31:

1078:, and a single manual fireman. Owing to the single-ended firing and the predominantly longitudinal gasflow, compared to the Yarrow's normal through-bank gasflow, there was a pronounced temperature difference between the front and back of the boiler. This led to the water circulation currents, especially in the second section, to be longitudinal through the water drums, like the Woolnough, rather than the usual Yarrow. The first section, which included some water-tubes to the rear wall, was radiant heated and effectively a water-wall furnace, without any gas flow through the tube bank. Despite this, it still used four rows of tubes. The second section had its gasflow arranged by steel and firebrick baffles so that the combustion gases entered through the centre and passed through the tube banks into the side flues, giving better convective heat transfer.

88:

497:

717:

741:

96:

425:. The outer bank of tubes was shallow, consisting of only two rows of tubes. These rows were spaced closely, so that the tubes formed a solid wall, without gasflow between them. The inner bank of tubes was similar: the two rows of tubes closest to the furnace formed a similar water wall. These tubes were splayed apart at their base, so as to provide space for gasflow between them. Within the tube bank, gas flow is mostly parallel to the tubes, similar to some early designs, but contrary to the crossflow design of later three-drum boilers. The exhaust gas emerged into the heart-shaped space below the upper central drum, exiting to the funnel through the rear wall.

709:

988:

272:

sufficiently straight that a single tube could be replaced from a tube bank, without requiring other tubes to be removed so as to permit access. This was one of many features of the White-Forster intended to make it reliable in naval service and easy to maintain. These tubes were of particularly small diameter, only 1 inch (2.5 cm) and especially numerous, a total of 3,744 being used in some boilers. The tubes were arranged in 24 rows to a bank, each requiring a different length of tube, and 78 rows per drum. All tubes were curved to the same radius, facilitating repair and replacement on board, but requiring the tube holes in the drums to be

407:

469:

104:

1066:. The forward "boiler" region was narrow-set, with its water drums placed between the frames. Although the outer casings were of similar width, the tube banks for the forward section were much closer. The space outboard of the tubes formed a pair of exhaust flues leading forwards. A large space outside these flue walls but inside the boiler casing was used as an air duct from the air inlet, a crude rectangular slot beneath the smokebox door, which had the effect of both pre-heating the combustion air and of cooling the outer casing to prevent overheating. Longitudinal

765:, once outwards and then again inwards. A single central chimney exhausted from the centre of the far end, not as usual from outside the tubes. The relative temperature difference between gas passage through the two sections of the bank led to a circulation current that was upwards through the first, hotter, part of the bank and downwards through the further, less hot, bank. Circulation was also controlled by an internal weir plate within the upper water drum, so as to keep a depth of water above the ends of the hotter tubes, thus avoiding overheating of dry tubes.

732:, intended for use in smaller boats. The tube banks separated into two groups, with the short tubes slightly curved away from each other. Entry into the lower water drum was perpendicular, requiring an almost rectangular drum with the tubes entering on separate faces. The mechanical weakness of such a shape was acceptable in this small size, but limited the boiler's potential. The casing was small and only enclosed part of the upper steam drum, leading directly to a funnel. A single inverted tee-shaped downcomer linked the drums at the rear of the boiler.

316:

377:

612:

829:

193:

unworkable for boilers like the

Thornycroft where the tubes first travelled horizontally or upwards. The eventual method was to use 'bullet' brushes that were fired from one drum into the other by use of compressed air. Sets of brushes were used, one for each tube, and they were carefully numbered and counted afterwards to ensure that none had been left behind, blocking a tube.

537:

Early water-tube designers had been concerned with the expansion of the boiler's tubes when heated. Efforts were made to permit them to expand freely, particularly so that those closest to the furnace might expand relatively more than those further away. Typically this was done by arranging the tubes

885:

The first boilers suffered problems with the superheaters and with poor circulation for the tube rows in the centre of the bank, leading to overheating and tube failure. The circulation problems were addressed by re-arranging the feedwater pipes and by placing baffles inside the steam drum, so as to

356:

from which to collect dry steam. The external boiler casing entered the flue uptake at one end, usually enclosing this dome. The ends of the drums extended outside the casing as hemispherical domes. Cold downcomers outside the casing linked these drums, providing a path for the return circulation of

280:

Downcomers were used, either the usual two large pipes, or an unusual but characteristic arrangement of four small 4-inch (10 cm) tubes to each drum. This was a feature intended to improve survivability after damage, when used on-board warships. The boiler could remain in service with a damaged

288:

were raised above the floor of the furnace on steel girder stools, increasing the furnace volume available for combustion. This feature was intended to encourage the use of oil burning, an innovation on warships around this time. The general appearance of the White-Forster is similar to that of the

176:

had demonstrated that straight tubes did not cause any problems with expansion, but circular drums and perpendicular tube entry were both valuable features for a long service life. Where tubes entered drums at an angle, heating and cooling tended to bend the tube back and forth, leading to leaks. A

1070:

tubes were placed in the central space between the steam generating tubes. The third area forwards contained superheater headers, the regulators and the smokebox, but no deliberate heating surface. The external boiler casing remained at much the same width throughout, giving an overall triangular,

962:

casing and did not form a closely packed solid wall. The concern was that a full water-wall would unbalance the existing header arrangement of the three-drum boiler, which indeed showed to be the case. Excess steam production at the rear of the steam drum led to disrupted circulation and a problem

649:

The circulation in a Yarrow boiler depended on a temperature difference between the inner and outer tube rows of a bank, and particularly upon the rates of boiling. Whilst this is easy to maintain at low powers, a higher pressure Yarrow boiler will tend to have less temperature difference and thus

131:

The new generation of "small-tube" water-tube boilers used water-tubes of around 2 inches (5 cm) diameter, compared to older designs of 3 or 4 inches. This gave a greater ratio of tube surface heating area to the tube volume, thus more rapid steaming. These small-tube boilers also became

480:

pattern, made the outer wings more important. The number of their tubes was increased, such that they became the majority of the heating surface and the main gas path for the exhaust gases. The wing drums became large enough to permit a man access inside, for cleaning and expanding new tubes into

435:

The upper and lower central drums are linked by downcomers. Unusually these are internal to the boiler and are heated, although not strongly, by the exhaust gases. They are formed as several (eight or nine) 4-inch (10 cm) vertical tubes on the centreline of the boiler. They are formed into a

259:. Water tubes were convoluted, arranged in four rows to a bank, and S-shaped with sharp right angle bends. This packed a large tube heating area into a small volume, but made tube cleaning impractical. The drums were cylindrical, with perpendicular tube entry and external downcomers between them.

192:

internally. Tubes were later cleaned internally by attempting to pass a hinged rod through, with a brush at the end. For the curved tube designs, often only part of the tube could be reached. Another method was to pass a chain down the tube from above, pulling a brush behind it, although this was

151:

The development of the three-drum pattern was generally one of simplification, rather than increasing complexity or sophistication. Even the first boilers packed a large heating area into a compact volume, their difficulty was in manufacturing and particularly for their maintenance on-board ship.

