22:

65:

96:

direction is met with an "equal and opposite" reaction of the axle housing and differential, making the differential want to spin in a reverse direction, in the same way that a cyclist "pops a wheelie", lifting the bicycle in the air in the opposite direction from the turn of the wheel. The essential problem is keeping the differential from rotating during acceleration and braking. The torque tube solves that problem by coupling the

83:

38:, often used in automobiles with a front engine and rear drive. The torque tube consists of a large diameter stationary housing between the transmission and rear end that fully encloses a rotating tubular steel or small-diameter solid drive shaft (known colloquially in the U.S. as a "rope drive") that transmits the power of the engine to a regular or

42:. The purpose of a torque tube is to hold the rear end in place during acceleration and braking. Otherwise, the axle housing would suffer axle wrap, which is when the front of the differential lifts excessively during acceleration and drops down during braking. Its use is not as widespread in modern automobiles as is the

95:

The "torque" referred to in the name is not that of the driveshaft along the axis of the car but that applied by the wheels. The engineering problem that the torque tube solves is getting the traction forces generated by the wheels to the car frame. The torque moving the wheels and axles in a forward

161:

The torque tube design is typically heavier and securely ties the rear end together, thus providing a rigid rear end and assuring good alignment under all conditions. However, because of the greater unsprung weight of the torque tube and radius rods, there may be a "little hopping around of the rear

145:

that allows relative motion between the two ends of the driveshaft. In most applications, the drive shaft uses a single universal joint, which has the disadvantage that it causes speed fluctuations in the driveshaft when the shaft is not straight. The

Hotchkiss drive uses two universal joints, which

104:

housing and, therefore, propels the car forward by pushing up on the engine/transmission and then through the engine mounts to the car frame, with the reverse happening during braking. In contrast, the

Hotchkiss drive transmits the traction forces to the car frame by using suspension components such

129:

is often used for this purpose. The combination of the panhard rod and the torque tube allows the easy implementation of soft coil springs in the rear to give good ride quality, as in Buicks after 1937. Before 1937, Buicks used leaf springs, so the panhard rod was not used, though the torque tube

254:(1976-1988) and the similar Pontiac T-1000 used a torque tube and center bearing. This design was unlike any other Chevrolet model "to isolate impacts to the rear wheels, cut down on road noise, and reduce engine vibration ... also allows a reduction in the height of the drive shaft and tunnel."

652:

146:

cancels the speed fluctuations and gives a constant speed even when the shaft is no longer straight The

Hotchkiss drive uses two universal joints, which has the effect of canceling the speed fluctuations and gives a constant speed even when the shaft is no longer straight .

209:) from the 1956 through the 1966 model year. The enclosed driveshaft made for more complicated gear swaps and hampered hot rodders. The discontinued torque-tube drive was replaced by a new design utilizing an open driveshaft and a four-link axle-location system.

509:

25:

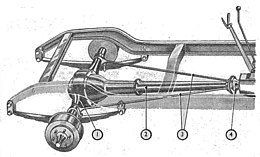

Number 2 is the torque tube, which ends on the left at the widest point at the flange with the bolts that hold it to the differential. Number 1 is the differential housing. Numbers 3 are the optional radius arms. Number 4 is the torque

322:

124:

Rambler models (1962 through 1966) used a flange and cushion mount in place of the ball and socket. Since the torque tube does not constrain the car's body to the axle in the lateral (side-to-side) direction, a

543:

669:

403, 404, and 504 models use a torque tube driveshaft. This type of driveshaft consists of an outer tube which takes the thrust of the rear wheels which are in turn driven by an inner shaft

727:

190:, but coil springs cannot. Buick's use of a torque tube and coil springs became a Buick "engineering trademark", until it was dropped with the 1961 model year full-sized models. The

186:

used it starting in 1906 (in the model D). The torque tube also allowed Buick, beginning in 1938, to use coil springs for a softer ride than traditional leaf springs, which can use a

46:, which holds the rear end in place and prevents it from flipping up or down, during acceleration and braking by anchoring the axle housings to the leaf springs using spring perches.

194:

model adopted torque-tube drive in 1941 without an enclosed joint, but utilized a "horizontal yoke at the front end of the torque tube is supported by rubber biscuits at each side."

88:

The Rover 8 had a torque-tube like backbone, lacking a pivoting joint between the transmission and the proper torque-tube to the rear differential casing, to allow suspension travel.

796:

120:

joint called a "torque ball" is used at one end of the torque tube to allow relative motion between the axle and transmission due to suspension travel. Later

682:

348:

21:

476:"Seventy Years of Buick" by George H. Damman, page 18 "Buick pioneered the torque tube this year" referring to the model D built in 1906.

243:

estate/station wagons, as well as most export-market sedans also had torque tubes, while domestic and

European-market sedan models had a

774:

692:

662:

610:

576:

454:

332:

764:

444:

158:

to eliminate driveshaft fluctuations, though six-cylinder and earlier V8 models used only one standard universal joint.

134:

suspension, which gives a softer ride than a center-mount axle on the leaf spring, as required by the

Hotchkiss setup.

