157:

149:

141:

133:

36:

429:

A hot-dip galvanized coating is relatively easier and cheaper to specify than an organic paint coating of equivalent corrosion protection performance. The

British, European and International standard for hot-dip galvanizing is BS EN ISO 1461, which specifies a minimum coating thickness to be applied

251:

Like other corrosion protection systems, galvanizing protects steel by acting as a barrier between steel and the atmosphere. However, zinc is a more electropositive (active) metal in comparison to steel. This is a unique characteristic for galvanizing, which means that when a galvanized coating is

356:

In some cases, it may be desirable to have designates parts of the metal as non-galvanized. This is often desired when metal will be welded after galvanization. To accomplish this, a galvanizer will typically use a masing compound to coat the areas that will not be galvanized during the hot dip

325:

easier and protect the kettle from uneven heat distribution from the burners. Environmental regulations in the United States disapprove of lead in the kettle bath. Lead is either added to primary Z1 grade zinc or already contained in used secondary zinc. A third, declining method is to use low Z5

437:

Further performance and design information for galvanizing can be found in BS EN ISO 14713-1 and BS EN ISO 14713-2. The durability performance of a galvanized coating depends solely on the corrosion rate of the environment in which it is placed. Corrosion rates for different environments can be

235:

Galvanized steel can be welded; however, one must exercise caution around the resulting toxic zinc fumes. Galvanized fumes are released when the galvanized metal reaches a certain temperature. This temperature varies by the galvanization process used. In long-term, continuous exposure, the

329:

Steel strip can be hot-dip galvanized in a continuous line. Hot-dip galvanized steel strip (also sometimes loosely referred to as galvanized iron) is extensively used for applications requiring the strength of steel combined with the resistance to corrosion of zinc, such as

236:

recommended maximum temperature for hot-dip galvanized steel is 200 °C (392 °F), according to the

American Galvanizers Association. The use of galvanized steel at temperatures above this will result in peeling of the zinc at the

247:

is often used in automotive manufacturing to enhance the corrosion performance of exterior body panels; this is, however, a completely different process which tends to achieve lower coating thicknesses of zinc.

264:

The process of hot-dip galvanizing results in a metallurgical bond between zinc and steel, with a series of distinct iron-zinc alloys. The resulting coated steel can be used in much the same way as uncoated.

304:

is applied to the steel to inhibit oxidation of the cleaned surface upon exposure to air. The flux is allowed to dry on the steel and aids in the process of the liquid zinc wetting and adhering to the steel.

430:

to steel in relation to the steels section thickness e.g. a steel fabrication with a section size thicker than 6 mm shall have a minimum galvanized coating thickness of 85

317:

is often added to the molten zinc bath to improve the fluidity of the bath (thus limiting excess zinc on the dipped product by improved drainage properties), help prevent floating

345:

gates, can be hot-dip galvanized by a process called batch galvanizing. Other modern techniques have largely replaced hot-dip for these sorts of roles. This includes

187:

in a bath of molten zinc at a temperature of around 450 °C (842 °F). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (

556:

438:

found in BS EN ISO 14713-1, where typical corrosion rates are given, along with a description of the environment in which the steel would be used.

310:

The steel is cooled in a quench tank to reduce its temperature and inhibit undesirable reactions of the newly formed coating with the atmosphere.

53:

380:, for whom galvanizing was named, discovered the electrochemical process that takes place between metals during an experiment with frog legs.

156:

119:

100:

307:

The steel is dipped into the molten zinc bath and held there until the temperature of the steel equilibrates with that of the bath.

72:

524:

387:

furthered the research on galvanizing when he discovered the electro-potential between two metals, creating a corrosion cell.

