1076:, such as desert racers, use straps called "limiting straps" to limit the suspensions' downward travel to a point within safe limits for the linkages and shock absorbers. This is necessary, since these trucks are intended to travel over very rough terrain at high speeds, and even become airborne at times. Without something to limit the travel, the suspension bushings would take all the force, when suspension reaches "full droop", and it can even cause the coil springs to come out of their "buckets", if they are held in by compression forces only. A limiting strap is a simple strap, often from nylon of a predetermined length, that stops downward movement at a pre-set point before theoretical maximum travel is reached. The opposite of this is the "bump-stop", which protects the suspension and the vehicle (as well as the occupants) from the violent "bottoming" of the suspension, caused when an obstruction (or a hard landing) causes suspension to run out of upward travel without fully absorbing the energy of the stroke. Without bump-stops, a vehicle that "bottoms out", will experience a very hard shock when the suspension contacts the bottom of the frame or body, which is transferred to the occupants and every connector and weld on the vehicle. Factory vehicles often come with plain rubber "nubs" to absorb the worst of the forces, and insulate the shock. A desert race vehicle, which must routinely absorb far higher impact forces, might be provided with pneumatic or hydro-pneumatic bump-stops. These are essentially miniature shock absorbers (dampers) that are fixed to the vehicle in a location, such, that the suspension will contact the end of the piston when it nears the upward travel limit. These absorb the impact far more effectively than a solid rubber bump-stop will, essential, because a rubber bump-stop is considered a "last-ditch" emergency insulator for the occasional accidental bottoming of the suspension; it is entirely insufficient to absorb repeated and heavy bottoming, such as a high-speed off-road vehicle encounters.

248:

2105:, had overlapping and sometimes interleaved road wheels to distribute the load more evenly on the tank's track, and therefore on the ground. This apparently made a significant contribution to speed, range and track life, as well as providing a continuous band of protection. It has not been used since the end of that war, probably due to the maintenance requirements of more complicated mechanical parts working in mud, sand, rocks, snow, and ice; as well as due to cost. Rocks and frozen mud often got stuck between the overlapping wheels, which could prevent them from turning, or would cause damage to the road wheels. If one of the interior road wheels were damaged, it would require other road wheels to be removed in order to access the damaged road wheel, making the process more complicated and time-consuming.

1175:, which are subject to decay over time. For high-stress suspensions, such as off-road vehicles, polyurethane bushings are available, which offer more longevity under greater stresses. However, due to weight and cost considerations, structures are not made more rigid than necessary. Some vehicles exhibit detrimental vibrations involving the flexing of structural parts, such as when accelerating while turning sharply. Flexibility of structures, such as frames and suspension links, can also contribute to springing, especially to damping out high-frequency vibrations. The flexibility of wire wheels contributed to their popularity in times when cars had less advanced suspensions.

815:

width, CG height, spring and damper rates, roll centre heights of front and rear, anti-roll bar stiffness and tire pressure/construction. The roll rate of a vehicle can, and usually, does differ front-to-rear, which allows for the tuning ability of a vehicle for transient and steady-state handling. The roll rate of a vehicle does not change the total amount of weight transfer on the vehicle, but shifts the speed and percentage of weight transferred on a particular axle to another axle through the vehicle chassis. Generally, the higher the roll rate on an axle of a vehicle, the faster and higher percentage the weight transfer on that

278:

1529:, fore-aft linked suspension system, together with in-board front brakes, had a much smaller unsprung weight than existing coil spring or leaf designs. The interconnection transmitted some of the force deflecting a front wheel up over a bump, to push the rear wheel down on the same side. When the rear wheel met that bump a moment later, it did the same in reverse, keeping the car level front to rear. The 2CV had a design brief to be able to be driven at speed over a ploughed field, such as by a farmer transporting chicken eggs. It originally featured friction dampers and

2094:, getting spring force from twisting bars inside the hull — this sometimes had less travel than the Christie type, but was significantly more compact, allowing more space inside the hull, with the consequent possibility to install larger turret rings, and thus, heavier main armament. Torsion-bar suspension, sometimes including shock absorbers, has been the dominant heavy armored vehicle suspension since World War II. Torsion bars may take space under or near the floor, which may interfere with making the tank low to reduce exposure.

1105:

rear, can be used to tune handling. Some racecars are tuned with -2 to -7° camber, depending on the type of handling desired, and tire construction. Often, too much camber will result in the decrease of braking performance due to a reduced contact patch size through excessive camber variation in suspension geometry. The amount of camber change in bump is determined by the instantaneous front view swing arm (FVSA) length of suspension geometry, or in other words, the tendency of the tire to camber inward when compressed in bump.

180:

1627:

363:

1770:

779:

they both have heavy springs, the actual spring rates for a 2,000 lb (910 kg) racecar and a 10,000 lb (4,500 kg) truck are very different. A luxury car, taxi, or passenger bus would be described as having soft springs, for the comfort of their passengers or driver. Vehicles with worn-out or damaged springs ride lower to the ground, which reduces the overall amount of compression available to the suspension, and increases the amount of body lean.

1929:(motorbikes) lean towards the center of curvature while turning, which improves stability and decreases the chances of toppling. But vehicles with more than two wheels, and equipped with a conventional suspension system, could not do the same until now, so the passengers feel the outward inertial force, which reduces the stability of riders and their comfort as well. This kind of tilting suspension system is the solution to the problem. If the road does not have

795:

wheel 1 in (2.5 cm) (without moving the car), the spring more than likely compresses a smaller amount. If the spring moved 0.75 in (19 mm), the lever arm ratio would be 0.75:1. The wheel rate is calculated by taking the square of the ratio (0.5625) times the spring rate, thus obtaining 281.25 lbs/inch (49.25 N/mm). The ratio is squared because it has two effects on the wheel rate: it applies to both the force and the distance traveled.

156:

799:

are not independent, when viewed from the side under acceleration or braking, the pivot point is at infinity (because both wheels have moved) and the spring is directly inline with the wheel contact patch. The result is often, that the effective wheel rate under cornering is different from what it is under acceleration and braking. This variation in wheel rate may be minimised by locating the spring as close to the wheel as possible.

1163:

values of anti-squat commonly cause wheel hop during braking. It is important to note, that the value of 100% means, that all of the weight transfer is being carried through suspension linkage. However, this does not mean that the suspension is incapable of carrying additional loads (aerodynamic, cornering, etc.) during an episode of braking, or forward acceleration. In other words, no "binding" of the suspension is to be implied.

1514:: two Championships; Lexus GX470 2004 as the 4×4 of the year with KDSS; the 2005 PACE award). These systems by Kinetic generally decouple at least two vehicle modes (roll, warp (articulation), pitch, and/or heave (bounce)) to simultaneously control each mode's stiffness and damping by using interconnected shock absorbers, and other methods. In 1999, Kinetic was bought out by Tenneco. Later developments by the Catalan company

1065:

wheel can cause serious control problems, or directly cause damage. "Bottoming" can be caused by the suspension, tires, fenders, etc. running out of space to move, or the body or other components of the car hitting the road. Control problems caused by lifting a wheel are less severe, if the wheel lifts when the spring reaches its unloaded shape than they are, if travel is limited by contact of suspension members (See

1156:

of braking effort at the front wheels must be known. Then, multiply the tangent by the front wheel braking effort percentage and divide by the ratio of the center of gravity height to the wheelbase. A value of 50% would mean, that half of the weight transfer to the front wheels; during braking, it is being transmitted through front suspension linkage, and half is being transmitted through front suspension springs.

