259:(regenerated cellulose) in 1894. In 1871 Thomas Taylor obtained the United States Patent for vulcanized fibre. The first organized industrial company to make vulcanized fibre was the Vulcanized Fibre Company, incorporated first as a New York Corporation formed June 19, 1873 listed with William Courtenay President and Charles F. Cobby Secretary. The first N.Y. corporation was also found in the 1873 N.Y. City Directory which also listed William Courtenay President and Charles F. Cobby Secretary in 1873. From 1873 until 1878 the Vulcanized Fiber Co. had a New York office address of 17 Dey St., while the factory was located in Wilmington Delaware. This can be seen in the many advertisements that were placed in different publications at this time in history. A special charter was granted by the state of Delaware in 1873 until the Delaware corporation was finally incorporated on February 8, 1875 which now listed William Courtenay President and Clement B. Smyth Secretary.

380:, thus promoting bonding between the cellulose chains. Once the bonding was established, the process of leaching out the zinc chloride from the vulcanized fibre could begin. The leaching (removal by diffusion out) of the zinc chloride was accomplished by subjecting the vulcanized fibre to successively less concentrated baths of zinc chloride. The rate at which this could occur was constrained by osmotic forces. If the rate at which the vulcanized fibre was subjected to lower and lower concentrations of zinc chloride solution were too rapid, the osmotic forces could result in ply separations. The final leaching bath concentration was 0.05% zinc chloride. Thicknesses up to 0.093” (=2.4 mm), can be made on continuous lines that stretch up to 1,000 feet (305m) in length.

389:

concentrated until the desired 0.05% was reached. The thicker the material, the longer it took to leach the zinc chloride to 0.05%. For the thickest products, times of 18 months to 2 years were needed. The zinc chloride used in these processes was for the most part not consumed in achieving the desired bonding. Indeed any dilution of the zinc chloride resulting from the leaching was dealt with by using evaporators to bring the zinc chloride solution back to the 70 Baume needed for using it again for saturating. In a sense, zinc chloride can be thought of as a catalyst in the making of the vulcanized fibre.

320:. Before the processing of wood pulp and chemical wood pulps in the mid-19th century, the dominant fibre source for paper making was cotton and linen rags. The cotton rag sheet produced for conversion to vulcanized fibre is made like a sheet suitable for saturating. A paper is made for saturating by omitting any sizing additive, either beater added or surface applied. Today most paper sheets made for writing, printing, and coating have internal (

167:; however, Leatheroid is made using a different chemical process. Since 2004, the scientific community has regained interest in this material due to its renewability and excellent physical properties, giving birth to the field of all-cellulose composites. These composites are all made of a matrix consisting of dissolved or partially dissolved cellulose, and the reinforcement remains cellulose fibres. A variety of solvents other than

1538:

22:

415:

thicknesses, it can be moulded to shape with steam and pressure. One application for vulcanized fibre that attests to its physical strength is that it is the preferred material for heavy sanding discs. Physical strength is anisotropic, owing to the roller calendering process, with it typically being 50% stronger in the sheet's longitudinal direction, rather than transverse.

1548:

121:

418:

The electrical properties exhibited by vulcanized fibre are high insulating value, and arc and track resistance with service temperature of up to 110 to 120 °C. Fibre was popular as an electrical insulator for a large part of the mid-20th century, not because its resistance as an insulator was

367:

the cellulose. The fibre swelling explains why paper filters cannot be used to filter zinc chloride solutions. It is also the reason why a number of paper plies were used to build up to the desired vulcanized fibre thickness, rather treating a single paperboard thickness. For instance, the practice

211:

Vulcanized fibre has a long history in engineering, from the

Victorian period onward. Although there are now many materials, mostly synthetic polymers, with higher performance, fibre has been applied widely and still retains many applications. As it is stronger in thin sections between mechanically

401:

to flatness. The continuous process-made vulcanized fibre could then be sheeted or wound up into rolls. The density of the finished vulcanized fibre is 2 to 3 times greater than the paper from which it starts. The density increase is the result of 10% machine direction shrinkage, 20% cross machine

414:

nearly 100%-cellulose mass free from any artificial glues, resins, or binders. The finished vulcanized fibre has useful mechanical and electrical properties. It offers high tear and tensile strength, while in the thinner thicknesses allowing flexibility to conform to curves and bends. In thicker

269:

In 1922 the name was changed again when it was directly purchased by the

National Fibre & Insulation Company of Yorklyn Delaware (who was also the owner of the Keystone Fibre Co.). The president of the National Fibre Company at this time was J. Warren Marshall, who took the same office after

265:

On

December 4, 1901, during a merger and consolidation the Vulcanized Fibre Co. changed its name to the "American Vulcanized Fiber Co." which was formed for the purpose of consolidating: Kartavert Mfg. Company, Wilmington, Delaware; American Hard Fibre Company, Newark, Delaware; Vulcanized Fibre

238:

Until the development of modern plastics from the 1930s, fibre was the standard electrical insulating material for many small components. It could be cut to size easily, either in mass production or hand-trimmed to fit. It was particularly common in the assembly of large machines, such as motor

299:

Some of the companies involved in vulcanized fibre development in the

Wilmington region were the Nunsuch Fiber Company, American Hard Fiber Company, American Vulcanized Fibre Company, Continental Fibre Co., Diamond State Fibre Co., and Franklin Fibre Company. In the 1965 Post’s Pulp and Paper

388:

For thickness above 0.093” (2.4 mm) and up to 0.375” (9.5 mm), a discrete laminated sheet (similar in size (l x w) to plywood) was produced by the cutdown process. The cutdown sheets were racked and moved from vat to vat by overhead tracked cranes. Each vat was successively less

227:

and general plumbing work. They swell slightly with exposure to water, making a good seal. They may also be used with hydrocarbons, provided the temperature is not too high. Unlike rubber, fibre washer seals are considered as a single-use item.

300:

Directory, National

Vulcanized Fibre Co. was listed as having two mills' producing rag paper for vulcanized fibre. They were at Newark, producing 15 tons a day; and Yorklyn, producing 18 tons a day. This compares with Spaulding Fibre’s

438:

Electrical Grade: high dielectric grey, 100% cotton, very flexible, (historically called fishpaper), this grade is suitable for layer and ground insulation and has variations including top-stick grade used for wedges in small

344:. A sheet made for saturating would have none of those chemical ingredients. The unsized saturating cotton fibre paper prepared for vulcanized fibre would be passed through a vat containing a zinc chloride solution.

448:

Wood

Laminating: Tough, multi-directional tensile and torsion strength, provides support and strength wherever wood laminations are used, particularly used under thin and exotic veneers as a stabilizer/strengthener.

532:

Dormanns, Jan; Schuermann, Jeremias; Müssig, Jorg; Duchemin, Benoit; Staiger, Mark (2016). "Solvent infusion processing of all-cellulose composite laminates using an aqueous NaOH/urea solvent system".

701:; Vol. II; Second Edition Revised and Enlarged: Interscience Publishers Inc., New York, John Wiley & Sons Inc., New York; 1952, 1960; Library of Congress 60-13120; Third Printing 1967, pp654-655

262:

In 1884 Courtenay & Trull Co. N.Y. was merged into the

Vulcanized Fibre Co. which gave the company control over a new invention called by the trade name "Gelatinized Fibre".

419:

particularly good, especially not if moisture levels were high, but it showed far better resistance to tracking and breakdown than early wood flour-filled polymers like

359:

in density (1.93 specific gravity) and about 43.3 °C (109.9 °F; 316.4 K). This is roughly a 70% percent zinc chloride solution. Zinc chloride is a mild

505:

Duchemin, Benoit; Mathew, Aji; Oksman, Kristiina (2009). "All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride".

1448:

625:

643:

Industries of

Delaware: historical and descriptive review : cities, towns and business interests, institutions, manufacturing and commercial advantages

363:

with a solution pH of about 4. Zinc chloride can dissolve cellulose, starch, and silk. The zinc chloride used in making vulcanized fibre swelled and

376:

Once the paper plies were saturated with the gelatinizing zinc chloride, they were pressed together. The pressing allowed intimate contact of the

308:, but marketed them under different names: Spaulding’s was Spauldite and National’s brand was Phenolite and Iten Industries' Resiten or Itenite.

235:

to complex shapes and so it is widely used for shaped gaskets. These may be used for sealing, as heat insulators, or as mechanical spacers.

273:

In 1965 the name was changed again to the NVF Company in order to avoid confusion over the years with a new and changing product line.

284:

led to a proliferation of companies in the vulcanized fibre business. Over the years, these companies reorganized and merged. In 1922

1433:

1428:

629:

105:

39:

1443:

1438:

747:

86:

675:

664:

58:

43:

1362:

251:

for vulcanized fibre was obtained in 1859 by the

Englishman Thomas Taylor. He gained the patent after the introduction of

435:

Commercial Grade; standard grey, black or red, used for many applications such as washers, gaskets, gears, handles, etc.

65:

397:

Once the vulcanized fibre is leached free of the zinc chloride, it is dried to 5 to 6 percent moisture, and pressed or

1013:

445:

Bone Fibre: Exceptionally hard and dense, used for tight machining, tubing, pool cue ferrules (tips), cut out fuses.

1309:

1230:

72:

426:

Vulcanized fibre shows high resistance to penetration by most organic solvents, oils, and petroleum derivatives.

285:

368:

was to use 8 paper plies of 0.04 mm thickness each, as opposed to a single paperboard ply of 0.32 mm.

911:

841:

289:

277:

711:

558:

288:

Company emerged as the main competitor to

Spaulding Fibre, which had begun developing vulcanized products in

54:

1423:

1357:

1314:

613:

442:

Trunk Fibre: Tough and abrasion resistant; used to surface steamer trunks, drum cases, wear and skid panels.

32:

1337:

1256:

981:

866:

1125:

479:

151:. The newer wood-laminating grade of vulcanized fibre is used to strengthen wood laminations used in

1460:

740:

293:

1582:

1120:

976:

966:

337:

333:

1488:

466:

Huber, Tim; Müssig, Jorg; Curnow, Owen; Pang, Shusheng; Bickerton, Simon; Staiger, Mark (2012).

224:

1551:

1033:

1018:

876:

767:

686:

653:

642:

599:

301:

232:

213:

79:

1513:

1372:

1210:

988:

781:

541:

514:

487:

321:

172:

1572:

1523:

1407:

1392:

1347:

1266:

1220:

1190:

1130:

1115:

956:

896:

846:

794:

789:

377:

483:

411:

1577:

1541:

1498:

1185:

1150:

998:

926:

901:

836:

733:

356:

266:

Company, Wilmington, Delaware. and the Laminar Fibre Company of North Cambridge, Mass.

148:

545:

518:

364:

304:

plant, then producing 40 tons a day (Post’s directory). The competitors also produced

212:

rigid components, rather than relying on its own strength, it has mostly been used as

1566:

1387:

1377:

1294:

1180:

1170:

1140:

1105:

1068:

1003:

971:

936:

352:

256:

200:

168:

1503:

1402:

1319:

1276:

1175:

1085:

1058:

1053:

1048:

993:

961:

941:

916:

176:

1518:

1483:

1478:

1397:

1367:

1160:

1145:

1090:

1080:

1063:

1043:

1028:

1008:

921:

871:

771:

160:

156:

21:

676:

VULCANIZED FIBER COMPANY - MERGES INTO A NEW NAME AMERICAN VULCANIZED FIBRE CO.

467:

1455:

1382:

1304:

1261:

1235:

1225:

1155:

1135:

1110:

1075:

1038:

951:

931:

491:

360:

223:

Fibre washers are one of the cheapest conformal elastomer gaskets for sealing

196:

164:

139:. This material is a tough, resilient, hornlike material that is lighter than

586:

569:

355:

is highly soluble in water. The solution used in saturating the paper was 70

1493:

1251:

1215:

1195:

1165:

1100:

1095:

946:

317:

252:

140:

136:

1508:

1352:

1342:

1299:

1023:

420:

398:

305:

281:

559:

Pike Creek: Industry And Farming Along A Northern Delaware River; p 4-8.

1271:

816:

810:

665:

Courtenay & Trull Co. N.Y. was merged into the Vulcanized Fibre Co.

270:

consolidating into the new company "National Vulcanized Fibre Company.

188:

163:. It could also be Blue. A product very similar to vulcanized fibre is

144:

584:

Taylor, Thomas, Improvement in the treatment of paper and paper-pulp,

120:

341:

325:

248:

217:

1286:

1205:

1200:

906:

756:

329:

180:

119:

296:, nearly a quarter century after the industry began in Delaware.

184:

179:. Whereas the original idea was to use long reinforcing fibres (

152:

729:

199:

mechanical properties, the field has also explored the use of

15:

626:"Early Known Insulating Materials (incl Vulcanized Fibre Co)"

124:

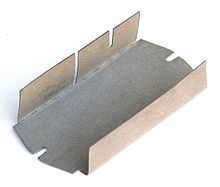

Formed electrical grade vulcanized fibre insulating shield

725:

570:"PLASTICS HISTORY: Plastic Distributor & Fabricator"

402:

direction shrinkage, and 30% shrinkage in thickness.

534:

Composites Part A: Applied Science and Manufacturing

507:

Composites Part A: Applied Science and Manufacturing

1471:

1416:

1328:

1285:

1244:

889:

859:

829:

803:

780:

46:. Unsourced material may be challenged and removed.

159:, support beams and as a sub-laminate under thin

699:Pulp and Paper Chemistry and Chemical Technology

468:"A critical review of all-cellulose composites"

741:

8:

220:, and a variety of shims or packing pieces.

856:

826:

800:

748:

734:

726:

195:) in order to confer the composites with

106:Learn how and when to remove this message

135:is a laminated plastic composed of only

687:Fiber Company History & Merger Tree

654:Laws of the state of Delaware, Volum 15

458:

340:(AKD) and surface sizing provided by

7:

1547:

255:in 1856 and before the invention of

44:adding citations to reliable sources

600:"History of the state of Delaware"

614:The New York City register page 34

14:

546:10.1016/j.compositesa.2015.12.002

519:10.1016/j.compositesa.2009.09.013

1546:

1537:

1536:

20:

712:"Tufnol Vulcanised Fibre Sheet"

31:needs additional citations for

1:

1363:Environmental impact of paper

171:has been explored, including

472:Journal of Materials Science

318:paper made from cotton rags

1599:

1310:Surface chemistry of paper

813:(Zuo Bo/Tso Po/Tso Tzǔ-yi)

1532:

763:

492:10.1007/s10853-011-5774-3

316:The process started with

286:National Vulcanized Fiber

842:Friedrich Gottlob Keller

334:alkyl succinic anhydride

290:Rochester, New Hampshire

175:at low temperatures and

147:, and stiffer than most

1358:Elemental chlorine free

1315:Units of paper quantity

590:, granted May 16, 1871.

410:The final product is a

276:The water power of the

1338:Bleaching of wood pulp

231:Fibre sheet is easily

125:

1257:Corrugated fiberboard

1014:Electrical insulation

867:Thomas Francis Carter

123:

280:streams in Northern

40:improve this article

587:U.S. patent 114,880

484:2012JMatS..47.1171H

294:Tonawanda, New York

632:on March 15, 2012.

338:alkyl ketene dimer

126:

55:"Vulcanized fibre"

1560:

1559:

885:

884:

877:Tsien Tsuen-hsuin

855:

854:

825:

824:

768:Paper engineering

602:Volume 2 Page 415

574:Plastics Magazine

513:(12): 1171–1186.

393:Dried and pressed

116:

115:

108:

90:

1590:

1550:

1549:

1540:

1539:

1524:Beverage cartons

1514:Watercolor paper

1373:Hollander beater

857:

827:

801:

750:

743:

736:

727:

720:

719:

708:

702:

697:James P. Casey,

695:

689:

684:

678:

673:

667:

662:

656:

651:

645:

640:

634:

633:

628:. Archived from

622:

616:

611:

605:

597:

591:

589:

582:

576:

567:

561:

556:

550:

549:

529:

523:

522:

502:

496:

495:

478:(3): 1171–1186.

463:

378:cellulose fibres

173:sodium hydroxide

129:Vulcanized fibre

111:

104:

100:

97:

91:

89:

48:

24:

16:

1598:

1597:

1593:

1592:

1591:

1589:

1588:

1587:

1563:

1562:

1561:

1556:

1528:

1467:

1412:

1408:Sulfite process

1393:Paper recycling

1348:Conical refiner

1330:

1324:

1281:

1267:Paper chemicals

1240:

881:

851:

847:Charles Fenerty

821:

799:

795:Missal of Silos

790:Battle of Talas

776:

759:

754:

724:

723:

710:

709:

705:

696:

692:

685:

681:

674:

670:

663:

659:

652:

648:

641:

637:

624:

623:

619:

612:

608:

598:

594:

585:

583:

579:

568:

564:

557:

553:

531:

530:

526:

504:

503:

499:

465:

464:

460:

455:

432:

408:

395:

386:

374:

350:

314:

245:

209:

143:, tougher than

112:

101:

95:

92:

49:

47:

37:

25:

12:

11:

5:

1596:

1594:

1586:

1585:

1580:

1575:

1565:

1564:

1558:

1557:

1555:

1554:

1544:

1533:

1530:

1529:

1527:

1526:

1521:

1516:

1511:

1506:

1501:

1496:

1491:

1486:

1481:

1475:

1473:

1469:

1468:

1466:

1465:

1464:

1463:

1453:

1452:

1451:

1446:

1441:

1436:

1431:

1424:Paper industry

1420:

1418:

1414:

1413:

1411:

1410:

1405:

1400:

1395:

1390:

1385:

1380:

1375:

1370:

1368:Handmade paper

1365:

1360:

1355:

1350:

1345:

1340:

1334:

1332:

1326:

1325:

1323:

1322:

1317:

1312:

1307:

1302:

1297:

1291:

1289:

1287:Specifications

1283:

1282:

1280:

1279:

1274:

1269:

1264:

1259:

1254:

1248:

1246:

1242:

1241:

1239:

1238:

1233:

1228:

1223:

1218:

1213:

1208:

1203:

1198:

1193:

1188:

1183:

1178:

1173:

1168:

1163:

1158:

1153:

1148:

1143:

1138:

1133:

1128:

1126:Plastic-coated

1123:

1118:

1113:

1108:

1103:

1098:

1093:

1088:

1083:

1078:

1073:

1072:

1071:

1061:

1056:

1051:

1046:

1041:

1036:

1031:

1026:

1021:

1016:

1011:

1006:

1001:

996:

991:

986:

985:

984:

974:

969:

964:

959:

954:

949:

944:

939:

934:

929:

924:

919:

914:

909:

904:

899:

893:

891:

887:

886:

883:

882:

880:

879:

874:

869:

863:

861:

853:

852:

850:

849:

844:

839:

837:Matthias Koops

833:

831:

823:

822:

820:

819:

814:

807:

805:

798:

797:

792:

786:

784:

778:

777:

775:

774:

764:

761:

760:

755:

753:

752:

745:

738:

730:

722:

721:

703:

690:

679:

668:

657:

646:

635:

617:

606:

592:

577:

562:

551:

524:

497:

457:

456:

454:

451:

450:

449:

446:

443:

440:

436:

431:

428:

407:

404:

394:

391:

385:

382:

373:

370:

349:

346:

313:

310:

244:

241:

208:

205:

149:thermoplastics

131:also known as

114:

113:

28:

26:

19:

13:

10:

9:

6:

4:

3:

2:

1595:

1584:

1581:

1579:

1576:

1574:

1571:

1570:

1568:

1553:

1545:

1543:

1535:

1534:

1531:

1525:

1522:

1520:

1517:

1515:

1512:

1510:

1507:

1505:

1502:

1500:

1497:

1495:

1492:

1490:

1487:

1485:

1482:

1480:

1477:

1476:

1474:

1470:

1462:

1459:

1458:

1457:

1454:

1450:

1449:United States

1447:

1445:

1442:

1440:

1437:

1435:

1432:

1430:

1427:

1426:

1425:

1422:

1421:

1419:

1415:

1409:

1406:

1404:

1401:

1399:

1396:

1394:

1391:

1389:

1388:Paper machine

1386:

1384:

1381:

1379:

1378:Kraft process

1376:

1374:

1371:

1369:

1366:

1364:

1361:

1359:

1356:

1354:

1351:

1349:

1346:

1344:

1341:

1339:

1336:

1335:

1333:

1327:

1321:

1318:

1316:

1313:

1311:

1308:

1306:

1303:

1301:

1298:

1296:

1293:

1292:

1290:

1288:

1284:

1278:

1275:

1273:

1270:

1268:

1265:

1263:

1260:

1258:

1255:

1253:

1250:

1249:

1247:

1243:

1237:

1234:

1232:

1229:

1227:

1224:

1222:

1219:

1217:

1214:

1212:

1209:

1207:

1204:

1202:

1199:

1197:

1194:

1192:

1189:

1187:

1184:

1182:

1179:

1177:

1174:

1172:

1169:

1167:

1164:

1162:

1159:

1157:

1154:

1152:

1149:

1147:

1144:

1142:

1139:

1137:

1134:

1132:

1129:

1127:

1124:

1122:

1119:

1117:

1114:

1112:

1109:

1107:

1104:

1102:

1099:

1097:

1094:

1092:

1089:

1087:

1084:

1082:

1079:

1077:

1074:

1070:

1067:

1066:

1065:

1062:

1060:

1057:

1055:

1052:

1050:

1047:

1045:

1042:

1040:

1037:

1035:

1032:

1030:

1027:

1025:

1022:

1020:

1017:

1015:

1012:

1010:

1007:

1005:

1002:

1000:

997:

995:

992:

990:

987:

983:

980:

979:

978:

975:

973:

970:

968:

965:

963:

960:

958:

955:

953:

950:

948:

945:

943:

940:

938:

935:

933:

930:

928:

925:

923:

920:

918:

915:

913:

910:

908:

905:

903:

900:

898:

895:

894:

892:

888:

878:

875:

873:

870:

868:

865:

864:

862:

858:

848:

845:

843:

840:

838:

835:

834:

832:

828:

818:

815:

812:

809:

808:

806:

802:

796:

793:

791:

788:

787:

785:

783:

779:

773:

769:

766:

765:

762:

758:

751:

746:

744:

739:

737:

732:

731:

728:

717:

713:

707:

704:

700:

694:

691:

688:

683:

680:

677:

672:

669:

666:

661:

658:

655:

650:

647:

644:

639:

636:

631:

627:

621:

618:

615:

610:

607:

604:

603:

596:

593:

588:

581:

578:

575:

571:

566:

563:

560:

555:

552:

547:

543:

539:

535:

528:

525:

520:

516:

512:

508:

501:

498:

493:

489:

485:

481:

477:

473:

469:

462:

459:

452:

447:

444:

441:

437:

434:

433:

429:

427:

424:

422:

416:

413:

405:

403:

400:

392:

390:

383:

381:

379:

371:

369:

366:

362:

358:

354:

353:Zinc chloride

348:Zinc chloride

347:

345:

343:

339:

335:

331:

327:

323:

319:

311:

309:

307:

303:

297:

295:

291:

287:

283:

279:

274:

271:

267:

263:

260:

258:

257:viscose rayon

254:

250:

242:

240:

236:

234:

229:

226:

221:

219:

215:

206:

204:

202:

201:nanocellulose

198:

194:

190:

186:

182:

178:

177:ionic liquids

174:

170:

169:zinc chloride

166:

162:

158:

154:

150:

146:

142:

138:

134:

130:

122:

118:

110:

107:

99:

88:

85:

81:

78:

74:

71:

67:

64:

60:

57: –

56:

52:

51:Find sources:

45:

41:

35:

34:

29:This article

27:

23:

18:

17:

1489:Papier-mâché

1484:Paper towels

1403:Soda pulping

1320:Wet strength

1121:Photographic

994:Cotton (rag)

967:Construction

715:

706:

698:

693:

682:

671:

660:

649:

638:

630:the original

620:

609:

601:

595:

580:

573:

565:

554:

537:

533:

527:

510:

506:

500:

475:

471:

461:

425:

417:

409:

396:

387:

375:

351:

328:provided by

315:

298:

275:

272:

268:

264:

261:

247:The British

246:

237:

230:

222:

210:

207:Applications

192:

161:wood veneers

132:

128:

127:

117:

102:

93:

83:

76:

69:

62:

50:

38:Please help

33:verification

30:

1519:Paper money

1479:Lined paper

1398:Papermaking

1331:and process

1329:Manufacture

1305:Paper sizes

1034:Greaseproof

1019:Genkō yōshi

872:Dard Hunter

804:Originators

772:Papermaking

540:: 130–140.

412:homogeneous

365:gelatinized

225:pipe unions

197:anisotropic

157:skateboards

1567:Categories

1456:Paper mill

1383:Organosolv

1262:Fiber crop

1252:China clay

1211:Waterproof

1111:Paperboard

989:Correction

982:Carbonless

830:Developers

453:References

406:Properties

399:calendered

361:Lewis acid

336:(ASA), or

165:leatheroid

66:newspapers

1583:Cellulose

1509:Notebooks

1494:Cardboard

1277:Wood pulp

1245:Materials

1221:Wood-free

1196:Wallpaper

1191:Tree-free

1131:Red rosin

1116:Parchment

1101:Onionskin

1096:Newsprint

957:Cartridge

952:Cardstock

947:Cardboard

897:Acid-free

302:Tonawanda

253:celluloid

239:winding.

141:aluminium

137:cellulose

133:red fibre

1542:Category

1499:Clothing

1417:Industry

1353:Deinking

1343:Calender

1300:Grammage

1186:Transfer

1151:Security

1024:Glassine

927:Blotting

902:Air-laid

860:Scholars

421:Bakelite

372:Pressing

306:bakelite

282:Delaware

278:Piedmont

96:May 2020

1552:Commons

1504:Tissues

1295:Density

1272:Papyrus

1231:Writing

1181:Tracing

1171:Thermal

1146:Scritta

1141:Rolling

1106:Origami

1069:Butcher

1004:Display

972:Contact

937:Bristol

912:Asphalt

817:Damjing

811:Cai Lun

782:History

480:Bibcode

439:motors.

324:added)

312:Process

243:History

233:die-cut

218:gaskets

214:washers

189:viscose

145:leather

80:scholar

1573:Fibers

1434:Europe

1429:Canada

1176:Tissue

1086:Manila

1059:Korean

1054:Ingres

1049:Inkjet

962:Coated

942:Carbon

917:Banana

716:Tufnol

430:Grades

342:starch

326:sizing

322:beater

249:patent

82:

75:

68:

61:

53:

1578:Paper

1444:Japan

1439:India

1206:Wasli

1201:Washi

1161:Stone

1091:Mummy

1081:Lokta

1064:Kraft

1044:India

1029:Graph

999:Crêpe

922:Bible

907:Amate

890:Types

757:Paper

357:Baumé

330:rosin

181:ramie

87:JSTOR

73:books

1472:Uses

1461:List

1236:Xuan

1226:Wove

1156:Seed

1136:Rice

1076:Laid

1039:Hemp

977:Copy

932:Bond

384:Vats

292:and

185:flax

153:skis

59:news

1216:Wax

1166:Tar

542:doi

515:doi

488:doi

193:etc

42:by

1569::

1009:Dó

770:/

714:.

572:,

538:82

536:.

511:40

509:.

486:.

476:47

474:.

470:.

423:.

332:,

216:,

203:.

191:,

187:,

183:,

155:,

749:e

742:t

735:v

718:.

548:.

544::

521:.

517::

494:.

490::

482::

109:)

103:(

98:)

94:(

84:·

77:·

70:·

63:·

36:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.