160:

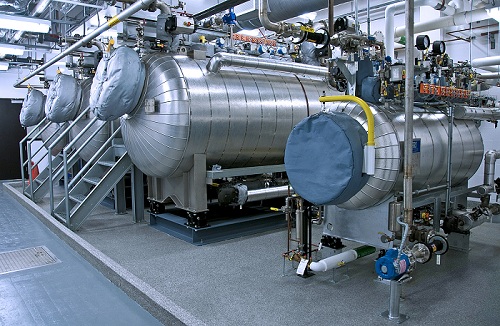

processing is offset against the volume of effluent that can be sterilised, as the steam takes up space that could be used to hold effluent. Steam injection is a very noisy process – steam rushing through the effluent can sound like a jet engine. The process can also cause solid material to stick to the sides of the sterilisation tank, which can hinder heat transference from the walls of a jacketed vessel. Low temperature and pressure variants of batch steam injection EDS have been shown capable of decontaminating biosafety level 2 waste by subjecting it to a sterilisation temperature of 82.2 °C. This low temperature requires a long time period of six hours to achieve sterilisation.

100:

139:

is passed through the cavity in the walls of jacketed vessel, raising its temperature of over 121 °C. Once all the effluent has been heated to at least 121 °C for at least 30 minutes, all biologically hazardous material within the kill tank will have been sterilised. At this point, the tank

159:

Batch steam injection systems function similarly to a batch steam EDS, but steam is passed directly through the effluent during the sterilisation stage. This procedure increases the speed at which the effluent can reach the required sterilisation temperature, increasing the throughput time. Speed of

168:

Continuous flow EDS pass liquid effluent through a distance of heated pipework to sterilise it. The heated pipework is frequently coiled to minimise heat loss and the space required. The length and bore of the heated pipework can vary greatly, depending on the rate of flow of the effluent and the

107:

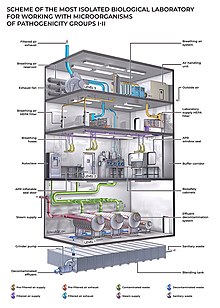

While EDS are designed chiefly to sterilise liquid waste, they can in some instances sterilise solid material carried by the liquid effluent. However the EDS may require grinders to break down the solid materials before they enter site of sterilisation in the EDS, and macerating paddles to stir

282:

Chmielewski, Revis; Day, Michael; Spatz, Stephen; Yu, Qingzhong; Gast, Richard; Zsak, Laslo; Swayne, David (1 December 2011). "Thermal

Inactivation of Avian Viral and Bacterial Pathogens in an Effluent Treatment System within a Biosafety Level 2 and 3 Enhanced Facility".

563:

Chmielewski, Revis; Day, Michael; Spatz, Stephen; Yu, Qingzhong; Gast, Richard; Zsak, Laslo; Swayne, David (December 2011). "Thermal

Inactivation of Avian Viral and Bacterial Pathogens in an Effluent Treatment System within a Biosafety Level 2 and 3 Enhanced Facility".

669:

Cote, Christopher K.; Weidner, Jessica M.; Klimko, Christopher; Piper, Ashley E.; Miller, Jeremy A.; Hunter, Melissa; Shoe, Jennifer L.; Hoover, Jennifer C.; Sauerbry, Brian R.; Buhr, Tony; Bozue, Joel A.; Harbourt, David E.; Glass, Pamela J. (9 July 2020).

198:

in the effluent have been sterilised. After sterilisation, the sterilant must be neutralised before the effluent can discarded into a sewer. As such, a batch chemical EDS requires a large quantity of chemicals, both sterilants and neutralisers, to operate

185:

For smaller scale systems of less than 100 gallons a day, chemical effluent decontamination systems can be used. Effluent is collected in a sterilisation tank, where it is mixed with a chemical sterilant such as

135:, which is a container with hollow walls. Effluent flows into the kill tank either by gravity or through being pumped into the tank. Once the tank is full of effluent, high-temperature pressurised

634:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

599:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

528:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

493:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

458:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

423:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

388:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

353:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent

Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

318:

Trembalay, Gilles; Langer-Curry, Rebecca; Chris, Kiley; Cory, Ziegler (2010). "Effluent Decontamination Systems: Addressing the Challenges of Planning, Designing, Testing, and Validation".

169:

temperature that the pipework is heated to. As a hotter temperature sterilises faster, the hotter the temperature of the pipework, the higher the flow rate of the continuous flow EDS.