760:

wall two-thirds of the way down the furnace. The furnace grate was on the longer side of this, with the combustion gases passing out through the tube bank, along inside a steel outer casing, then back within the shorter tube bank. Coiled tube superheaters were placed in the gas flow outside the

871:

were sometimes, but not always, used. The only major difference was in the tube banks. Rather than straight tubes, each tube was mostly straight, but slightly cranked towards their ends. These were installed in two groups within the bank, so that they formed a gap between them within the bank.

271:

was of simple construction, with tubes that had only a gentle curvature to them. This was sufficient to allow them to be replaced in-situ, working through the manhole at the end of the large steam drum. Each tube was sufficiently curved to allow it to be extracted through the steam drum, but

276:

to precise angles on a jig during manufacture. This small tube diameter gave a high heating surface, but probably too much: the ratio of surface to volume became excessive and gas flow through the tube banks was affected, giving the boiler furnaces something of a reputation as poor burners.

876:

this gap and hung by hooks from the steam drum. The advantage of placing the superheaters here was that they increased the temperature differential between the inner and outer tubes of the bank, thus encouraging circulation. In the developed form, the boiler had four rows of tubes on the

1058:, placed end to end. Both had the usual Yarrow arrangement of a central large steam drum above two separated water drums, linked by four rows of slightly curved tubes. The upper drum was shared, but the lower water drums were separate. The rearward "firebox" area was wide and spanned the

351:

The design of the

Normand gave a particularly large heating area (tube surface area) in relation to the grate area. The cost of this was a dense nest of tubes, where each of the numerous rows of tubes was bent into a different and complex shape. Tube ends entered the cylindrical drums

571:, did not appear for another thirty years and even then they were initially unreliable. The assumption was that flow through the water-tubes would be upwards, owing to their heating by the furnace, and that the counterbalancing downward flow would require external unheated

420:

boiler is a variant that splits the usual central furnace into two. There are four drums: two main drums vertically in the centre – a steam and a water drum – also two wing drums at the outside edges of the furnace. The design was notable for its early use of the

906:, the feedwater was also routed upwards through 'spray pots' and thus passed through the steam space as droplets. The cold feedwater was thus heated to the same temperature as the boiler water before mixing with it, avoiding disturbance to the circulation path.

205:

were used by most designs, even after Yarrow's experiments had demonstrated that circulation could still take place amongst the heated tubes alone. Again, the

Admiralty boiler (which omitted downcomers) was the culmination of this approach, placing the

541:

Yarrow recognised that the temperature of the water-tubes was held relatively low and was consistent amongst them, provided that they remained full of water and boiling was not allowed to occur within the tubes themselves, i.e. they would remain as

628:

This D shape is not ideal for a pressure drum though, as pressure will tend to distort it into a more circular section. This flexing led to leakage where the water tubes entered the drum; a problem, termed 'wrapperitis', which was shared with the

624:

The first Yarrow water drums or "troughs" were D-shaped with a flat tubeplate, so as to provide an easy perpendicular mounting for the tubes. The tubeplate was bolted to the trough and could be dismantled for maintenance and tube cleaning.

30:

524:

were lagging behind other shipbuilders. His initial thoughts already defined the key features of the design, a three-drum boiler with straight tubes, yet it took ten years of research before the first boiler was supplied for a

602:

The Yarrow boiler could thus dispense with separate external downcomers. Flow was entirely within the heated watertubes, upwards within those closest to the furnace and downwards through those in the outer rows of the bank.

119:

Development of the three-drum boiler began in the late 19th century, with the demand from naval ships that required high power and a compact boiler. The move to water-tube boilers had already begun, with designs such as the

918:

performance was disappointing. Superheat at full power was limited deliberately to 100 °F (37.8 °C) so as to avoid reliability problems, which then meant that it was ineffective at low powers. Development work by

666:

after 1900, the first Yarrow boilers placed their superheater coil outside the main tube bank. Later designs became asymmetrical, with the tube bank on one side doubled and a hairpin-tube superheater placed between them.

957:

constructed a trial boiler with a partial water-wall to the rear of the furnace. Unlike other water-wall designs, this additional water drum spanned only the centre of the furnace, the vertical tubes were enclosed in a

49:. They are compact and of high evaporative power, factors that encourage this use. Other boiler designs may be more efficient, although bulkier, and so the three-drum pattern was rare as a land-based stationary boiler.

945:

Unlike contemporary

American practice, British naval boilers had a large proportion of furnace brickwork, leading to a high temperature within the furnace and consequently a high loading upon the tubes. The use of a

460:. The first small version of this also dispensed with the wing drum, the water-wall tubes bending at right angles and passing back to the central water drum, the tubes also forming the grate to support the fire.

335:. It was used by the navies of several nations, notably those of France, Russia, Britain and United States. In 1896, the Royal Navy had them installed in twenty-six boats, more than any other water-tube design.

3155:

436:

shallow S-shape to give a little flexibility against thermal expansion. The small wing drums are connected to the lower central drum alone, by large external pipes outside the rear casing of the boiler.

923:

resolved this by increasing the steam flow speed through the superheater to 150 ft/s (45.72 m/s), avoiding the problems of tube distortion and metallurgical failure. New boilers for the

890:, a steel trough, was placed over the tops of the furnace-side tubes, encouraging a single central upwelling flow to above the water level, encouraging steam bubbles to escape and acting as a

428:

The steam drum is circular, with perpendicular tube entry. The tube ends span a considerable circumference of the drum, so that the upper tubes enter above the water level. They are thus '

696:

with a Yarrow boiler for comparison. The trials were successful and the Yarrow boiler was adopted for naval service, particularly in small ships. In time the Navy would develop its own

2175:

820:, but first shipped to Belgium for testing. Most photographs that exist of these locomotives were taken in Belgium. Little is known of their history after arrival in Colombia.

172:

were the first to go. A multi-row bank of tubes could provide adequate heating area, without this complexity. Tubes also became straighter, mostly to ease their cleaning.

809:

1036:

The boiler was not the usual Yarrow design. In operation, particularly its circulation paths, the boiler had more in common with other three-drum designs such as the

591:

When heat was also applied to the unheated arm, conventional theory predicted that the circulatory flow would slow or stop completely. In practice, the flow actually

3150:

514:

boiler design is characterised by its use of straight water-tubes, without downcomers. Circulation, both upwards and downwards, occurs within this same tube bank.

352:

perpendicularly, for good sealing. The space needed for all these tubes filled the entire lower half of the steam drum, requiring both a large drum and a separate

87:

496:

364:, where two Normand boilers were coupled back-to-back, for use in large ships. This effectively gave a double-ended Normand (as was later common with the

1891:

1047:

Working pressure was of 450 pounds per square inch (31 bar) as opposed to the 180 pounds per square inch (12 bar) of the contemporary

Gresley

599:

asymmetry to the heating, Yarrow's experiment showed that circulation could continue and heating of the cooler downcomer could even increase this flow.

2168:

1739:

1584:

716:

549:

His conclusion was thus that straight water-tubes were acceptable, and these would have obvious advantages for manufacture and cleaning in service.

864:

of 1927. These boilers established new Royal Navy standard operating conditions for boilers of 300 psi (2.0 MPa) / 600 °F (316 °C).

581:

conducted a famous experiment where he disproved this assumption. A vertical U-shaped tube was arranged so that it could be heated by a series of

488:

design of water-tube boiler used horizontal hairpin water-tubes fitted into sectional headers. It has little relation to the types described here.

