129:

117:

194:

turned on, the bearings may be noisy due to damage, and may fail completely within a few days or weeks even though the unit and its bearings are otherwise new. Common solutions include: keeping the spare unit at a distance from the one which is on and vibrating; manually rotating shafts of the spare units on a regular (for example, weekly) basis; or regularly switching between the units so that both are in regular (for example, weekly) operation.

140:

162:

for the damaged bearings were micro-oscillations which occurred due to the shipping. The small oscillations result in fatigue cracking, followed by release of particles that subsequently start to abrasively damage the contact area between a ball and the bearing race, resulting in a typical wear damage. Because the damage has a similar look to brinelling, it was called false brinelling.

166:

193:

may fail or need service because of this damage, so it is common to have a nearby spare unit which is left off most of the time but brought into service when needed. Surprisingly, however, vibration from the operating unit can cause bearing failure in the unit which is switched off. When that unit is

52:

without large rotational movement of all bearing surfaces in the raceway. Lubricant is pushed out of a loaded region during small oscillatory movements and vibration where the bearings surfaces repeatedly do not move very far. Without lubricant, wear is increased when the small oscillatory movements

88:

If the lubricant is removed, the bearings and races can touch directly. While bearings and races appear smooth to the eye, they are microscopically rough. Thus, high points of each surface can touch, but "valleys" do not. The bearing load is thus spread over much less area increasing the contact

161:

False brinelling was first mentioned by Almen in 1937. Almen found that wheel bearings were damaged before they were used by customers. Furthermore, he found that the bearings were more damaged for long-distance shipping of the cars and that the season of shipping also had an influence. The reason

112:

The simulation of false brinelling is possible with the help of the finite element method. For the simulation, the relative displacements (slip) between rolling element and raceway as well as the pressure in the rolling contact are determined. For comparison between simulation and experiments, the

124:

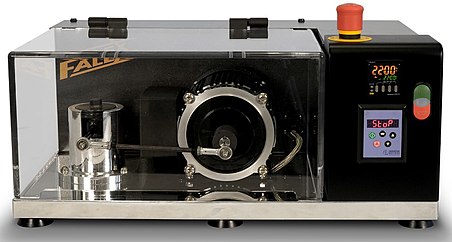

Physical simulation of the false brinelling mechanism has been standardized since the 1980's in the Fafnir

Bearing test instrument, where two sets of thrust ball bearings are compressed with a fixed load, and the bearings are oscillated by an excentric arm under standardised conditions. This

177:, for which specialty greases had to be developed that result in almost no false brinelling damage. Similar damage may also occur in electric and electronic contacts that are subjected to vibrations during use, think of aerospace and automotive connectors and even

181:

battery compartments. Although the damage in these areas may not be as severe as the false brinelling in bearings, the damage mechanisms are similar and result in the creation of particles in the contact that can severely influence the electrical connection.

478:

Tonazzi, D.; Komba, E. Houara; Massi, F.; Le Jeune, G.; Coudert, J. B.; Maheo, Y.; Berthier, Y. (15 April 2017). "Numerical analysis of contact stress and strain distributions for greased and ungreased high loaded oscillating bearings".

113:

friction work density is used, which is the product of friction coefficient, slip and local pressure. The simulation results can be used to determine critical application parameters or to explain the damage mechanisms.

100:. Wear debris is bad because it is relatively large compared to the surrounding surface finish and thus creates more regions of high contact stress. Worse, the steel in ordinary bearings can oxidize (

754:

125:

culminated in the ASTM D4170 standard. Although an old method, this is still the leading quality control method for greases that need to avoid the false brinelling damage.

201:

tended to suffer from false brinelling in the "straight ahead" steering position, due to small movements caused by flexing of the fork. Good modern headsets incorporate a

378:

Maruyama, Taisuke; Saitoh, Tsuyoshi; Yokouchi, Atsushi (4 May 2017). "Differences in

Mechanisms for Fretting Wear Reduction between Oil and Grease Lubrication".