580:

79:

57:

600:

581:

European

Commission, Reference Document on Best Available Techniques in the Non Ferrous Metals Industries, December 2001

86:

478:

462:

457:

331:

68:

46:

560:

301:

334:, safety barriers, handrails, consumer appliances and automotive body parts. One common use is in metal

148:

447:

366:

241:

221:

93:

140:

253:

132:

212:), a usually dull grey, fairly strong material that protects the steel underneath from further

605:

498:

493:

414:

410:

297:

503:

488:

483:

384:

283:

252:

damaged and steel is exposed to the atmosphere, zinc can continue to protect steel through

391:

229:

228:, and is considered superior in terms of cost and life-cycle. It can be identified by the

225:

160:

Steel strip coming out of the zinc pot of a continuous vertical hot-dip galvanizing line

473:

350:

338:. Galvanised steel is also used in most heating and cooling duct systems in buildings

256:(often within an annulus of 5 mm, above which electron transfer rate decreases).

610:

594:

399:

377:

168:

152:

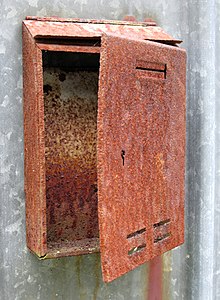

Protective effect: completely rusted letter box mounted to a hot-dip galvanized wall

531:

467:

342:

17:

244:

206:

35:

431:

287:

273:

322:

213:

144:

Crystalline surface of a hot-dip galvanized handrail, known as "spangle"

452:

335:

188:

183:, which alloys with the surface of the base metal when immersing the

349:, which deposits the layer of zinc from an aqueous electrolyte by

318:

184:

176:

155:

147:

139:

131:

395:

370:

314:

180:

172:

525:"GalvInfoNote / The Spangle on Hot-Dip Galvanized Steel Sheet"

199:

195:

29:

369:

described a method of coating iron by dipping it in molten

268:

A typical hot-dip galvanizing line operates as follows:

232:

patterning on the surface (often called a "spangle").

394:

obtained a patent for a method of coating iron with

341:

Individual metal articles, such as steel girders or

276:

solution. This removes oil/grease, dirt, and paint.

60:. Unsourced material may be challenged and removed.

398:, after first cleaning it with 9% sulfuric acid (

27:Process of coating iron or steel with molten zinc

373:in a presentation to the French Royal Academy.

198:), which further reacts with carbon dioxide (

8:

559:. V&S Hot Dip Galvanzing. Archived from

353:, forming a thinner and much stronger bond.

279:The caustic cleaning solution is rinsed off.

120:Learn how and when to remove this message

515:

220:is widely used in applications where

7:

293:The pickling solution is rinsed off.

58:adding citations to reliable sources

584:Primary zinc grade table on page 15

25:

557:"The Hot-Dip Galvanizing Process"

286:in an acidic solution to remove

34:

171:. It is the process of coating

45:needs additional citations for

224:is needed without the cost of

1:

470:– galvanization and annealing

413:it with ammonium chloride (

627:

530:. GalvInfo. Archived from

479:Liquid metal embrittlement

463:Corrugated galvanised iron

458:Bolt manufacturing process

205:) to form zinc carbonate (

272:Steel is cleaned using a

523:GalvInfo (August 2011).

390:In 1836, French chemist

365:In 1742, French chemist

216:in many circumstances.

69:"Hot-dip galvanization"

302:zinc ammonium chloride

194:) to form zinc oxide (

161:

153:

145:

137:

165:Hot-dip galvanization

159:

151:

143:

135:

601:Corrosion prevention

448:Electrogalvanization

367:Paul Jacques Malouin

222:corrosion resistance

136:Galvanised hand rail

54:improve this article

332:roofing and walling

18:Hot-dip galvanizing

347:electrogalvanizing

254:galvanic corrosion

162:

154:

146:

138:

499:Surface finishing

494:Sendzimir process

242:Electrogalvanized

130:

129:

122:

104:

16:(Redirected from

618:

585:

578:

572:

571:

569:

568:

553:

547:

546:

544:

542:

536:

529:

520:

504:Thermal spraying

489:Prepainted metal

484:Metal fume fever

385:Alessandro Volta

218:Galvanized steel

125:

118:

114:

111:

105:

103:

62:

38:

30:

21:

626:

625:

621:

620:

619:

617:

616:

615:

591:

590:

589:

588:

583:

579:

575:

566:

564:

555:

554:

550:

540:

538:

537:on 2 March 2014

534:

527:

522:

521:

517:

512:

444:

427:

418:

407:

403:

392:Stanislas Sorel

363:

262:

230:crystallization

226:stainless steel

210:

203:

192:

126:

115:

109:

106:

63:

61:

51:

39:

28:

23:

22:

15:

12:

11:

5:

624:

622:

614:

613:

608:

603:

593:

592:

587:

586:

573:

548:

514:

513:

511:

508:

507:

506:

501:

496:

491:

486:

481:

476:

471:

465:

460:

455:

450:

443:

440:

426:

423:

416:

405:

401:

362:

359:

351:electroplating

312:

311:

308:

305:

294:

291:

280:

277:

261:

258:

238:inter-metallic

208:

201:

190:

128:

127:

42:

40:

33:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

623:

612:

609:

607:

604:

602:

599:

598:

596:

582:

577:

574:

563:on 2013-06-23

562:

558:

552:

549:

533:

526:

519:

516:

509:

505:

502:

500:

497:

495:

492:

490:

487:

485:

482:

480:

477:

475:

472:

469:

466:

464:

461:

459:

456:

454:

451:

449:

446:

445:

441:

439:

435:

433:

425:Specification

424:

422:

420:

412:

408:

397:

393:

388:

386:

381:

379:

378:Luigi Galvani

374:

372:

368:

360:

358:

354:

352:

348:

344:

339:

337:

333:

327:

324:

321:, make dross

320:

316:

309:

306:

303:

299:

295:

292:

289:

285:

282:The steel is

281:

278:

275:

271:

270:

269:

266:

259:

257:

255:

249:

246:

243:

239:

233:

231:

227:

223:

219:

215:

211:

204:

197:

193:

186:

182:

178:

174:

170:

169:galvanization

167:is a form of

166:

158:

150:

142:

134:

124:

121:

113:

110:November 2013

102:

99:

95:

92:

88:

85:

81:

78:

74:

71: –

70:

66:

65:Find sources:

59:

55:

49:

48:

43:This article

41:

37:

32:

31:

19:

576:

565:. Retrieved

561:the original

551:

539:. Retrieved

532:the original

518:

468:Galvannealed

436:

428:

389:

382:

375:

364:

355:

346:

343:wrought iron

340:

328:

326:grade zinc.

313:

267:

263:

250:

237:

234:

217:

164:

163:

116:

107:

97:

90:

83:

76:

64:

52:Please help

47:verification

44:

541:27 February

357:process.

245:sheet steel

595:Categories

567:2012-11-30

510:References

288:mill scale

80:newspapers

474:Jewelling

383:In 1801,

376:In 1772,

323:recycling

214:corrosion

606:Coatings

442:See also

300:, often

453:Plating

411:fluxing

361:History

284:pickled

274:caustic

260:Process

240:layer.

94:scholar

409:) and

96:

89:

82:

75:

67:

535:(PDF)

528:(PDF)

336:pails

319:dross

185:metal

179:with

177:steel

101:JSTOR

87:books

611:Zinc

543:2014

396:zinc

371:zinc

315:Lead

298:flux

207:ZnCO

181:zinc

175:and

173:iron

73:news

421:).

196:ZnO

56:by

597::

434:.

432:μm

419:Cl

415:NH

404:SO

296:A

200:CO

570:.

545:.

417:4

406:4

402:2

400:H

290:.

209:3

202:2

191:2

189:O

123:)

117:(

112:)

108:(

98:·

91:·

84:·

77:·

50:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.