3779:

3769:

1565:) with suspension units on each side connected to each other by a fluid-filled pipe. The fluid transmitted the force of road bumps from one wheel to the other (on the same principle as Citroën 2CV's mechanical system described above), and because each suspension unit contained valves to restrict the flow of fluid, also served as a shock absorber. Moulton went on to develop a replacement for

999:

860:

664:

458:

59:

1312:

259:-drawn carts had the platform swing on iron chains attached to the wheeled frame of the carriage. This system remained the basis for most suspension systems until the turn of the 19th century, although the iron chains were replaced with the use of leather straps called thoroughbraces by the 17th century. No modern automobiles have used the thoroughbrace suspension system.

382:. With the advantage of a damped suspension system on his 'Mors Machine', Henri Fournier won the prestigious Paris-to-Berlin race on 20 June 1901. Fournier's superior time was 11 hours 46 minutes and 10 seconds, while the best competitor was Léonce Girardot in a Panhard with a time of 12 hours, 15 minutes, and 40 seconds.

164:

725:

1525:. Suspension in the 2CV was extremely soft — the longitudinal link was making pitch softer, instead of making roll stiffer. It relied on extreme anti-dive and anti-squat geometries to compensate for that. This resulted in a softer axle-crossing stiffness that anti-roll bars would have otherwise compromised. The leading arm / trailing arm

1994:

225:, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the

1881:

In semi-independent suspensions, the wheels of an axle are able to move relative to one another, as in an independent suspension, but the position of one wheel has an effect on the position and attitude of the other wheel. This effect is achieved through the twisting or deflecting of suspension parts

1151:

The method of determining anti-dive or anti-squat depends on whether suspension linkages react to the torque of braking and accelerating. For example, with inboard brakes and half-shaft-driven rear wheels, the suspension linkages do not react, but with outboard brakes and a swing-axle driveline, they

1138:

In this respect, the instant centers are more important to the handling of the vehicle, than the kinematic roll center alone, in that the ratio of geometric-to-elastic weight transfer is determined by the forces at the tires and their directions in relation to the position of their respective instant

1104:

changes due to wheel travel, body roll and suspension system deflection or compliance. In general, a tire wears and brakes best at -1 to -2° of camber from vertical. Depending on the tire and the road surface, it may hold the road best at a slightly different angle. Small changes in camber, front and

946:

Unsprung weight transfer is calculated based on weight of the vehicle's components that are not supported by the springs. This includes tires, wheels, brakes, spindles, half the control arm's weight, and other components. These components are then (for calculation purposes) assumed to be connected to

798:

Wheel rate on independent suspension is fairly straightforward. However, special consideration must be taken with some non-independent suspension designs. Take the case of the straight axle. When viewed from the front or rear, the wheel rate can be measured by the means above. Yet, because the wheels

769:

of the spring. Vehicles that carry heavy loads, will often have heavier springs to compensate for the additional weight that would otherwise collapse a vehicle to the bottom of its travel (stroke). Heavier springs are also used in performance applications, where the loading conditions experienced are

1861:

Because the wheels are not constrained to remain perpendicular to a flat road surface in turning, braking, and varying load conditions, control of the wheel camber is an important issue. Swinging-arm was common in small cars that were sprung softly, and could carry large loads, because the camber is

1505:

have also been explored in some recent studies, and their potential benefits in enhancing vehicle ride and handling have been demonstrated. The control system can also be used for further improving performance of interconnected suspensions. Apart from academic research, an

Australian company Kinetic

1497:

Interconnected suspension, unlike semi-active/active suspensions, could easily decouple different vehicle vibration modes in a passive manner. Interconnections can be realized by various means, such as mechanical, hydraulic, and pneumatic. Anti-roll bars are one of the typical examples of mechanical

1155:

To determine the percentage of front suspension braking anti-dive for outboard brakes, it is first necessary to determine the tangent of the angle between a line drawn, in side view, through the front tire patch and the front suspension instant center, and the horizontal. In addition, the percentage

1064:

Travel is the measure of distance from the bottom of the suspension stroke (such as when the vehicle is on a jack, and the wheel hangs freely) to the top of the suspension stroke (such as when the vehicle's wheel can no longer travel in an upward direction toward the vehicle). Bottoming or lifting a

1162:

Forward acceleration anti-squat is calculated in a similar manner and with the same relationship between percentage and weight transfer. Anti-squat values of 100% and more are commonly used in drag racing, but values of 50% or less are more common in cars that have to undergo severe braking. Higher

1147:

Anti-dive and anti-squat are percentages that indicate the degree to which the front dives under braking, and the rear squats under acceleration. They can be thought of as the counterparts for braking and acceleration, as jacking forces are to cornering. The main reason for the difference is due to

1091:

Damping controls the travel speed and resistance of the vehicle's suspension. An undamped car will oscillate up and down. With proper damping levels, the car will settle back to a normal state in a minimal amount of time. Most damping in modern vehicles can be controlled by increasing or decreasing

937:

In most conventional applications, when weight is transferred through intentionally compliant elements, such as springs, dampers, and anti-roll bars, the weight transfer is said to be "elastic", while the weight which is transferred through more rigid suspension links, such as A-arms and toe links,

794:

Wheel rate is usually equal to or considerably less than the spring rate. Commonly, springs are mounted on control arms, swing arms or some other pivoting suspension member. Consider the example above, where the spring rate was calculated to be 500 lbs/inch (87.5 N/mm), if one were to move the

1134:

of the vertical load on the tire and the lateral force generated by it points directly into the instant center, the suspension links will not move. In this case, all weight transfer at that end of the vehicle will be geometric in nature. This is key information used in finding the force-based roll

814:

Roll rate is analogous to a vehicle's ride rate, but for actions that include lateral accelerations, causing a vehicle's sprung mass to roll. It is expressed as torque per degree of roll of the vehicle sprung mass. It is influenced by factors including but not limited to vehicle sprung mass, track

773:

Springs that are too hard or too soft cause the suspension to become ineffective – mostly because they fail to properly isolate the vehicle from the road. Vehicles that commonly experience suspension loads heavier than normal, have heavy or hard springs, with a spring rate close to the upper limit

2097:

As with cars, wheel travel and spring rate affect the bumpiness of ride, and the speed at which rough terrain can be negotiated. It may be significant, that a smooth ride, which is often associated with comfort, increases the accuracy when firing on the move. It also reduces shock on optics and

1760:

Because it assures constant camber, dependent (and semi-independent) suspension is most common on vehicles that need to carry large loads as a proportion of the vehicle's weight, that have relatively soft springs and that do not (for cost and simplicity reasons) use active suspensions. The use of

1196:

For most purposes, the weight of suspension components is unimportant. But at high frequencies caused by road surface roughness, the parts isolated by rubber bushings act as a multi-stage filter to suppress noise and vibration better than can be done with only tires and springs. (The springs work

1183:

Automobiles can be heavily laden with luggage, passengers, and trailers. This loading will cause a vehicle's tail to sink downwards. Maintaining a steady chassis level is essential to achieving the proper handling that the vehicle was designed for. Oncoming drivers can be blinded by the headlight

1126:

Due to the fact that the wheel and tire's motion is constrained by the vehicle's suspension links, the motion of the wheel package in the front view will scribe an imaginary arc in space with an "instantaneous center" of rotation at any given point along its path. The instant center for any wheel

778:

of the load. Riding in an empty truck meant for carrying loads can be uncomfortable for passengers, because of its high spring rate relative to the weight of the vehicle. A race car could also be described as having heavy springs, and would also be uncomfortably bumpy. However, even though we say

1928:

The tilting suspension system improves stability, traction, the turning radius of a vehicle, and the comfort of riders as well. While turning right or left, passengers or objects on a vehicle feel the G-force or inertial force outward the radius of the curvature, which is why two-wheeler riders

1488:

With the help of a control system, various semi-active/active suspensions realize an improved design compromise among different vibration modes of the vehicle; namely: bounce, roll, pitch and warp modes. However, the applications of these advanced suspensions are constrained by cost, packaging,

841:

percentage is a simplified method of describing lateral load transfer distribution front to rear, and subsequently handling balance. It is the effective wheel rate, in roll, of each axle of the vehicle as a ratio of the vehicle's total roll rate. It is commonly adjusted through the use of

929:

The total amount of weight transfer is only affected by four factors: the distance between wheel centers (wheelbase in the case of braking, or track width in the case of cornering), the height of the center of gravity, the mass of the vehicle, and the amount of acceleration experienced.