551:

Schwack, F.; Prigge, F.; Poll, G. (October 2018). "Finite element simulation and experimental analysis of false brinelling and fretting corrosion".

19:

362:

173:

Although the car-delivery problem has been solved, there are many modern examples. A major maintenance problem are the pitch bearings in

824:

819:

764:

345:

Feng, Chen; Maruyama, Taisuke; Saito, Tsuyoshi (2009). "Oil Film

Behavior under Minute Vibrating Conditions in EHL Point Contacts".

45:, but are caused by a different mechanism. False brinelling may occur in bearings which act under small oscillations or vibrations.

809:

81:. Although these lubricants normally appear liquid (not solid), under high pressure they act as solids and keep the bearing and

850:

814:

93:, causing pieces of each surface to break off or to become pressure-welded then break off when the bearing rolls on.

48:

The basic cause of false brinelling is that the design of the bearing does not have a method for redistribution of

422:

128:

715:"Comparison of Life Calculations for Oscillating Bearings Considering Individual Pitch Control in Wind Turbines"

273:

Pittroff, Hans (1 September 1965). "Fretting

Corrosion Caused by Vibration With Rolling Bearings Stationary".

198:

726:

515:

186:

70:

30:

116:

845:

308:

Schwack, Fabian; Bader, Norbert; Leckner, Johan; Demaille, Claire; Poll, Gerhard (15 August 2020).

622:

Pittroff, Hans (1965). "Fretting

Corrosion Caused by Vibration With Rolling Bearings Stationary".

840:

781:

576:

403:

90:

74:

760:

651:"Service Life of Blade Bearings - Problems Faced in Service Life Estimation of Blade Bearings"

568:

533:

395:

358:

327:

290:

249:"Service Life of Blade Bearings - Problems Faced in Service Life Estimation of Blade Bearings"

223:"Time-dependent analyses of wear in oscillating bearing applications (PDF Download Available)"

508:

Proceedings of the Royal

Society of London A: Mathematical, Physical and Engineering Sciences

734:

631:

560:

523:

484:

387:

350:

317:

282:

793:

739:

714:

205:

to accommodate this flexing, leaving the ball race to provide pure rotational movement.

139:

730:

519:

449:"Another perspective: False brinelling and fretting corrosion (PDF Download Available)"

178:

82:

18:

834:

695:

676:

650:

580:

448:

407:

248:

222:

202:

593:

ASTM D4170, Standard Test Method for

Fretting Wear Protection by Lubricating Greases

603:

Almen, J.O. (1937). "Lubricants and False

Brinelling of Ball and Roller Bearings".

564:

174:

483:. 21st International Conference on Wear of Materials. 376–377, Part B: 1164–1175.

391:

354:

488:

322:

309:

42:

572:

537:

399:

331:

294:

49:

38:

528:

503:

165:

310:"A study of grease lubricants under wind turbine pitch bearing conditions"

73:

has the rollers and races separated by a thin layer of lubricant such as

34:

635:

286:

164:

138:

127:

115:

58:

17:

423:"Fretting Corrosion or False Brinelling | Wear | Surface Science"

825:

US Motors service bulletin case study, explanation, and pictures

190:

132:

Test bearings for ASTM D4170 False

Brinelling fretting wear test

101:

54:

104:), producing a more abrasive compound which accelerates wear.

78:

61:

and form an abrasive compound which further accelerates wear.

169:

Example of an application in which false brinelling may occur

120:

Comparison between simulated frictional work density and wear

677:"Time-depending analyses of wear in oscillating bearings"

696:"Blade bearings: Damage mechanisms and test strategies"

756:

False brinelling standstill marks on roller bearings

815:Precision Spindle explanation of false Brinelling

759:. Technische Informationsbibliothek (TIB). 2011.

349:. Springer, Berlin, Heidelberg. pp. 42–43.