217:

can be deactivated in a bleach-based chemical EDS effectively at a sterilant concentration of less than 5700 part per million over two hours of exposure

17:

131:

A Batch EDS consists of at least one sterilisation tank (also known as a kill tank, or a cook tank). The sterilisation tank is commonly a

234:

Daugelat, Sabine; Phyu, Sabai; Taillens, Charles; Wee, Hooi Leong; Mattila, Juha; Nurminen, Teppo; McDonnell, Gerald (1 June 2008).

143:

While a batch EDS must have at least one sterilisation tank, multiple sterilisation tanks can be used and fed from dedicated

723:

120:

116:

99:

37:

147:. It is noteworthy that when a kill tank is not running, it can function like a storage tank – collecting effluent and

728:

88:. Examples of liquids sterilised in an EDS include the shower water from personnel decontamination rooms, and the

77:

65:

57:

16:

235:

687:

651:

616:

581:

545:

510:

475:

440:

405:

370:

335:

300:

257:

214:

671:

718:

44:

materials in fluid and liquid waste material. Facility types that may utilise an EDS include

679:

643:

608:

573:

537:

502:

467:

432:

397:

362:

327:

292:

247:

103:

Effluent Decontamination Systems are an essential feature of Biosafety Level 4 laboratories.

195:

132:

81:

236:"The Design and Testing of a Continuous Effluent Sterilization System for Liquid Waste"

85:

61:

712:

691:

655:

620:

549:

514:

479:

444:

409:

374:

339:

144:

49:

33:

585:

304:

261:

174:

170:

109:

89:

647:

612:

577:

541:

506:

471:

436:

401:

366:

331:

296:

252:

84:

2 and above must decontaminate their waste before discharging it into a public

210:

148:

69:

53:

683:

191:

41:

203:

93:

73:

45:

672:"Biological Validation of a Chemical Effluent Decontamination System"

206:

187:

136:

98:

115:

EDS vary in their design and function, however the use of either

209:

within effluent containing a mixture of animal effluent,

194:

mixture are then held for sufficient time to ensure all

155:

Batch steam injection effluent decontamination system

140:

may be emptied by gravity or by fluid displacement.

177:can provide the heat required for sterilisation.

164:Continuous flow effluent decontamination systems

32:) is a device, or suite of devices, designed to

181:Batch chemical effluent decontamination systems

8:

127:Batch steam effluent decontamination system

76:facilities. In fact, all facilities in the

251:

96:animal rooms in laboratory environments.

15:

226:

20:A batch Effluent Decontamination System

151:until it is full enough to sterilise.

7:

14:

108:effluent held in tanks, reducing

50:food and beverage industry plants

26:effluent decontamination system

1:

80:that produce liquid waste of

68:production facilities, and

745:

648:10.1177/153567601001500304

613:10.1177/153567601001500304

578:10.1177/153567601101600402

542:10.1177/153567601001500304

507:10.1177/153567601001500304

472:10.1177/153567601001500304

437:10.1177/153567601001500304

402:10.1177/153567601001500304

367:10.1177/153567601001500304

332:10.1177/153567601001500304

297:10.1177/153567601101600402

253:10.1177/153567600801300205

684:10.1177/1535676020937967

78:United States of America

40:biologically active or

104:

21:

102:

19:

724:Laboratory equipment

190:. The effluent and

215:fetal bovine serum

202:Studies show that

121:heat sterilisation

105:

22:

729:Medical equipment

676:Applied Biosafety

636:Applied Biosafety

601:Applied Biosafety

566:Applied Biosafety

530:Applied Biosafety

495:Applied Biosafety

460:Applied Biosafety

425:Applied Biosafety

390:Applied Biosafety

355:Applied Biosafety

320:Applied Biosafety

285:Applied Biosafety

240:Applied Biosafety

736:

703:

702:

700:

698:

666:

660:

659:

631:

625:

624:

596:

590:

589:

560:

554:

553:

525:

519:

518:

490:

484:

483:

455:

449:

448:

420:

414:

413:

385:

379:

378:

350:

344:

343:

315:

309:

308:

279:

273:

272:

270:

268:

255:

231:

744:

743:

739:

738:

737:

735:

734:

733:

709:

708:

707:

706:

696:

694:

668:

667:

663:

633:

632:

628:

598:

597:

593:

562:

561:

557:

527:

526:

522:

492:

491:

487:

457:

456:

452:

422:

421:

417:

387:

386:

382:

352:

351:

347:

317:

316:

312:

281:

280:

276:

266:

264:

233:

232:

228:

223:

196:micro-organisms

183:

166:

157:

133:jacketed vessel

129:

82:Biosafety Level

62:animal research

12:

11:

5:

742:

740:

732:

731:

726:

721:

711:

710:

705:

704:

661:

642:(3): 119–129.