933:

The speed at which weight transfer occurs, as well as through which components it transfers, is complex, and is determined by many factors; including, but not limited to: roll center height, spring and damper rates, anti-roll bar stiffness, and the kinematic design of suspension links.

1666:

that holds wheels parallel to each other and perpendicular to the axle. When the camber of one wheel changes, the camber of the opposite wheel changes in the same way (by convention, on one side, this is a positive change in the camber, and on the other side, this a negative change).

1484:

have also been developed for vehicles. Examples include the electromagnetic suspension of Bose, and the electromagnetic suspension developed by prof. Laurentiu Encica. In addition, the new

Michelin wheel with embedded suspension functioning on an electric motor is also similar.

963:(total weight less the unsprung weight), the front and rear roll center heights, and the sprung center of gravity height (used to calculate the roll moment arm length). Calculating the front and rear sprung weight transfer will also require knowing the roll couple percentage.

1959:

system is a suspension arrangement, in which there are some trailing arms fitted with some idler wheels. Due to articulation between the driving section and the followers, this suspension is very flexible. This kind of suspension is appropriate for extremely rough terrain.

971:

times the sprung weight times the roll moment arm length divided by the effective track width. The front sprung weight transfer is calculated by multiplying the roll couple percentage times the total sprung weight transfer. The rear is the total minus the front transfer.

289:

Automobiles were initially developed as self-propelled versions of horse-drawn vehicles. However, horse-drawn vehicles had been designed for relatively slow speeds, and their suspension was not well suited to the higher speeds permitted by the internal combustion engine.

631:, or their equivalent from the centre of the differential to each wheel. But the wheels cannot entirely rise and fall independently of each other; they are tied by a yoke that goes around the differential, below and behind it. This method has had little use in the

966:

The roll axis is the line through the front and rear roll centers that the vehicle rolls around during cornering. The distance from this axis to the sprung center of gravity height is the roll moment arm length. The total sprung weight transfer is equal to the

1087:

is the control of motion or oscillation, as seen with the use of hydraulic gates and valves in a vehicle's shock absorber. This may also vary, intentionally or unintentionally. Like spring rate, the optimal damping for comfort may be less, than for control.

731:

729:

726:

1340:

Automakers are aware of the inherent limitations of steel springs — that these springs tend to produce undesirable oscillations, and carmakers have developed other types of suspension materials and mechanisms in attempts to improve performance:

1113:

Roll center height is a product of suspension instant center heights and is a useful metric in analyzing weight transfer effects, body roll and front to rear roll stiffness distribution. Conventionally, roll stiffness distribution is tuned adjusting

730:

756:

The spring rate (or suspension rate) is a component in setting the vehicle's ride height or its location in the suspension stroke. When a spring is compressed or stretched, the force it exerts, is proportional to its change in length. The

980:

Jacking forces are the sum of the vertical force components experienced by suspension links. The resultant force acts to lift the sprung mass, if the roll center is above ground, or compress it, if underground. Generally, the higher the

1373:

Shock absorbers damp out the (otherwise simple harmonic) motions of a vehicle up and down on its springs. They must also damp out much of the wheel bounce when the unsprung weight of a wheel, hub, axle, and sometimes brakes and the

728:

950:

The weight transfer for cornering in the front would be equal to the total unsprung front weight times the G-force times the front unsprung center of gravity height divided by the front track width. The same is true for the rear.

604:, invented by Albert Hotchkiss, was the most popular rear suspension system used in American cars from the 1930s to the 1970s. The system uses longitudinal leaf springs attached both forward and behind the differential of the

1579:, worked with the same principle, but instead of rubber spring units, it used metal spheres divided internally by a rubber diaphragm. The top half contained pressurised gas, and the lower half the same fluid as used on the

1869:

Wishbone and multi-link allow the engineer more control over the geometry, to arrive at the best compromise, than swing axle, MacPherson strut, or swinging arm do; however, the cost and space requirements may be greater.

1933:

or banking, it will not affect the comfort with this suspension system, the vehicle tilt and decrease in the height of the center of gravity with an increase in stability. This suspension is also used in fun vehicles.

1243:

in order to improve aerodynamics and fuel efficiency. Modern formula cars that have exposed wheels and suspension typically use streamlined tubing rather than simple round tubing for their suspension arms to reduce

2019:, have specialized suspension requirements. They can weigh more than seventy tons, and are required to move as quickly as possible over very rough or soft ground. Their suspension components must be protected from

2497:

1248:. Also typical is the use of rocker-arm, push rod, or pull rod-type suspensions, that, among other things, place the spring/damper unit inboard and out of the air stream to further reduce air resistance.

1834:

Transverse leaf springs when used as a suspension link, or four-quarter elliptics on one end of a car are similar to wishbones in geometry, but are more compliant. Examples are the front of the original

1395:

For example, a hydropneumatic Citroën will "know" how far off the ground the car is supposed to be, and constantly resets to achieve that level, regardless of load. However, this type of suspension will

1736:

Longitudinal semi-elliptical springs used to be common, and are still used in heavy-duty trucks and aircraft. They have the advantage, that the spring rate can easily be made progressive (non-linear).

1208:

This is the main functional advantage of aluminum wheels over steel wheels. Aluminum suspension parts have been used in production cars, and carbon fiber suspension parts are common in racing cars.

1118:

rather than roll center height (as both tend to have a similar effect on the sprung mass), but the height of the roll center is significant when considering the amount of jacking forces experienced.

1130:

A component of the tire's force vector points from the contact patch of the tire through instant center. The larger this component is, the less suspension motion will occur. Theoretically, if the

1256:

Production methods improve, but cost is always a factor. The continued use of the solid rear axle, with unsprung differential, especially on heavy vehicles, seems to be the most obvious example.

1583:

system. The fluid transmitted suspension forces between the units on each side, whilst the gas acted as the springing medium through the diaphragm. This is the same principle as the Citroën

959:

Sprung weight transfer is the weight transferred by only the weight of the vehicle resting on its springs, and not by total vehicle weight. Calculating this requires knowing the vehicle's

2807:

247:

2673:

1654:

Suspension systems can be broadly classified into two subgroups: dependent and independent. These terms refer to the ability of opposite wheels to move independently of each other. A

1701:

Dependent systems may be differentiated by the system of linkages used to locate them, both longitudinally and transversely. Often, both functions are combined in a set of linkages.

1437:

systems use electronic monitoring of vehicle conditions, coupled with the means to change the behavior of vehicle suspension in real time to directly control the motion of the car.

1518:

have devised a simpler system design based on single-acting cylinders. After some projects on competition, Creuat is active in providing retrofit systems for some vehicle models.

332:

was later refined and made to work years later. Springs were not only made of metal; a sturdy tree branch could be used as a spring, such as with a bow. Horse-drawn carriages and

727:

2031:

to reduce ground loading on poor surfaces. Some wheels are too big and too confined to turn, so skid steering is used with some wheeled, as well as with tracked vehicles.

2098:

other equipment. The unsprung weight and track link weight may limit speed on roads, and can affect the useful lifetime of the vehicle's track, and its other components.

2501:

1607:

in 2002. The system was changed in favour of coil springs over dampers due to cost reasons towards the end of the vehicle's life. When it was decommissioned in 2006, the

1498:

interconnections, while it has been stated, that fluidic interconnections offer greater potential and flexibility in improving both the stiffness and damping properties.

