177:

185:

232:(Ausra) built a linear Fresnel reflector plant in New South Wales, Australia. Initially a 1 MW test in 2005, it was expanded to 5MW in 2006. This reflector plant supplemented the 2,000 MW coal-fired Liddell Power Station. The power generated by the solar thermal steam system is used to provide electricity for the plant's operation, offsetting the plant's internal power usage. AREVA Solar built the 5 MW

310:

245:

4.4 acres). The steam is generated by concentrating sunlight directly onto a linear receiver, which is 7.40 metres (24.28 ft) above the ground. An absorber tube is positioned in the focal line of the mirror field where water is heated into 270 °C (543 K; 518 °F) saturated steam. This steam in turn powers a generator. The commercial success of the PE 1 led

151:

A major challenge that must be addressed in any solar concentrating technology is the changing angle of the incident rays (the rays of sunlight striking the mirrors) as the sun progresses throughout the day. The reflectors of a CLFR are typically aligned in a north-south orientation and turn about a

244:

Biosol constructed a

Fresnel solar power plant known as PE 1. The solar thermal power plant uses a standard linear Fresnel optical design (not CLFR) and has an electrical capacity of 1.4 MW. PE 1 comprises a solar boiler with mirror surface of approximately 18,000 m (1.8 ha;

61:

Linear

Fresnel reflectors use long, thin segments of mirrors to focus sunlight onto a fixed absorber located at a common focal point of the reflectors. This concentrated energy is transferred through the absorber into some thermal fluid (this is typically oil capable of maintaining liquid state at

204:

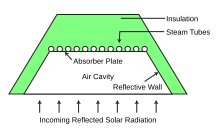

Second, the absorber must be designed so that the temperature distribution across the selective surface is uniform. Non-uniform temperature distribution leads to accelerated degradation of the surface. Typically, a uniform temperature of 300 °C (573 K; 572 °F) is desired. Uniform

236:

in

Bakersfield, California in 2009. This is the first commercial linear Fresnel reflector plant in the United States. The solar collectors were produced at the Ausra factory in Las Vegas. In April 2008, AREVA opened a large factory in Las Vegas, Nevada to produce linear Fresnel reflectors. The

172:

of the mirrors. It runs parallel to and above the reflector segments to transport radiation into some working thermal fluid. The basic design of the absorber for the CLFR system is an inverted air cavity with a glass cover enclosing insulated steam tubes, shown in Fig.2. This design has been

200:

optimizes the ratio of energy absorbed to energy emitted. Acceptable surfaces generally absorb 96% of incident radiation while emitting only 7% through infra-red radiation. Electro-chemically deposited black chrome is generally used for its ample performance and ability to withstand high

127:

The reflectors are located at the base of the system and converge the sun's rays into the absorber. A key component that makes all LFR's more advantageous than traditional parabolic trough mirror systems is the use of "Fresnel reflectors". These reflectors make use of the

209:

As opposed to the traditional LFR, the CLFR makes use of multiple absorbers within the vicinity of its mirrors. These additional absorbers allow the mirrors to alternate their inclination, as illustrated in Fig. 3. This arrangement is advantageous for several reasons.

260:. It uses molten salts as heat transfer fluid in the collector which is directly transferred to a thermal energy storage. A salt temperature of up to 550 °C (823 K; 1,022 °F) facilitates the running of a conventional steam turbine for

290:

design for a small, manually operated, 12 kW peak

Fresnel concentrator that generates temperatures up to 750 °C (1,020 K; 1,380 °F) and can be used for various thermal applications including steam powered electricity generation.

297:

In China, a 50 MW commercial scale

Fresnel project using molten salt as its heat transfer medium has been under construction since 2016. After grid connection in 2019 it now seems to operate successfully as of 2021.

54:, in which many small, thin lens fragments are combined to simulate a much thicker simple lens. These mirrors are capable of concentrating the sun's energy to approximately 30 times its normal

205:

distributions are obtained by changing absorber parameters such as the thickness of insulation above the plate, the size of the aperture of the absorber and the shape and depth of the air cavity.

