605:

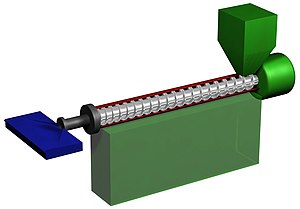

while the other spins counter clockwise. It has been shown that, for a given cross sectional area and degree of overlap (intermeshing), axial velocity and degree of mixing is higher in co-rotating twin extruders. However, pressure buildup is higher in counter-rotating extruders. The screw design is commonly modular in that various conveying and mixing elements are arranged on the shafts to allow for rapid reconfiguration for a process change or replacement of individual components due to wear or corrosive damage. The machine sizes range from as small as 12 mm to as large as 380mm

531:

563:

292:, plastic conducts its heat away 2,000 times more slowly. In a tube or pipe extrusion line, a sealed water bath is acted upon by a carefully controlled vacuum to keep the newly formed and still molten tube or pipe from collapsing. For products such as plastic sheeting, the cooling is achieved by pulling through a set of cooling rolls. For films and very thin sheeting, air cooling can be effective as an initial cooling stage, as in blown film extrusion.

376:

124:

313:

479:. If the film is drawn more than it is blown (the final tube diameter is close to the extruded diameter) the polymer molecules will be highly aligned with the draw direction, making a film that is strong in that direction, but weak in the transverse direction. A film that has significantly larger diameter than the extruded diameter will have more strength in the transverse direction, but less in the draw direction.

2529:

25:

255:

193:

527:, such as PVC pipes, is manufactured using very similar dies as used in blown film extrusion. Positive pressure can be applied to the internal cavities through the pin, or negative pressure can be applied to the outside diameter using a vacuum sizer to ensure correct final dimensions. Additional lumens or holes may be introduced by adding the appropriate inner mandrels to the die.

448:

471:

exiting the die; this can result in uneven flow. Spider dies consist of a central mandrel attached to the outer die ring via a number of "legs"; while flow is more symmetrical than in annular dies, a number of weld lines are produced which weaken the film. Spiral dies remove the issue of weld lines and asymmetrical flow, but are by far the most complex.

321:

549:

There are two different types of die tooling used for coating over a wire, tubing (or jacketing) and pressure. In jacketing tooling, the polymer melt does not touch the inner wire until immediately before the die lips. In pressure tooling, the melt contacts the inner wire long before it reaches the

183:

This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into

596:

traditional extrusion, there is a wide range in machine sizes depending on application and desired throughput. While either single- or double-screw extruders may be used in traditional extrusion, the necessity of adequate mixing in compounding extrusion makes twin-screw extruders all but mandatory.

582:

is using a blown or cast film process to coat an additional layer onto an existing rollstock of paper, foil or film. For example, this process can be used to improve the characteristics of paper by coating it with polyethylene to make it more resistant to water. The extruded layer can also be used

498:

that are too thick to be blown. There are two types of dies used: T-shaped and coat hanger. The purpose of these dies is to reorient and guide the flow of polymer melt from a single round output from the extruder to a thin, flat planar flow. In both die types ensure constant, uniform flow across

250:

Extra heat is contributed by the intense pressure and friction taking place inside the barrel. In fact, if an extrusion line is running certain materials fast enough, the heaters can be shut off and the melt temperature maintained by pressure and friction alone inside the barrel. In most extruders,

604:

There are two sub-types of twin screw extruders: co-rotating and counter-rotating. This nomenclature refers to the relative direction each screw spins compared to the other. In co-rotation mode, both screws spin either clockwise or counter clockwise; in counter-rotation, one screw spins clockwise

558:

Coextrusion is the extrusion of multiple layers of material simultaneously. This type of extrusion utilizes two or more extruders to melt and deliver a steady volumetric throughput of different viscous plastics to a single extrusion head (die) which will extrude the materials in the desired form.

474:

The melt is cooled somewhat before leaving the die to yield a weak semi-solid tube. This tube's diameter is rapidly expanded via air pressure, and the tube is drawn upwards with rollers, stretching the plastic in both the transverse and draw directions. The drawing and blowing cause the film to be

279:

in the barrel. Back pressure is required for uniform melting and proper mixing of the polymer, and how much pressure is generated can be "tweaked" by varying screen pack composition (the number of screens, their wire weave size, and other parameters). This breaker plate and screen pack combination

595:

Compounding extrusion is a process that mixes one or more polymers with additives to give plastic compounds. The feeds may be pellets, powder and/or liquids, but the product is usually in pellet form, to be used in other plastic-forming processes such as extrusion and injection molding. As with

355:

Often screw length is referenced to its diameter as L:D ratio. For instance, a 6-inch-diameter (150 mm) screw at 24:1 will be 144 inches (12 ft) long, and at 32:1 it is 192 inches (16 ft) long. An L:D ratio of 25:1 is common, but some machines go up to 40:1 for more mixing and more

283:

After passing through the breaker plate, molten plastic enters the die. The die is what gives the final product its profile and must be designed so that the molten plastic evenly flows from a cylindrical profile, to the product's profile shape. Uneven flow at this stage can produce a product with

503:

or "chill" rolls). In sheet extrusion, these rolls not only deliver the necessary cooling but also determine sheet thickness and surface texture. Often co-extrusion is used to apply one or more layers on top of a base material to obtain specific properties such as UV-absorption, texture, oxygen

570:

In many real-world scenarios, a single polymer cannot meet all the demands of an application. Compound extrusion allows a blended material to be extruded, but coextrusion retains the separate materials as different layers in the extruded product, allowing appropriate placement of materials with

470:

This process is the same as a regular extrusion process up until the die. There are three main types of dies used in this process: annular (or crosshead), spider, and spiral. Annular dies are the simplest, and rely on the polymer melt channeling around the entire cross section of the die before

238:

The material enters through the feed throat (an opening near the rear of the barrel) and comes into contact with the screw. The rotating screw (normally turning at e.g. 120 rpm) forces the plastic beads forward into the heated barrel. The desired extrusion temperature is rarely equal to the set

613:

A great advantage of extrusion is that profiles such as pipes can be made to any length. If the material is sufficiently flexible, pipes can be made at long lengths even coiling on a reel. Another advantage is the extrusion of pipes with integrated coupler including rubber seal.

132:

243:-controlled heater zones gradually increase the temperature of the barrel from the rear (where the plastic enters) to the front. This allows the plastic beads to melt gradually as they are pushed through the barrel and lowers the risk of overheating which may cause

550:

die lips; this is done at a high pressure to ensure good adhesion of the melt. If intimate contact or adhesion is required between the new layer and existing wire, pressure tooling is used. If adhesion is not desired/necessary, jacketing tooling is used instead.

308:

There are five possible zones in a thermoplastic screw. Since terminology is not standardized in the industry, different names may refer to these zones. Different types of polymer will have differing screw designs, some not incorporating all of the possible zones.

200:

The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas

Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into

266:

plastic leaves the screw and travels through a screen pack to remove any contaminants in the melt. The screens are reinforced by a breaker plate (a thick metal puck with many holes drilled through it) since the pressure at this point can exceed 5,000

141:

434:

There are a variety of dies used in plastics extrusion. While there can be significant differences between die types and complexity, all dies allow for the continuous extrusion of polymer melt, as opposed to non-continuous processing such as

559:

This technology is used on any of the processes described above (blown film, overjacketing, tubing, sheet). The layer thicknesses are controlled by the relative speeds and sizes of the individual extruders delivering the materials.

225:

into the barrel of the extruder. Additives such as colorants and UV inhibitors (in either liquid or pellet form) are often used and can be mixed into the resin prior to arriving at the hopper. The process has much in common with

515:. Orientation (i.e. ability/ available density of the sheet to be drawn to the mold which can vary in depths from 1 to 36 inches typically) is highly important and greatly affects forming cycle times for most plastics.

379:

HDPE pipe during extrusion. The HDPE material is coming from the heater, into the die, then into the cooling tank. This Acu-Power conduit pipe is co-extruded - black inside with a thin orange jacket, to designate power

347:

Decompression zone. In this zone, about two-thirds down the screw, the channel suddenly gets deeper, which relieves the pressure and allows any trapped gases (moisture, air, solvents, or reactants) to be drawn out by

299:

or other raw materials after cleaning, sorting and/or blending. This material is commonly extruded into filaments suitable for chopping into the bead or pellet stock to use as a precursor for further processing.

287:

The product must now be cooled, and this is usually achieved by pulling the extrudate through a water bath. Plastics are very good thermal insulators and are therefore difficult to cool quickly. Compared to

135:

338:

Metering zone (also called the melt conveying zone): this zone melts the last particles and mixes to a uniform temperature and composition. Like the feed zone, the channel depth is constant throughout this

139:

138:

134:

133:

140:

234:

can offer many similar profiles in continuous lengths, usually with added reinforcing, this is achieved by pulling the finished product out of a die instead of extruding the polymer melt through a die.

351:

Second metering zone. This zone is similar to the first metering zone, but with greater channel depth. It serves to repressurize the melt to get it through the resistance of the screens and the die.

486:. As the film continues to cool, it is drawn through several sets of nip rollers to flatten it into lay-flat tubing, which can then be spooled or slit into two or more rolls of sheeting.

137:

251:

cooling fans are present to keep the temperature below a set value if too much heat is generated. If forced air cooling proves insufficient then cast-in cooling jackets are employed.

367:

in the barrel wall for temperature control. The "temperature profile" i.e., the temperature of each zone is very important to the quality and characteristics of the final extrudate.

284:

unwanted residual stresses at certain points in the profile which can cause warping upon cooling. A wide variety of shapes can be created, restricted to continuous profiles.

983:

546:

Over jacketing extrusion allows for the application of an outer layer of plastic onto an existing wire or cable. This is the typical process for insulating wires.

239:

temperature of the barrel due to viscous heating and other effects. In most processes, a heating profile is set for the barrel in which three or more independent

335:

Melting zone (also called the transition or compression zone): most of the polymer is melted in this section, and the channel depth gets progressively smaller.

332:

Feed zone (also called the solids conveying zone): this zone feeds the resin into the extruder, and the channel depth is usually the same throughout the zone.

2117:

136:

2027:

538:

Multi-layer tubing applications are also ever present within the automotive industry, plumbing & heating industry and packaging industry.

852:

825:

699:

1429:

867:

Shah, A and Gupta, M (2004). "Comparison of the flow in co-rotating and counter-rotating twin-screw extruders". ANTEC, www.plasticflow.com.