1925:)). With the addition of these suspension systems, there is a further tilting or leaning mechanism that connects the suspension system with the vehicle body (chassis).

3037:

2994:

926:

Weight transfer during cornering, acceleration, or braking is usually calculated per individual wheel, and compared with the static weights for the same wheels.

3099:

1430:, whose viscosity can be changed electromagnetically — thereby giving variable control without switching valves, which is faster and thus more effective.

3808:

1392:

If suspension is externally controlled, then it is a semi-active or active suspension — the suspension is reacting to signals from an electronic controller.

616:

to manufacture. Also, the dynamic defects of this design were suppressed by the enormous weight of U.S. passenger vehicles before the implementation of the

3803:

1689:

suspension is a third type. In this case, the motion of one wheel does affect the position of the other, but they are not rigidly attached to each other.

2727:

1148:

the different design goals between front and rear suspension, whereas suspension is usually symmetrical between the left and the right of the vehicle.

2789:

2811:

1985:

that are part of the vehicle. Although either sort helps to smooth the path and reduce ground pressure, many of the same considerations apply.

806:

in ride (also referred to as "heave"). This can be useful in creating a metric for suspension stiffness and travel requirements for a vehicle.

1465:, announced in 2009, uses linear electric motors in place of hydraulic or pneumatic actuators that have generally been used up until recently.

2399:

3013:

2970:

2941:

3382:

2114:

1757:, depending on whether or not differential is carried on the axle. Live-axle is simpler, but unsprung weight contributes to wheel bounce.

1457:

1990 as an option that added an extra 20% to the price of luxury models. Citroën has also developed several active suspension models (see

2746:

2643:

2613:

2583:

2553:

2523:

2355:

2282:

1400:

instantly compensate for body roll due to cornering. Citroën's system adds about 1% to the cost of the car versus passive steel springs.

2027:

weapons. Tracked AFVs can have as many as nine road wheels on each side. Many wheeled AFVs have six or eight large wheels. Some have a

802:

Wheel rates are usually summed and compared with the sprung mass of a vehicle to create a "ride rate" and the corresponding suspension

3498:

3299:

2481:

293:

The first workable spring-suspension required advanced metallurgical knowledge and skill, and only became possible with the advent of

2700:

1862:

independent of load. Some active and semi-active suspensions maintain ride height, and therefore the camber, independent of load. In

3092:

2430:

2259:

1910:) is not a different type or geometry of construction; moreover, it is a technology addition to the conventional suspension system.

1046:

907:

711:

585:

at the extreme rear of the transmission, which was attached to the engine. A similar method like this was used in the late 1930s by

505:

142:

3508:

1747:, even on expensive models. It had the advantages of simplicity and low unsprung weight (compared to other solid-axle designs).

1020:

881:

685:

612:

to the frame. Although scorned by many

European car makers of the time, it was accepted by American car makers, because it was

479:

76:

3063:

359:

re-introduced leather strap suspension, which gave a swinging motion instead of the jolting up-and-down of spring suspension.

3455:

1220:

are the most compact arrangement for front-engined vehicles, where space between the wheels is required to place the engine.

1024:

885:

689:

617:

483:

123:

80:

277:

31:

2071:

was a variation which used a combination of bell crank and exterior coil springs, in use from the 1930s to the 1990s. The

95:

3533:

2028:

1679:

allows wheels to rise and fall on their own without affecting the opposite wheel. Suspensions with other devices, such as

1275:

systems, which can be treated as an integrated unit of gas spring and damping components, used by the French manufacturer

791:

Wheel rate is the effective spring rate when measured at the wheel, as opposed to simply measuring the spring rate alone.

774:

for that vehicle's weight. This allows the vehicle to perform properly under a heavy load, when control is limited by the

429:

1591:, but is self-contained, and does not require an engine-driven pump to provide hydraulic pressure. The downside is, that

229:. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and

3140:

3085:

1826:

1240:

635:. Its use around 1900 was probably due to the poor quality of tires, which wore out quickly. By removing a good deal of

251:

American carriage showcasing thoroughbrace suspension—note the black straps running across the side of the undercarriage

1650:

This diagram is not exhaustive; notably, it excludes elements, such as trailing arm links, and those that are flexible.

3813:

3608:

2141:

1426:

Toyota introduced switchable shock absorbers in the 1983 Soarer. Delphi currently sells shock absorbers filled with a

102:

38:

1303:

Traditional springs and dampers are referred to as passive suspensions — most vehicles are suspended in this manner.

1205:

These are usually small, except that the suspension is related to whether the brakes and differential(s) are sprung.

1873:

Semi-trailing arm is in between, being a variable compromise between the geometries of swinging arm and swing axle.

3445:

3294:

3276:

2214:

1922:

1886:

1815:

1739:

A single transverse leaf spring for both front wheels and/or both back wheels, supporting solid axles, was used by

1690:

1481:

1223:

Inboard brakes (which reduce unsprung weight) are probably avoided more due to space considerations than to cost.

3818:

3744:

3633:

3573:

3538:

3328:

2204:

2046:

suspensions adopted from agricultural, automotive, or railway machinery, but even these had very limited travel.

2012:

1584:

1540:

1521:

Historically, the first mass-production car with front-to-rear mechanical interconnected suspension was the 1948

1502:

1501:

Considering the considerable commercial potentials of hydro-pneumatic technology (Corolla, 1996), interconnected

1408:

1358:

1288:

1185:

738:

1159:

For inboard brakes, the same procedure is followed, but using the wheel center instead of contact patch center.

297:. Obadiah Elliott registered the first patent for a spring-suspension vehicle; each wheel had two durable steel

109:

3523:

3375:

3180:

3155:

2385:

1507:

1375:

1009:

870:

766:

674:

566:

468:

440:

of wheel suspension using a geared flywheel, but without adding significant mass. It was initially employed in

1127:

package can be found by following imaginary lines drawn through suspension links to their intersection point.

2049:

Speeds increased due to more powerful engines, and the quality of ride had to be improved. In the 1930s, the

3493:

3465:

1028:

1013:

889:

874:

693:

678:

487:

472:

69:

2447:

2038:

had fixed suspension with no designed movement whatsoever. This unsatisfactory situation was improved with

179:

91:

3483:

3473:

3286:

2226:

2091:

1978:

1782:

1675:

1474:

1329:

1216:

Designs differ as to how much space they take up, and where it is located. It is generally accepted, that

543:

532:

415:

404:

356:

45:

3323:

3135:

2833:

2124:

1821:

643:

627:, which is sometimes called "semi-independent". Like true independent rear suspension, this employs two

352:

336:

used this system, and it is still used today in larger vehicles, mainly mounted in the rear suspension.

294:

269:

By the middle of the 19th century, elliptical springs might additionally start to be used on carriages.

362:

301:

on each side and the body of the carriage was fixed directly to the springs which were attached to the

3578:

3513:

3165:

2157:

2068:

206:

1626:

3603:

3583:

3368:

3306:

3120:

2174:

2050:

1769:

1733:

Fully elliptical springs usually need supplementary location links, and are no longer in common use

1470:

780:

218:

3768:

2249:

2217:— also known as "unequal length A arm", one of the design parameters of double wishbone suspension

2057:

inside a vehicle's armored hull, by changing the direction of force deforming the spring, using a

3749:

3654:

3031:

2988:

2169:

1740:

1346:

838:

389:

542:, rear suspension has many constraints, and the development of the superior, but more expensive

2083:

vehicles was similar to the

Hortsmann type, with suspension sequestered within the track oval.