691:

752:

Purohit, I. Purohit, P. 2017. Technical and economic potential of concentrating solar thermal power generation in India. Renewable and

Sustainable Energy Reviews, 78, pp. 648–667,

220:

Finally, having the panels in close proximity reduces the length of absorber lines, which reduces both thermal losses through the absorber lines and overall cost for the system.

86:. Francia demonstrated that such a system could create elevated temperatures capable of making a fluid do work. The technology was further investigated by companies such as the

188:

Fig.3: CLFR solar systems alternate the inclination of their mirrors to focus solar energy on multiple absorbers, improving system efficiency and reducing overall cost.

214:

First, alternating inclinations minimize the effect of reflectors blocking adjacent reflectors' access to sunlight, thereby improving the system's efficiency.

98:

in 1993 and patented in 1995. In 1999, the CLFR design was enhanced by the introduction of the advanced absorber. In 2003 the concept was extended to

217:

Second, multiple absorbers minimize the amount of ground space required for installation. This in turn reduces cost to procure and prepare the land.

196:

First, heat transfer between the absorber and the thermal fluid must be maximized. This relies on the surface of the steam tubes being selective. A

701:

233:

103:

343:

140:

while simultaneously reducing the volume of material required for the reflector. This greatly reduces the system's cost since sagged-glass

272:. A molten salt demonstration plant was realized on PE 1 to proof the technology. Since 2015 FRENELL GmbH, a management buy-out of

507:

478:

769:

CSTA, 2021, 50 MW molten salt

Fresnel CSP plant reached the highest single day generation, Beijing, China Solar Thermal Association,

114:, placing them at a varying height (on a wave-shape curve) and combining the resulting primary with nonimaging secondaries.

294:

The largest CSP systems using

Compact linear Fresnel reflector technology is the 125 MW Reliance Areva CSP plant in India.

787:

677:"Novatec Solar und BASF nehmen solarthermische Demonstrations-anlage mit neuartiger Flüssigsalz-Technologie in Betrieb"

157:

676:

249:

to design a 30 MW solar power plant known as PE 2. PE 2 has been in commercial operation since 2012.

237:

factory was planned to be capable of producing enough solar collectors to provide 200 MW of power per month.

723:

323:

646:

176:

67:

315:

99:

70:. As opposed to traditional LFR's, the CLFR utilizes multiple absorbers within the vicinity of the mirrors.

280:

261:

528:

Mills, D.R.; Morrison, Graham L. (2000). "Compact linear

Fresnel reflector solar thermal power plants".

265:

94:, but remained relatively untouched until the early 1990s. In 1993, the first CLFR was developed at the

537:

424:

384:

338:

333:

95:

632:

110:

to explore different degrees of freedom in the system such as varying the size and curvature of the

141:

83:

55:

180:

Fig.2: Incident solar rays are concentrated on insulated steam tubes to heat working thermal fluid

696:

192:

For optimum performance of the CLFR, several design factors of the absorber must be optimized.

184:

474:

197:

107:

753:

545:

432:

392:

580:

Jahanshahi, M. (August 2008). "Liddell thermal power station – greening coal-fired power".

91:

87:

541:

428:

388:

173:

demonstrated to be simple and cost effective with good optical and thermal performance.

169:

145:

102:

geometry. Research published in 2010 showed that higher concentrations and / or higher

63:

549:

436:

781:

273:

253:

246:

241:

153:

770:

328:

269:

137:

129:

51:

598:

511:

396:

563:

464:

17:

309:

287:

229:

79:

757:

305:

27:

Type of linear

Fresnel reflector, named for their similarity to a Fresnel lens

470:

160:

between the sun's rays and the mirrors, thereby optimizing energy transfer.

111:

276:

took over the commercial development of the direct molten salt technology.

731:

375:

Dey, C.J. (2004). "Heat transfer aspect of an elevated linear absorber".

133:

415:

Mills, D.R. (2004). "Advances in solar thermal electricity technology".

654:

612:

Schlesinger, V. (July 2008). "Solar Thermal Power Just Got Hotter".