626:

607:(3): 119–129.

591:

572:(4): 206–217.

555:

536:(3): 119–129.

520:

501:(3): 119–129.

485:

466:(3): 119–129.

450:

431:(3): 119–129.

415:

396:(3): 119–129.

380:

361:(3): 119–129.

345:

326:(3): 119–129.

310:

291:(4): 206–217.

274:

246:(2): 105–112.

225:

224:

222:

219:

182:

179:

165:

162:

156:

153:

128:

125:

66:pharmaceutical

13:

10:

9:

6:

4:

3:

2:

741:

730:

727:

725:

722:

720:

717:

716:

714:

693:

689:

685:

681:

677:

673:

665:

662:

657:

653:

649:

645:

641:

637:

630:

627:

622:

618:

614:

610:

606:

602:

595:

592:

587:

583:

579:

575:

571:

567:

559:

556:

551:

547:

543:

539:

535:

531:

524:

521:

516:

512:

508:

504:

500:

496:

489:

486:

481:

477:

473:

469:

465:

461:

454:

451:

446:

442:

438:

434:

430:

426:

419:

416:

411:

407:

403:

399:

395:

391:

384:

381:

376:

372:

368:

364:

360:

356:

349:

346:

341:

337:

333:

329:

325:

321:

314:

311:

306:

302:

298:

294:

290:

286:

278:

275:

263:

259:

254:

249:

245:

241:

237:

230:

227:

220:

218:

216:

212:

208:

205:

200:

197:

193:

189:

180:

178:

176:

172:

163:

161:

154:

152:

150:

146:

145:storage tanks

141:

138:

134:

126:

124:

122:

118:

113:

111:

101:

97:

95:

91:

87:

83:

79:

75:

71:

67:

63:

59:

55:

51:

47:

43:

39:

35:

34:decontaminate

31:

27:

18:

695:. Retrieved

675:

664:

639:

635:

629:

604:

600:

594:

569:

565:

558:

533:

529:

523:

498:

494:

488:

463:

459:

453:

428:

424:

418:

393:

389:

383:

358:

354:

348:

323:

319:

313:

288:

284:

277:

265:. Retrieved

243:

239:

229:

201:

184:

167:

158:

142:

130:

114:

106:

94:washing down

86:sewer system

70:governmental

64:facilities,

58:agricultural

54:laboratories

42:biohazardous

29:

25:

23:

175:electricity

173:, steam or

171:Natural gas

123:is common.

110:congelation

90:waste water

52:, research

713:Categories

697:12 October

267:12 October

221:References

211:humic acid

149:wastewater

692:225637669

656:114865675

621:114865675

550:114865675

515:114865675

480:114865675

445:114865675

410:114865675

375:114865675

340:114865675

192:sterilant

46:hospitals

38:sterilise

719:Sewerage

586:15883828

305:15883828

262:16186873

204:Bacillus

117:chemical

74:military

690:

654:

619:

584:

548:

513:

478:

443:

408:

373:

338:

303:

260:

213:, and

207:spores

188:bleach

688:S2CID

652:S2CID

617:S2CID

582:S2CID

546:S2CID

511:S2CID

476:S2CID

441:S2CID

406:S2CID

371:S2CID

336:S2CID

301:S2CID

258:S2CID

137:steam

92:from

699:2020

269:2020

60:and

680:doi

644:doi

609:doi

574:doi

538:doi

503:doi

468:doi

433:doi

398:doi

363:doi

328:doi

293:doi

248:doi

119:or

72:or

36:or

30:EDS

24:An

715::

686:.

678:.

674:.

650:.

640:15

638:.

615:.

605:15

603:.

580:.

570:16

568:.

544:.

534:15

532:.

509:.

499:15

497:.

474:.

464:15

462:.

439:.

429:15

427:.

404:.

394:15

392:.

369:.

359:15

357:.

334:.

324:15

322:.

299:.

289:16

287:.

256:.

244:13

242:.

238:.

112:.

56:,

48:,

701:.

682::

658:.

646::

623:.

611::

588:.

576::

552:.

540::

517:.

505::

482:.

470::

447:.

435::

412:.

400::

377:.

365::

342:.

330::

307:.

295::

271:.

250::

28:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.