3543:

3430:

3412:

3343:

3019:

3009:

2976:

2966:

2947:

2937:

2651:

2621:

2591:

2561:

2531:

2477:

2426:

2363:

2290:

2255:

1965:

1716:

1534:

1530:

1434:

1387:

521:

371:

263:

262:

By approximately 1750, leaf springs began appearing on certain types of carriage, such as the

217:

and allows relative motion between the two. Suspension systems must support both road holding/

3618:

3425:

3311:

3190:

2318:

2119:

1982:

1930:

1914:

1801:

1774:

1462:

1245:

1217:

1073:

590:

536:

433:

309:

were equipped with springs; wooden springs in the case of light one-horse vehicles to avoid

116:

3638:

3568:

3205:

3195:

3072:

2200:

1570:

1265:

1231:

The suspension attachment must match the frame design in geometry, strength and rigidity.

921:

636:

628:

601:

230:

198:

2936:. Geoffrey Howard, John P. Whitehead (4th ed.). Warrendale, Pa.: SAE International.

1753:

In a front-engine rear-drive vehicle, dependent rear suspension is either "live-axle" or

2336:

2160:- independent suspension combined with a transverse fiber reinforced plastic leaf spring

155:

3739:

3553:

3548:

3439:

3435:

3229:

3224:

3125:

1840:

1796:

1600:

1522:

1412:

1404:

1352:

1272:

1172:

843:

827:

400:

393:

379:

202:

1188:

counteracts this by inflating cylinders in the suspension to lift the chassis higher.

366:

Henri

Fournier on his uniquely damped and racewinning 'Mors Machine', photo taken 1902

339:

Leaf springs were the first modern suspension system, and, along with advances in the

3797:

3782:

3721:

3706:

3686:

3613:

3450:

3420:

3316:

3185:

3150:

2312:

2245:

2135:

1938:

1805:

1466:

1084:

960:

947:

a vehicle with zero sprung weight. They are then put through the same dynamic loads.

735:

632:

411:

348:

343:, heralded the single greatest improvement in road transport until the advent of the

242:

3051:

2874:

2771:

2101:

Most German WWII half-tracks and their tanks introduced during the war, such as the

1671:

suspensions are also in this category, as they rigidly connect the wheels together.

3691:

3628:

3598:

3593:

3338:

3260:

3058:

2209:

2179:

2146:

2102:

2087:

1950:

1744:

1668:

1604:

1588:

1561:, and used rubber cones as the springing medium (these were first used on the 1959

1558:

1526:

1115:

1101:

1066:

647:

642:

Rear-wheel drive vehicles today frequently use a fairly complex fully-independent,

624:

333:

325:

314:

282:

222:

324:. Ancient military engineers used leaf springs in the form of bows to power their

2901:"Leaning vehicle with tilting front wheels and suspension therefor US 8317207 B2"

1981:

fixed to the ground; and some, such as tractors, snow vehicles, and tanks run on

17:

3772:

3696:

3669:

3664:

3528:

3518:

3478:

3219:

3214:

3145:

2728:"The Bose 'Magic Carpet' Car Suspension System Is Finally Headed For Production"

2186:

2054:

2043:

2039:

2035:

1913:

This kind of suspension system mainly consists of independent suspension (e.g.,

1844:

1754:

1727:

1711:

1575:

1545:

1511:

1444:

1416:

1334:

1323:

1280:

998:

982:

859:

783:

can sometimes have spring rate requirements other than vehicle weight and load.

751:

663:

613:

574:

562:

457:

441:

385:

298:

159:

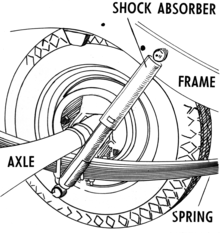

Part of car suspension system consists of shock absorber, axle, frame and spring

58:

1311:

3754:

3716:

3558:

3391:

3333:

3023:

2980:

2951:

2900:

2192:

2080:

2058:

1863:

1791:

1761:

dependent front suspension has become limited to heavier commercial vehicles.

1458:

1440:

1362:

1276:

1268:

to absorb impacts and dampers (or shock absorbers) to control spring motions.

582:

578:

554:

539:

524:

414:, and became more common in mass market cars from 1932. Today, most cars have

344:

183:

172:

1319:

The majority of land vehicles are suspended by steel springs of these types:

597:

in 1948, which used helical springs that could not take fore-and-aft thrust.

3711:

3701:

3623:

3588:

3255:

3175:

3130:

2851:

2220:

2163:

2020:

1663:

1659:

1550:

803:

605:

528:

422:

396:

made by the Brush Motor

Company. Today, coil springs are used in most cars.

321:

3003:

2960:

2931:

765:

of a spring is the change in the force it exerts, divided by the change in

3503:

3160:

2196:

2152:

2129:

2024:

1998:

1852:

1836:

1680:

1595:

is, unlike the Citroën system, not height-adjustable, or self-levelling.

1427:

1420:

1284:

329:

310:

306:

168:

2790:"After 30 years, Bose-developed suspension tech will go into production"

1573:. This system, manufactured under licence by Dunlop in Coventry, called

1543:

was also an early adopter of interconnected suspension. A system dubbed

1615:

1443:

developed several prototypes from 1982 onwards, and introduced them to

968:

775:

570:

558:

437:

340:

210:

163:

3077:

3674:

3488:

2076:

1848:

1537:

at the front with telescopic dampers/shock absorbers front and rear.

1450:

609:

1683:

that link the wheels in some way, are still classed as independent.

1993:

1447:, where they have been fairly effective, but have now been banned.

3659:

3563:

2072:

2003:

1992:

1918:

1811:

1625:

1310:

723:

586:

375:

361:

276:

246:

214:

194:

178:

162:

154:

2747:"Bose's Revolutionary Adaptive Suspension Gets a Reboot for 2019"

2448:"2022 Rivian R1T First Drive Review: Electric Off-Road Dominance"

2317:. Wilkesbarre, Pennsylvania: Sheldon Axle Company. 1912. p.

313:, and steel springs in larger vehicles. These were often made of

3681:

3170:

2314:

Leaf

Springs: Their Characteristics and Methods of Specification

2062:

2016:

1562:

1292:

846:, but can also be changed through the use of different springs.

816:

639:, as independent rear suspensions do, it made them last longer.

302:

226:

3364:

3081:

1603:, and was used on several models; the last car to use it being

3402:

2001:

tank's suspension has road wheels mounted on wheel trucks, or

1506:

had some success with various passive or semi-active systems (

992:

853:

657:

451:

421:

The part on which pre-1950 springs were supported is called a

52:

3360:

2701:"Bose Sells Off Its Revolutionary Electromagnetic Suspension"

1787:

The variety of independent systems is greater, and includes:

2837:

2065:'s suspension was directly descended from Christie designs.

347:. The British steel springs were not well-suited for use on

1885:

The most common type of semi-independent suspension is the

646:

to locate the rear wheels securely, while providing decent

328:, with little success at first. The use of leaf springs in

256:

3005:

Car suspension : repair, maintenance and modification

317:

and usually took the form of multiple layer leaf springs.

1866:, optimal camber change when turning, is more important.

577:

and two narrow rods. The torque tube surrounded the true

2166:— a Greek all-terrain supercar, with a unique suspension

1515:

527:, rear suspension has few constraints, and a variety of

2498:"BMW Technology Guide : Self-levelling suspension"

448:

Difference between rear suspension and front suspension

410:

In 1922, independent front suspension was pioneered on

171:

mechanism: tie rod, steering arm, king pin axis (using

1295:. A number of different types of each have been used:

1167:

Flexibility and vibration modes of suspension elements

444:

in secrecy, but has since spread to wider motorsport.

1553:, and went on to be used on a variety of BMC models.

1092:

the resistance to fluid flow in the shock absorber.

3732:

3647:

3464:

3411:

3285:

3269:

3248:

3238:

3204:

3113:

83:. Unsourced material may be challenged and removed.

2341:. London, United Kingdom: Charles Knight & Co.