183:

175:

144:

are typically very expensive. However, in recent years thin-film

82:

system was developed in Italy in 1961 by Giovanni Francia of the

257:

495:

Etendue-matched two-stage concentrators with multiple receivers

512:"Solar Energy Technologies Program: Concentrating Solar Power"

283:

132:

effect, which allows for a concentrating mirror with a large

148:

has significantly reduced the cost of parabolic mirrors.

62:

very high temperatures). The fluid then goes through a

50:) technology. They are named for their similarity to a

156:

system. This allows the system to maintain the proper

692:"'Solar fire' to quench energy thirst at grassroots"

256:developed a molten salt system in cooperation with

466:Introduction to Nonimaging Optics, Second Edition

771:http://en.cnste.org/html/csp/2021/0603/1087.html

633:"World First in Solar Power Plant Technology"

8:

627:

625:

623:

493:Julio Chaves and Manuel Collares-Pereira,

593:

591:

152:single axis using a computer controlled

410:

408:

406:

354:

564:"SolMax, Solar Selective Surface Foil"

40:concentrating linear Fresnel reflector

724:"Solar Fire P32 - Solar Fire Project"

449:Philipp Schramek and David R. Mills,

370:

368:

366:

364:

362:

360:

358:

234:Kimberlina Solar Thermal Energy Plant

7:

497:, Solar Energy 84, pp. 196-207, 2010

453:, Solar Energy 75, pp. 249-260, 2003

344:List of solar thermal power stations

78:The first linear Fresnel reflector

508:United States Department of Energy

240:In March 2009, the German company

25:

690:Parmar, Vijaysinh (Feb 5, 2011).

653:. 27 October 2011. Archived from

308:

32:compact linear Fresnel reflector

168:The absorber is located at the

1:

550:10.1016/S0038-092X(99)00068-7

437:10.1016/S0038-092X(03)00102-6

397:10.1016/j.solener.2003.08.030

286:in India, has developed an

106:could be obtained by using

804:

758:10.1016/j.rser.2017.04.059

38:) – also referred to as a

324:Concentrating solar power

44:linear Fresnel reflector

42:– is a specific type of

451:Multi-tower solar array

316:Renewable energy portal

730:. 2011. Archived from

463:Chaves, Julio (2015).

281:appropriate technology

262:Electricity generation

189:

181:

651:www.puertoerrado2.com

266:Enhanced oil recovery

187:

179:

788:Solar thermal energy

339:Solar thermal energy

334:Solar power in Italy

142:parabolic reflectors

96:University of Sydney

704:on November 5, 2012

542:2000SoEn...68..263M

429:2004SoEn...76...19M

389:2004SoEn...76..243D

84:University of Genoa

697:The Times of India

599:"Ausra Technology"

190:

182:

158:angle of incidence

734:on April 30, 2011

198:selective surface

108:nonimaging optics

104:acceptance angles

18:Fresnel reflector

16:(Redirected from

795:

773:

767:

761:

750:

744:

743:

741:

739:

720:

714:

713:

711:

709:

700:. Archived from

687:

681:

680:

673:

667:

666:

664:

662:

643:

637:

636:

629:

618:

617:

609:

603:

602:

595:

586:

585:

577:

571:

570:

568:

560:

554:

553:

525:

519:

518:

516:

504:

498:

491:

485:

484:

460:

454:

447:

441:

440:

412:

401:

400:

383:(1–3): 243–249.

372:

318:

313:

312:

21:

803:

802:

798:

797:

796:

794:

793:

792:

778:

777:

776:

768:

764:

751:

747:

737:

735:

722:

721:

717:

707:

705:

689:

688:

684:

675:

674:

670:

660:

658:

657:on 6 April 2016

645:

644:

640:

631:

630:

621:

614:Plenty Magazine

611:

610:

606:

597:

596:

589:

579:

578:

574:

566:

562:

561:

557:

527:

526:

522:

514:

506:

505:

501:

492:

488:

481:

462:

461:

457:

448:

444:

414:

413:

404:

374:

373:

356:

352:

314:

307:

304:

279:Solar Fire, an

227:

166:

125:

120:

92:1973 oil crisis

88:FMC Corporation

76:

68:steam generator

28:

23:

22:

15:

12:

11:

5:

801:

799:

791:

790:

780:

779:

775:

774:

762:

745:

715:

682:

668:

638:

619:

604:

587:

572:

555:

536:(3): 263–283.

