319:

327:

133:

367:-based optical profilometers scan surfaces with optical probes which send light interference signals back to the profilometer detector via an optical fiber. Fiber-based probes can be physically located hundreds of meters away from the detector enclosure, without signal degradation. The additional advantages of using fiber-based optical profilometers are flexibility, long profile acquisition, ruggedness, and ease of incorporating into industrial processes. With the small diameter of certain probes, surfaces can be scanned even inside hard-to-reach spaces, such as narrow crevices or small-diameter tubes.

141:

310:

electronics. For doing large steps, a 3D scan on an optical profiler can be much slower than a 2D scan on a stylus profiler. Optical profilometers do not touch the surface and therefore cannot be damaged by surface wear or careless operators. Many non-contact profilometers are solid-state which tends to reduce the required maintenance significantly. The spot size, or lateral resolution, of optical methods ranges from a few micrometres down to sub micrometre.

277:

measure small vertical features ranging in height from 10 nanometres to 1 millimetre. The height position of the diamond stylus generates an analog signal which is converted into a digital signal, stored, analyzed, and displayed. The radius of diamond stylus ranges from 20 nanometres to 50 μm, and the horizontal resolution is controlled by the scan speed and data signal sampling rate. The stylus tracking force can range from less than 1 to 50 milligrams.

281:

required. Contacting the surface is often an advantage in dirty environments where non-contact methods can end up measuring surface contaminants instead of the surface itself. Because the stylus is in contact with the surface, this method is not sensitive to surface reflectance or color. The stylus tip radius can be as small as 20 nanometres, significantly better than white-light optical profiling. Vertical resolution is typically sub-nanometer as well.

196:

36:

355:

vertical measurement has an intrinsic vertical calibration based on laser source wavelength. Samples are not static and there is response of the specimen topography to external stimulus. With on-flight measurement the topography of a moving sample is acquired with short exposure time. MEMS vibrations

280:

Advantages of contact profilometers include acceptance, surface independence, resolution, it is a direct technique with no modeling required. Most of the world's surface finish standards are written for contact profilometers. To follow the prescribed methodology, this type of profilometer is often

338:

enable 3D topography measurement in real-time. 3D topography is measured from a single camera acquisition as a consequence the acquisition rate is only limited by the camera acquisition rate, some systems measure topography at a frame rate of 1000 fps. Time-resolved systems enable measurement of

276:

A diamond stylus is moved vertically in contact with a sample and then moved laterally across the sample for a specified distance and specified contact force. A profilometer can measure small surface variations in vertical stylus displacement as a function of position. A typical profilometer can

350:

The advantage of time-resolved profilometers is that they are robust against vibrations. Unlike scanning methods, time-resolved profilometer acquisition time is in the milliseconds range. There is no need of vertical calibration: vertical measurement does not depend on a scanning mechanism,

309:

Advantages of optical profilometers are speed, reliability and spot size. For small steps and requirements to do 3D scanning, because the non-contact profilometer does not touch the surface the scan speeds are dictated by the light reflected from the surface and the speed of the acquisition

186:

Non-scanning technologies measure the surface topography within a single camera acquisition, XYZ scanning is no longer needed. As a consequence, dynamic changes of topography are measured in real-time. Contemporary profilometers are not only measuring static topography, but now also dynamic

375:

temperatures, or in radioactive chambers, while the detector is located at a distance, in a human-safe environment. Fiber-based probes are easily installed in-process, such as above moving webs or mounted onto a variety of positioning systems.

436:

W J Walecki, F Szondy, and M M Hilali, "Fast in-line surface topography metrology enabling stress calculation for solar cell manufacturing for throughput in excess of 2000 wafers per hour" 2008 Meas. Sci. Technol. 19 025302 (6pp)

289:

An optical profilometer is a non-contact method for providing much of the same information as a stylus based profilometer. There are many different techniques which are currently being employed, such as laser triangulation

370:

Because these probes generally acquire one point at a time and at high sample speeds, acquisition of long (continuous) surface profiles is possible. Scanning can take place in hostile environments, including very hot or

577:

145:

318:

231:

677:

347:

vibrations in the MHz range. The stroboscopic unit provides excitation signal to the MEMS and provides trigger signal to light source and camera.

465:

326:

299:

119:

672:

424:

Jean M. Bennett, Lars

Mattsson, Introduction to Surface Roughness and Scattering, Optical Society of America, Washington, D.C.

352:

335:

215:

57:

100:

266:

53:

72:

219:

132:

623:

343:

or measurement of moving specimens. Time-resolved profilometers can be combined with a stroboscopic unit to measure

79:

227:

223:

46:

255:

165:

86:

262:

639:

586:

68:

340:

140:

291:

247:

157:

591:

295:

239:

523:

546:

397:

303:

643:

604:

504:

461:

402:

322:

Self-Healing-Polymer from Tosoh

Corporation (Japan) measured by Digital Holographic Microscope

243:

183:, this notion is changing with the emergence of numerous non-contact profilometry techniques.

169:

455:

172:. Critical dimensions as step, curvature, flatness are computed from the surface topography.

635:

596:

538:

494:

438:

261:

Contact and pseudo-contact methods include stylus profilometer (mechanical profilometer),

235:

93:

238:, differential detection, critical angle method, astigmatic method, Foucault method, and

442:

573:"Low-Coherence Interferometry, an Advanced Technique for Optical Metrology in Industry"

211:

179:

that measures a surface as the surface is moved relative to the contact profilometer's

161:

356:

measurement can be accomplished when the system is combined with a stroboscopic unit.

666:

550:

384:

A furrow profilometer is used for the measurement of the cross-sectional geometry of

364:

200:

195:

572:

571:

Dufour, M. L.; Lamouche, G.; Detalle, V.; Gauthier, B.; Sammut, P. (April 2005).

522:

Dufour, Marc; Lamouche, G.; Gauthier, B.; Padioleau, C.; Monchalin, J.P. (2006).

600:

35:

499:

482:

176:

647:

608:

372:

234:(Nomarski microscopy); focus detection methods such as intensity detection,

17:

542:

508:

187:

topography – such systems are described as time-resolved profilometers.

175:

While the historical notion of a profilometer was a device similar to a

385:

180:

524:"Inspectionofhard-to-reachindustrialpartsusingsmalldiameterprobes"

330:

MEMS Ultrasonic-Transducers measured at 8 MHz in stroboscopic mode

325:

317:

251:

194:

534:

344:

29:

388:

and corrugations, and is important in furrow assessments.

578:

Insight: Non-Destructive

Testing and Condition Monitoring

27:

Measuring instrument for surface profile and roughness

60:. Unsourced material may be challenged and removed.

481:Binnig, Gerd; Quate, Calvin F; Gerber, Ch (1986).

628:Journal of Irrigation and Drainage Engineering

232:differential interference contrast microscopy

8:

148:technological facility in Toulouse, France.

460:(2nd ed.). Penton Press. p. 22.

590:

498:

432:

430:

298:(used for profiling very small objects),

120:Learn how and when to remove this message

139:

131:

640:10.1061/(ASCE)0733-9437(1995)121:1(114)

414:

420:

418:

242:; pattern projection methods such as

7:

457:Three-Dimensional Surface Topography

58:adding citations to reliable sources

678:Metalworking measuring instruments

454:Stout, K. J.; Blunt, Liam (2000).

25:

360:Fiber-based optical profilometers

339:topography changes as healing of

300:coherence scanning interferometry

206:surface profile measuring machine

622:Cahoon, Joel E. (January 1995).

220:vertical scanning interferometry

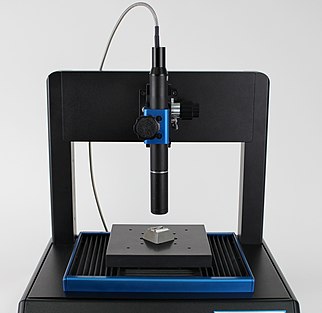

136:Non-Contact Optical Profilometer

34:

624:"Defining Furrow Cross Section"

45:needs additional citations for

353:digital holographic microscopy

336:digital holographic microscopy

216:digital holographic microscopy

1:

443:10.1088/0957-0233/19/2/025302

334:Non-scanning technologies as

267:scanning tunneling microscopy

228:phase shifting interferometry

601:10.1784/insi.47.4.216.63149

314:Time-resolved profilometers

694:

500:10.1103/PhysRevLett.56.930

256:pattern reflection methods

224:white light interferometry

144:A contact profilometer at

483:"Atomic force microscope"

285:Non-contact profilometers

210:Optical methods include

673:Dimensional instruments

487:Physical Review Letters

263:atomic force microscopy

543:10.1117/2.1200610.0467

331:

323:

214:based methods such as

207:

149:

137:

329:

321:

272:Contact profilometers

198:

143:

135:

292:triangulation sensor

248:Fourier profilometry

158:measuring instrument

54:improve this article

296:confocal microscopy

240:confocal microscopy

398:Road profilometery

332:

324:

304:digital holography

208:

160:used to measure a

150:

138:

467:978-1-85718-026-8

403:Surface metrology

244:fringe projection

162:surface's profile

130:

129:

122:

104:

16:(Redirected from

685:

652:

651:

619:

613:

612:

594:

568:

562:

561:

559:

557:

528:

519:

513:

512:

502:

478:

472:

471:

451:

445:

434:

425:

422:

125:

118:

114:

111:

105:

103:

62:

38:

30:

21:

693:

692:

688:

687:

686:

684:

683:

682:

663:

662:

661:

656:

655:

621:

620:

616:

592:10.1.1.159.5249

570:

569:

565:

555:

553:

526:

521:

520:

516:

480:

479:

475:

468:

453:

452:

448:

435:

428:

423:

416:

411:

394:

382:

362:

341:smart materials

316:

287:

274:

236:focus variation

199:Original 1940s

193:

126:

115:

109:

106:

63:

61:

51:

39:

28:

23:

22:

15:

12:

11:

5:

691:

689:

681:

680:

675:

665:

664:

660:

659:External links

657:

654:

653:

634:(1): 114–119.

614:

585:(4): 216–219.

563:

514:

493:(9): 930–933.

473:

466:

446:

426:

413:

412:

410:

407:

406:

405:

400:

393:

390:

381:

378:

361:

358:

315:

312:

286:

283:

273:

270:

212:interferometry

192:

189:

164:, in order to

128:

127:

69:"Profilometer"

42:

40:

33:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

690:

679:

676:

674:

671:

670:

668:

658:

649:

645:

641:

637:

633:

629:

625:

618:

615:

610:

606:

602:

598:

593:

588:

584:

580:

579:

574:

567:

564:

552:

548:

544:

540:

536:

532:

531:SPIE Newsroom

525:

518:

515:

510:

506:

501:

496:

492:

488:

484:

477:

474:

469:

463:

459:

458:

450:

447:

444:

440:

433:

431:

427:

421:

419:

415:

408:

404:

401:

399:

396:

395:

391:

389:

387:

379:

377:

374:

368:

366:

365:Optical fiber

359:

357:

354:

348:

346:

342:

337:

328:

320:

313:

311:

307:

305:

301:

297:

293:

284:

282:

278:

271:

269:

268:

264:

259:

257:

253:

249:

245:

241:

237:

233:

229:

225:

221:

217:

213:

205:

202:

201:Taylor-Hobson

197:

190:

188:

184:

182:

178:

173:

171:

167:

163:

159:

155:

147:

142:

134:

124:

121:

113:

110:November 2009

102:

99:

95:

92:

88:

85:

81:

78:

74:

71: –

70:

66:

65:Find sources:

59:

55:

49:

48:

43:This article

41:

37:

32:

31:

19:

631:

627:

617:

582:

576:

566:

556:December 15,

554:. Retrieved

530:

517:

490:

486:

476:

456:

449:

383:

380:Applications

369:

363:

349:

333:

308:

288:

279:

275:

260:

209:

203:

185:

174:

154:profilometer

153:

151:

116:

107:

97:

90:

83:

76:

64:

52:Please help

47:verification

44:

18:Profilometry

667:Categories

409:References

177:phonograph

80:newspapers

648:0733-9437

609:1354-2575

587:CiteSeerX

551:120476700

373:cryogenic

170:roughness

509:10033323

392:See also

204:Talysurf

166:quantify

386:furrows

94:scholar

646:

607:

589:

549:

507:

464:

302:, and

265:, and

254:, and

230:, and

181:stylus

96:

89:

82:

75:

67:

547:S2CID

527:(PDF)

252:Moire

191:Types

156:is a

101:JSTOR

87:books

644:ISSN

605:ISSN

558:2010

535:SPIE

505:PMID

462:ISBN

345:MEMS

168:its

146:LAAS

73:news

636:doi

632:121

597:doi

539:doi

495:doi

439:doi

294:),

56:by

669::

642:.

630:.

626:.

603:.

595:.

583:47

581:.

575:.

545:.

537:.

533:.

529:.

503:.

491:56

489:.

485:.

429:^

417:^

306:.

258:.

250:,

246:,

226:,

218:,

152:A

650:.

638::

611:.

599::

560:.

541::

511:.

497::

470:.

441::

290:(

222:/

123:)

117:(

112:)

108:(

98:·

91:·

84:·

77:·

50:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.