3050:

756:

for their larger railway locomotives. It resembled most other three-drum designs, having almost-straight tubes. Its distinguishing feature was a

650:

will have less effective circulation. Some later and higher-pressure boilers were fitted with external downcomers, outside the heated flue area.

177:

perpendicular entry was easier to expand the tubes for a reliable seal and to avoid these sideways stresses. It was worth the compromise of the

1107:

895:

781:

391:

141:

137:

133:

937:

cruisers could achieve a superheat of 200–250 °F (93–121 °C) throughout the operating power range at 250 psi (1.7 MPa).

740:

2161:

95:

3160:

2625:

2620:

1820:

1747:

1687:

1548:

1291:

1264:

1234:

1202:

1147:

987:

777:

557:

It was already recognised that a water-tube boiler relied on a continuous flow through the water-tubes, and that this must be by a

708:

3084:

2996:

1014:

416:

226:. The circular water drums, and their raising above the furnace floor, are White-Forster features. The first reduces the risk of

1095:

867:

The design was broadly similar to later high-pressure and oil-fired versions of the Yarrow. The waterdrums were cylindrical and

894:

before the water re-circulated down the outer-side tubes. In a manner similar to work taking place around the same time on the

468:

3055:

2890:

2699:

2061:

797:

638:

543:

429:

285:

227:

189:

406:

103:

2343:

1308:

853:

2729:

2719:

1224:

3135:

3130:

2923:

2787:

2768:

2759:

2643:

2255:

2198:

588:

When only one side of the U was heated, there was the expected upward flow of heated water in that arm of the tube.

2537:

2004:

1949:

1793:

1281:

1176:

813:

121:

398:. It was similar to the Normand, with downcomers and curved tubes that entered cylindrical drums perpendicularly.

3089:

3078:

2635:

1931:

562:

181:'s bent tube ends to keep these two features, and these tubes were still simple enough in shape to clean easily.

546:. High temperatures and variations only arose when tubes became steam filled, which also disrupted circulation.

3125:

2863:

2795:

1974:

1364:, but later expanded to cover internal combustion engines and so re-titled. London: Longmans. pp. 207–210.

861:

72:

57:

3140:

3099:

3094:

3015:

2739:

2684:

2406:

2362:

1984:

1525:

924:

376:

348:, with the sharp corners of the tubes replaced by a smooth radiused bend, but still retaining the S shape.

140:), most were some variation of this. As the tubes of the three-drum are close to vertical (compared to the

3104:

3002:

2843:

2724:

2375:

2313:

2051:

967:. The development of water-walls for this type of boiler was abandoned, although trials did continue with

964:

785:

682:

440:

385:

304:

76:

768:

Sentinel used the

Woolnough boiler on a number of their larger locomotives, instead of their usual small

3060:

2969:

2694:

2615:

2588:

2318:

2303:

2213:

2127:

2030:

2025:

1813:

1041:

1018:

947:

753:

641:. Later boilers used a more rounded section, although still asymmetrical rather than fully cylindrical.

422:

60:, in a triangular layout. Water tubes fill in the two sides of this triangle between the drums, and the

3029:

611:

315:

2714:

2653:

2514:

2380:

2328:

2265:

2218:

1921:

1896:

1771:

1623:

931:

219:

1564:

1071:

but curved, appearance. The lower edge of each section stepped upwards, and was obvious externally.

3023:

2557:

2431:

2348:

2338:

1994:

1451:

1118:

and thus the circulating water increases, making it more sensitive to disruption by cold feedwater.

1022:

920:

521:

2956:

2950:

2944:

2936:

2931:

2519:

1954:

1906:

1111:

968:

61:

1657:

520:

developed his boiler as a response to other water-tube designs, and his perception in 1877 that

252:

218:

The

Admiralty boiler is usually considered to be a direct evolution of the Yarrow, although the

828:

2820:

2668:

2658:

2607:

2542:

2529:

2509:

2491:

2436:

2390:

2260:

2203:

1959:

1941:

1926:

1911:

1868:

1743:

1683:

1544:

1287:

1260:

1230:

1198:

1143:

1137:

793:

690:

686:

675:

538:

in large looping curves. These had difficulties in manufacturing and required support in use.

443:

248:

125:

42:

1114:

in response to the same problem. As boiler pressure increases, the saturation temperature of

3145:

2896:

2884:

2857:

2583:

2501:

2471:

2323:

2122:

2035:

1883:

1853:

1806:

1059:

1048:

1037:

1026:

1002:

903:

634:

328:

1106:

Although there is no record of any shared development here, between the Royal Navy and the

3069:

2802:

2744:

2663:

2552:

2547:

2461:

2416:

1989:

1979:

1863:

954:

891:

769:

256:

64:

is in the centre. The whole assembly is then enclosed in a casing, leading to the exhaust

2988:

2837:

2809:

2486:

2385:

2308:

2298:

2208:

2137:

2091:

1901:

1848:

1353:

976:

296:. Features such as the raised mud drums and the shape of the tubes were an influence.

3119:

2776:

2749:

2648:

2567:

2403:

2112:

2009:

1969:

1916:

1063:

1055:

1030:

1010:

1006:

996:

663:

582:

578:

517:

505:

300:

222:

also had an influence, probably as a result of the large number in service with the

2977:

2734:

2481:

2466:

2421:

2275:

2270:

2184:

2117:

2066:

2056:

1964:

1873:

1858:

849:

637:

had shown that sharp internal corners inside boilers were also prone to erosion by

566:

558:

526:

457:

145:

1643:

1603:

1509:((1912 edition) ed.). Admiralty, via HMSO, via Eyre & Spottiswoode. 1901.

52:

The fundamental characteristic of the "three-drum" design is the arrangement of a

17:

1218:

1216:

1214:

2902:

2876:

2829:

2426:

2400:

2370:

2248:

2243:

2142:

2096:

2076:

1763:

1067:

915:

845:

805:

801:

789:

659:

207:

1074:

Firing was with coal, at just one end through a conventional locomotive single

210:

within the tube bank, so as to encourage the necessary temperature difference.

2908:

2851:

2476:

2411:

2395:

2333:

2290:

2280:

2086:

2081:

1843:

1787:

1679:

959:

841:

729:

353:

223:

128:. The three-drum arrangement was lighter and more compact for the same power.

108:

53:

1465:

1463:

1461:

1381:

1379:

1377:

1375:

1373:

1371:

2704:

2689:

1115:

757:

572:

202:

46:

1348:

1346:

1344:

1044:

water-tube firebox, with the firebox extended to become the entire boiler.

71:

Firing can be by either coal or oil. Many coal-fired boilers used multiple

2593:

2132:

2071:

1617:"200/250 h.p. articulated railcar with a Woolnough boiler, L.N.E.R. 2291

1094:

1075:

899:

817:

332:

299:

White-Forster boilers were introduced into the Royal Navy from 1906, for

1426:

1424:

1131:

1129:

773:

1188:

1186:

800:

of 550 psi (3.8 MPa) and each axle was driven by a separate

720:

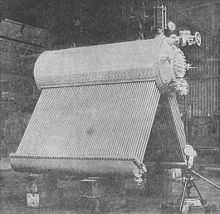

Mumford boiler, half-section showing the shape of the lower water drum

2709:

2446:

1829:

857:

784:. Sentinel's best-known use of the Woolnough was for the 'Colombian'

395:

273:

1033:, Harold Yarrow was keen to expand the market for Yarrow's boiler.