1378:bounces up and down on the springiness of a tire.

1403:Semi-active suspensions include devices, such as

436:. This has the ability to increase the effective

428:In 2002, a new passive suspension component, the

1618:models also featured interconnected suspension.

1326:– AKA Hotchkiss, Cart, or semi-elliptical spring

1201:Contribution to unsprung weight and total weight

2223:— a part to make a suspension setup more rigid.

1730:used for location (transverse or longitudinal)

2644:"Suspension Basics 9 - Hydropneumatic Springs"

2425:. London: Tata McGraw-Hill. pp. 293–294.

2075:, but nonetheless independent, suspensions of

1489:weight, reliability, and/or other challenges.

1469:introduced an active suspension system called

1171:In some modern cars, flexibility is mainly in

320:Leaf springs have been around since the early

3376:

3093:

2915:Encyclopedia of German Tanks of World War Two

2472:Milliken, William; Milliken, Douglas (1994).

8:

2962:Automotive suspension & steering systems

2524:"Suspension Basics 4 - Torsion Bar Springs"

1977:Some vehicles, such as trains, run on long

1453:introduced low-bandwidth active suspension

1027:. Unsourced material may be challenged and

888:. Unsourced material may be challenged and

692:. Unsourced material may be challenged and

486:. Unsourced material may be challenged and

3383:

3369:

3361:

3245:

3100:

3086:

3078:

3036:: CS1 maint: location missing publisher (

2993:: CS1 maint: location missing publisher (

2810:. Amt.nl. 19 November 2008. Archived from

2402:. chroniclingamerica.loc.gov. 30 June 1901

1941:) which increases the speed at cornering.

1611:manufacturing line was over 40 years old.

1264:Most conventional suspensions use passive

3066:The ABCs of Chassis Frame and Suspensions

2251:Vehicle Dynamics: Theory and Applications

1937:Some trains also use tilting suspension (

1630:Common types seen from behind; in order:

1357:Gas and hydraulic fluid under pressure -

1047:Learn how and when to remove this message

985:, the more jacking force is experienced.

908:Learn how and when to remove this message

712:Learn how and when to remove this message

506:Learn how and when to remove this message

143:Learn how and when to remove this message

2053:was developed, which allowed the use of

1963:This kind of suspension was used in the

1768:

1407:and switchable shock absorbers, various

44:For broader coverage of this topic, see

2476:. SAE International. pp. 617–620.

2237:

1704:Examples of location linkages include:

3029:

2986:

2584:"Suspension Basics 6 - Rubber Springs"

2283:"Suspension Basics 1 - Why We Need It"

305:. Within a decade, most British horse

2446:Moloughney, Tom (28 September 2021).

2350:

2348:

2203:- conceptually similar to automobile

1662:(a simple 'cart' axle) or a (driven)

1557:was developed by suspension engineer

1100:See dependent and independent below.

822:By 2021, some vehicles were offering

281:The front suspension components of a

7:

2913:Peter Chamberlain and Hilary Doyle,

2836:. Australia: Kinetic. Archived from

2554:"Suspension Basics 5 - Coil Springs"

2356:"Suspension Basics 3 - Leaf Springs"

2138:– a test rig for high-speed vehicles

2115:Automotive suspension design process

1989:Armoured fighting vehicle suspension

1411:solutions, as well as systems, like

1287:and rubber cone systems used by the

1025:adding citations to reliable sources

886:adding citations to reliable sources

690:adding citations to reliable sources

484:adding citations to reliable sources

81:adding citations to reliable sources

3809:Armoured fighting vehicle equipment

3052:Tie Rods Part of Suspension Systems

2614:"Suspension Basics 8 - Air Springs"

1197:mainly in the vertical direction.)

1192:Isolation from high frequency shock

351:'s rough roads of the time, so the

3804:Automotive suspension technologies

3499:Continuously variable transmission

2421:Jain, K.K.; Asthana, R.B. (2002).

1773:Rear independent suspension on an

1382:Semi-active and active suspensions

741:- maximum to minimum demonstration

25:

2699:Howard, Bill (15 November 2017).

2674:"Technical Development | Chassis"

1315:Pneumatic spring on a semitrailer

167:Part of car front suspension and

3778:

3777:

3767:

997:

858:

662:

565:to restrain this force, for his

456:

378:first fitted an automobile with

57:

2873:Harris, William (11 May 2005).

2834:"Kinetic Suspension Technology"

2726:Cheromcha, Kyle (22 May 2018).

2335:Adams, William Bridges (1837).

623:Another Frenchman invented the

255:An early form of suspension on

68:needs additional citations for

27:Suspension system for a vehicle

3073:Suspension Geometry Calculator

1461:). A fully active system from

618:Corporate Average Fuel Economy

1:

3534:Automated manual transmission

2029:Central Tire Inflation System

1587:system, and provides similar

1239:Certain modern vehicles have

654:Spring, wheel, and roll rates

581:and exerted the force to its

3141:Electronic Stability Control

2808:"Electromagnetic suspension"

2195:- design used in most large

2090:, the other common type was

1843:, and the early examples of

1827:Semi-trailing arm suspension

1634:Live axle with a Watt's link

1271:Some notable exceptions are

1241:height adjustable suspension

826:with ride-height adjustable

3609:Semi-automatic transmission

2965:(7th ed.). Australia.

2933:Car suspension and handling

2852:"Alex Moulton Mgf Hydragas"

2745:Chin, Chris (21 May 2018),

2388:. Encyclopaedia Britannica.

2142:Ackermann steering geometry

1877:Semi-independent suspension

1510:: three Championships; the

1482:electromagnetic suspensions

938:is said to be "geometric".

546:layout has been difficult.

233:of a car may be different.

186:RF01 Racing Car Suspension.

39:Suspension (disambiguation)

32:Driver's license suspension

3835:

3446:Internal combustion engine

2875:"How Car Suspensions Work"

2772:"How Car Suspensions Work"

2338:English Pleasure Carriages

2215:Short long arms suspension

2199:, with compressed gas and

2189:- vehicle ground clearance

2013:armoured fighting vehicles

1948:

1780:

1691:Twist-beam rear suspension

1643:Double wishbone suspension

1614:Some of the last post-war

1599:was introduced in 1973 on

1549:was introduced in 1962 on

1503:hydropneumatic suspensions

1493:Interconnected suspensions

1385:

1369:Dampers or shock absorbers

919:

749:

240:

43:

36:

29:

3763:

3745:Hybrid vehicle drivetrain

3634:Transmission control unit

3574:Limited-slip differential

3539:Electrorheological clutch

3398:

2474:Race Car Vehicle Dynamics

2205:Hydropneumatic suspension

2149:– self centering steering

1908:Leaning Suspension System

1904:Tilting Suspension System

1898:Tilting Suspension System

1541:British Motor Corporation

1428:magneto-rheological fluid

1359:hydropneumatic suspension

1289:British Motor Corporation

1186:Self-levelling suspension

739:Hydropneumatic suspension

608:. These springs transmit

3524:Dual-clutch transmission

3059:How Car Suspensions Work

3002:Spender, Julian (2019).

1743:, before and soon after

1143:Anti-dive and anti-squat

942:Unsprung weight transfer

407:in a suspension system.

30:Not to be confused with

3494:Constant-velocity joint

2959:Schnubel, Mark (2020).

2930:Bastow, Donald (2004).

2254:. Spring. p. 455.

1765:Independent suspensions

1473:in its top-of-the-line

533:independent suspensions

3474:Automatic transmission

2423:Automobile Engineering

2400:"The Washington Times"

2092:torsion bar suspension

2034:The earliest tanks of

2008:

1945:Rocker bogie mechanism

1783:Independent suspension

1778:

1676:Independent suspension

1651:

1475:Mercedes-Benz CL-Class

1330:Torsion bar suspension

1316:

1291:, most notably on the

955:Sprung weight transfer

834:Roll couple percentage

830:and adaptive dampers.