53:occur again. It is possible for the resulting

8:

41:, that causes imprints that look similar to

810:Emerson Bearing picture of false Brinelling

504:"The Rusting of Steel Surfaces in Contact"

738:

527:

321:

213:

69:In normal operation, a rolling-element

789:

779:

96:The broken-off pieces are also called

719:Journal of Physics: Conference Series

143:False Brinelling Fretting wear tester

7:

14:

694:Stammler, Matthias (March 2015).

447:Errichello, Robert (April 2004).

649:Schwack, Fabian; Poll, Gerhard.

502:Tomlinson, G. A. (1 July 1927).

247:Schwack, Fabian; Poll, Gerhard.

740:10.1088/1742-6596/753/11/112013

221:Schwack, Fabian (25 May 2017).

565:10.1016/j.triboint.2018.05.013

108:Simulation of false brinelling

1:

392:10.1080/10402004.2016.1180469

22:False brinelling of a bearing

820:MRO Today on rotating spares

624:Journal of Basic Engineering

355:10.1007/978-3-642-03653-8_16

275:Journal of Basic Engineering

867:

489:10.1016/j.wear.2016.11.037

323:10.1016/j.wear.2020.203335

713:Schwack, Fabian (2016).

675:Schwack, Fabian (2017).

197:Until recently, bicycle

553:Tribology International

453:Lubrication Engineering

605:Mechanical Engineering

529:10.1098/rspa.1927.0104

380:Tribology Transactions

170:

144:

133:

121:

23:

851:Bearings (mechanical)

168:

142:

131:

119:

21:

731:2016JPhCS.753k2013S

520:1927RSPSA.115..472T

316:. 454–455: 203335.

65:Mechanism of action

421:Godfrey, Douglas.

347:Advanced Tribology

171:

145:

134:

122:

37:, with or without

24:

636:10.1115/1.3650657

364:978-3-642-03652-1

287:10.1115/1.3650657

33:damage caused by

858:

798:

797:

791:

787:

785:

777:

775:

773:

751:

745:

744:

742:

710:

704:

703:

691:

685:

684:

672:

666:

665:

663:

661:

646:

640:

639:

619:

613:

612:

600:

594:

591:

585:

584:

548:

542:

541:

531:

514:(771): 472–483.

499:

493:

492:

475:

469:

468:

466:

464:

444:

438:

437:

435:

433:

418:

412:

411:

375:

369:

368:

342:

336:

335:

325:

305:

299:

298:

270:

264:

263:

261:

259:

244:

238:

237:

235:

233:

218:

27:False brinelling

866:

865:

861:

860:

859:

857:

856:

855:

831:

830:

806:

801:

788:

778:

771:

769:

767:

753:

752:

748:

712:

711:

707:

693:

692:

688:

674:

673:

669:

659:

657:

648:

647:

643:

621:

620:

616:

602:

601:

597:

592:

588:

550:

549:

545:

501:

500:

496:

477:

476:

472:

462:

460:

446:

445:

441:

431:

429:

420:

419:

415:

377:

376:

372:

365:

344:

343:

339:

307:

306:

302:

272:

271:

267:

257:

255:

246:

245:

241:

231:

229:

220:

219:

215:

211:

159:

153:

150:

147:

136:

110:

85:from touching.

67:

12:

11:

5:

864:

862:

854:

853:

848:

843:

833:

832:

829:

828:

822:

817:

812:

805:

804:External links

802:

800:

799:

790:|website=

765:

746:

705:

686:

667:

641:

630:(3): 713–723.

614:

595:

586:

543:

494:

470:

439:

413:

386:(3): 497–505.

370:

363:

337:

300:

281:(3): 713–723.

265:

239:

212:

210:

207:

179:remote control

158:

155:

109:

106:

66:

63:

13:

10:

9:

6:

4:

3:

2:

863:

852:

849:

847:

844:

842:

839:

838:

836:

826:

823:

821:

818:

816:

813:

811:

808:

807:

803:

795:

783:

768:

766:9783901657382

762:

758:

757:

750:

747:

741:

736:

732:

728:

724:

720:

716:

709:

706:

701:

697:

690:

687:

682:

678:

671:

668:

656:

652:

645:

642:

637:

633:

629:

625:

618:

615:

611:(6): 415–422.