520:

499:

486:

480:978-1482206739

479:

455:

442:

423:(1–3): 19–31.

402:

353:

351:

348:

347:

346:

341:

336:

331:

326:

320:

319:

303:

300:

226:

223:

222:

221:

218:

215:

207:

206:

202:

165:

162:

146:nanotechnology

124:

121:

119:

116:

75:

72:

64:heat exchanger

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

800:

789:

786:

785:

783:

772:

766:

763:

759:

755:

749:

746:

733:

729:

728:solarfire.org

725:

719:

716:

703:

699:

698:

693:

686:

683:

678:

672:

669:

656:

652:

648:

642:

639:

634:

628:

626:

624:

620:

615:

608:

605:

600:

594:

592:

588:

583:

582:Ecogeneration

576:

573:

565:

559:

556:

551:

547:

543:

539:

535:

531:

524:

521:

513:

509:

503:

500:

496:

490:

487:

482:

476:

472:

468:

467:

459:

456:

452:

446:

443:

438:

434:

430:

426:

422:

418:

411:

409:

407:

403:

398:

394:

390:

386:

382:

378:

371:

369:

367:

365:

363:

361:

359:

355:

349:

345:

342:

340:

337:

335:

332:

330:

327:

325:

322:

321:

317:

311:

306:

301:

299:

295:

292:

289:

285:

282:

277:

275:

274:Novatec Solar

271:

267:

263:

259:

255:

254:Novatec Solar

252:From 2013 on

250:

248:

247:Novatec Solar

243:

238:

235:

231:

224:

219:

216:

213:

212:

211:

203:

201:temperatures.

199:

195:

194:

193:

186:

178:

174:

171:

163:

161:

159:

155:

154:solar tracker

149:

147:

143:

139:

135:

131:

122:

117:

115:

113:

109:

105:

101:

97:

93:

89:

85:

81:

73:

71:

69:

65:

59:

57:

53:

49:

45:

41:

37:

33:

19:

765:

748:

736:. Retrieved

732:the original

727:

718:

706:. Retrieved

702:the original

695:

685:

671:

659:. Retrieved

655:the original

650:

641:

613:

607:

581:

575:

558:

533:

530:Solar Energy

529:

523:

502:

494:

489:

465:

458:

450:

445:

420:

417:Solar Energy

416:

380:

377:Solar Energy

376:

329:Solar energy

296:

293:

278:

270:Desalination

251:

239:

228:

225:Applications

208:

191:

167:

150:

138:focal length

130:Fresnel lens

126:

77:

60:

52:Fresnel lens

47:

43:

39:

35:

31:

29:

288:open source

230:Areva Solar

90:during the

80:solar power

66:to power a

350:References

170:focal line

136:and short

123:Reflectors

112:heliostats

471:CRC Press

164:Absorbers

56:intensity

782:Category

661:19 April

510:(2009).

302:See also

134:aperture

738:May 15,

708:May 15,

538:Bibcode

425:Bibcode

385:Bibcode

242:Novatec

74:History

647:"Home"

477:

118:Design

567:(PDF)

515:(PDF)

740:2011

710:2011

663:2016

475:ISBN

258:BASF

36:CLFR

754:doi

546:doi

433:doi

393:doi

284:NGO

268:or

48:LFR

784::

726:.

694:.

649:.

622:^

590:^

544:.

534:68

532:.

473:.

469:.

431:.

421:76

419:.

405:^

391:.

381:76

379:.

357:^

264:,

100:3D

58:.

30:A

760:.

756::

742:.

712:.

679:.

665:.

635:.

616:.

601:.

584:.

569:.

552:.

548::

540::

517:.

483:.

439:.

435::

427::

399:.

395::

387::

46:(

34:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.