:

1509:

1506:

1505:

1503:

1501:

1497:

1490:

1487:

1486:

1484:

1482:

1478:

1469:

1466:

1463:

1460:

1457:

1454:

1451:

1450:

1449:Puffing Devil

1446:

1445:

1444:

1441:

1440:

1438:

1436:

1435:High-pressure

1432:

1421:

1418:

1415:

1412:

1409:

1406:

1403:

1400:

1397:

1394:

1393:

1391:

1389:

1388:Rotative beam

1385:

1378:

1377:

1373:

1370:

1367:

1364:

1361:

1358:

1357:

1353:

1350:

1347:

1346:

1344:

1342:

1338:

1335:

1333:

1329:

1322:

1319:

1316:

1315:

1311:

1308:

1305:

1304:

1302:

1300:

1296:

1289:

1288:Savery Engine

1286:

1285:

1283:

1281:

1277:

1274:

1272:

1268:

1262:

1261:Working fluid

1259:

1257:

1254:

1252:

1249:

1247:

1244:

1242:

1239:

1237:

1234:

1232:

1229:

1227:

1224:

1222:

1219:

1217:

1214:

1212:

1209:

1207:

1204:

1202:

1199:

1197:

1194:

1193:

1191:

1187:

1181:

1178:

1176:

1173:

1171:

1168:

1166:

1163:

1161:

1158:

1156:

1153:

1152:

1150:

1148:

1144:

1138:

1135:

1133:

1130:

1128:

1125:

1124:

1122:

1120:

1116:

1106:

1103:

1101:

1098:

1096:

1093:

1092:

1090:

1086:

1080:

1077:

1075:

1072:

1070:

1067:

1065:

1062:

1060:

1057:

1055:

1052:

1050:

1047:

1046:

1044:

1042:

1038:

1032:

1029:

1027:

1024:

1022:

1019:

1018:

1016:

1014:

1010:

1004:

1001:

999:

996:

994:

991:

989:

986:

984:

981:

979:

976:

974:

971:

970:

968:

964:

961:

959:

955:

949:

946:

944:

941:

939:

938:Rotative beam

936:

934:

931:

929:

926:

924:

921:

919:

916:

915:hypocycloidal

913:

910:

908:

905:

903:

900:

898:

895:

893:

890:

888:

885:

883:

880:

879:

877:

875:

871:

861:

858:

856:

853:

851:

848:

846:

843:

841:

838:

836:

833:

831:

828:

826:

823:

821:

818:

816:

813:

811:

808:

807:

805:

803:

799:

793:

790:

788:

785:

783:

780:

778:

775:

773:

770:

768:

765:

761:

758:

757:

756:

753:

752:

750:

746:

743:

741:

737:

731:

728:

726:

723:

721:

718:

716:

713:

711:

708:

707:

705:

701:

697:

696:Steam engines

690:

685:

683:

678:

676:

671:

670:

667:

657:

654:

650:

647:

642:

639:

635:

630:

627:

622:

616:

608:

606:0-07-019435-1

602:

598:

591:

589:

585:

580:

578:0-9634570-0-4

574:

570:

563:

561:

557:

552:

547:|author=

540:

532:

528:

522:

519:

512:

507:

504:

502:

501:Power station

499:

497:

496:Jet condenser

494:

492:

489:

487:

484:

482:

479:

477:

474:

472:

469:

468:

463:

461:

459:

451:

446:

443:

440:

438:

435:

432:

430:

427:

426:

422:

420:

418:

408:

406:

405:zebra mussels

402:

398:

389:

387:

385:

381:

377:

370:

368:

366:

358:

356:

352:

349:

347:

343:

338:

336:

332:

328:

327:

322:

320:

316:

310:

304:

302:

300:

295:

293:

289:

285:

281:

277:

272:

265:

263:

260:

256:

252:

244:

242:

239:

234:

230:

222:

220:

218:

214:

209:

207:

203:

199:

191:

190:steam ejector

186:

180:Vacuum system

179:

177:

175:

170:

168:

164:

159:

156:

148:

146:

144:

140:

139:steam turbine

131:

124:

122:

120:

115:

111:

107:

103:

98:

96:

92:

88:

84:

76:

74:

71:

69:

65:

61:

57:

53:

52:steam turbine

49:

45:

41:

32:

19:

1601:Modern steam

1588:

1573:

1535:Porter-Allen

1514:

1448:

1375:

1355:

1312:

1246:Safety valve

1179:

1175:"Pickle-pot"

1069:Thimble tube

655:

641:

629:

596:

568:

530:

521:

455:

409:

393:

374:

362:

353:

350:

339:

325:

324:

323:

311:

308:

296:

273:

269:

255:cupro nickel

248:

226:

213:vacuum pumps

210:

195:

171:

160:

155:carbon steel

152:

136:

119:condensation

99:

80:

72:

39:

37:

1652:Steam power

1332:Watt engine

1132:Oscillating

1088:Boiler feed

933:Plate chain

912:Tusi couple

825:Walschaerts

710:Atmospheric

315:electrolyte

292:thermometer

223:Tube sheets

217:liquid ring

141:driving an

1631:Categories

1541:Ljungström

1527:High-speed

1420:Lap Engine

1376:Resolution

1280:Precursors

1165:Kirchweger

1127:Locomotive

1074:Three-drum

1054:Field-tube

1021:Locomotive

1003:Lancashire

923:Link chain

907:Crankshaft

874:Mechanisms

802:Valve gear

513:References

397:biofouling

335:pollutants

331:pollutants

266:Waterboxes

87:efficiency

60:condensers

1572:Cugnot's

1515:Salamanca

1216:Hydrolock

1201:Crosshead

1147:Condenser

983:Egg-ended

615:cite book

539:cite book

481:Deaerator

471:Tube tool

319:corrosion

305:Corrosion

299:cast iron

238:expansion

158:lengths.

1555:See also

1481:Compound

1356:Old Bess

1196:Blowback

1119:Cylinder

1105:Injector

1064:Stirling

1059:Sentinel

973:Haystack

887:Cataract

860:Southern

850:Caprotti

725:Compound

649:Archived

464:See also

401:biofilms

346:chlorine

259:titanium

114:kilogram

83:condense

58:. These

1271:History

1180:Surface

998:Cornish

958:Boilers

840:Corliss

777:Corliss

760:D slide

730:Uniflow

720:Cornish

452:Testing

77:Purpose

50:from a

1583:(1784)

1577:(1769)

1543:(1908)

1537:(1862)

1518:(1812)

1510:(1805)

1500:Murray

1491:(1803)

1470:(1804)

1464:(1803)

1458:(1803)

1452:(1801)

1422:(1788)

1416:(1786)

1410:(1785)

1404:(1783)

1398:(1782)

1379:(1781)

1371:(1779)

1365:(1778)

1359:(1777)

1351:(1768)

1323:(1795)

1317:(1760)

1309:(1725)

1290:(1698)

1256:Stroke

1221:Piston

1206:Cutoff

1079:Yarrow

1031:Launch

1026:Scotch

787:Sleeve

782:Poppet

767:Piston

748:Valves

740:Valves

603:

575:

233:eddies

174:vacuum

95:boiler

1189:Other

993:Flued

978:Wagon

902:Crank

845:Lentz

835:Baker

830:Allan

755:Slide

344:, or

284:valve

280:valve

257:, or

245:Tubes

149:Shell

110:pound

106:power

48:steam

1341:Beam

882:Beam

792:Bash

772:Drop

715:Watt

621:link

601:ISBN

573:ISBN

551:help

458:ASME

384:zinc

163:sump

102:heat

62:are

1160:Jet

988:Box

820:Joy

810:Gab

382:of

112:or

93:or

54:in

1633::

617:}}

613:{{

587:^

559:^

543::

541:}}

537:{{

301:.

169:.

38:A

688:e

681:t

674:v

623:)

609:.

581:.

553:)

413:2

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.