610:

606:

599:

596:

590:

587:

582:

578:

574:

570:

566:

562:

558:

554:

547:

544:

539:

535:

530:

525:

521:

517:

513:

509:

505:

498:

495:

490:

486:

482:

474:

471:

458:

454:

450:

443:

440:

428:

424:

417:

414:

409:

405:

401:

397:

393:

389:

385:

381:

374:

371:

366:

360:

356:

352:

348:

341:

338:

333:

329:

324:

319:

315:

311:

304:

301:

296:

292:

288:

284:

280:

276:

269:

266:

254:

250:

243:

240:

228:

224:

217:

214:

208:

206:

204:

203:plain bearing

200:

195:

192:

188:

183:

180:

176:

175:wind turbines

167:

163:

156:

154:

151:

148:

141:

137:

130:

126:

118:

114:

107:

105:

103:

99:

94:

92:

86:

84:

80:

76:

72:

64:

62:

60:

56:

51:

46:

44:

40:

36:

32:

28:

20:

16:

770:. Retrieved

755:

749:

722:

718:

708:

699:

689:

680:

670:

658:. Retrieved

655:ResearchGate

654:

644:

627:

623:

617:

608:

604:

598:

589:

556:

552:

546:

511:

507:

497:

480:

473:

461:. Retrieved

456:

452:

442:

430:. Retrieved

426:

416:

383:

379:

373:

346:

340:

313:

303:

278:

274:

268:

256:. Retrieved

253:ResearchGate

252:

242:

230:. Retrieved

227:ResearchGate

226:

216:

196:

184:

172:

160:

152:

149:

146:

135:

123:

111:

97:

95:

87:

68:

47:

26:

25:

15:

725:(753): 11.

559:: 352–362.

98:wear debris

846:Metallurgy

835:Categories

702:: 371–379.

209:References

187:generators

57:debris to

43:brinelling

841:Tribology

792:ignored (

782:cite book

581:139773784

573:0301-679X

538:1364-5021

408:138588351

400:1040-2004

332:0043-1648

295:0098-2202

50:lubricant

39:corrosion

700:CWD 2015

199:headsets

157:Examples

35:fretting

772:27 June

727:Bibcode

683:(72nd).

660:27 June

516:Bibcode

463:27 June

459:: 34–36

432:27 June

258:27 June

232:27 June

71:bearing

59:oxidize

31:bearing

763:

579:

571:

536:

427:Scribd

406:

398:

361:

330:

293:

185:Also,

91:stress

75:grease

827:(PDF)

577:S2CID

404:S2CID

191:pumps

29:is a

794:help

774:2017

761:ISBN

681:STLE

662:2017

569:ISSN

534:ISSN

481:Wear

465:2017

434:2017

396:ISSN

359:ISBN

328:ISSN

314:Wear

291:ISSN

260:2017

234:2017

102:rust

83:race

55:wear

735:doi

723:753

632:doi

561:doi

557:126

524:doi

512:115

485:doi

388:doi

351:doi

318:doi

283:doi

189:or

79:oil

77:or

837::

786::

784:}}

780:{{

733:.

721:.

717:.

698:.

679:.

653:.

628:87

626:.

609:59

607:.

575:.

567:.

555:.

532:.

522:.

510:.

506:.

457:60

455:.

451:.

425:.

402:.

394:.

384:60

382:.

357:.

326:.

312:.

289:.

279:87

277:.

251:.

225:.

796:)

776:.

743:.

737::

729::

664:.

638:.

634::

583:.

563::

540:.

526::

518::

491:.

487::

467:.

436:.

410:.

390::

367:.

353::

334:.

320::

297:.

285::

262:.

236:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.