370:

297:

39:

174:

Examples of torque tubes are the

American cars of the Ford brand, built through 1948, including over 19 million

178:. Ford used the less expensive transverse springs that could not take forward thrust. For many of those years,

101:

97:

486:

155:

262:

201:(AMC) continued to use the coil spring and torque tube rear suspension design on their large-sized cars (

276:

34:

system is a power transmission and braking technology that involves a stationary housing around the

749:

272:

251:

137:

In addition to transmitting traction forces, the torque tube is hollow and contains the rotating

770:

708:

688:

658:

606:

600:

572:

566:

525:

450:

417:

328:

626:

151:

64:

213:

202:

198:

187:

142:

131:

121:

117:

43:

206:

790:

268:

The

Mercedes SLS has a torque tube, but only to align the transaxle with the engine.

82:

258:

175:

163:

110:

106:

240:

236:

232:

228:

126:

35:

745:

138:

261:

switched to a new chassis in 1986 that utilized a torque tube along with an

244:

221:

179:

147:

217:

191:

224:

via a torque tube, giving it a perfect 50-50 front-rear weight balance.

71:

183:

526:"Big Buick models have new bodies, frame, suspension for '61"

633:. Vol. 189, no. 4. October 1966. p. 96 and 98

752:

from the original on 13 December 2021 – via YouTube.

275:

has used a torque tube since the 1996 introduction of the

511:

Fundamentals of

Automobile Chassis and Power Transmission

715:. Vol. 207, no. 4. October 1975. p. 116.

532:. Vol. 114, no. 4. October 1960. p. 103.

141:. Inside the hollow torque ball is the driveshaft's

657:. Vol. 2. Chilton Book. 1971. p. 989.

298:"Cut-Down Engine of the Week: Pontiac Trophy 4"

681:Kovacik, Robert T.; Creager, Clifford (1983).

508:Kuns, Ray Forest; Hall, Morris Albert (1948).

197:After the merger of Nash and Hudson in 1954,

8:

766:High-Performance C5 Corvette Builder's Guide

554:. Society of Automotive Engineers: 30. 1949.

216:was introduced as a new model, featuring an

514:. American Technical Society. p. 335.

466:– via Horseless Carriage Foundation.

734:. Vol. 161, no. 10. p. 42.

411:

409:

257:The continuing limited production of the

16:Power transmission and braking technology

424:. Vol. 104, no. 4. p. 131

403:1963-1966 AMC Technical Service Manuals.

20:

728:"Detroit Listening Post - Avanti garde"

627:"Steering and Suspension Stress Safety"

487:"When was the first torque tube Buick?"

394:1962-1966 AMC Technical Service Manuals

364:

362:

288:

602:Steve Magnante's 1001 Muscle Car Facts

568:Steve Magnante's 1001 Muscle Car Facts

726:Ross, Daniel Charles (October 1984).

687:. Thomson South-Western. p. 66.

296:Martin, Murilee (20 September 2017).

156:double-Cardan constant velocity joint

7:

797:Automotive transmission technologies

746:"Mercedes SLS Torque Tube animation"

684:Manual Transmissions and Drivetrains

489:. Antique Automobile Club of America

327:. Prentice Hall. 1991. p. 456.

654:Chilton's Foreign Car Repair Manual

418:"Clymer Tests the Hudson Hornet V8"

446:Buick: "The Golden Era", 1903-1915

14:

369:Severson, Aaron (22 March 2009).

279:version in the 1997 model year.

247:and individual rear suspension.

150:models of the 1963 through 1966

81:

63:

709:"Chevette: U.S. Economy Champ?"

235:models used a torque tube. The

416:Clymer, Floyd (October 1955).

162:end when cornering fast or on

1:

182:used the torque tube, while

263:independent rear suspension

199:American Motors Corporation

813:

641:– via Google Books.

588:– via Google Books.

432:– via Google Books.

74:chassis in side and plan.

40:limited-slip differential

605:. CarTech. p. 372.

599:Magnante, Steve (2013).

571:. Caltech. p. 372.

443:Therou, Francis (1971).

769:. CarTech. p. 67.

565:Magnant, Steve (2013).

349:"Open Shaft Advantages"

57:Rudimentary torque tube

324:Mitchell Automechanics

27:

24:

763:Thurn, Walt (2007).

449:. Decir Publishing.

375:ateupwithmotor.com

353:The Glasgow Herald

273:Chevrolet Corvette

252:Chevrolet Chevette

28:

732:Popular Mechanics

530:Popular Mechanics

422:Popular Mechanics

371:"Hotchkiss Drive"

132:cantilever spring

804:

781:

780:

760:

754:

753:

742:

736:

735:

723:

717:

716:

705:

699:

698:

678:

672:

671:

649:

643:

642:

640:

638:

623:

617:

616:

596:

590:

589:

587:

585:

562:

556:

555:

540:

534:

533:

522:

516:

515:

505:

499:

498:

496:

494:

483:

477:

474:

468:

467:

465:

463:

440:

434:

433:

431:

429:

413:

404:

401:

395:

392:

386:

385:

383:

381:

366:

357:

356:

345:

339:

338:

319:

313:

312:

310:

308:

293:

85:

67:

812:

811:

807:

806:

805:

803:

802:

801:

787:

786:

785:

784:

777:

762:

761:

757:

744:

743:

739:

725:

724:

720:

713:Popular Science

707:

706:

702:

695:

680:

679:

675:

665:

651:

650:

646:

636:

634:

631:Popular Science

625:

624:

620:

613:

598:

597:

593:

583:

581:

579:

564:

563:

559:

548:The SAE Journal

542:

541:

537:

524:

523:

519:

507:

506:

502:

492:

490:

485:

484:

480:

475:

471:

461:

459:

457:

442:

441:

437:

427:

425:

415:

414:

407:

402:

398:

393:

389:

379:

377:

368:

367:

360:

355:. 23 July 1929.

347:

346:

342:

335:

321:

320:

316:

306:

304:

295:

294:

290:

285:

214:Pontiac Tempest

203:Rambler Classic

188:Hotchkiss drive

172:

143:universal joint

122:American Motors

118:ball and socket

100:housing to the

93:

92:

91:

90:

89:

86:

77:

76:

75:

68:

59:

58:

52:

44:Hotchkiss drive

17:

12:

11:

5:

810:

808:

800:

799:

789:

788:

783:

782:

775:

755:

737:

718:

700:

693:

673:

663:

644:

618:

611:

591:

577:

557:

535:

517:

500:

478:

469:

455:

435:

405:

396:

387:

358:

340:

333:

314:

287:

286:

284:

281:

171:

168:

87:

80:

79:

78:

69:

62:

61:

60:

56:

55:

54:

53:

51:

48:

15:

13:

10:

9:

6:

4:

3:

2:

809:

798:

795:

794:

792:

778:

776:9781932494334

772:

768:

767:

759:

756:

751:

747:

741:

738:

733:

729:

722:

719:

714:

710:

704:

701:

696:

694:9780538330503

690:

686:

685:

677:

674:

670:

666:

664:9780801956324

660:

656:

655:

648:

645:

632:

628:

622:

619:

614:

612:9781613250570

608:

604:

603:

595:

592:

580:

578:9781613250570

574:

570:

569:

561:

558:

553:

549:

545:

544:"Drivetrains"

539:

536:

531:

527:

521:

518:

513:

512:

504:

501:

488:

482:

479:

473:

470:

458:

456:9780912346007

452:

448:

447:

439:

436:

423:

419:

412:

410:

406:

400:

397:

391:

388:

376:

372:

365:

363:

359:

354:

350:

344:

341:

336:

334:9780135837825

330:

326:

325:

318:

315:

303:

299:

292:

289:

282:

280:

278:

274:

269:

266:

264:

260:

255:

253:

248:

246:

242:

238:

234:

230:

225:

223:

220:coupled to a

219:

215:

210:

208:

204:

200:

195:

193:

189:

185:

181:

177:

169:

167:

165:

159:

157:

153:

149:

144:

140:

135:

133:

128:

123:

119:

114:

112:

111:trailing arms

108:

103:

99:

84:

73:

66:

49:

47:

45:

41:

37:

33:

23:

19:

765:

758:

740:

731:

721:

712:

703:

683:

676:

668:

653:

647:

635:. Retrieved

630:

621:

601:

594:

582:. Retrieved

567:

560:

551:

547:

538:

529:

520:

510:

503:

491:. Retrieved

481:

472:

460:. Retrieved

445:

438:

426:. Retrieved

421:

399:

390:

378:. Retrieved

374:

352:

343:

323:

317:

305:. Retrieved

302:autoweek.com

301:

291:

270:

267:

256:

249:

226:

211:

196:

173:

160:

136:

115:

107:leaf springs

102:transmission

98:differential

94:

50:Construction

31:

29:

18:

241:Peugeot 505

237:Peugeot 504

229:Peugeot 403

170:Application

152:AMC Rambler

127:panhard rod

36:drive shaft

32:torque tube

283:References

207:Ambassador

148:V8-powered

139:driveshaft

130:allowed a

116:A type of

245:transaxle

222:transaxle

212:The 1961

180:Chevrolet

164:washboard

70:The 1904

791:Category

750:Archived

493:27 April

218:inline 4

192:Nash 600

176:Model Ts

166:roads".

637:11 July

584:11 July

462:11 July

428:11 July

380:11 July

307:11 July

154:used a

72:Rover 8

773:

691:

661:

609:

575:

453:

331:

259:Avanti

239:, and

184:Buick

26:ball.

771:ISBN

689:ISBN

659:ISBN

639:2024

607:ISBN

586:2024

573:ISBN

495:2019

464:2024

451:ISBN

430:2024

382:2024

329:ISBN

309:2024

271:The

250:The

231:and

227:The

205:and

233:404

109:or

105:as

793::

748:.

730:.

711:.

667:.

629:.

552:57

550:.

546:.

528:.

420:.

408:^

373:.

361:^

351:.

300:.

277:C5

265:.

113:.

30:A

779:.

697:.

615:.

497:.

384:.

337:.

311:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.