2228:

986:

827:

739:

715:

707:

610:

495:

467:

456:

A small single-sided version of this boiler was also produced for

405:

375:

314:

102:

94:

86:

29:

27:

Compact furnace with two side water drums and one steam drum above

1025:, Gresley was keen to experiment with this approach in a railway

877:

furnace-side of the superheater and thirteen for the outer-side.

136:. Although not all of these were three-drum designs (notably the

2153:

65:

2157:

1802:

1017:

company. Having observed the benefits of higher pressures and

761:

tubes. The combustion gases thus passed through the tube bank

1250:

1248:

1246:

796:

wheel arrangement, built in 1934. They ran at the unusually

111:

sailor cleans the water tubes inside a ship's boiler with a

1798:

1717:

1715:

1713:

1711:

1709:

1707:

1705:

1703:

1701:

1699:

728:

boiler was a variety built by the boilermakers

Mumford of

1592:(34, 35): 121–125, 141–142. December 1934 – January 1935.

1259:. Vol. 1: 1827–1939. Spellmount. pp. 241–245.

3156:

History of science and technology in the United

Kingdom

1195:

970 Mechanical Appliances and Novelties of Construction

1323:

860:

and the first boilers were installed in three of the

852:

World Wars. Much of the design work was conducted at

1481:

1040:. It has also been described as an evolution of the

3043:

3014:

2987:

2968:

2922:

2875:

2828:

2819:

2786:

2767:

2758:

2677:

2634:

2606:

2576:

2528:

2500:

2454:

2445:

2361:

2289:

2236:

2227:

2191:

2105:

2044:

2018:

1940:

1882:

1836:

1766:(1966). "9: Unconventional Locomotives 1929–1935".

1390:(Vol. VI ed.). London: Caxton. pp. 92–93.

1400:

1335:

561:effect rather than requiring an impractical pump.

160:The convoluted tubes of early designs such as the

1493:

1469:

1163:

1161:

1159:

184:Some of the first boiler tubes, particularly the

439:Owing to its early use in the Thornycroft-built

188:with its sharp corners, could not be cleaned of

178:

1641:. Loco. Rly Carr. Wagon Rev., 1940, 46, 83. in

1569:The Book of Modern Engines and Power Generators

1415:The Book of Modern Engines and Power Generators

1388:The Book of Modern Engines and Power Generators

1062:, placing the water drums at the limits of the

979:replacing one of its three three-drum boilers.

1257:The evolution of engineering in the Royal Navy

814:Société National des Chemins de Fer en Colombe

2169:

1814:

144:), this encourages strong circulation by the

8:

1110:, the two solutions represent an example of

975:which was trialled with a single water-wall

230:, the latter is appropriate for oil firing.

1001:The only large three-drum boiler used in a

886:give a more clearly defined circulation. A

45:used to generate steam, typically to power

2825:

2764:

2451:

2233:

2176:

2162:

2154:

1821:

1807:

1799:

1096:Admiralty Marine Engineering Establishment

1054:The boiler resembled two elongated marine

836:A later development of the Yarrow was the

685:, was built with the then current form of

615:Asymmetric Yarrow boiler, with superheater

1740:Railway Correspondence and Travel Society

1585:Steam Car Developments and Steam Aviation

812:, the following three were built for the

630:

449:of 1893, this design became known as the

255:in France and was tested in a Royal Navy

99:A Yarrow boiler, with the casing removed

3051:Glossary of steam locomotive components

1125:

1087:

552:

251:, patented in 1876. It was invented by

3151:Maritime history of the United Kingdom

1721:

1658:"The Colombian Steam Motor Locomotive"

697:

368:) that could be fired from both ends.

148:effect, further encouraging steaming.

1644:"Sentinel locomotives & railcars"

1604:"Sentinel locomotives & railcars"

744:Woolnough boiler, as used by Sentinel

343:

290:

185:

161:

7:

1768:The British Steam Railway Locomotive

662:was adopted, primarily for use with

1789:"Raising Steam" 1942 training video

1770:. Vol. II, from 1925 to 1965.

1675:

1172:

854:Admiralty Fuel Experimental Station

342:boiler was as a development of the

327:boiler was developed by the French

167:

2903:National Museum of Scotland engine

1360:. Originally published in 1889 as

1197:. Algrove Publishing. p. 58.

365:

173:

25:

1672:Naval Marine Engineering Practice

1520:Burgess, Malcolm William (1936).

34:Three-drum boiler, casing removed

3085:List of steam technology patents

1470:Yarrows, The First Hundred Years

1448:Yarrows: the first hundred years

1324:Cisin, Modern Marine Engineering

1280:Brassey, Thomas Allnutt (1896).

1229:. BiblioBazaar. pp. 78–84.

1136:Brassey, Thomas Allnutt (1896).

553:Yarrow's circulation experiments

1482:Kennedy, Modern Engines, Vol VI

1417:. Vol. VI. London: Caxton.

868:

788:. These were a series of four,

3070:Murdoch's model steam carriage

3056:History of steam road vehicles

2062:Internally rifled boiler tubes

1571:. Vol. V. London: Caxton.

360:A further development was the

91:A flat of three Yarrow boilers

1:

2997:Murray's Hypocycloidal Engine

1401:Kennedy, Modern Engines, 1912

1336:Robertson, Water-tube boilers

1307:Robertson, Leslie S. (1901).

1286:. Brassey. pp. 118–119.

1142:. Brassey. pp. 118–119.

2720:Return connecting rod engine

1674:. later replacement for the

1494:Yarrows, First Hundred Years

1446:Borthwick, Alastair (1965).

1223:Cisin, Harry George (1921).

1171:. later replacement for the

808:. The first was supplied to

390:The Reed boiler was used by

2644:Condensing steam locomotive

1582:"Boilers. Woolnough Type".

1193:Gardner D. Hiscox (2001) .

838:Admiralty three-drum boiler

832:Admiralty three-drum boiler

3177:

3161:Maritime history of France

2951:"Coalbrookdale Locomotive"

994:

671:Adoption by the Royal Navy

595:. Provided that there was

563:Forced-circulation boilers

503:

383:

2957:"Pen-y-Darren" locomotive

2626:Single- and double-acting

1386:Kennedy, Rankin (1912) .

1255:Rippon, Cmdr. PM (1988).

1226:Modern Marine Engineering

872:Superheaters were placed

607:Later evolution in design

472:Thornycroft-Schulz boiler

464:Thornycroft-Schulz boiler

2796:Newcomen Memorial Engine

1736:Raising Steam on the LMS

1413:Kennedy, Rankin (1912).

1169:BR 77 Machinery Handbook

565:with pumps, such as the

281:downcomer tube plugged.

79:, often from both ends.

3100:Timeline of steam power

3095:Stationary steam engine

2978:Woolf's compound engine

2885:Soho Manufactory engine

2740:Steeple compound engine

2407:straight line mechanism

1526:Oxford University Press

1435:(2nd ed.). Newnes.

