144:

249:, which are adjusted during end testing until the desired function of the circuit is reached. In many applications, the end user of the product would prefer not to have potentiometers, as they can drift, be mis-adjusted or develop noise. Therefore, manufacturers determine the needed resistance or capacitance values by measurement and calculation methods and afterwards solder the suitable component into the final PCB; this approach is called "Select on Test" (SOT) and is quite labor-intensive.

25:

198:

163:

The resistance value of a film resistor is defined by its geometric dimensions (length, width, height) and the resistor material. A lateral cut in the resistor material by the laser narrows or lengthens the current flow path and increases the resistance value. The same effect is obtained whether the

193:

boards are contacted by test probes on the assembly side and trimmed with a laser beam from the resistor side. This trimming method requires no contact points between the resistances, because the fine pitch adapter contacts the component on the opposite side of where the trimming occurs. Therefore,

260:

chip resistor or chip capacitor, and the potentiometer adjusting screwdriver is replaced by the laser trimming. The achieved accuracy can be higher, the procedure can be automated, and the long-term stability is better than with potentiometers and at least as good as with SOT components. Often the

284:

but only requires four banks for full operation. During testing, each cache bank is exercised. If a defect is found in one bank, that bank can be disabled by blowing its programming fuse. This built-in redundancy allows higher chip

147:

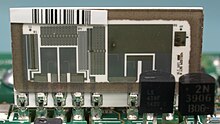

Laser-trimmed precision thin-film resistor network from Fluke, used in the

Keithley DMM7510 multimeter. Ceramic backed with glass hermetic seal cover. Laser trim marks are visible in the grey resistive

181:. During the trim process, the corresponding parameter is measured continuously and compared to the programmed nominal value. The laser stops automatically when the value reaches the nominal value.

171:

Trimmable chip capacitors are built up as multilayer plate capacitors. Vaporizing part of the top layer with a laser decreases the capacitance by reducing the area of the top electrode.

177:

is the adjustment of a resistor to a given value. If the trimming adjusts the whole circuit output such as output voltage, frequency, or switching threshold, this is called

289:

than would be possible if all cache banks had to be perfect in every chip. If no bank is defective, a fuse can be blown arbitrarily, leaving just four banks.

301:

217:

From the top side the chamber is pressurized to 1 to 4 bars, with a controlled exhaust port to achieve air flow through the chamber.

116:

190:

46:

97:

50:

143:

69:

286:

197:

76:

35:

54:

39:

83:

165:

157:

156:, raising their resistance value. The burning operation can be conducted while the circuit is being tested by

168:

resistor. The surface-mount resistor is produced with the same technology and may be laser trimmed as well.

65:

189:

One type of passive trimmer uses a pressure chamber to enable resistor trimming in a single run. The

230:

Trimming of unlimited number of printed resistors in one step without obstruction from test probes.

261:

laser for active trimming can be integrated in existing measurement systems by the manufacturer.

137:

273:

are blown by the laser, enabling or disabling various logic circuits. An example of this is the

270:

90:

220:

As the resistance material is vaporized, the waste particles are removed in the air flow.

295:

246:

281:

269:

A similar approach can be used to program digital logic circuits. In this case,

164:

laser changes a thick-film or a thin-film resistor on a ceramic substrate or an

152:

One of the most common applications uses a laser to burn away small portions of

24:

153:

160:, leading to optimum final values for the resistor(s) in the circuit.

277:

142:

133:

274:

194:

the LTCC can be arranged more compactly and less expensively.

18:

214:

From the opposite side a rigid probe contacts the circuit.

280:

microprocessor where the chip contains five banks of

201:High speed R-Laser Trimmer with a pressure chamber

233:No contamination on board, adapter or in system.

185:Trimming LTCC resistances in a pressure chamber

8:

53:. Unsourced material may be challenged and

136:to adjust the operating parameters of an

117:Learn how and when to remove this message

211:The LTCC is mounted in the contact unit.

196:

132:is the manufacturing process of using a

16:Electronic circuit manufacturing method

7:

51:adding citations to reliable sources

265:Program from digital logic circuits

14:

302:Semiconductor device fabrication

252:It is simpler to substitute the

23:

1:

236:Density up to 280 points/cm².

318:

225:Advantages of this method:

158:automatic test equipment

256:or the SOT part with a

241:Trimming potentiometers

202:

149:

200:

146:

245:Often designers use

47:improve this article

203:

150:

138:electronic circuit

127:

126:

119:

101:

309:

122:

115:

111:

108:

102:

100:

66:"Laser trimming"

59:

27:

19:

317:

316:

312:

311:

310:

308:

307:

306:

292:

291:

267:

243:

187:

123:

112:

106:

103:

60:

58:

44:

28:

17:

12:

11:

5:

315:

313:

305:

304:

294:

293:

266:

263:

247:potentiometers

242:

239:

238:

237:

234:

231:

222:

221:

218:

215:

212:

206:Function mode:

186:

183:

130:Laser trimming

125:

124:

31:

29:

22:

15:

13:

10:

9:

6:

4:

3:

2:

314:

303:

300:

299:

297:

290:

288:

283:

279:

276:

272:

264:

262:

259:

255:

254:potentiometer

250:

248:

240:

235:

232:

229:

228:

227:

226:

219:

216:

213:

210:

209:

208:

207:

199:

195:

192:

184:

182:

180:

176:

172:

169:

167:

166:surface-mount

161:

159:

155:

145:

141:

139:

135:

131:

121:

118:

110:

99:

96:

92:

89:

85:

82:

78:

75:

71:

68: –

67:

63:

62:Find sources:

56:

52:

48:

42:

41:

37:

32:This article

30:

26:

21:

20:

282:cache memory

268:

257:

253:

251:

244:

224:

223:

205:

204:

188:

178:

175:Passive trim

174:

173:

170:

162:

151:

129:

128:

113:

104:

94:

87:

80:

73:

61:

45:Please help

33:

179:active trim

77:newspapers

258:trimmable

154:resistors

148:material.

107:June 2015

34:does not

296:Category

91:scholar

55:removed

40:sources

287:yields

278:POWER4

93:

86:

79:

72:

64:

271:fuses

134:laser

98:JSTOR

84:books

191:LTCC

70:news

38:any

36:cite

275:IBM

49:by

298::

140:.

120:)

114:(

109:)

105:(

95:·

88:·

81:·

74:·

57:.

43:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.