1603:(MISCAPs). In short, parylene N and AF-4 (those parylenes with no functional groups) are pin-hole free at ~14 Å. This results because the parylene repeat units possess a phenyl ring and due to the high electronic polarizability of the phenyl ring adjacent repeat units order themselves in the XY-plane. As a result of this interaction parylene MLs are surface independent, except for transition metals, which de-activate the triplet (benzoid) state and therefore the parylenes cannot be initiated. This finding of parylenes as molecular layers is very powerful for industrial applications because of the robustness of the process and that the MLs are deposited at room temperature. In this way parylenes can be used as diffusion barriers and for reducing the polarizability of surface (de-activation of oxide surfaces). Combining the properties of the reactive parylenes with the observation that they can form dense pin-hole-free molecular layers, parylene X has been utilized as a genome sequencing interface layer.

1440:

727:

barrier against water then the apolar chemistries such as parylene E are much more effective. For moisture barriers the three principal material parameters to be optimized are: coating density, coating polarity (olefin chemistry is best) and a glass-transition temperature above room temperature and ideally above the service limit of the printed-circuit board, device or part. In this regard parylene E is a best choice although it has a low density compared to, for example, parylene C.

1352:

1240:

600:

342:

20:

1587:(SAMs). SAMs are long-chain alkyl chains, which interact with surfaces based on sulfur-metal interaction (alkylthiolates) or a sol-gel type reaction with a hydroxylated oxide surface (trichlorosilyl alkyls or trialkoxy alkyls). However, unless the gold or oxide surface is carefully treated and the alkyl chain is long, these SAMs form disordered monolayers, which do not pack well. This lack of packing causes issues in, for example,

1459:

1135:, meaning that it is stronger at lower temperatures than higher temperatures. There is critical threshold temperature above which there is practically no physisorption, and hence no deposition. The closer the deposition temperature is to the threshold temperature the weaker the physisorption. Parylene C has a higher threshold temperature, 90 °C, and therefore has a much higher deposition rate, greater than 1

389:

mitigates the deposition of a parylene-like material on the downside of the pyrolysis tube. This material becomes carbonized and generates particles in situ to contaminate clean rooms and create defects on printed-circuit boards that are often called "stringers and nodules". Parylene N and E do not have this problem and therefore are preferred for manufacturing and clean room use.

1161:

1115:

28:

1080:-xylylene intermediate has two quantum mechanical states, the benzoid state (triplet state) and the quinoid state (singlet state). The triplet state is effectively the initiator and the singlet state is effectively the monomer. The triplet state can be de-activated when in contact with transition metals or metal oxides including Cu/CuO

1393:

491:

1146:

Another relevant property for the deposition process is polarizability, which determines how strongly the monomer interacts with the surface. Deposition of halogenated parylenes strongly correlates with molecular weight of the monomer. The fluorinated variants are an exception: the polarizability of

1057:

Parts to be coated need to be clean in order to ensure good adherence of the film. Since the monomer diffuses, areas that are not to be coated must be hermetically sealed, without gaps, crevices or other openings. The part must be maintained in a relatively narrow window of pressure and temperature.

713:

Parylenes are relatively flexible (0.5 GPa for parylene N), except for cross-linked parylene X (1.0 GPa), and have poor oxidative resistance (~60–100 °C, depending on failure criteria) and UV stability, except for parylene AF-4. However, parylene AF-4 is more expensive due to

704:

in its as-deposited condition and it does not appreciably become more crystalline until it undergoes a crystallographic phase transformation at ~220 °C to hexagonal, at which point it becomes highly crystalline like the fluorinated parylenes. It can reach 80% crystallinity at anneal temperatures

1602:

measurements, where MLs thicker than 10 Å had an equilibrium contact angle of 80 degrees (same as bulk parylene N) but those thinner had a reduced contact angle. This was also confirmed with electrical measurements (bias-temperature stress measurements) using metal-insulator-semiconductor capacitors

1294:

Selection of a leaving group may consider its toxicity (which excludes sulfur and amine-based reactions), how easily it leaves the precursor, and possible interference with the polymerization. The leaving group can either be trapped before the deposition chamber, or it can be highly volatile so that

311:

Union

Carbide went on to undertake research into the synthesis of numerous parylene precursors, including parylene AF-4, throughout the 1960s into the early 1970s. Union Carbide purchased NovaTran (a parylene coater) in 1984 and combined it with other electronic chemical coating businesses to

726:

As a moisture diffusion barrier, the efficacy of halogneated parylene coatings scales non-linearly with their density. Halogen atoms such as F, Cl and Br add much density to the coating and therefore allow the coating to be a better diffusion barrier; however, if parylenes are used as a diffusion

388:

that may harm vacuum pumps and other equipment. The chlorine atom leaves the phenyl ring in the pyrolysis tube at all temperatures; however, optimizing the pyrolysis temperature will minimize this problem. The free-radical (phenyl radical) generated in this process is not resonance-stabilized and

693:

Parylene thin films and coatings are transparent; however, they are not amorphous except for the alkylated parylenes. i.e. parylene E. As a result, of the coatings being semi-crystalline, they scatter light. Parylene N and C have a low degree of crystallinity; however, parylene VT-4 and AF-4 are

364:

Parylene C is the most used variety, due to its low cost of its precursor and to the balance of its properties as dielectric and moisture barrier properties and ease of deposition. A major disadvantage for many applications is its insolubility in any solvent at room temperature, which prevents

315:

There are parylene coating service companies located around the world, but there is limited commercial availability of parylene. The paracyclophane precursors can be purchased for parylene N, C, D, AF-4 and VT-4. Parylene services are provided for N, C, AF-4, VT-4 and E (copolymer of N and E).

479:

467:

1606:

One caveat with the molecular layer parylenes, namely they are deposited as oligomers and not high polymer. As a result, a vacuum anneal is needed to convert the oligomers to high polymer. For parylene N that temperature is 250 °C, whereas it is 300 °C for payrlene AF-4.

2598:

Laibinis, Paul E.; Whitesides, George M.; Allara, David L.; Tao, Yu Tai; Parikh, Atul N.; Nuzzo, Ralph G. (1991). "Comparison of the structures and wetting properties of self-assembled monolayers of n-alkanethiols on the coinage metal surfaces, copper, silver, and gold".

717:

Nearly all the parylenes are insoluble at room temperature, except for the alkylated parylenes, one of which is parylene E, and the alkylated-ethynyl parylenes. This lack of solubility has made it difficult to re-work printed circuit boards coated with parylene.

1054:-xylylene or a derivative thereof. This method has one very strong benefit, namely it does not generate any byproducts besides the parylene polymer, which would need to be removed from the reaction chamber and could interfere with the polymerization.

2653:

Fadeev, Alexander Y.; McCarthy, Thomas J. (2000). "Self-Assembly is Not the Only

Reaction Possible between Alkyltrichlorosilanes and Surfaces: Monomolecular and Oligomeric Covalently Attached Layers of Dichloro- and Trichloroalkylsilanes on Silicon".

546:

While parylene coatings are mostly used to protect an object from water and other chemicals, some applications require a coating that can bind to adhesives or other coated parts, or immobilize various molecules such as dyes, catalysts, or enzymes.

501:

These substitutions increase the intermolecular (chain-to-chain) distance, which makes the polymer more soluble and permeable. For example, compared to parylene C, parylene M was shown to have a lower dielectric constant (2.48 vs. 3.2 at

432:

Another fluorinated variant is parylene VT-4 (also called parylene F), with fluorine substituted for the four hydrogens on the aryl ring. This variant is marketed by Kisco with the trademark

Parylene CF. Because of the aliphatic

369:

Parylene C is also the most commonly used because of its relatively low cost. It can be deposited at room temperature while still possessing a high degree of conformality and uniformity and a moderate deposition rate in a batch process.

594:

Parylene AM is more reactive than the A variant. The amine of the latter, being adjacent to the phenyl ring, is in resonance stabilization and therefore less basic. However, parylene A is much easier to synthesize and hence cheaper.

307:

at temperatures exceeding 550 °C and in vacuum below 1 Torr. This process did not require a solvent and resulted in chemically resistant films free from pinholes. Union

Carbide commercialized a parylene coating system in 1965.

1358:

The advantage to this process is the low cost of synthesis for the precursor. The precursor is also a liquid and can be delivered by standard methods developed in the semiconductor industry, such as with a vaporizer, vaporizer with a

1142:

An important property of the monomer is the so-called 'sticking coefficient', that expresses the degree to which it adsorbs on the polymer. A lower coefficient results more uniform deposition thickness and a more conformal coating.

672:/parylene C) of parylene have been deposited at near-room temperature previously. With strongly electron withdrawing comonomers, parylene can be used as an initiator to initiate polymerizations, such as with N-phenyl

1575:. There are numerous other applications as parylene is an excellent moisture barrier. It is the most bio-accepted coating for stents, defibrillators, pacemakers and other devices permanently implanted into the body.

2315:

P. K. Wu; G. -R. Yang; L. You; D. Mathur; A. Cocoziello; C. -I. Lang; J. A. Moore; T. -M. Lu; H. Bakru (1997). "Deposition of High Purity

Parylene- F Using Low Pressure Low Temperature Chemical Vapor Deposition".

1551:

Since the coating process takes place at ambient temperature in a mild vacuum, it can be applied even to temperature-sensitive objects such as dry biological specimens. The low temperature also results in low

1139:/s, while still yielding fairly uniform coatings. In contrast, the threshold temperature of parylene AF-4 is very close to room temperature (30–35 °C), as a result, its deposition efficiency is poor.

1251:-cyclophane precursor dimer can be sublimed below <100 °C and cracked at 700–750 °C, higher than the temperature (680 °C) used to crack the unsubstituted cyclophane since the −CF

2455:

D.M. Dobkin, S. Mokhtari, M. Schmidt, A. Pant, L. Robinson, Mechanisms of

Deposition of SiO2 from TEOS and Related Organosilicon Compounds and Ozone" J. Electrochem. Soc. 142(7), 2332-40 (1995).

381:

manufacture. Moreover, some of the dimer precursor is decomposed by breaking of the aryl-chlorine bond during pyrolysis, generating carbonaceous material that contaminates the coating, and

2626:

Wasserman, Stephen R.; Tao, Yu Tai; Whitesides, George M. (1989). "Structure and reactivity of alkylsiloxane monolayers formed by reaction of alkyltrichlorosilanes on silicon substrates".

714:

a three-step synthesis of its precursor with low yield and poor deposition efficiency. Their UV stability is so poor that parylene cannot be exposed to regular sunlight without yellowing.

2235:

P. Kramer; A. K. Sharma; E. E. Hennecke; H. Yasuda (2003). "Polymerization of para-xylylene derivatives (parylene polymerization). I. Deposition kinetics for parylene N and parylene C".

1559:

Parylene AF-4 and VT-4 are both fluorinated and as a result very expensive compared to parylene N and C, which has severely limited their commercial use, except for niche applications.

1267:− bond. This resonance-stabilized intermediate is transported to a room temperature deposition chamber where polymerization occurs under low pressure (1–100 mTorr) conditions.

1978:

J. J. Senkevich; B. W. Woods; J. J. McMahon; P.-I Wang (2007). "Thermomechanical

Properties of Parylene X, A Room-Temperature Chemical Vapor Depositable Crosslinkable Polymer".

2681:

Senkevich, Jay J.; Mitchell, Christopher J.; Yang, G.-R.; Lu, T.-M. (2002). "Surface

Chemistry of Mercaptan and Growth of Pyridine Short-Chain Alkoxy Silane Molecular Layers".

2208:

H. J. Reich; D. J. Cram (1969). "Macro rings. XXXVI. Ring expansion, racemization, and isomer interconversions in the paracyclophane system through a diradical intermediate".

1833:

J. J. Senkevich; C. J. Mitchell; A. Vijayaraghavan; E. V. Barnat; J. F. McDonald; T.-M. Lu (2002). "The Unique

Structure/Properties of Chemical Vapor Deposited Parylene E".

1428:− is the leaving group; while it condenses in the deposition chamber, it does not interfere with the deposition of the polymer. This precursor is much less expensive than

1382:

and removed from monomer flow. Special precautions are needed since bromine and HBr are toxic and corrosive towards most metals and metal alloys, and bromine can damage

168:. Some of these variants are designated in commerce by letter-number codes such as "parylene C" and "parylene AF-4". Some of these names are registered

1556:

in the thin film. Moreover, the only gas in the deposition chamber is the monomer, without any solvents, catalysts, or byproducts that could attack the object.

550:

These "reactive" parylene coatings can be obtained with chemically active substituents. Two commercially available products are parylene A, featuring one

2129:

J.J. Senkevich; C.J. Wiegand; G.-R. Yang; T.-M. Lu (2004). "Selective

Deposition of Ultra-thin Poly(p-xylylene) Films on Dielectrics versus Copper Surfaces".

1868:

J. F. Gaynor; J. J. Senkevich; S. B. Desu (1996). "A New Method for Fabricating High Performance Polymeric Thin Films by Chemical Vapor Polymerization".

694:

highly crystalline ~60% in their as-deposited condition (hexagonal crystal structure) and therefore are generally not suitable as optical materials.

518:

for a 1-mil coating) but better solubility. However, the copolymer of parylene N and E has equivalent barrier performance of parylene C.

357:

bridge by other functional groups. The most common of these variants is parylene C, which has one hydrogen atom in the aryl ring replaced by

303:

A more efficient route was found in 1965 by William F. Gorham at Union Carbide. He deposited parylene films by the thermal decomposition of

2582:

1734:

1700:

1061:

The process involves three steps: generation of the gaseous monomer, adsorption on the part's surface, and polymerization of adsorbed film.

1087:

Polymerization may proceed by a variety of routes that differ in the transient termination of the growing chains, such as a radical group −

2114:

2097:

1951:

1439:

1220:

The same method can be used to deposit substituted parylenes. For example, parylene C can be obtained from the dimeric precursor

2305:-xylylene) from Alkoxide Precursors I: Optical Properties and Thermal Stability". Chemical Vapor Deposition, volume 17, pages 235-240.

1084:. Many of the parylenes exhibit this selectivity based on quantum mechanical deactivation of the triplet state, including parylene X.

680:

nanocomposites, parylene C could be used as a sacrificial layer to make nanoporous silica thin films with a porosity of >90%.

1505:, chemically resistant, and mostly impermeable to gases (including water vapor) and inorganic and organic liquids (including strong

2753:"Bias-Temperature Stability of Ultra Thin Parylene Capped PETEOS Dielectrics: Influence of Surface Oxygen on Copper Ion Diffusion"

641:, allowing parylene-to-parylene bonding without any by-products during processing. Unlike most other variants, parylene X is

613:

attached to the phenyl ring in some of the units. This variant, which contains no elements other than hydrogen and carbon, can be

2492:

J. J. Senkevich; S. B. Desu (1999). "Compositional studies of near-room temperature thermal CVD of poly(chloro-p-xylylene)/SiO

1654:

1592:

1239:

2173:

J. B. Fortin & T.-M. Lu (2000). "Mass spectrometry study during the vapor deposition of poly-para-xylylene thin films".

2005:

J.B. Fortin & T.-M. Lu (2001). "Ultraviolet radiation induced degradation of poly-para-xylylene (parylene) thin films".

510:), a lower dielectric constant (2.34 vs. 3.05 at 10 kHz), slightly worse moisture barrier properties (4.1 vs. 0.6

1751:

1436:; whereas the generation and delivery of the gaseous monomer of the Gorham process are difficult to measure and control.

1371:

lower the pyrolysis temperature, resulting in less char residue and a better coating. By either method an atomic bromine

1073:-xylylene monomer requires a minimum threshold temperature. For parylene N, its threshold temperature is 40 °C.

490:

397:

Another common halogenated variant is parylene AF-4, with the four hydrogen atoms on the aliphatic chain replaced by

697:

Parylene C will become more crystalline if heated at elevated temperatures until its melting point at 270 °C.

221:

or other chemicals to terminate the chain; and the coatings can be applied at or near room temperature, without any

47:

425:(Teflon), consistent with its superior oxidative and UV stability. Parylene AF-4 has been used to protect outdoor

406:

1432:-cyclophane. Moreover, being a liquid just above room temperature, this precursor can delivered reliably using a

701:

200:

1771:

1722:

1584:

1451:

The same chemistry can generate parylene AM-2 can be generated from the precursor α,α'-dimethyl-α,α'-dimethoxy-

538:-substituted variant trademarked by Kisco). The solubility of parylene AM-2 is not as good as parylene E.

478:

466:

1470:

Another example of this approach is the synthesis of parylene AF-4 from α,α'-diphenoxy-α,α,α',α'-tetrafluoro-

1537:

422:

2359:

Pebalk, A. V.; Kardash, I. E.; Kozlova, N. V.; Zaitseva, E. L.; Kozlov, Yu. A.; Pravednikov, A. N. (1980).

1903:

J.J. Senkevich; S. B. Desu (1999). "Near-Room-Temperature Thermal Chemical Vapor Deposition of Poly(chloro-

294:

1364:

1198:. This method (Gorham process) yields 100% monomer with no by-products or decomposition of the monomer.

1194:

at a relatively low temperature, then decomposing the vapor at 450–700 °C and pressure 0.01–1.0

2084:

2372:

1568:

515:

378:

1795:

W. F. Gorham (1966). "A New, General Synthetic Method for the Preparation of Linear Poly-p-xylylenes".

1498:

Parylenes may confer several desirable qualities to the coated parts. Among other properties, they are

1392:

2067:

1553:

2764:

2717:

2505:

2325:

2244:

2182:

2014:

1877:

1842:

1804:

1433:

1405:

1050:

Parylene coatings are generally applied by chemical vapor deposition in an atmosphere of the monomer

426:

402:

312:

form the Specialty Coating Systems division. The division was sold to Cookson Electronics in 1994.

1521:

1372:

1214:

626:

304:

1458:

1351:

2733:

2521:

2341:

1132:

196:

176:

521:

Replacement of one hydrogen by methyl on each carbon of the ethyl bridge yields parylene AM-2,

2797:

2578:

2572:

2276:

1730:

1696:

1666:

1184:

382:

188:

165:

1628:

Microwave electronics (e.g., protection of PTFE dielectric substrates from oil contamination)

2772:

2725:

2690:

2663:

2635:

2608:

2553:

2513:

2474:

2438:

2333:

2252:

2217:

2190:

2138:

2109:

2049:

2022:

1987:

1947:

1920:

1885:

1850:

1812:

1690:

1510:

1376:

630:

373:

Also, the chlorine on the phenyl ring of the parylene C repeat unit is problematic for

1567:

Parylene C and to a lesser extent AF-4, SF, HT (all the same polymer) are used for coating

2385:

1755:

1726:

1692:

Chemical vapor deposition polymerization: the growth and properties of parylene thin films

1181:

642:

634:

567:

214:

2768:

2721:

2509:

2329:

2248:

2186:

2018:

1881:

1846:

1808:

1180:-xylylene monomer is normally generated during the coating process by evaporating the

2465:

Senkevich, Jay J. (2013). "Parylene AF-4 via the Trapping of a Phenoxy Leaving Group".

1572:

599:

361:. Another common variant is parylene D, with two such substitutions on the ring.

341:

234:

19:

2098:"Selective growth of poly(p-phenylene vinylene) prepared by chemical vapor deposition"

2026:

2791:

2737:

1599:

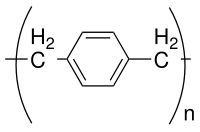

1413:

1128:

606:

2544:

J. J. Senkevich & P.-I. Wang (2009). "Molecular Layer Chemistry via Parylenes".

2525:

2345:

449:. Substitution may occur on either the phenyl ring or the ethylene bridge, or both.

2040:

Senkevich, Jay J. (2014). "Tert-Butylethynyl-parylene and Phenylethynyl-parylene".

1598:

The observation that parylenes could form ordered molecular layers (MLs) came with

1284:

453:

437:− units, it has poor oxidative and UV stability, but still better than N, C, or D.

1524:(average in-plane and out-of-plane: 2.67 parylene N and 2.5 parylene AF-4, SF, HT)

1737:

2271:

1748:

1502:

1206:

654:

457:

446:

2256:

1816:

1114:

2415:

2400:

2337:

1517:

1221:

1191:

614:

421:− unit that comprises the ethylene chain is the same as the repeating unit of

180:

160:

The name is also used for several polymers with the same backbone, where some

2429:

Senkevich, Jay J. (2011). "Non-Halogen Liquid Precursor Route to Parylene".

2115:

10.1002/(SICI)1521-4095(199907)11:10<814::AID-ADMA814>3.0.CO;2-Z

1247:

The standard Gorham process is shown above for parylene AF-4. The octafluoro

1210:

1136:

673:

665:

503:

354:

184:

169:

2557:

2478:

2442:

2142:

2053:

1991:

1160:

401:

atoms. This variant is also marketed under the trade names of parylene SF (

349:

Derivatives of parylene can be obtained by replacing hydrogen atoms on the

329:

Parylene N is the un-substituted polymer obtained by polymerization of the

2517:

1952:

10.1002/(SICI)1521-3862(199912)5:6<257::AID-CVDE257>3.0.CO;2-J

1889:

1646:

Protection of plastic, rubber, etc., from harmful environmental conditions

657:

directly to the paracyclophane base molecule to impart color to parylene.

293:-xylylene as the precursor by observing that reaction with iodine yielded

1650:

1588:

1368:

1229:

638:

398:

358:

238:

218:

192:

161:

106:

2639:

2612:

2221:

2729:

1527:

Stable and accepted in biological tissues, having been approved by the

1475:

1360:

1343:

222:

204:

53:

43:

27:

2777:

2752:

2751:

Senkevich, Jay J.; Wang, Pei-I.; Wiegand, Chris J.; Lu, T.-M. (2004).

2694:

2667:

2194:

2159:

2085:

https://www.paryleneconformalcoating.com/#TheParyleneDepositionProcess

1924:

1854:

1528:

1386:

1228:, except that the temperature must be carefully controlled since the

622:

618:

350:

78:

1719:

1367:. Originally the precursor was just thermally cracked, but suitable

429:

displays and lighting from water, salt and pollutants successfully.

2160:"GlobalTop Technology | Taiwan | Aluminum Nitride Powder"

1622:

Hydrophobic coating (moisture barriers, e.g., for biomedical hoses)

1457:

1438:

1391:

1383:

1159:

1113:

551:

535:

452:

Specifically, replacement of one hydrogen on the phenyl ring by a

340:

26:

18:

1618:

Parylene films have been used in various applications, including

300:

as the only product. The reaction yield was only a few percent.

1634:

Sensors in rough environment (e.g., automotive fuel/air sensors)

1506:

1233:

1195:

374:

2708:

Z. Yapu (2003). "Stiction and anti-stiction in MEMS and NEMS".

2574:

Dekker encyclopédia of nanoscience and nanotechnology, Volume 1

2571:

James A. Schwarz; Cristian I. Contescu; Karol Putyera (2004).

2272:"Tricyclo[8.2.2.24,7]hexadeca-4,6,10,12,13,15-hexaene"

1375:

is given off from each methyl end, which can be converted to

1298:

For example, the precursor α,α'-dibromo-α,α,α',α'-tetrafluoro-

1127:

The monomer polymerizes only after it is physically adsorbed (

2083:

Horn, Sean "The Parylene Deposition Process: Pre-Deposition"

1238:

1147:

parylene AF-4 is low, resulting in inefficient deposition.

365:

removal of the coating when the part has to be re-worked.

817:

Linear coefficient of thermal expansion at 25 °C (ppm)

625:

salts to generate the corresponding metalorganic complexes

605:

Another reactive variant is parylene X, which features an

1490:−, which can be condensed before the deposition chamber.

1964:

C. Chiang, A. S. Mack, C. Pan, Y.-L. Ling, D. B. Fraser

1653:, e.g., for guiding catheters, acupuncture needles and

1279:

Another route to generation of the monomer is to use a

2398:

Lee, Chung J.; Wang, Hui; Foggiato, Giovanni Antonio,

1797:

Journal of Polymer Science Part A-1: Polymer Chemistry

1404:

A similar synthesis for parylene N uses the precursor

1283:-xylene precursor with a suitable substituent on each

2237:

Journal of Polymer Science: Polymer Chemistry Edition

1625:

Barrier layers (e.g., for filter, diaphragms, valves)

1938:

J. J. Senkevich (1999). "CVD of NanoPorous Silica".

514:), and equivalent dielectric breakdown 5–6 kV/

2293:J.J. Senkevich (2011): "CVD of Poly(α,α'-dimethyl-

1534:Dense and pinhole free, for thickness above 1.4 nm

1131:) on the part's surface. This process has inverse

705:up to 400 °C, after which point it degrades.

2068:"Specialty Coating Systems - Parylene Properties"

1772:"Parylene: The Truly Conformal Thin Film Coating"

506:). Parylene E had a lower tensile modulus (

237:as one of the thermal decomposition products of

195:and in medicine to prevent adverse reactions to

1543:Stable to oxidation up to 350 °C (AF-4, SF, HT)

566:in each unit, and parylene AM, with one

8:

2539:

2537:

2535:

1720:The foundations of vacuum coating technology

1583:The classic molecular layer chemistries are

1474:-xylene. In this case, the leaving group is

834:Thermal conductivity at 25 °C (W/(m·K))

617:by heat or with UV light and can react with

2289:

2287:

2154:

2152:

1828:

1826:

1758:. Scscoatings.com. Retrieved on 2012-06-04.

460:yields parylene M and E respectively.

445:The hydrogen atoms can be replaced also by

183:, moisture barriers, or protection against

105:−. It can be obtained by polymerization of

2175:Journal of Vacuum Science and Technology A

1835:Journal of Vacuum Science and Technology A

1790:

1788:

1766:

1764:

1714:

1712:

1640:Corrosion protection for metallic surfaces

1546:Low coefficient of friction (AF-4, HT, SF)

1540:and uniformly thick, even within cavities.

1205:-xylene involving several steps involving

199:. These coatings are typically applied by

175:Coatings of parylene are often applied to

2776:

2361:Vysokomolekulyarnye Soedineniya, Seriya A

2297:-xylylene and Poly(α,α,α',α'-tetramethyl-

2113:

1342:yields parylene AF-4 with elimination of

2601:Journal of the American Chemical Society

2270:H. E. Winberg and F. S. Fawcett (1973).

2210:Journal of the American Chemical Society

1637:Electronics for space travel and defense

745:

591:per unit. Both are trademarks of Kisco.

2096:K. M. Vaeth & K. F. Jensen (1999).

1689:Jeffrey B. Fortin; Toh-Ming Lu (2003).

1676:

1118:Possible parylene polymerization routes

462:

2381:

2370:

1684:

1682:

1680:

289:above 1000 °C. Szwarc identified

1462:α,α'-diphenoxy-α,α,α',α'-tetrafluoro-

7:

1295:it does not condense in the latter.

217:because its polymerization needs no

976:Water absorption (% after 24 hours)

800:Short-term service temperature (°C)

783:Continuous service temperature (°C)

233:Parylene was discovered in 1947 by

1201:The dimer can be synthesized from

14:

1643:Reinforcement of micro-structures

1531:for various medical applications.

345:Repeating unit of parylene C

1350:

1243:Gorham process for parylene AF-4

598:

489:

477:

465:

191:). They are also used to reduce

2404:, Issue date: October 31, 2000.

2318:Journal of Electronic Materials

1259:− bond is stronger than the −CH

1069:Polymerization of the adsorbed

1027:Dynamic coefficient of friction

851:Specific heat at 20°C (J/(g·K))

377:compliance, especially for the

1655:microelectromechanical systems

1494:Characteristics and advantages

1287:, whose elimination generates

1010:Static coefficient of friction

689:Transparency and crystallinity

1:

2027:10.1016/S0040-6090(01)01355-4

1443:α,α'-dimethyl-α,α'-dimethoxy-

2419:, Issue date: March 9, 2004.

1236:bond breaks at 680 °C.

702:monoclinic crystal structure

534:(not to be confused with an

164:atoms are replaced by other

1779:Plasma Ruggedized Solutions

1631:Implantable medical devices

653:It is possible to attach a

441:Alkyl-substituted parylenes

46:whose backbone consists of

2814:

2577:. CRC Press. p. 263.

2257:10.1002/pol.1984.170220218

1966:Mat. Res. Soc. Symp. Proc.

1817:10.1002/pol.1966.150041209

1695:. Springer. pp. 4–7.

1099:or a negative anion group

676:. Using the parylene C/SiO

23:Repeating unit of parylene

2546:Chemical Vapor Deposition

2467:Chemical Vapor Deposition

2431:Chemical Vapor Deposition

2338:10.1007/s11664-997-0280-8

2131:Chemical Vapor Deposition

2042:Chemical Vapor Deposition

1980:Chemical Vapor Deposition

1940:Chemical Vapor Deposition

1585:self-assembled monolayers

213:Parylene is considered a

201:chemical vapor deposition

661:Parylene-like copolymers

637:" and can be used as an

633:. It can also undergo "

333:-xylylene intermediate.

203:in an atmosphere of the

42:is the common name of a

2757:Applied Physics Letters

925:Elongation to break (%)

731:Industry specifications

709:Mechanical and chemical

668:and nanocomposites (SiO

179:and other equipment as

2558:10.1002/cvde.200804266

2498:Chemistry of Materials

2479:10.1002/cvde.201304321

2443:10.1002/cvde.201104304

2143:10.1002/cvde.200304179

2054:10.1002/cvde.201307071

1992:10.1002/cvde.200606541

1913:Chemistry of Materials

1569:printed circuit boards

1467:

1448:

1401:

1244:

1173:

1119:

512:g-mil/atom-100in2-24hr

346:

36:

24:

2710:Acta Mechanica Sinica

2518:10.1007/s003390051076

2473:(10–11–12): 327–331.

2416:U.S. patent 6,703,462

2401:U.S. patent 6,140,456

1968:vol. 381, 123 (1995).

1890:10.1557/JMR.1996.0233

1461:

1442:

1395:

1242:

1163:

1156:From the cyclic dimer

1117:

868:Young's modulus (psi)

393:Fluorinated parylenes

379:printed circuit board

344:

337:Chlorinated parylenes

187:and chemical attack (

181:electrical insulation

30:

22:

1749:SCS Coatings History

1614:Typical applications

1518:electrical insulator

1434:mass-flow controller

1365:mass-flow controller

942:Yield elongation (%)

508:175 kpi vs. 460 kpsi

405:) and HT parylene (

2769:2004ApPhL..84.2617S

2722:2003AcMSn..19....1Z

2640:10.1021/la00088a035

2613:10.1021/ja00019a011

2510:2000ApPhA..70..541S

2330:1997JEMat..26..949W

2301:-xylylene)-co-poly(

2249:1984JPoSA..22..475K

2222:10.1021/ja01041a016

2187:2000JVSTA..18.2459F

2019:2001TSF...397..223F

1882:1996JMatR..11.1842G

1847:2002JVSTA..20.1445S

1809:1966JPoSA...4.3027G

1522:dielectric constant

1215:Hofmann elimination

645:(non-crystalline).

298:-xylylene di-iodide

177:electronic circuits

172:in some countries.

2730:10.1007/BF02487448

2102:Advanced Materials

1754:2012-01-12 at the

1725:2009-10-07 at the

1468:

1449:

1402:

1245:

1174:

1151:Monomer generation

1133:Arrhenius kinetics

1120:

766:Melting point (°C)

542:Reactive parylenes

347:

37:

25:

2778:10.1063/1.1691488

2695:10.1021/la010970f

2668:10.1021/la000471z

2584:978-0-8247-5047-3

2496:nanocomposites".

2380:Missing or empty

2277:Organic Syntheses

2216:(13): 3517–3526.

2195:10.1116/1.1289773

1925:10.1021/cm990042q

1911:Nanocomposites".

1855:10.1116/1.1487870

1803:(12): 3027–3039.

1735:978-3-540-20410-7

1729:, Springer, 2003

1702:978-1-4020-7688-6

1667:Conformal coating

1271:From substituted

1043:

1042:

993:Rockwell hardness

885:Tensile strength

700:Parylene N has a

649:Colored parylenes

383:hydrogen chloride

197:implanted devices

189:conformal coating

166:functional groups

35:-xylylene monomer

16:Chemical compound

2805:

2783:

2782:

2780:

2748:

2742:

2741:

2705:

2699:

2698:

2678:

2672:

2671:

2650:

2644:

2643:

2623:

2617:

2616:

2595:

2589:

2588:

2568:

2562:

2561:

2541:

2530:

2529:

2489:

2483:

2482:

2462:

2456:

2453:

2447:

2446:

2426:

2420:

2418:

2411:

2405:

2403:

2396:

2390:

2389:

2383:

2378:

2376:

2368:

2356:

2350:

2349:

2312:

2306:

2291:

2282:

2280:

2267:

2261:

2260:

2232:

2226:

2225:

2205:

2199:

2198:

2170:

2164:

2163:

2156:

2147:

2146:

2126:

2120:

2119:

2117:

2093:

2087:

2081:

2075:

2074:

2072:

2064:

2058:

2057:

2048:(1–2–3): 39–43.

2037:

2031:

2030:

2013:(1–2): 223–228.

2007:Thin Solid Films

2002:

1996:

1995:

1975:

1969:

1962:

1956:

1955:

1935:

1929:

1928:

1900:

1894:

1893:

1865:

1859:

1858:

1830:

1821:

1820:

1792:

1783:

1782:

1776:

1768:

1759:

1746:

1740:

1716:

1707:

1706:

1686:

1579:Molecular layers

1554:intrinsic stress

1489:

1487:

1486:

1427:

1425:

1424:

1381:

1377:hydrogen bromide

1354:

1341:

1339:

1338:

1330:

1329:

1321:

1320:

1312:

1311:

1168:-xylylene dimer

1110:

1109:

1108:

1098:

1097:

1096:

908:

888:

761:Parylene HT/AF4

746:

743:

742:

738:

612:

602:

590:

589:

588:

580:

579:

565:

564:

563:

533:

532:

531:

513:

509:

493:

481:

469:

420:

419:

418:

387:

288:

287:

286:

276:

275:

274:

266:

265:

255:

253:

252:

156:

155:

154:

144:

143:

142:

134:

133:

123:

121:

120:

104:

103:

102:

92:

91:

90:

76:

75:

74:

66:

65:

2813:

2812:

2808:

2807:

2806:

2804:

2803:

2802:

2788:

2787:

2786:

2750:

2749:

2745:

2707:

2706:

2702:

2680:

2679:

2675:

2652:

2651:

2647:

2625:

2624:

2620:

2597:

2596:

2592:

2585:

2570:

2569:

2565:

2543:

2542:

2533:

2495:

2491:

2490:

2486:

2464:

2463:

2459:

2454:

2450:

2428:

2427:

2423:

2414:

2413:Lee, Chung J.,

2412:

2408:

2399:

2397:

2393:

2379:

2369:

2358:

2357:

2353:

2314:

2313:

2309:

2292:

2285:

2269:

2268:

2264:

2234:

2233:

2229:

2207:

2206:

2202:

2172:

2171:

2167:

2158:

2157:

2150:

2128:

2127:

2123:

2108:(10): 814–820.

2095:

2094:

2090:

2082:

2078:

2070:

2066:

2065:

2061:

2039:

2038:

2034:

2004:

2003:

1999:

1977:

1976:

1972:

1963:

1959:

1937:

1936:

1932:

1910:

1902:

1901:

1897:

1867:

1866:

1862:

1832:

1831:

1824:

1794:

1793:

1786:

1774:

1770:

1769:

1762:

1756:Wayback Machine

1747:

1743:

1727:Wayback Machine

1717:

1710:

1703:

1688:

1687:

1678:

1674:

1664:

1616:

1610:

1581:

1573:medical devices

1565:

1550:

1496:

1485:

1482:

1481:

1480:

1478:

1423:

1420:

1419:

1418:

1416:

1406:α,α'-dimethoxy-

1396:α,α'-dimethoxy-

1379:

1337:

1334:

1333:

1332:

1328:

1325:

1324:

1323:

1319:

1316:

1315:

1314:

1310:

1307:

1306:

1305:

1303:

1277:

1266:

1262:

1258:

1254:

1158:

1153:

1125:

1107:

1104:

1103:

1102:

1100:

1095:

1092:

1091:

1090:

1088:

1083:

1067:

1048:

1046:Coating process

906:

905:Yield strength

886:

744:

740:

736:

734:

733:

724:

711:

691:

686:

679:

671:

663:

651:

635:click chemistry

610:

587:

584:

583:

582:

578:

575:

574:

573:

571:

562:

559:

558:

557:

555:

544:

530:

525:

524:

523:

522:

511:

507:

497:

494:

485:

482:

473:

470:

443:

436:

417:

414:

413:

412:

410:

395:

385:

368:

339:

327:

322:

285:

282:

281:

280:

278:

273:

270:

269:

268:

264:

261:

260:

259:

257:

251:

248:

247:

246:

244:

231:

215:"green" polymer

153:

150:

149:

148:

146:

141:

138:

137:

136:

132:

129:

128:

127:

125:

119:

116:

115:

114:

112:

101:

98:

97:

96:

94:

89:

86:

85:

84:

82:

77:− connected by

73:

70:

69:

68:

64:

61:

60:

59:

57:

17:

12:

11:

5:

2811:

2809:

2801:

2800:

2790:

2789:

2785:

2784:

2743:

2700:

2673:

2645:

2618:

2590:

2583:

2563:

2552:(4–6): 91–94.

2531:

2493:

2484:

2457:

2448:

2437:(4–6): 76–79.

2421:

2406:

2391:

2351:

2324:(8): 949–953.

2307:

2283:

2262:

2243:(2): 475–491.

2227:

2200:

2165:

2148:

2121:

2088:

2076:

2059:

2032:

1997:

1970:

1957:

1930:

1919:(7): 1814–21.

1908:

1907:-xylylene)/SiO

1895:

1876:(7): 1842–50.

1860:

1822:

1784:

1760:

1741:

1718:Mattox, D. M.

1708:

1701:

1675:

1673:

1670:

1663:

1660:

1659:

1658:

1647:

1644:

1641:

1638:

1635:

1632:

1629:

1626:

1623:

1615:

1612:

1580:

1577:

1564:

1561:

1548:

1547:

1544:

1541:

1535:

1532:

1525:

1514:

1495:

1492:

1483:

1421:

1356:

1355:

1335:

1326:

1317:

1308:

1276:

1269:

1264:

1260:

1256:

1252:

1157:

1154:

1152:

1149:

1124:

1121:

1105:

1093:

1081:

1066:

1065:Polymerization

1063:

1047:

1044:

1041:

1040:

1037:

1034:

1031:

1028:

1024:

1023:

1020:

1017:

1014:

1011:

1007:

1006:

1003:

1000:

997:

994:

990:

989:

986:

983:

980:

977:

973:

972:

969:

966:

963:

960:

959:Density (g/cm)

956:

955:

952:

949:

946:

943:

939:

938:

935:

932:

929:

926:

922:

921:

918:

915:

912:

909:

902:

901:

898:

895:

892:

889:

882:

881:

878:

875:

872:

869:

865:

864:

861:

858:

855:

852:

848:

847:

844:

841:

838:

835:

831:

830:

827:

824:

821:

818:

814:

813:

810:

807:

804:

801:

797:

796:

793:

790:

787:

784:

780:

779:

776:

773:

770:

767:

763:

762:

759:

756:

753:

750:

732:

729:

723:

720:

710:

707:

690:

687:

685:

682:

677:

669:

662:

659:

650:

647:

585:

576:

560:

543:

540:

526:

499:

498:

495:

488:

486:

483:

476:

474:

471:

464:

442:

439:

434:

415:

394:

391:

338:

335:

326:

323:

321:

318:

305:paracyclophane

283:

271:

262:

249:

235:Michael Szwarc

230:

227:

151:

139:

130:

117:

99:

87:

79:1,2-ethanediyl

71:

62:

15:

13:

10:

9:

6:

4:

3:

2:

2810:

2799:

2796:

2795:

2793:

2779:

2774:

2770:

2766:

2762:

2758:

2754:

2747:

2744:

2739:

2735:

2731:

2727:

2723:

2719:

2715:

2711:

2704:

2701:

2696:

2692:

2688:

2684:

2677:

2674:

2669:

2665:

2661:

2657:

2649:

2646:

2641:

2637:

2633:

2629:

2622:

2619:

2614:

2610:

2606:

2602:

2594:

2591:

2586:

2580:

2576:

2575:

2567:

2564:

2559:

2555:

2551:

2547:

2540:

2538:

2536:

2532:

2527:

2523:

2519:

2515:

2511:

2507:

2503:

2499:

2488:

2485:

2480:

2476:

2472:

2468:

2461:

2458:

2452:

2449:

2444:

2440:

2436:

2432:

2425:

2422:

2417:

2410:

2407:

2402:

2395:

2392:

2387:

2374:

2366:

2362:

2355:

2352:

2347:

2343:

2339:

2335:

2331:

2327:

2323:

2319:

2311:

2308:

2304:

2300:

2296:

2290:

2288:

2284:

2279:

2278:

2273:

2266:

2263:

2258:

2254:

2250:

2246:

2242:

2238:

2231:

2228:

2223:

2219:

2215:

2211:

2204:

2201:

2196:

2192:

2188:

2184:

2180:

2176:

2169:

2166:

2161:

2155:

2153:

2149:

2144:

2140:

2136:

2132:

2125:

2122:

2116:

2111:

2107:

2103:

2099:

2092:

2089:

2086:

2080:

2077:

2069:

2063:

2060:

2055:

2051:

2047:

2043:

2036:

2033:

2028:

2024:

2020:

2016:

2012:

2008:

2001:

1998:

1993:

1989:

1985:

1981:

1974:

1971:

1967:

1961:

1958:

1953:

1949:

1946:(6): 257–60.

1945:

1941:

1934:

1931:

1926:

1922:

1918:

1914:

1906:

1899:

1896:

1891:

1887:

1883:

1879:

1875:

1871:

1870:J. Mater. Res

1864:

1861:

1856:

1852:

1848:

1844:

1841:(4): 1445–9.

1840:

1836:

1829:

1827:

1823:

1818:

1814:

1810:

1806:

1802:

1798:

1791:

1789:

1785:

1780:

1773:

1767:

1765:

1761:

1757:

1753:

1750:

1745:

1742:

1739:

1736:

1732:

1728:

1724:

1721:

1715:

1713:

1709:

1704:

1698:

1694:

1693:

1685:

1683:

1681:

1677:

1671:

1669:

1668:

1661:

1656:

1652:

1649:Reduction of

1648:

1645:

1642:

1639:

1636:

1633:

1630:

1627:

1624:

1621:

1620:

1619:

1613:

1611:

1608:

1604:

1601:

1600:contact angle

1596:

1594:

1590:

1586:

1578:

1576:

1574:

1570:

1562:

1560:

1557:

1555:

1545:

1542:

1539:

1536:

1533:

1530:

1526:

1523:

1519:

1515:

1512:

1508:

1504:

1501:

1500:

1499:

1493:

1491:

1477:

1473:

1465:

1460:

1456:

1454:

1446:

1441:

1437:

1435:

1431:

1415:

1414:methoxy group

1411:

1409:

1399:

1394:

1390:

1388:

1385:

1378:

1374:

1370:

1366:

1362:

1353:

1349:

1348:

1347:

1345:

1301:

1296:

1292:

1291:-xylylene.

1290:

1286:

1285:methyl groups

1282:

1274:

1270:

1268:

1250:

1241:

1237:

1235:

1231:

1227:

1225:

1218:

1216:

1212:

1208:

1204:

1199:

1197:

1193:

1189:

1186:

1183:

1179:

1171:

1167:

1162:

1155:

1150:

1148:

1144:

1140:

1138:

1134:

1130:

1123:Physisorption

1122:

1116:

1112:

1085:

1079:

1074:

1072:

1064:

1062:

1059:

1055:

1053:

1045:

1038:

1035:

1032:

1029:

1026:

1025:

1021:

1018:

1015:

1012:

1009:

1008:

1004:

1001:

998:

995:

992:

991:

987:

984:

981:

978:

975:

974:

970:

967:

964:

961:

958:

957:

953:

950:

947:

944:

941:

940:

936:

933:

930:

927:

924:

923:

919:

916:

913:

910:

904:

903:

899:

896:

893:

890:

884:

883:

879:

876:

873:

870:

867:

866:

862:

859:

856:

853:

850:

849:

845:

842:

839:

836:

833:

832:

828:

825:

822:

819:

816:

815:

811:

808:

805:

802:

799:

798:

794:

791:

788:

785:

782:

781:

777:

774:

771:

768:

765:

764:

760:

757:

754:

751:

748:

747:

739:

730:

728:

721:

719:

715:

708:

706:

703:

698:

695:

688:

683:

681:

675:

667:

660:

658:

656:

648:

646:

644:

640:

636:

632:

628:

624:

620:

616:

608:

607:ethinyl group

603:

601:

596:

592:

570:amine group −

569:

554:substituent −

553:

548:

541:

539:

537:

529:

519:

517:

505:

496:Parylene AM-2

492:

487:

480:

475:

468:

463:

461:

459:

455:

450:

448:

440:

438:

430:

428:

424:

408:

404:

400:

392:

390:

384:

380:

376:

371:

366:

362:

360:

356:

352:

343:

336:

334:

332:

324:

319:

317:

313:

309:

306:

301:

299:

297:

292:

243:

241:

236:

228:

226:

224:

220:

216:

211:

209:

206:

202:

198:

194:

190:

186:

182:

178:

173:

171:

167:

163:

158:

111:

109:

80:

55:

51:

50:

45:

41:

34:

29:

21:

2763:(14): 2617.

2760:

2756:

2746:

2713:

2709:

2703:

2686:

2682:

2676:

2662:(18): 7268.

2659:

2655:

2648:

2631:

2627:

2621:

2607:(19): 7152.

2604:

2600:

2593:

2573:

2566:

2549:

2545:

2501:

2497:

2487:

2470:

2466:

2460:

2451:

2434:

2430:

2424:

2409:

2394:

2382:|title=

2373:cite journal

2364:

2360:

2354:

2321:

2317:

2310:

2302:

2298:

2294:

2275:

2265:

2240:

2236:

2230:

2213:

2209:

2203:

2178:

2174:

2168:

2137:(5): 247–9.

2134:

2130:

2124:

2105:

2101:

2091:

2079:

2062:

2045:

2041:

2035:

2010:

2006:

2000:

1986:(1): 55–59.

1983:

1979:

1973:

1965:

1960:

1943:

1939:

1933:

1916:

1912:

1904:

1898:

1873:

1869:

1863:

1838:

1834:

1800:

1796:

1778:

1744:

1738:Google books

1691:

1665:

1617:

1609:

1605:

1597:

1582:

1566:

1563:Applications

1558:

1549:

1497:

1471:

1469:

1463:

1452:

1450:

1444:

1429:

1407:

1403:

1397:

1373:free-radical

1357:

1299:

1297:

1293:

1288:

1280:

1278:

1272:

1248:

1246:

1223:

1219:

1202:

1200:

1187:

1177:

1175:

1169:

1165:

1145:

1141:

1126:

1086:

1077:

1075:

1070:

1068:

1060:

1056:

1051:

1049:

725:

722:Permeability

716:

712:

699:

696:

692:

664:

652:

631:Ag-acetylide

627:Cu-acetylide

615:cross-linked

604:

597:

593:

549:

545:

527:

520:

500:

454:methyl group

451:

447:alkyl groups

444:

431:

396:

372:

367:

363:

353:ring or the

348:

330:

328:

314:

310:

302:

295:

290:

239:

232:

212:

210:-xylylene.

207:

174:

159:

107:

48:

39:

38:

32:

2689:(5): 1587.

2634:(4): 1074.

2504:(5): 1814.

2367:(5): 972–6.

2181:(5): 2459.

1571:(PCBs) and

1538:Homogeneous

1520:with a low

1503:Hydrophobic

1226:-cyclophane

1207:bromination

1164:The cyclic

1129:physisorbed

655:chromophore

458:ethyl group

54:benzenediyl

1672:References

1455:-xylene.

1192:cyclophane

1172:cyclophane

758:Parylene D

755:Parylene C

752:Parylene N

749:Properties

684:Properties

666:Copolymers

484:Parylene E

472:Parylene M

325:Parylene N

170:trademarks

2738:110540114

1595:devices.

1369:catalysts

1211:amination

988:<0.01

674:maleimide

643:amorphous

568:methylene

355:aliphatic

320:Varieties

219:initiator

185:corrosion

110:-xylylene

81:bridges −

2798:Polymers

2792:Category

2716:(1): 1.

2683:Langmuir

2656:Langmuir

2628:Langmuir

2526:96072554

2346:94987047

1752:Archived

1723:Archived

1662:See also

1651:friction

1589:stiction

1302:-xylene

1275:-xylenes

1230:chlorine

1222:dichloro

962:1.1–1.12

880:370,000

778:>500

639:adhesive

409:). The −

399:fluorine

359:chlorine

193:friction

162:hydrogen

40:Parylene

2765:Bibcode

2718:Bibcode

2506:Bibcode

2326:Bibcode

2245:Bibcode

2183:Bibcode

2015:Bibcode

1878:Bibcode

1843:Bibcode

1805:Bibcode

1476:phenoxy

1466:-xylene

1447:-xylene

1410:-xylene

1400:-xylene

1387:O-rings

1363:, or a

1361:bubbler

1344:bromine

985:<0.1

982:<0.1

979:<0.1

877:380,000

874:400,000

871:350,000

502:1

242:-xylene

229:History

223:solvent

205:monomer

56:rings −

44:polymer

2736:

2581:

2524:

2344:

1781:. PRS.

1733:

1699:

1529:US FDA

1412:. The

1182:cyclic

920:5,000

900:7,500

897:11,000

894:10,000

846:0.096

735:": -->

623:silver

619:copper

456:or an

351:phenyl

2734:S2CID

2522:S2CID

2342:S2CID

2071:(PDF)

1775:(PDF)

1516:Good

1511:bases

1507:acids

1384:viton

1185:dimer

1039:0.13

1022:0.15

1005:R122

971:1.32

968:1.418

965:1.289

917:9,000

914:8,000

911:6,100

907:(psi)

891:7,000

887:(psi)

863:1.04

857:0.712

854:0.837

840:0.084

837:0.126

552:amine

536:amine

403:Kisco

2579:ISBN

2386:help

1731:ISBN

1697:ISBN

1593:MEMS

1509:and

1472:para

1430:para

1300:para

1289:para

1281:para

1249:para

1234:aryl

1224:para

1213:and

1196:Torr

1188:para

1176:The

1170:para

1166:para

1076:The

1052:para

1036:0.31

1033:0.29

1030:0.25

1019:0.33

1016:0.29

1013:0.25

954:2.0

937:200

812:450

795:350

737:edit

611:C≡CH

423:PTFE

375:RoHS

331:para

296:para

291:para

240:para

208:para

157:.

108:para

49:para

33:para

31:The

2773:doi

2726:doi

2691:doi

2664:doi

2636:doi

2609:doi

2605:113

2554:doi

2514:doi

2475:doi

2439:doi

2334:doi

2253:doi

2218:doi

2191:doi

2139:doi

2110:doi

2050:doi

2023:doi

2011:397

1988:doi

1948:doi

1921:doi

1886:doi

1851:doi

1813:doi

1591:in

1380:HBr

1313:Br)

1304:(CF

1263:−CH

1255:−CF

1002:R80

999:R80

996:R85

951:3.0

948:2.9

945:2.5

934:200

931:200

928:250

829:36

809:120

806:100

792:100

775:380

772:290

769:420

629:or

621:or

516:mil

504:kHz

433:−CH

427:LED

407:SCS

386:HCl

2794::

2771:.

2761:84

2759:.

2755:.

2732:.

2724:.

2714:19

2712:.

2687:18

2685:.

2660:16

2658:.

2630:.

2603:.

2550:15

2548:.

2534:^

2520:.

2512:.

2502:11

2500:.

2471:19

2469:.

2435:17

2433:.

2377::

2375:}}

2371:{{

2365:22

2363:.

2340:.

2332:.

2322:26

2320:.

2286:^

2274:.

2251:.

2241:22

2239:.

2214:91

2212:.

2189:.

2179:18

2177:.

2151:^

2135:10

2133:.

2106:11

2104:.

2100:.

2046:20

2044:.

2021:.

2009:.

1984:13

1982:.

1942:.

1917:11

1915:.

1884:.

1874:11

1872:.

1849:.

1839:20

1837:.

1825:^

1811:.

1799:.

1787:^

1777:.

1763:^

1711:^

1679:^

1513:).

1479:CH

1426:CO

1389:.

1346:.

1322:(C

1217:.

1209:,

1137:nm

1111::

1101:CH

1089:CH

826:38

823:35

820:69

803:80

789:80

786:60

581:NH

572:CH

556:NH

411:CF

279:CH

225:.

147:CH

95:CH

83:CH

2781:.

2775::

2767::

2740:.

2728::

2720::

2697:.

2693::

2670:.

2666::

2642:.

2638::

2632:5

2615:.

2611::

2587:.

2560:.

2556::

2528:.

2516::

2508::

2494:2

2481:.

2477::

2445:.

2441::

2388:)

2384:(

2348:.

2336::

2328::

2303:p

2299:p

2295:p

2281:.

2259:.

2255::

2247::

2224:.

2220::

2197:.

2193::

2185::

2162:.

2145:.

2141::

2118:.

2112::

2073:.

2056:.

2052::

2029:.

2025::

2017::

1994:.

1990::

1954:.

1950::

1944:5

1927:.

1923::

1909:2

1905:p

1892:.

1888::

1880::

1857:.

1853::

1845::

1819:.

1815::

1807::

1801:4

1705:.

1657:.

1488:O

1484:5

1464:p

1453:p

1445:p

1422:3

1417:H

1408:p

1398:p

1340:)

1336:4

1331:H

1327:6

1318:2

1309:2

1273:p

1265:2

1261:2

1257:2

1253:2

1232:-

1203:p

1190:-

1178:p

1106:2

1094:2

1082:x

1078:p

1071:p

860:—

843:—

741:]

678:2

670:2

609:−

586:2

577:2

561:2

528:n

435:2

416:2

284:3

277:−

272:4

267:H

263:6

258:C

256:−

254:C

250:3

245:H

152:2

145:=

140:4

135:H

131:6

126:C

124:=

122:C

118:2

113:H

100:2

93:−

88:2

72:4

67:H

63:6

58:C

52:-

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.