1431:Milton, J. H. (1961) .

1179:. 1941. pp. 12–13.

898:and the development of

862:A class destroyers

786:articulated locomotives

683:Havock class destroyers

681:, the lead ship of the

305:torpedo boat destroyers

3105:Water-returning engine

3079:Lean's Engine Reporter

2852:Chacewater Mine engine

2725:Six-column beam engine

992:

833:

745:

721:

713:

700:of three-drum boiler.

616:

501:

473:

411:

386:Reed water tube boiler

381:

338:Initial design of the

320:

116:

100:

92:

35:

2945:London Steam Carriage

2031:Electric water boiler

2026:Electric steam boiler

995:Further information:

990:

888:circulation augmenter

831:

743:

719:

711:

614:

504:Further information:

499:

471:

409:

379:

318:

106:

98:

90:

33:

2891:Bradley Works engine

2715:Reciprocating engine

2538:Babcock & Wilcox

2381:Centrifugal governor

1950:Babcock & Wilcox

1772:Ian Allan Publishing

1682:. 1971 . p. 4.

1624:The Railway Magazine

1541:The First Destroyers

1539:Lyon, David (1996).

1433:Marine Steam Boilers

1354:Prof. William Ripper

930:battleships and the

921:Babcock & Wilcox

840:, developed for the

486:Thornycroft-Marshall

263:White-Forster boiler

142:Babcock & Wilcox

122:Babcock & Wilcox

2432:Sun and planet gear

1774:. pp. 106–109.

1734:Cook, A.F. (1999).

1543:. Caxton Editions.

950:could reduce this.

752:design was used by

500:Early Yarrow boiler

476:Later designs, the

247:was an early naval

115:, c. 1939–1945

3136:Steam boiler types

3131:Water-tube boilers

2932:Richard Trevithick

2530:Water-tube boilers

2344:Gresley conjugated

2106:Boiler peripherals

1942:Water-tube boilers

1724:, pp. 241–245

1310:Water-tube boilers

1112:parallel evolution

1031:land-based boilers

1003:railway locomotive

993:

948:water-wall furnace

834:

746:

722:

714:

689:; its sister ship

617:

502:

478:Thornycroft-Schulz

474:

423:water-wall furnace

412:

410:Thornycroft boiler

402:Thornycroft boiler

382:

321:

117:

101:

93:

39:Three-drum boilers

36:

18:Thornycroft boiler

3113:

3112:

3039:

3038:

2918:

2917:

2602:

2601:

2502:Fire-tube boilers

2357:

2356:

2151:

2150:

2045:Boiler components

1884:Fire-tube boilers

904:steam locomotives

772:. These included

698:Admiralty pattern

687:locomotive boiler

635:boiler explosions

249:water-tube boiler

134:"express" boilers

43:water-tube boiler

16:(Redirected from

3168:

3063:fardier à vapeur

2897:Whitbread Engine

2858:Smethwick Engine

2826:

2765:

2584:Feedwater heater

2452:

2234:

2178:

2171:

2164:

2155:

2123:Feedwater heater

2036:Electrode boiler

2019:Electric boilers

1823:

1816:

1809:

1800:

1790:

1776:

1775:

1760:

1754:

1753:

1731:

1725:

1719:

1694:

1693:

1668:

1662:

1661:

1654:

1648:

1647:

1639:

1633:

1632:

1614:

1608:

1607:

1600:

1594:

1593:

1579:

1573:

1572:

1561:

1555:

1554:

1536:

1530:

1529:

1517:

1511:

1510:

1503:

1497:

1491:

1485:

1479:

1473:

1467:

1456:

1455:

1443:

1437:

1436:

1428:

1419:

1418:

1410:

1404:

1403:, pp. 82–91

1398:

1392:

1391:

1383:

1366:

1365:

1350:

1339:

1333:

1327:

1321:

1315:

1314:

1304:

1298:

1297:

1283:The Naval Annual

1277:

1271:

1270:

1252:

1241:

1240:

1220:

1209:

1208:

1190:

1181:

1180:

1165:

1154:

1153:

1139:The Naval Annual

1133:

1119:

1104:

1098:

1092:

1019:compound engines

1013:of 1924 for the

1009:'s experimental

824:Admiralty boiler

810:Belgian Railways

736:Woolnough boiler

633:. Experience of

329:Normand shipyard

239:du Temple boiler

179:Admiralty boiler

21:

3176:

3175:

3171:

3170:

3169:

3167:

3166:

3165:

3126:Express boilers

3116:

3115:

3114:

3109:

3035:

3010:

2983:

2964:

2914:

2871:

2815:

2803:Fairbottom Bobs

2788:Newcomen engine

2782:

2754:

2700:Expansion valve

2673:

2659:Watt's separate

2630:

2598:

2572:

2524:

2496:

2441:

2417:Parallel motion

2353:

2304:Stephenson link

2285:

2223:

2192:Operating cycle

2187:

2182:

2152:

2147:

2101:

2040:

2014:

1936:

1878:

1832:

1827:

1788:

1784:

1779:

1762:

1761:

1757:

1750:

1742:. p. 106.

1733:

1732:

1728:

1720:

1697:

1690:

1678:. Vol. 1.

1670:

1669:

1665:

1656:

1655:

1651:

1642:

1640:

1636:

1616:

1615:

1611:

1602:

1601:

1597:

1581:

1580:

1576:

1565:Kennedy, Rankin

1563:

1562:

1558:

1551:

1538:

1537:

1533:

1522:Warships To-day

1519:

1518:

1514:

1505:

1504:

1500:

1492:

1488:

1484:, pp. ????

1480:

1476:

1468:

1459:

1445:

1444:

1440:

1430:

1429:

1422:

1412:

1411:

1407:

1399:

1395:

1385:

1384:

1369:

1352:

1351:

1342:

1334:

1330:

1322:

1318:

1306:

1305:

1301:

1294:

1279:

1278:

1274:

1267:

1254:

1253:

1244:

1237:

1222:

1221:

1212:

1205:

1192:

1191:

1184:

1167:

1166:

1157:

1150:

1135:

1134:

1127:

1123:

1122:

1105:

1101:

1093:

1089:

1084:

1023:marine practice

999:

985:

955:Hawthorn Leslie

943:

912:

892:steam separator

883:

826:

792:locomotives of

770:vertical boiler

738:

706:

673:

656:

647:

622:

609:

555:

535:

522:Yarrow & Co

508:

494:

466:

404:

388:

374:

362:Normand-Sigaudy

313:

265:

257:torpedo gunboat

253:Félix du Temple

241:

236:

216:

199:

158:

85:

41:are a class of

28:

23:

22:

15:

12:

11:

5:

3174:

3172:

3164:

3163:

3158:

3153:

3148:

3143:

3141:Marine boilers

3138:

3133:

3128:

3118:

3117:

3111:

3110:

3108:

3107:

3102:

3097:

3092:

3087:

3082:

3075:

3074:

3073:

3067:

3053:

3047:

3045:

3041:

3040:

3037:

3036:

3034:

3033:

3027:

3020:

3018:

3012:

3011:

3009:

3008:

3000:

2993:

2991:

2985:

2984:

2982:

2981:

2974:

2972:

2966:

2965:

2963:

2962:

2961:

2960:

2954:

2948:

2942:

2928:

2926:

2920:

2919:

2916:

2915:

2913:

2912:

2906:

2900:

2894:

2888:

2881:

2879:

2873:

2872:

2870:

2869:

2861:

2855:

2849:

2841:

2838:Kinneil Engine

2834:

2832:

2823:

2817:

2816:

2814:

2813:

2810:Elsecar Engine

2807:

2799:

2792:

2790:

2784:

2783:

2781:

2780:

2773:

2771:

2762:

2756:

2755:

2753:

2752:

2747:

2742:

2737:

2732:

2730:Steeple engine

2727:

2722:

2717:

2712:

2707:

2702:

2697:

2692:

2687:

2681:

2679:

2675:

2674:

2672:

2671:

2666:

2661:

2656:

2651:

2646:

2640:

2638:

2632:

2631:

2629:

2628:

2623:

2618:

2612:

2610:

2604:

2603:

2600:

2599:

2597:

2596:

2591:

2589:Feedwater pump

2586:

2580:

2578:

2574:

2573:

2571:

2570:

2565:

2560:

2555:

2550:

2545:

2540:

2534:

2532:

2526:

2525:

2523:

2522:

2517:

2512:

2506:

2504:

2498:

2497:

2495:

2494:

2489:

2484:

2479:

2474:

2469:

2464:

2458:

2456:

2455:Simple boilers

2449:

2443:

2442:

2440:

2439:

2437:Watt's linkage

2434:

2429:

2424:

2419:

2414:

2409:

2398:

2393:

2388:

2386:Connecting rod

2383:

2378:

2373:

2367:

2365:

2359:

2358:

2355:

2354:

2352:

2351:

2346:

2341:

2336:

2331:

2326:

2321:

2316:

2311:

2306:

2301:

2295:

2293:

2287:

2286:

2284:

2283:

2278:

2273:

2268:

2263:

2258:

2253:

2252:

2251:

2240:

2238:

2231:

2225:

2224:

2222:

2221:

2216:

2211:

2206:

2201:

2195:

2193:

2189:

2188:

2183:

2181:

2180:

2173:

2166:

2158:

2149:

2148:

2146:

2145:

2140:

2138:Snifting valve

2135:

2130:

2128:Feedwater pump

2125:

2120:

2115:

2109:

2107:

2103:

2102:

2100:

2099:

2094:

2092:Thermic siphon

2089:

2084:

2079:

2074:

2069:

2064:

2059:

2054:

2048:

2046:

2042:

2041:

2039:

2038:

2033:

2028:

2022:

2020:

2016:

2015:

2013:

2012:

2007:

2002:

1997:

1992:

1987:

1982:

1977:

1972:

1967:

1962:

1957:

1952:

1946:

1944:

1938:

1937:

1935:

1934:

1929:

1924:

1919:

1914:

1909:

1904:

1899:

1894:

1888:

1886:

1880:

1879:

1877:

1876:

1871:

1866:

1861:

1856:

1851:

1846:

1840:

1838:

1837:Simple boilers

1834:

1833:

1828:

1826:

1825:

1818:

1811:

1803:

1797:

1796:

1783:

1782:External links

1780:

1778:

1777:

1755:

1748:

1726:

1695:

1688:

1676:Stokers Manual

1663:

1649:

1634:

1609:

1595:

1574:

1556:

1549:

1531:

1512:

1507:Stokers Manual

1498:

1486:

1474:

1457:

1438:

1420:

1405:

1393:

1367:

1340:

1328:

1316:

1299:

1292:

1272:

1265:

1242:

1235:

1210:

1203:

1182:

1173:Stokers Manual

1155:

1148:

1124:

1121:

1120:

1099:

1086:

1085:

1083:

1080:

1056:Yarrow boilers

1049:A1 locomotives

1042:Brotan-Deffner

1029:. As with the

984:

981:

977:Johnson boiler

942:

939:

911:

908:

882:

879:

825:

822:

804:, designed by

737:

734:

712:Mumford boiler

705:

704:Mumford boiler

702:

672:

669:

664:steam turbines

655:

652:

646:

643:

621:

618:

608:

605:

585:on each side.

583:Bunsen burners

554:

551:

534:

533:Straight tubes

531:

493:

490:

465:

462:

403:

400:

384:Main article:

373:

370:

319:Normand boiler

312:

311:Normand boiler

309:

301:light cruisers

264:

261:

240:

237:

235:

232:

215:

212:

198:

195:

157:

154:

84:

81:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

3173:

3162:

3159:

3157:

3154:

3152:

3149:

3147:

3144:

3142:

3139:

3137:

3134:

3132:

3129:

3127:

3124:

3123:

3121:

3106:

3103:

3101:

3098:

3096:

3093:

3091:

3088:

3086:

3083:

3081:

3080:

3076:

3071:

3068:

3065:

3064:

3059:

3058:

3057:

3054:

3052:

3049:

3048:

3046:

3042:

3031:

3028:

3025:

3022:

3021:

3019:

3017:

3013:

3006:

3005:

3001:

2998:

2995:

2994:

2992:

2990:

2986:

2979:

2976:

2975:

2973:

2971:

2967:

2958:

2955:

2952:

2949:

2946:

2943:

2940:

2939:

2938:Puffing Devil

2935:

2934:

2933:

2930:

2929:

2927:

2925:

2924:High-pressure

2921:

2910:

2907:

2904:

2901:

2898:

2895:

2892:

2889:

2886:

2883:

2882:

2880:

2878:

2877:Rotative beam

2874:

2867:

2866:

2862:

2859:

2856:

2853:

2850:

2847:

2846:

2842:

2839:

2836:

2835:

2833:

2831:

2827:

2824:

2822:

2818:

2811:

2808:

2805:

2804:

2800:

2797:

2794:

2793:

2791:

2789:

2785:

2778:

2777:Savery Engine

2775:

2774:

2772:

2770:

2766:

2763:

2761:

2757:

2751:

2750:Working fluid

2748:

2746:

2743:

2741:

2738:

2736:

2733:

2731:

2728:

2726:

2723:

2721:

2718:

2716:

2713:

2711:

2708:

2706:

2703:

2701:

2698:

2696:

2693:

2691:

2688:

2686:

2683:

2682:

2680:

2676:

2670:

2667:

2665:

2662:

2660:

2657:

2655:

2652:

2650:

2647:

2645:

2642:

2641:

2639:

2637:

2633:

2627:

2624:

2622:

2619:

2617:

2614:

2613:

2611:

2609:

2605:

2595:

2592:

2590:

2587:

2585:

2582:

2581:

2579:

2575:

2569:

2566:

2564:

2561:

2559:

2556:

2554:

2551:

2549:

2546:

2544:

2541:

2539:

2536:

2535:

2533:

2531:

2527:

2521:

2518:

2516:

2513:

2511:

2508:

2507:

2505:

2503:

2499:

2493:

2490:

2488:

2485:

2483:

2480:

2478:

2475:

2473:

2470:

2468:

2465:

2463:

2460:

2459:

2457:

2453:

2450:

2448:

2444:

2438:

2435:

2433:

2430:

2428:

2427:Rotative beam

2425:

2423:

2420:

2418:

2415:

2413:

2410:

2408:

2405:

2404:hypocycloidal

2402:

2399:

2397:

2394:

2392:

2389:

2387:

2384:

2382:

2379:

2377:

2374:

2372:

2369:

2368:

2366:

2364:

2360:

2350:

2347:

2345:

2342:

2340:

2337:

2335:

2332:

2330:

2327:

2325:

2322:

2320:

2317:

2315:

2312:

2310:

2307:

2305:

2302:

2300:

2297:

2296:

2294:

2292:

2288:

2282:

2279:

2277:

2274:

2272:

2269:

2267:

2264:

2262:

2259:

2257:

2254:

2250:

2247:

2246:

2245:

2242:

2241:

2239:

2235:

2232:

2230:

2226:

2220:

2217:

2215:

2212:

2210:

2207:

2205:

2202:

2200:

2197:

2196:

2194:

2190:

2186:

2185:Steam engines

2179:

2174:

2172:

2167:

2165:

2160:

2159:

2156:

2144:

2141:

2139:

2136:

2134:

2131:

2129:

2126:

2124:

2121:

2119:

2116:

2114:

2113:Air preheater

2111:

2110:

2108:

2104:

2098:

2095:

2093:

2090:

2088:

2085:

2083:

2080:

2078:

2075:

2073:

2070:

2068:

2065:

2063:

2060:

2058:

2055:

2053:

2050:

2049:

2047:

2043:

2037:

2034:

2032:

2029:

2027:

2024:

2023:

2021:

2017:

2011:

2008:

2006:

2003:

2001:

1998:

1996:

1993:

1991:

1988:

1986:

1983:

1981:

1978:

1976:

1973:

1971:

1968:

1966:

1963:

1961:

1958:

1956:

1953:

1951:

1948:

1947:

1945:

1943:

1939:

1933:

1930:

1928:

1925:

1923:

1920:

1918:

1915:

1913:

1910:

1908:

1905:

1903:

1900:

1898:

1897:Franco-Crosti

1895:

1893:

1890:

1889:

1887:

1885:

1881:

1875:

1872:

1870:

1867:

1865:

1862:

1860:

1857:

1855:

1852:

1850:

1847:

1845:

1842:

1841:

1839:

1835:

1831:

1824:

1819:

1817:

1812:

1810:

1805:

1804:

1801:

1795:

1791:

1786:

1785:

1781:

1773:

1769:

1765:

1759:

1756:

1751:

1749:0-901115-85-1

1745:

1741:

1737:

1730:

1727:

1723:

1718:

1716:

1714:

1712:

1710:

1708:

1706:

1704:

1702:

1700:

1696:

1691:

1689:0-11-770223-4

1685:

1681:

1677:

1673:

1667:

1664:

1659:

1653:

1650:

1645:

1638:

1635:

1630:

1626:

1625:

1620:

1613:

1610:

1605:

1599:

1596:

1591:

1587:

1586:

1578:

1575:

1570:

1566:

1560:

1557:

1552:

1550:1-84067-364-8

1546:

1542:

1535:

1532:

1528:. p. 68.

1527:

1523:

1516:

1513:

1508:

1502:

1499:

1495:

1490:

1487:

1483:

1478:

1475:

1471:

1466:

1464:

1462:

1458:

1453:

1449:

1442:

1439:

1434:

1427:

1425:

1421:

1416:

1409:

1406:

1402:

1397:

1394:

1389:

1382:

1380:

1378:

1376:

1374:

1372:

1368:

1363:

1359:

1355:

1349:

1347:

1345:

1341:

1337:

1332:

1329:

1325:

1320:

1317:

1313:. p. 37.

1312:

1311:

1303:

1300:

1295:

1293:1-4212-4178-1

1289:

1285:

1284:

1276:

1273:

1268:

1266:0-946771-55-3

1262:

1258:

1251:

1249:

1247:

1243:

1238:

1236:0-559-03423-7

1232:

1228:

1227:

1219:

1217:

1215:

1211:

1206:

1204:1-894572-37-8

1200:

1196:

1189:

1187:

1183:

1178:

1174:

1170:

1164:

1162:

1160:

1156:

1151:

1149:1-4212-4178-1

1145:

1141:

1140:

1132:

1130:

1126:

1117:

1113:

1109:

1103:

1100:

1097:

1091:

1088:

1081:

1079:

1077:

1072:

1069:

1065:

1064:loading gauge

1061:

1057:

1052:

1050:

1045:

1043:

1039:

1034:

1032:

1028:

1024:

1020:

1016:

1012:

1008:

1007:Nigel Gresley

1004:

998:

997:LNER Class W1

989:

982:

980:

978:

974:

972:

966:

961:

956:

951:

949:

940:

938:

936:

934:

929:

927:

922:

917:

909:

907:

905:

901:

897:

893:

889:

880:

878:

875:

870:

865:

863:

859:

855:

851:

847:

843:

839:

830:

823:

821:

819:

815:

811:

807:

803:

799:

798:high pressure

795:

791:

787:

783:

779:

775:

771:

766:

764:

759:

755:

751:

742:

735:

733:

731:

727:

718:

710:

703:

701:

699:

695:

694:

688:

684:

680:

679:

670:

668:

665:

661:

653:

651:

644:

642:

640:

636:

632:

631:White-Forster

626:

619:

613:

606:

604:

600:

598:

594:

589:

586:

584:

580:

579:Alfred Yarrow

576:

574:

570:

569:

564:

560:

550:

547:

545:

544:drowned tubes

539:

532:

530:

528:

523:

519:

518:Alfred Yarrow

515:

513:

507:

506:Yarrow boiler

498:

492:Yarrow boiler

491:

489:

487:

482:

479:

470:

463:

461:

459:

454:

452:

448:

447:

442:

437:

433:

431:

426:

424:

419:

418:

408:

401:

399:

397:

393:

387:

378:

371:

369:

367:

363:

358:

355:

349:

347:

346:

341:

336:

334:

330:

326:

317:

310:

308:

306:

302:

297:

295:

293:

287:

282:

278:

275:

270:

269:White-Forster

262:

260:

258:

254:

250:

246:

238:

233:

231:

229:

225:

221:

220:White-Forster

213:

211:

209:

204:

196:

194:

191:

187:

182:

180:

175:

171:

170:

165:

164:

155:

153:

149:

147:

143:

139:

135:

129:

127:

123:

114:

110:

105:

97:

89:

82:

80:

78:

75:and teams of

74:

69:

67:

63:

59:

55:

50:

48:

44:

40:

32:

19:

3090:Modern steam

3077:

3062:

3024:Porter-Allen

3003:

2937:

2864:

2844:

2801:

2735:Safety valve

2664:"Pickle-pot"

2562:

2558:Thimble tube

2118:Boiler water

2067:Safety valve

2057:Fusible plug

1999:

1995:Thimble tube

1767:

1758:

1735:

1729:

1671:

1666:

1652:

1637:

1628:

1622:

1618:

1612:

1598:

1589:

1583:

1577:

1568:

1559:

1540:

1534:

1521:

1515:

1506:

1501:

1489:

1477:

1447:

1441:

1432:

1414:

1408:

1396:

1387:

1361:

1358:Heat Engines

1357:

1338:, p. 38

1331:

1319:

1309:

1302:

1282:

1275:

1256:

1225:

1194:

1168:

1138:

1102:

1090:

1073:

1053:

1046:

1035:

1011:Engine 10000

1000:

991:Engine 10000

983:Engine 10000

970:

952:

944:

932:

925:

913:

910:Superheaters

887:

884:

873:

866:

844:between the

837:

835:

767:

762:

749:

747:

725:

723:

692:

677:

674:

660:superheating

657:

654:Superheaters

648:

627:

623:

601:

596:

592:

590:

587:

577:

567:

559:thermosyphon

556:

548:

540:

536:

527:torpedo boat

516:

511:

509:

485:

484:The earlier

483:

477:

475:

455:

450:

445:

438:

434:

427:

415:

413:

389:

361:

359:

357:cold water.

350:

344:

339:

337:

324:

322:

298:

291:

283:

279:

268:

266:

244:

242:

217:

200:

183:

168:

162:

159:

150:

146:thermosyphon

130:

118:

113:ribbon brush

112:

70:

51:

38:

37:

2821:Watt engine

2621:Oscillating

2577:Boiler feed

2422:Plate chain

2401:Tusi couple

2314:Walschaerts

2199:Atmospheric

2143:Superheater

2097:Water gauge

1955:Corner tube

1722:Rippon 1988

1631:(73). 1931.

1496:, pp.

1472:, pp. 36–37

1326:, pp. 84–86

1108:LMS railway

1068:superheater

973: (H97)

953:From 1929,

896:LMS railway

806:Abner Doble

802:steam motor

790:metre gauge

620:Water drums

430:non-drowned

417:Thornycroft

380:Reed boiler

372:Reed boiler

208:superheater

138:Thornycroft

83:Development

58:water drums

3120:Categories

3030:Ljungström

3016:High-speed

2909:Lap Engine

2865:Resolution

2769:Precursors

2654:Kirchweger

2616:Locomotive

2563:Three-drum

2543:Field-tube

2510:Locomotive

2492:Lancashire

2412:Link chain

2396:Crankshaft

2363:Mechanisms

2291:Valve gear

2087:Steam drum

2082:Steam dome

2000:Three-drum

1960:Field-tube

1927:Transverse

1912:Locomotive

1869:Lancashire

1764:Nock, O.S.

1680:Royal Navy

1524:. Oxford:

1082:References

1027:locomotive

960:refractory

869:downcomers

842:Royal Navy

730:Colchester

645:Downcomers

573:downcomers

354:steam dome

224:Royal Navy

203:downcomers

197:Downcomers

126:Belleville

109:Royal Navy

56:above two

54:steam drum

3061:Cugnot's

3004:Salamanca

2705:Hydrolock

2690:Crosshead

2636:Condenser

2472:Egg-ended

1854:Egg-ended

1619:Phenomena

1356:(1913) .

1177:Admiralty

1116:wet steam

1038:Woolnough

969:HMS

916:superheat

881:Feedwater

758:firebrick

750:Woolnough

593:increased

529:of 1887.

441:destroyer

432:' tubes.

345:Du Temple

292:Admiralty

286:mud drums

245:du Temple

201:Separate

186:du Temple

163:du Temple

132:known as

73:firedoors

3044:See also

2970:Compound

2845:Old Bess

2685:Blowback

2608:Cylinder

2594:Injector

2553:Stirling

2548:Sentinel

2462:Haystack

2376:Cataract

2349:Southern

2339:Caprotti

2214:Compound

2133:Injector

2072:Smokebox

2005:Vertical

1990:Stirling

1980:Sentinel

1975:Monotube

1932:Vertical

1864:Haystack

1567:(1905).

1076:firedoor

971:Hyperion

941:Backwall

914:Initial

900:top feed

818:Colombia

776:for the

774:railcars

754:Sentinel

639:grooving

458:launches

453:boiler.

451:'Daring'

333:Le Havre

228:grooving

214:Furnaces

3146:Boilers

2760:History

2669:Surface

2487:Cornish

2447:Boilers

2329:Corliss

2266:Corliss

2249:D slide

2219:Uniflow

2209:Cornish

2052:Firebox

1902:Haycock

1892:Cochran

1849:Cornish

1830:Boilers

1794:YouTube

1452:Yarrows

965:priming

726:Mumford

481:place.

392:Palmers

340:Normand

325:Normand

294:pattern

169:Normand

124:or the

77:stokers

62:furnace

3072:(1784)

3066:(1769)

3032:(1908)

3026:(1862)

3007:(1812)

2999:(1805)

2989:Murray

2980:(1803)

2959:(1804)

2953:(1803)

2947:(1803)

2941:(1801)

2911:(1788)

2905:(1786)

2899:(1785)

2893:(1783)

2887:(1782)

2868:(1781)

2860:(1779)

2854:(1778)

2848:(1777)

2840:(1768)

2812:(1795)

2806:(1760)

2798:(1725)

2779:(1698)

2745:Stroke

2710:Piston

2695:Cutoff

2568:Yarrow

2520:Launch

2515:Scotch

2276:Sleeve

2271:Poppet

2256:Piston

2237:Valves

2229:Valves

2010:Yarrow

1985:Spiral

1970:LaMont

1922:Scotch

1917:Pistol

1907:Launch

1746:

1686:

1547:

1290:

1263:

1233:

1201:

1146:

1060:frames

935:-class

928:-class

926:Nelson

874:inside

858:Haslar

850:Second

693:Hornet

678:Havock

512:Yarrow

446:Daring

396:Jarrow

366:Yarrow

289:later

274:reamed

174:Yarrow

2678:Other

2482:Flued

2467:Wagon

2391:Crank

2334:Lentz

2324:Baker

2319:Allan

2244:Slide

1965:Flash

1874:Wagon

1859:Flued

1362:Steam

963:with

846:First

794:Co-Co

763:twice

658:When

568:Velox

234:Types

190:scale

156:Tubes

47:ships

2830:Beam

2371:Beam

2281:Bash

2261:Drop

2204:Watt

2077:Stay

1744:ISBN

1684:ISBN

1545:ISBN

1288:ISBN

1261:ISBN

1231:ISBN

1199:ISBN

1144:ISBN

1015:LNER

1005:was

933:Kent

902:for

848:and

780:and

778:LNER

748:The

724:The

691:HMS

676:HMS

597:some

510:The

444:HMS

414:The

323:The

303:and

284:The

267:The

243:The

166:and

66:flue

2649:Jet

2477:Box

2309:Joy

2299:Gab

1844:Box

1792:on

1621:".

1590:III

1021:in

856:at

816:of

782:LMS

394:of

331:of

3122::

1738:.

1698:^

1629:68

1627:.

1588:.

1460:^

1450:.

1423:^

1370:^

1343:^

1245:^

1213:^

1185:^

1175:.

1158:^

1128:^

1051:.

575:.

307:.

107:A

68:.

2177:e

2170:t

2163:v

1822:e

1815:t

1808:v

1752:.

1692:.

1660:.

1646:.

1606:.

1553:.

1454:.

1296:.

1269:.

1239:.

1207:.

1152:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.