511:, where the sheet is heated until soft (plastic), and formed via a mold into a new shape. When vacuum is used, this is often described as

938:

2413:

42:

2383:

1231:

907:

720:

108:

2353:

748:

475:

thinner than the extruded tube, and also preferentially aligns the polymer molecular chains in the direction that sees the most

89:

2087:

1941:

1786:

413:

364:

61:

2192:

46:

482:

In the case of polyethylene and other semi-crystalline polymers, as the film cools it crystallizes at what is known as the

2303:

1256:

68:

1459:

788:

2348:

2232:

1464:

1246:

268:

356:

output at the same screw diameter. Two-stage (vented) screws are typically 36:1 to account for the two extra zones.

2557:

2552:

1991:

476:

75:

35:

2446:

2408:

2338:

2328:

1266:

1126:

1053:

968:

644:

230:

from the point of the extruder technology, although it differs in that it is usually a continuous process. While

2333:

2202:

1801:

1221:

1191:

1081:

530:

157:

57:

499:

the entire cross sectional area of the die. Cooling is typically by pulling through a set of cooling rolls (

2363:

1986:

1906:

1766:

1294:

931:

2082:

1791:

1494:

1226:

1206:

429:

320:

280:

also eliminates the "rotational memory" of the molten plastic and creates instead, "longitudinal memory".

2511:

2461:

2441:

2388:

1721:

1671:

1394:

1389:

1048:

1038:

1013:

483:

2481:

2343:

1871:

1186:

1018:

654:

209:, Germany. Shortly after, Roberto Colombo of LMP developed the first twin screw extruders in Italy.

2368:

2177:

1976:

1816:

1696:

1156:

649:

634:

244:

2533:

2496:

2456:

2308:

2217:

2182:

2132:

2017:

1726:

1596:

1566:

1504:

1241:

1141:

1121:

1116:

1023:

924:

409:

205:. The first thermoplastic extrusion was in 1935 by Paul Troester and his wife Ashley Gershoff in

464:

562:

82:

2501:

2486:

2358:

2278:

2273:

2187:

2147:

2127:

2097:

2077:

1956:

1926:

1761:

1334:

1216:

1176:

1058:

1043:

998:

973:

903:

848:

842:

821:

815:

716:

695:

639:

579:

524:

436:

296:

227:

2516:

2506:

2323:

2152:

2107:

2067:

2057:

1921:

1836:

1616:

1514:

1409:

1384:

1299:

1251:

1196:

1028:

993:

978:

963:

659:

571:

differing properties such as oxygen permeability, strength, stiffness, and wear resistance.

161:

2476:

2471:

2451:

2373:

2293:

2248:

2212:

2167:

2102:

2072:

1826:

1811:

1716:

1611:

1509:

1106:

1003:

375:

123:

2436:

2431:

2403:

2253:

2227:

2222:

2112:

2032:

2022:

1936:

1911:

1881:

1841:

1656:

1591:

1534:

1439:

1424:

1404:

1314:

1166:

1161:

1086:

512:

312:

240:

2546:

2393:

2288:

2258:

2207:

2197:

2142:

2122:

1931:

1901:

1846:

1571:

1434:

1181:

1008:

988:

508:

417:

397:

389:

384:

Typical plastic materials that are used in extrusion include but are not limited to:

276:

218:

177:

694:

Tadmor and Gogos (2006). ‘’Principles of

Polymer Processing’’. John Wiley and Sons.

2037:

1966:

1896:

1886:

1876:

1861:

1796:

1701:

1581:

1561:

1554:

1544:

1539:

1444:

1369:

1339:

1304:

1271:

1171:

1146:

495:

460:

456:

385:

360:

217:

In the extrusion of plastics, the raw compound material is commonly in the form of

173:

165:

794:

897:

2318:

2283:

2157:

1946:

1821:

1806:

1771:

1751:

1741:

1711:

1681:

1661:

1606:

1529:

1344:

1276:

1261:

1211:

1096:

629:

405:

24:

254:

192:

2398:

2378:

2268:

2137:

2062:

1951:

1866:

1731:

1691:

1666:

1631:

1601:

1524:

1499:

1449:

1319:

1151:

1136:

1111:

1091:

1033:

393:

231:

878:

681:

2491:

2298:

2092:

1981:

1971:

1961:

1916:

1891:

1736:

1621:

1576:

1519:

1286:

1131:

1063:

947:

447:

221:(small beads, often called resin) that are gravity fed from a top mounted

184:

a die, which shapes the polymer into a shape that hardens during cooling.

2313:

2263:

2172:

2042:

2001:

1831:

1756:

1746:

1651:

1586:

1489:

1474:

1419:

1359:

1236:

1201:

1101:

584:

500:

263:

222:

2052:

2047:

1996:

1706:

1454:

1309:

206:

153:

2466:

1851:

1549:

1414:

1379:

1374:

1349:

1329:

202:

169:

1856:

1776:

1676:

1399:

624:

561:

529:

446:

401:

374:

319:

311:

295:

Plastic extruders are also extensively used to reprocess recycled

289:

253:

191:

130:

122:

1686:

1626:

1364:

275:). The screen pack/breaker plate assembly also serves to create

920:

1781:

1484:

1479:

1469:

1354:

1324:

841:

Giles, Harold F.; Wagner, John R.; Mount, Eldridge M. (2005),

272:

18:

877:

TEPPFA, The

European Plastic Pipes and Fittings Association.

790:

Process, Methods and

Features of plastic extrusion technology

680:

TEPPFA, The

European Plastic Pipes and Fittings Association.

916:

507:

A common post-extrusion process for plastic sheet stock is

494:

Sheet/film extrusion is used to extrude plastic sheets or

844:

Extrusion: the definitive processing guide and handbook

583:

as an adhesive to bring two other materials together.

896:

Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994),

127:

Cross-section of a plastic extruder to show the screw

777:. Intermediate Technology Publication. pp. 6–7.

152:

is a high-volume manufacturing process in which raw

2422:

2241:

2010:

1640:

1285:

1072:

954:

258:

Plastic extruder cut in half to show the components

49:. Unsourced material may be challenged and removed.

566:5 :5 Layer co-extrusion of cosmetic "squeeze" tube

160:. Extrusion produces items such as pipe/tubing,

984:Modified atmosphere/modified humidity packaging

735:

463:, and continuous sheeting is achieved using a

932:

504:permeation resistance, or energy reflection.

343:In addition, a vented (two-stage) screw has:

145:Short video on injection molding (9 min 37 s)

8:

2118:Hazard analysis and critical control points

939:

925:

917:

2028:Automatic identification and data capture

587:is a commercial example of this process.

109:Learn how and when to remove this message

534:A Boston Matthews Medical Extrusion Line

899:Manufacturing Processes Reference Guide

672:

359:Each zone is equipped with one or more

156:is melted and formed into a continuous

7:

1430:Flexible intermediate bulk container

459:for products such as food packages,

328:Most screws have these three zones:

324:Extruder screws From Boston Matthews

47:adding citations to reliable sources

16:Melted plastic manufacturing process

2414:Vertical form fill sealing machine

749:"HOW TO SOLVE BLOWN FILM PROBLEMS"

14:

2384:Rotary wheel blow molding systems

1232:Purdue Improved Crop Storage bags

775:Small Scale Recycling of Plastics

2528:

2527:

2354:Mechanical brake stretch wrapper

817:Concise encyclopedia of plastics

316:A simple plastic extrusion screw

262:At the front of the barrel, the

23:

2088:Electronic article surveillance

1942:Shock and vibration data logger

1787:Linear low-density polyethylene

847:, William Andrew, p. 151,

414:acrylonitrile butadiene styrene

180:coatings, and wire insulation.

34:needs additional citations for

2193:Radio-frequency identification

451:Blow extrusion of plastic film

1:

2304:Extended core stretch wrapper

1257:Single-serve coffee container

736:Todd, Allen & Alting 1994

1460:Insulated shipping container

2349:Material-handling equipment

2233:Verification and validation

1465:Intermediate bulk container

1247:Self-heating food packaging

814:Rosato, Marlene G. (2000),

754:. Lyondell Chemical Company

371:Typical extrusion materials

2576:

1992:Time temperature indicator

711:Rauwendaal, Chris (2001),

427:

2525:

2447:Environmental engineering

2409:Turntable stretch wrapper

2339:Lineshaft roller conveyor

2329:Injection molding machine

1267:Toothpaste pump dispenser

1127:Disposable food packaging

969:Child-resistant packaging

902:, Industrial Press Inc.,

820:, Springer, p. 245,

713:Polymer Extrusion, 4th ed

645:Fused deposition modeling

228:plastic injection molding

2334:Label printer applicator

2203:Shearing (manufacturing)

1802:Low-density polyethylene

1222:Pharmaceutical packaging

1192:Low plastic water bottle

1082:Alternative wine closure

542:Over jacketing extrusion

2364:Orbital stretch wrapper

1987:Temperature data logger

1907:Pressure-sensitive tape

1767:Humidity indicator card

1295:Aerosol spray dispenser

2083:Die forming (plastics)

1792:Liquid packaging board

1495:Multilayered packaging

1227:Plastic milk container

1207:Optical disc packaging

879:"Production Processes"

682:"Production Processes"

567:

535:

452:

430:Die forming (plastics)

381:

325:

317:

259:

197:

146:

128:

2512:Sustainable packaging

2462:Life-cycle assessment

2442:Closed-loop box reuse

2389:Seed-counting machine

1722:Corrugated fiberboard

1672:Biodegradable plastic

1395:Corrugated box design

1049:Sustainable packaging

1039:Shelf-ready packaging

1014:Packaging engineering

565:

533:

450:

378:

323:

315:

257:

195:

144:

126:

2482:PET bottle recycling

2344:Logistics automation

1872:Plastic-coated paper

1019:Resealable packaging

773:John Vogler (1984).

655:Industrial finishing

490:Sheet/film extrusion

443:Blown film extrusion

43:improve this article

2534:Category: Packaging

2369:Packaging machinery

2178:Product development

1977:Tamper-evident band

1817:Modified atmosphere

1157:Foam food container

738:, pp. 223–227.

650:Gravimetric blender

635:3D printer extruder

591:Compound extrusions

455:The manufacture of

245:polymer degradation

58:"Plastic extrusion"

2497:Reusable packaging

2457:Industrial ecology

2218:Ultrasonic welding

2183:Production control

2133:Injection moulding

2018:Aseptic processing

1727:Corrugated plastic

1597:Steel and tin cans

1567:Shipping container

1505:Packet (container)

1242:Seasonal packaging

1142:Evidence packaging

1122:Currency packaging

1117:Cosmetic packaging

1024:Reusable packaging

568:

536:

453:

410:polyvinyl chloride

382:

326:

318:

260:

198:

150:Plastics extrusion

147:

129:

2558:Forming processes

2553:Plastics industry

2540:

2539:

2502:Reverse logistics

2487:Plastic recycling

2359:Multihead weigher

2279:Cartoning machine

2274:Cap torque tester

2188:Quality assurance

2163:Plastic extrusion

2128:Induction sealing

2098:Extrusion coating

1957:Staple (fastener)

1927:Security printing

1762:Hot-melt adhesive

1335:Biodegradable bag

1177:Glass milk bottle

1059:Tamper resistance

999:Package pilferage

974:Contract packager

854:978-0-8155-1473-2

827:978-0-7923-8496-0

700:978-0-471-38770-1

640:Extrusion coating

600:Types of extruder

580:Extrusion coating

575:Extrusion coating

437:injection molding

142:

119:

118:

111:

93:

2565:

2531:

2530:

2517:Waste management

2507:Source reduction

2324:Industrial robot

2228:Vacuum packaging

2153:Package tracking

2108:Glass production

2068:Corona treatment

2058:Containerization

1922:Screw cap (wine)

1837:Oxygen scavenger

1300:Aluminium bottle

1252:Screw cap (wine)

1197:Luxury packaging

1029:Reuse of bottles

994:Package delivery

979:Edible packaging

964:Active packaging

941:

934:

927:

918:

912:

883:

882:

874:

868:

865:

859:

857:

838:

832:

830:

811:

805:

804:

803:

802:

793:, archived from

785:

779:

778:

770:

764:

763:

761:

759:

753:

745:

739:

733:

727:

725:

708:

702:

692:

686:

685:

677:

660:Thermal cleaning

519:Tubing extrusion

162:weatherstripping

143:

114:

107:

103:

100:

94:

92:

51:

27:

19:

2575:

2574:

2568:

2567:

2566:

2564:

2563:

2562:

2543:

2542:

2541:

2536:

2521:

2477:Paper recycling

2472:Packaging waste

2452:Glass recycling

2424:

2418:

2374:Pallet inverter

2294:Conveyor system

2249:Barcode printer

2237:

2213:Track and trace

2168:Plastic welding

2103:Flame treatment

2073:Curtain coating

2006:

1827:Nonwoven fabric

1812:Metallised film

1717:Container glass

1644:

1642:

1636:

1612:Tub (container)

1510:Padded envelope

1281:

1107:Case-ready meat

1074:

1068:

1004:Package testing

956:

950:

945:

910:

895:

892:

887:

886:

876:

875:

871:

866:

862:

855:

840:

839:

835:

828:

813:

812:

808:

800:

798:

787:

786:

782:

772:

771:

767:

757:

755:

751:

747:

746:

742:

734:

730:

723:

710:

709:

705:

693:

689:

679:

678:

674:

669:

664:

620:

611:

602:

593:

577:

556:

544:

521:

492:

445:

432:

426:

373:

306:

215:

190:

131:

115:

104:

98:

95:

52:

50:

40:

28:

17:

12:

11:

5:

2573:

2572:

2569:

2561:

2560:

2555:

2545:

2544:

2538:

2537:

2526:

2523:

2522:

2520:

2519:

2514:

2509:

2504:

2499:

2494:

2489:

2484:

2479:

2474:

2469:

2464:

2459:

2454:

2449:

2444:

2439:

2437:Can collecting

2434:

2432:Biodegradation

2428:

2426:

2420:

2419:

2417:

2416:

2411:

2406:

2404:Tape dispenser

2401:

2396:

2391:

2386:

2381:

2376:

2371:

2366:

2361:

2356:

2351:

2346:

2341:

2336:

2331:

2326:

2321:

2316:

2311:

2306:

2301:

2296:

2291:

2286:

2281:

2276:

2271:

2266:

2261:

2256:

2254:Barcode reader

2251:

2245:

2243:

2239:

2238:

2236:

2235:

2230:

2225:

2223:Vacuum forming

2220:

2215:

2210:

2205:

2200:

2195:

2190:

2185:

2180:

2175:

2170:

2165:

2160:

2155:

2150:

2145:

2140:

2135:

2130:

2125:

2120:

2115:

2113:Graphic design

2110:

2105:

2100:

2095:

2090:

2085:

2080:

2075:

2070:

2065:

2060:

2055:

2050:

2045:

2040:

2035:

2033:Blow fill seal

2030:

2025:

2023:Authentication

2020:

2014:

2012:

2008:

2007:

2005:

2004:

1999:

1994:

1989:

1984:

1979:

1974:

1969:

1964:

1959:

1954:

1949:

1944:

1939:

1937:Shock detector

1934:

1929:

1924:

1919:

1914:

1912:Pump dispenser

1909:

1904:

1899:

1894:

1889:

1884:

1882:Plastic pallet

1879:

1874:

1869:

1864:

1859:

1854:

1849:

1844:

1842:Package handle

1839:

1834:

1829:

1824:

1819:

1814:

1809:

1804:

1799:

1794:

1789:

1784:

1779:

1774:

1769:

1764:

1759:

1754:

1749:

1744:

1739:

1734:

1729:

1724:

1719:

1714:

1709:

1704:

1699:

1694:

1689:

1684:

1679:

1674:

1669:

1664:

1659:

1657:Aluminium foil

1654:

1648:

1646:

1638:

1637:

1635:

1634:

1629:

1624:

1619:

1614:

1609:

1604:

1599:

1594:

1592:Stand-up pouch

1589:

1584:

1579:

1574:

1569:

1564:

1559:

1558:

1557:

1547:

1542:

1537:

1535:Plastic bottle

1532:

1527:

1522:

1517:

1512:

1507:

1502:

1497:

1492:

1487:

1482:

1477:

1472:

1467:

1462:

1457:

1452:

1447:

1442:

1440:Folding carton

1437:

1432:

1427:

1425:Euro container

1422:

1417:

1412:

1407:

1405:Disposable cup

1402:

1397:

1392:

1387:

1382:

1377:

1372:

1367:

1362:

1357:

1352:

1347:

1342:

1337:

1332:

1327:

1322:

1317:

1315:Antistatic bag

1312:

1307:

1302:

1297:

1291:

1289:

1283:

1282:

1280:

1279:

1274:

1269:

1264:

1259:

1254:

1249:

1244:

1239:

1234:

1229:

1224:

1219:

1214:

1209:

1204:

1199:

1194:

1189:

1184:

1179:

1174:

1169:

1167:Fuel container

1164:

1162:Food packaging

1159:

1154:

1149:

1144:

1139:

1134:

1129:

1124:

1119:

1114:

1109:

1104:

1099:

1094:

1089:

1087:Ammunition box

1084:

1078:

1076:

1070:

1069:

1067:

1066:

1061:

1056:

1054:Tamper-evident

1051:

1046:

1041:

1036:

1031:

1026:

1021:

1016:

1011:

1006:

1001:

996:

991:

986:

981:

976:

971:

966:

960:

958:

952:

951:

946:

944:

943:

936:

929:

921:

915:

914:

908:

891:

888:

885:

884:

869:

860:

853:

833:

826:

806:

780:

765:

740:

728:

721:

703:

687:

671:

670:

668:

665:

663:

662:

657:

652:

647:

642:

637:

632:

627:

621:

619:

616:

610:

607:

601:

598:

592:

589:

576:

573:

555:

552:

543:

540:

520:

517:

513:vacuum forming

491:

488:

477:plastic strain

444:

441:

428:Main article:

425:

422:

404:(polyamides),

372:

369:

353:

352:

349:

341:

340:

336:

333:

305:

302:

214:

211:

189:

186:

176:and sheeting,

117:

116:

31:

29:

22:

15:

13:

10:

9:

6:

4:

3:

2:

2571:

2570:

2559:

2556:

2554:

2551:

2550:

2548:

2535:

2524:

2518:

2515:

2513:

2510:

2508:

2505:

2503:

2500:

2498:

2495:

2493:

2490:

2488:

2485:

2483:

2480:

2478:

2475:

2473:

2470:

2468:

2465:

2463:

2460:

2458:

2455:

2453:

2450:

2448:

2445:

2443:

2440:

2438:

2435:

2433:

2430:

2429:

2427:

2421:

2415:

2412:

2410:

2407:

2405:

2402:

2400:

2397:

2395:

2394:Shrink tunnel

2392:

2390:

2387:

2385:

2382:

2380:

2377:

2375:

2372:

2370:

2367:

2365:

2362:

2360:

2357:

2355:

2352:

2350:

2347:

2345:

2342:

2340:

2337:

2335:

2332:

2330:

2327:

2325:

2322:

2320:

2317:

2315:

2312:

2310:

2307:

2305:

2302:

2300:

2297:

2295:

2292:

2290:

2289:Check weigher

2287:

2285:

2282:

2280:

2277:

2275:

2272:

2270:

2267:

2265:

2262:

2260:

2259:Bottling line

2257:

2255:

2252:

2250:

2247:

2246:

2244:

2240:

2234:

2231:

2229:

2226:

2224:

2221:

2219:

2216:

2214:

2211:

2209:

2208:Thermoforming

2206:

2204:

2201:

2199:

2198:Roll slitting

2196:

2194:

2191:

2189:

2186:

2184:

2181:

2179:

2176:

2174:

2171:

2169:

2166:

2164:

2161:

2159:

2156:

2154:

2151:

2149:

2146:

2144:

2143:Laser cutting

2141:

2139:

2136:

2134:

2131:

2129:

2126:

2124:

2123:Hermetic seal

2121:

2119:

2116:

2114:

2111:

2109:

2106:

2104:

2101:

2099:

2096:

2094:

2091:

2089:

2086:

2084:

2081:

2079:

2076:

2074:

2071:

2069:

2066:

2064:

2061:

2059:

2056:

2054:

2051:

2049:

2046:

2044:

2041:

2039:

2036:

2034:

2031:

2029:

2026:

2024:

2021:

2019:

2016:

2015:

2013:

2009:

2003:

2000:

1998:

1995:

1993:

1990:

1988:

1985:

1983:

1980:

1978:

1975:

1973:

1970:

1968:

1965:

1963:

1960:

1958:

1955:

1953:

1950:

1948:

1945:

1943:

1940:

1938:

1935:

1933:

1932:Security tape

1930:

1928:

1925:

1923:

1920:

1918:

1915:

1913:

1910:

1908:

1905:

1903:

1902:Polypropylene

1900:

1898:

1895:

1893:

1890:

1888:

1885:

1883:

1880:

1878:

1875:

1873:

1870:

1868:

1865:

1863:

1860:

1858:

1855:

1853:

1850:

1848:

1847:Packaging gas

1845:

1843:

1840:

1838:

1835:

1833:

1830:

1828:

1825:

1823:

1820:

1818:

1815:

1813:

1810:

1808:

1805:

1803:

1800:

1798:

1795:

1793:

1790:

1788:

1785:

1783:

1780:

1778:

1775:

1773:

1770:

1768:

1765:

1763:

1760:

1758:

1755:

1753:

1750:

1748:

1745:

1743:

1740:

1738:

1735:

1733:

1730:

1728:

1725:

1723:

1720:

1718:

1715:

1713:

1710:

1708:

1705:

1703:

1700:

1698:

1695:

1693:

1690:

1688:

1685:

1683:

1680:

1678:

1675:

1673:

1670:

1668:

1665:

1663:

1660:

1658:

1655:

1653:

1650:

1649:

1647:

1639:

1633:

1630:

1628:

1625:

1623:

1620:

1618:

1615:

1613:

1610:

1608:

1605:

1603:

1600:

1598:

1595:

1593:

1590:

1588:

1585:

1583:

1580:

1578:

1575:

1573:

1572:Shipping tube

1570:

1568:

1565:

1563:

1560:

1556:

1553:

1552:

1551:

1548:

1546:

1543:

1541:

1538:

1536:

1533:

1531:

1528:

1526:

1523:

1521:

1518:

1516:

1513:

1511:

1508:

1506:

1503:

1501:

1498:

1496:

1493:

1491:

1488:

1486:

1483:

1481:

1478:

1476:

1473:

1471:

1468:

1466:

1463:

1461:

1458:

1456:

1453:

1451:

1448:

1446:

1443:

1441:

1438:

1436:

1435:Flexible tank

1433:

1431:

1428:

1426:

1423:

1421:

1418:

1416:

1413:

1411:

1408:

1406:

1403:

1401:

1398:

1396:

1393:

1391:

1388:

1386:

1383:

1381:

1378:

1376:

1373:

1371:

1368:

1366:

1363:

1361:

1358:

1356:

1353:

1351:

1348:

1346:

1343:

1341:

1338:

1336:

1333:

1331:

1328:

1326:

1323:

1321:

1318:

1316:

1313:

1311:

1308:

1306:

1303:

1301:

1298:

1296:

1293:

1292:

1290:

1288:

1284:

1278:

1275:

1273:

1270:

1268:

1265:

1263:

1260:

1258:

1255:

1253:

1250:

1248:

1245:

1243:

1240:

1238:

1235:

1233:

1230:

1228:

1225:

1223:

1220:

1218:

1215:

1213:

1210:

1208:

1205:

1203:

1200:

1198:

1195:

1193:

1190:

1188:

1185:

1183:

1180:

1178:

1175:

1173:

1170:

1168:

1165:

1163:

1160:

1158:

1155:

1153:

1150:

1148:

1145:

1143:

1140:

1138:

1135:

1133:

1130:

1128:

1125:

1123:

1120:

1118:

1115:

1113:

1110:

1108:

1105:

1103:

1100:

1098:

1095:

1093:

1090:

1088:

1085:

1083:

1080:

1079:

1077:

1071:

1065:

1062:

1060:

1057:

1055:

1052:

1050:

1047:

1045:

1042:

1040:

1037:

1035:

1032:

1030:

1027:

1025:

1022:

1020:

1017:

1015:

1012:

1010:

1009:Package theft

1007:

1005:

1002:

1000:

997:

995:

992:

990:

989:Overpackaging

987:

985:

982:

980:

977:

975:

972:

970:

967:

965:

962:

961:

959:

953:

949:

942:

937:

935:

930:

928:

923:

922:

919:

911:

909:0-8311-3049-0

905:

901:

900:

894:

893:

889:

880:

873:

870:

864:

861:

856:

850:

846:

845:

837:

834:

829:

823:

819:

818:

810:

807:

797:on 2013-02-02

796:

792:

791:

784:

781:

776:

769:

766:

750:

744:

741:

737:

732:

729:

724:

722:3-446-21774-6

718:

714:

707:

704:

701:

697:

691:

688:

683:

676:

673:

666:

661:

658:

656:

653:

651:

648:

646:

643:

641:

638:

636:

633:

631:

628:

626:

623:

622:

617:

615:

608:

606:

599:

597:

590:

588:

586:

581:

574:

572:

564:

560:

553:

551:

547:

541:

539:

532:

528:

526:

518:

516:

514:

510:

509:thermoforming

505:

502:

497:

489:

487:

485:

480:

478:

472:

468:

466:

462:

461:shopping bags

458:

449:

442:

440:

438:

431:

423:

421:

419:

418:polycarbonate

415:

411:

407:

403:

399:

395:

391:

390:polypropylene

387:

377:

370:

368:

366:

362:

361:thermocouples

357:

350:

346:

345:

344:

337:

334:

331:

330:

329:

322:

314:

310:

303:

301:

298:

297:plastic waste

293:

291:

285:

281:

278:

277:back pressure

274:

270:

265:

256:

252:

248:

246:

242:

236:

233:

229:

224:

220:

212:

210:

208:

204:

194:

187:

185:

181:

179:

178:thermoplastic

175:

174:plastic films

171:

170:window frames

167:

166:deck railings

163:

159:

155:

151:

125:

121:

113:

110:

102:

91:

88:

84:

81:

77:

74:

70:

67:

63:

60: –

59:

55:

54:Find sources:

48:

44:

38:

37:

32:This article

30:

26:

21:

20:

2423:Environment,

2162:

2038:Blow molding

1967:Stretch wrap

1897:Polyethylene

1887:Plastic wrap

1877:Plastic film

1862:Paper pallet

1797:Living hinge

1702:Coated paper

1582:Spray bottle

1562:Security bag

1555:Water sachet

1545:Salvage drum

1540:Retort pouch

1445:Glass bottle

1340:Blister pack

1305:Aluminum can

1272:Water bottle

1172:Gas cylinder

1147:Field ration

1044:Shelf-stable

898:

890:Bibliography

872:

863:

843:

836:

816:

809:

799:, retrieved

795:the original

789:

783:

774:

768:

756:. Retrieved

743:

731:

712:

706:

690:

675:

612:

603:

594:

578:

569:

557:

548:

545:

537:

522:

506:

493:

481:

473:

469:

457:plastic film

454:

433:

386:polyethylene

383:

358:

354:

342:

327:

307:

304:Screw design

294:

286:

282:

261:

249:

237:

216:

199:

182:

149:

148:

120:

105:

99:October 2009

96:

86:

79:

72:

65:

53:

41:Please help

36:verification

33:

2319:Heat sealer

2284:Case sealer

2158:Papermaking

2078:Die cutting

2043:Calendering

1947:Shrink wrap

1822:Molded pulp

1807:Meat diaper

1772:Kraft paper

1752:Foam peanut

1742:Double seam

1712:Coextrusion

1682:Bubble wrap

1662:Bail handle

1607:Thermal bag

1530:Plastic bag

1345:Boil-in-bag

1277:Wine bottle

1262:Spray paint

1217:Popcorn bag

1212:Oyster pail

1097:Beer bottle

630:3D printing

554:Coextrusion

406:polystyrene

164:, fencing,

2547:Categories

2399:Staple gun

2379:Palletizer

2269:Can seamer

2138:Lamination

2063:Converting

1952:Slip sheet

1867:Paperboard

1732:Cushioning

1692:Cellophane

1667:Bioplastic

1645:components

1632:Wooden box

1602:Tetra Brik

1525:Paper sack

1500:Multi-pack

1450:Gunny sack

1320:Bag-in-box

1287:Containers

1152:Flour sack

1137:Egg carton

1112:Coffee bag

1092:Banana box

1034:Shelf life

801:2012-08-01

715:, Hanser,

667:References

609:Advantages

484:frost line

465:blown film

416:(ABS) and

394:polyacetal

232:pultrusion

69:newspapers

2492:Recycling

2299:Drum pump

2242:Machinery

2093:Extrusion

2011:Processes

1982:Tear tape

1972:Susceptor

1962:Strapping

1917:Screw cap

1892:Polyester

1737:Desiccant

1641:Materials

1622:Unit load

1577:Skin pack

1520:Paper bag

1390:Clamshell

1132:Drink can

1064:Wrap rage

948:Packaging

758:31 August

523:Extruded

424:Die types

2425:post-use

2314:Heat gun

2264:Calender

2173:Printing

2002:Velostat

1997:Tinplate

1832:Overwrap

1757:Gel pack

1747:Flip-top

1652:Adhesive

1587:Squround

1490:Mesh bag

1475:Jerrycan

1420:Envelope

1360:Bulk box

1237:Sand bag

1202:Milk bag

1187:Juicebox

1102:Box wine

1075:packages

618:See also

585:Tetrapak

501:calender

196:اکسترودر

2148:Molding

2053:Coating

2048:Canning

1707:Coating

1697:Closure

1455:Inhaler

1310:Ampoule

1182:Growler

1073:Product

955:General

412:(PVC),

398:acrylic

380:cables.

348:vacuum.

219:nurdles

213:Process

207:Hamburg

188:History

158:profile

154:plastic

83:scholar

2532:

2467:Litter

2309:Filler

1852:Pallet

1550:Sachet

1415:Endcap

1380:Carton

1375:Carboy

1350:Bottle

1330:Barrel

957:topics

906:

851:

824:

719:

698:

525:tubing

467:line.

388:(PE),

264:molten

223:hopper

203:rubber

85:

78:

71:

64:

56:

1857:Paper

1777:Label

1677:BoPET

1400:Crate

752:(PDF)

625:Craft

496:films

402:nylon

339:zone.

290:steel

90:JSTOR

76:books

1687:Bung

1627:Vial

1617:Tube

1515:Pail

1410:Drum

1385:Chub

1370:Case

1365:Cage

904:ISBN

849:ISBN

822:ISBN

760:2012

717:ISBN

696:ISBN

365:RTDs

271:(34

62:news

1782:Lid

1643:and

1485:Keg

1480:Jug

1470:Jar

1355:Box

1325:Bag

363:or

273:MPa

269:psi

241:PID

45:by

2549::

439:.

420:.

408:,

400:,

396:,

392:,

247:.

172:,

168:,

940:e

933:t

926:v

913:.

881:.

858:.

831:.

762:.

726:.

684:.

112:)

106:(

101:)

97:(

87:·

80:·

73:·

66:·

39:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.