742:

544:independent suspension

416:independent suspension

367:

357:Concord, New Hampshire

286:

252:

187:

176:

160:

46:Suspension (mechanics)

2500:. BMW. Archived from

2125:Multi-link suspension

1996:

1822:Multi-link suspension

1772:

1697:Dependent suspensions

1629:

1351:Gas under pressure -

1314:

1235:Air resistance (drag)

750:Further information:

734:

644:multi-link suspension

365:

353:Abbot-Downing Company

341:construction of roads

280:

250:

182:

166:

158:

3579:Locking differential

3514:Direct-shift gearbox

2386:"wagon and carriage"

2158:Corvette leaf spring

2069:Horstmann suspension

1656:dependent suspension

1569:for BMC's successor

1021:improve this section

882:improve this section

824:dynamic roll control

781:Performance vehicles

686:improve this section

569:was attached to the

480:improve this section

418:on all four wheels.

388:first appeared on a

77:improve this article

37:For other uses, see

3604:Preselector gearbox

3584:Manual transmission

3108:Automotive handling

2594:on 28 November 2014

2175:Magnetic levitation

2051:Christie suspension

1906:(also known as the

1847:, and the backs of

1533:. Later models had

1471:Active Body Control

1299:Passive suspensions

1260:Springs and dampers

3814:Vehicle technology

3750:Electric generator

3655:Wheel hub assembly

3064:Robert W. Temple,

2678:75 Years of TOYOTA

2654:on 29 January 2015

2624:on 29 January 2015

2293:on 29 January 2015

2170:List of auto parts

2015:(AFVs), including

2009:

1779:

1741:Ford Motor Company

1693:is such a system.

1652:

1535:tuned mass dampers

1531:tuned mass dampers

1317:

1227:Force distribution

1109:Roll center height

770:more significant.

743:

432:, was invented by

390:production vehicle

368:

287:

253:

188:

177:

161:

3791:

3790:

3544:Epicyclic gearing

3413:Automotive engine

3358:

3357:

3354:

3353:

3347:

3344:Semi-trailing arm

3320:

3303:

3015:978-1-78500-661-6

2972:978-1-337-56733-6

2943:978-1-4686-0339-2

2840:on 11 April 2009.

2814:on 4 January 2010

1983:continuous tracks

1435:active suspension

1388:Active suspension

1218:MacPherson struts

1074:off-road vehicles

1057:

1056:

1049:

918:

917:

910:

804:natural frequency

732:

722:

721:

714:

620:(CAFE) standard.

522:front-wheel drive

516:

515:

508:

295:industrialisation

273:Modern suspension

193:is the system of

153:

152:

145:

127:

18:Suspension system

16:(Redirected from

3826:

3819:Vehicle dynamics

3781:

3780:

3771:

3648:Wheels and tires

3619:Torque converter

3385:

3378:

3371:

3362:

3341:

3314:

3312:MacPherson strut

3297:

3270:Semi-independent

3246:

3191:Vehicle dynamics

3102:

3095:

3088:

3079:

3068:, September 1969

3041:

3035:

3027:

2998:

2992:

2984:

2955:

2918:

2911:

2905:

2904:

2897:

2891:

2890:

2888:

2886:

2870:

2864:

2863:

2861:

2859:

2848:

2842:

2841:

2830:

2824:

2823:

2821:

2819:

2804:

2798:

2797:

2786:

2780:

2779:

2768:

2762:

2761:

2760:

2758:

2742:

2736:

2735:

2723:

2717:

2716:

2714:

2712:

2696:

2690:

2689:

2687:

2685:

2670:

2664:

2663:

2661:

2659:

2650:. Archived from

2640:

2634:

2633:

2631:

2629:

2620:. Archived from

2610:

2604:

2603:

2601:

2599:

2590:. Archived from

2580:

2574:

2573:

2571:

2569:

2560:. Archived from

2550:

2544:

2543:

2541:

2539:

2530:. Archived from

2520:

2514:

2513:

2511:

2509:

2494:

2488:

2487:

2469:

2463:

2462:

2460:

2458:

2443:

2437:

2436:

2418:

2412:

2411:

2409:

2407:

2396:

2390:

2389:

2382:

2376:

2375:

2373:

2371:

2362:. Archived from

2352:

2343:

2342:

2332:

2326:

2325:

2309:

2303:

2302:

2300:

2298:

2289:. Archived from

2279:

2273:

2272:

2270:

2268:

2242:

2227:Other suspension

2120:MacPherson strut

1973:Tracked vehicles

1915:MacPherson strut

1810:Upper and lower

1802:MacPherson strut

1463:Bose Corporation

1246:aerodynamic drag

1135:center as well.

1052:

1045:

1041:

1038:

1032:

1001:

993:

989:Other properties

913:

906:

902:

899:

893:

862:

854:

733:

717:

710:

706:

703:

697:

666:

658:

629:universal joints

537:rear-wheel drive

511:

504:

500:

497:

491:

460:

452:

434:Malcolm C. Smith

315:low-carbon steel

209:that connects a

148:

141:

137:

134:

128:

126:

92:"Car suspension"

85:

61:

53:

21:

3834:

3833:

3829:

3828:

3827:

3825:

3824:

3823:

3794:

3793:

3792:

3787:

3759:

3728:

3643:

3639:Universal joint

3569:Hotchkiss drive

3460:

3407:

3394:

3389:

3359:

3350:

3295:Double wishbone

3281:

3265:

3234:

3200:

3196:Weight transfer

3109:

3106:

3048:

3028:

3016:

3001:

2985:

2973:

2958:

2944:

2929:

2926:

2924:Further reading

2921:

2912:

2908:

2899:

2898:

2894:

2884:

2882:

2881:. United States

2872:

2871:

2867:

2857:

2855:

2850:

2849:

2845:

2832:

2831:

2827:

2817:

2815:

2806:

2805:

2801:

2794:Motor Authority

2788:

2787:

2783:

2770:

2769:

2765:

2756:

2754:

2744:

2743:

2739:

2725:

2724:

2720:

2710:

2708:

2698:

2697:

2693:

2683:

2681:

2672:

2671:

2667:

2657:

2655:

2642:

2641:

2637:

2627:

2625:

2612:

2611:

2607:

2597:

2595:

2582:

2581:

2577:

2567:

2565:

2552:

2551:

2547:

2537:

2535:

2522:

2521:

2517:

2507:

2505:

2496:

2495:

2491:

2484:

2471:

2470:

2466:

2456:

2454:

2445:

2444:

2440:

2433:

2420:

2419:

2415:

2405:

2403:

2398:

2397:

2393:

2384:

2383:

2379:

2369:

2367:

2354:

2353:

2346:

2334:

2333:

2329:

2311:

2310:

2306:

2296:

2294:

2281:

2280:

2276:

2266:

2264:

2262:

2244:

2243:

2239:

2235:

2201:hydraulic fluid

2111:

1991:

1975:

1953:

1947:

1931:super-elevation

1923:double wishbone

1900:

1895:

1893:Other instances

1879:

1816:double wishbone

1785:

1767:

1724:Mumford linkage

1699:

1658:normally has a

1649:

1624:

1571:British Leyland

1495:

1390:

1384:

1371:

1309:

1301:

1262:

1254:

1237:

1229:

1214:

1203:

1194:

1181:

1173:rubber bushings

1169:

1145:

1124:

1111:

1098:

1082:

1062:

1053:

1042:

1036:

1033:

1018:

1002:

991:

978:

957:

944:

924:

922:Weight transfer

914:

903:

897:

894:

879:

863:

852:

850:Weight transfer

836:

812:

789:

763:spring constant

754:

748:

724:

718:

707:

701:

698:

683:

667:

656:

637:unsprung weight

602:Hotchkiss drive

552:

512:

501:

495:

492:

477:

461:

450:

392:in 1906 in the

380:shock absorbers

275:

245:

239:

231:rear suspension

203:shock absorbers

149:

138:

132:

129:

86:

84:

74:

62:

49:

42:

35:

28:

23:

22:

15:

12:

11:

5:

3832:

3830:

3822:

3821:

3816:

3811:

3806:

3796:

3795:

3789:

3788:

3786:

3785:

3775:

3764:

3761:

3760:

3758:

3757:

3752:

3747:

3742:

3740:Electric motor

3736:

3734:

3730:

3729:

3727:

3726:

3725:

3724:

3719:

3714:

3709:

3704:

3699:

3694:

3689:

3679:

3678:

3677:

3672:

3667:

3657:

3651:

3649:

3645:

3644:

3642:

3641:

3636:

3631:

3626:

3621:

3616:

3611:

3606:

3601:

3596:

3591:

3586:

3581:

3576:

3571:

3566:

3561:

3556:

3554:Friction drive

3551:

3549:Fluid coupling

3546:

3541:

3536:

3531:

3526:

3521:

3516:

3511:

3506:

3501:

3496:

3491:

3486:

3481:

3476:

3470:

3468:

3462:

3461:

3459:

3458:

3453:

3448:

3443:

3440:Plug-in hybrid

3433:

3428:

3423:

3417:

3415:

3409:

3408:

3399:

3396:

3395:

3390:

3388:

3387:

3380:

3373:

3365:

3356:

3355:

3352:

3351:

3349:

3348:

3336:

3331:

3329:Sliding pillar

3326:

3321:

3309:

3304:

3291:

3289:

3283:

3282:

3280:

3279:

3273:

3271:

3267:

3266:

3264:

3263:

3258:

3252:

3250:

3243:

3236:

3235:

3233:

3232:

3227:

3222:

3217:

3211:

3209:

3202:

3201:

3199:

3198:

3193:

3188:

3183:

3178:

3173:

3168:

3163:

3158:

3153:

3148:

3143:

3138:

3133:

3128:

3126:Center of mass

3123:

3117:

3115:

3111:

3110:

3107:

3105:

3104:

3097:

3090:

3082:

3076:

3075:

3070:

3061:

3055:

3054:

3047:

3046:External links

3044:

3043:

3042:

3014:

3008:. Wiltshire .

2999:

2971:

2956:

2942:

2925:

2922:

2920:

2919:

2906:

2892:

2865:

2843:

2825:

2799:

2796:. 15 May 2018.

2781:

2778:. 11 May 2005.

2763:

2751:Digital Trends

2737:

2718:

2691:

2680:. Toyota. 2012

2665:

2635:

2605:

2575:

2545:

2534:on 10 May 2010

2515:

2504:on 16 May 2018

2489:

2483:978-1560915263

2482:

2464:

2438:

2431:

2413:

2391:

2377:

2344:

2327:

2304:

2274:

2260:

2246:Jazar, Reza N.

2236:

2234:

2231:

2230:

2229:

2224:

2218:

2212:

2207:

2190:

2184:

2183:

2182:

2172:

2167:

2161:

2155:

2150:

2144:

2139:

2133:

2127:

2122:

2117:

2110:

2107:

1990:

1987:

1974:

1971:

1949:Main article:

1946:

1943:

1899:

1896:

1894:

1891:

1878:

1875:

1859:

1858:

1857:

1856:

1841:Panhard Dyna Z

1829:

1824:

1819:

1808:

1799:

1797:Sliding pillar

1794:

1781:Main article:

1766:

1763:

1751:

1750:

1749:

1748:

1737:

1734:

1725:

1722:

1719:

1717:Watt's linkage

1714:

1709:

1698:

1695:

1687:Semi-dependent

1648:

1647:

1644:

1641:

1638:

1637:Sliding pillar

1635:

1631:

1623:

1620:

1601:Austin Allegro

1585:hydropneumatic

1494:

1491:

1413:hydropneumatic

1409:self-levelling

1386:Main article:

1383:

1380:

1370:

1367:

1366:

1365:

1355:

1349:

1338:

1337:

1332:

1327:

1308:

1305:

1300:

1297:

1273:hydropneumatic

1261:

1258:

1253:

1250:

1236:

1233:

1228:

1225:

1213:

1212:Space occupied

1210:

1202:

1199:

1193:

1190:

1180:

1179:Load levelling

1177:

1168:

1165:

1144:

1141:

1123:

1122:Instant center

1120:

1110:

1107:

1097:

1096:Camber control

1094:

1081:

1078:

1061:

1058:

1055:

1054:

1005:

1003:

996:

990:

987:

977:

976:Jacking forces

974:

956:

953:

943:

940:

920:Main article:

916:

915:

866:

864:

857:

851:

848:

844:anti-roll bars

835:

832:

828:air suspension

811:

808:

788:

785:

747:

744:

720:

719:

670:

668:

661:

655:

652:

551:

548:

535:are used. For

514:

513:

464:

462:

455:

449:

446:

401:Leyland Motors

394:Brush Runabout

274:

271:

238:

235:

151:

150:

65:

63:

56:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

3831:

3820:

3817:

3815:

3812:

3810:

3807:

3805:

3802:

3801:

3799:

3784:

3776:

3774:

3770:

3766:

3765:

3762:

3756:

3753:

3751:

3748:

3746:

3743:

3741:

3738:

3737:

3735:

3731:

3723:

3720:

3718:

3715:

3713:

3710:

3708:

3705:

3703:

3700:

3698:

3695:

3693:

3690:

3688:

3685:

3684:

3683:

3680:

3676:

3673:

3671:

3668:

3666:

3663:

3662:

3661:

3658:

3656:

3653:

3652:

3650:

3646:

3640:

3637:

3635:

3632:

3630:

3627:

3625:

3622:

3620:

3617:

3615:

3614:Shift-by-wire

3612:

3610:

3607:

3605:

3602:

3600:

3597:

3595:

3592:

3590:

3587:

3585:

3582:

3580:

3577:

3575:

3572:

3570:

3567:

3565:

3562:

3560:

3557:

3555:

3552:

3550:

3547:

3545:

3542:

3540:

3537:

3535:

3532:

3530:

3527:

3525:

3522:

3520:

3517:

3515:

3512:

3510:

3507:

3505:

3502:

3500:

3497:

3495:

3492:

3490:

3487:

3485:

3482:

3480:

3477:

3475:

3472:

3471:

3469:

3467:

3463:

3457:

3454:

3452:

3451:Petrol engine

3449:

3447:

3444:

3441:

3437:

3434:

3432:

3429:

3427:

3424:

3422:

3421:Diesel engine

3419:

3418:

3416:

3414:

3410:

3406:

3404:

3397:

3393:

3386:

3381:

3379:

3374:

3372:

3367:

3366:

3363:

3345:

3340:

3337:

3335:

3332:

3330:

3327:

3325:

3322:

3318:

3317:Chapman strut

3313:

3310:

3308:

3305:

3301:

3296:

3293:

3292:

3290:

3288:

3284:

3278:

3275:

3274:

3272:

3268:

3262:

3259:

3257:

3254:

3253:

3251:

3247:

3244:

3241:

3237:

3231:

3228:

3226:

3223:

3221:

3218:

3216:

3213:

3212:

3210:

3207:

3203:

3197:

3194:

3192:

3189:

3187:

3186:Unsprung mass

3184:

3182:

3179:

3177:

3174:

3172:

3169:

3167:

3164:

3162:

3159:

3157:

3154:

3152:

3151:Inboard brake

3149:

3147:

3144:

3142:

3139:

3137:

3134:

3132:

3129:

3127:

3124: