29:

285:

217:

121:. Also known as pulsed direct current (PDC) electrolysis, the increased number of variables that it introduces to the electrolysis method can change the application of the current to the electrodes and the resulting outcome. This varies from direct current (DC) electrolysis, which only allows the variation of one value, the voltage applied. By utilising conventional

281:

or producing a cubic meter of hydrogen. It was discovered a magnetic field of 11T was needed for effective electrolysis, more than 16 times greater than what was originally used. Since superconducting magnets would be required, and they can become too expensive to justify their use, ruling this out as a possible method.

384:

In theoretical electrolysis of water, a voltage of only 1.23 V is required to split water into hydrogen and oxygen, The formation of an EDL increases this to its thermo-neutral voltage of 1.45 V. Minimising the EDL formed during pulse electrolysis is advantageous, as it can reduce the thermo-neutral

325:

Initial observations revealed that the off-period resulted in a reversal in polarity, causing the reaction to reverse. This effected the cathode, which displayed a 2g loss after experimentation. A diode was input into the circuit to rectify the polarity. However, the cell was prevented from dropping

280:

created by the electrolyte, that slowed down the motion of the disc. The two ways they could fix this is to rotate the disc and solution together or increase the magnetic field used. The latter being most practicable, the required magnetic field was calculated according to the power consumption rate

156:

The various and alterable effects of using intermittent pulses in PDC electrolysis has resulted in an area of interest that could benefit industry. However, as it is still being researched and has produced conflicting results, a consistent and reliable answer to how dependent electrolysis efficiency

248:

Poláčik and Pospíšil believe that by manipulating the dependent variables, such as the duty cycle, can increase or decrease the effectiveness of pulse electrolysis at reducing this layer. A theoretical equation, the Sand equation, is used to calculate the amount of time required to allow the EDL to

212:

replacement. For this to be feasible, the production of hydrogen, through methods such as electrolysis, must be efficient in terms of the energy, cost and time required. Whilst multiple methods of pulse electrolysis have been studied, and experimental results are mixed, the underlying theory behind

173:

PDC electrolysis was first considered theoretically in 1952, and experimental research began as early as 1960 however it was originally focused on its technical applications to industry and the possibilities of improving the quality and rate of metal deposition. It partially succeeded, providing

393:

Whilst the method of PDC electrolysis has been proven by

Ghoroghichian and Bockris in 1952 and 1985 to work extremely well in theory, it is difficult to replicate with consistently positive results in practical experimentation. Hence, the many mechanisms that have been patented are unable to be

375:

These effects were first researched on zinc by Coehn. It was discovered a pulsed current at a high frequency can produce deposits of higher quality, with properties ranging from a smoother finish by the reduction in grain size, as well as lowering its corrosion rate. This is beneficial as it is

371:

of the deposition metal is directly affected and can have favourable or unfavourable circumstances if specific conditions are not met. It is reported that pulse plating can encourage nucleation causing grain refinement, and reducing grain size, as well as increasing the deposit density that can

362:

A pulsed current can be varied in many ways that increases the possible outcomes and can vary the properties of deposited metals during electroplating. Hansel and Roy, in their review of the third

European Pulse Plating Seminar, concluded that each deposition system must have a unique sequence

326:

to 0 V during the off-period, maintaining a higher value of 2.3V. This further impacted the experiment, distorting the square wave produced by the function generator

Shaaban used, as the electrical potential provided needed to overcome the cell voltage of 2.3V before current could flow. Bokris

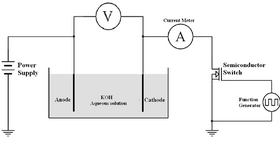

299:

The generator was constructed with a magnetic flux density of 0.6T, a propeller radius of 30 cm and a loop coated with copper strips. To increase the output potential, and reducing the rotation speed required, these were connected in series. Pulses of 2-3V that were sustained for 1ms were

401:

can reverse. This can cause the cathode to deteriorate. In electrolysis, the cathode is where the reduction of hydrogen occurs, forming the desired hydrogen gas. Any loss in mass can reduce the speed and effectiveness of the electrolytic reaction, reducing the overall efficiency of the pulse

350:

The possible increased effect a pulsed current will have on the corrodibility of metals was first looked at by de la Rive in 1837. It was investigated around 60 years later by Coehn regarding the effect of a current with a rectangular waveform, on the plating of zinc deposits, resulting in a

145:

Although theoretical research has made large promise for the efficiencies and benefits of utilising pulse electrolysis, it has many contradictions including a common issue that it is difficult to replicate the successes of patents experimentally and produces its own negative effects on the

196:, discovering an electrolysis method with the greatest efficiency is valued. With early experimental and theoretical success, many patents began to be developed until as recent as 2002, but since 1985, it has only been researched intermittently with varying levels of success.

316:

The experimental electrolyser separated the anolyte and catholyte compartments and used a 324-Naflon membrane to allow the ion exchange. The distance between the anode, made with platinum coated titanium, and the cathode, stainless steel, was 3mm and was immersed in a 10

245:. One of the aims of PDC electrolysis is to overcome this, and theoretically, when the PMW switches the current on, a capacitance will be stored, and when the duty cycle is over, it will be released, continuing the flow of current whilst reducing the EDL that is formed.

241:, or can cause the electrolyser to act as a capacitor. When this is present, excess voltage must be supplied by the direct current to compensate for the loss in the 'capacitor', which rises the required voltage supplied to what is called the

321:

sulfuric acid electrolyte. He conducted tests under several different frequencies that included '0.01 Hz, 0.5 kHz, 5 kHz, i kHz, 10 kHz, 25 kHz, and 40 kHz' and with four duty cycles, '10, 25, 50, and 80%'.

141:. Past research has demonstrated that there is a possibility it can result in a higher electrical efficiency in comparison to DC electrolysis. This would allow electrolysis procedures to produce greater volumes of hydrogen with a reduced

330:

records that current would continue to flow, discharging ions from the EDL, but this was contradicted in this experiment. This only occurred when the diode was in place but it prevented a current spike in the duty cycle as well.

312:

A comparison between a pulsed and non-pulsed dc current electrolysers was explored in 1993 by

Shaaban, that demonstrated a non-pulsed current used the least electrical power. This opposes the previous and future works conducted.

303:

This was the first instance of a successful application of pulse electrolysis for the production of hydrogen. However, it still presents its own limitations in the possibility for it to be used in industry.

945:

Clément, N.; Nishiguchi, K.; Dufreche, J. F.; Guerin, D.; Fujiwara, A.; Vuillaume, D. (2013-08-14). "Water

Electrolysis and Energy Harvesting with Zero-Dimensional Ion-Sensitive Field-Effect Transistors".

334:

With a 10% duty cycle at a 1 kHz pulse, temperature increases of nearly 7 °C greater than in the non-pulsed experimental electrolysis, were found. Temperature increases can prevent the circuit

295:

In this method, a pulse potential was created to take advantage of previous studies that give an effectiveness factor of 2 when either a nickel electrode or a Teflon-bonded platinum electrode was used.

338:

Calculating the power consumption, it was determined a non-pulsed current had power demand losses of 3.5%, and a pulsed current resulted in 13 - 16% losses. It also opposes the idea from

Bockris

405:

Shaaban also states that due to expected internal losses, such as through heat, the current density required will increase, which increases the required voltage. As a result, greater

1288:

Giurlani, Walter; Zangari, Giovanni; Gambinossi, Filippo; Passaponti, Maurizio; Salvietti, Emanuele; Di

Benedetto, Francesco; Caporali, Stefano; Innocenti, Massimo (2018-07-25).

185:. Ghoroghichian and Bockris conducted this experimental research to determine how a pulsed current can impact the rate of hydrogen production and provide economic advantages. A

273:

for electrolysis. The difference between

Faraday's original model and Bockris and Ghorogchian's is that their disc will only rotate when it is in contact with an electrolyte.

177:

The first instance it was considered to initialise the electrolysis of water was from the perspective of magnetolysis in 1985, where high strength magnets, or in this case

1018:

Tseung, A.C.C.; Vassie, P.R. (1976). "A study of gas evolution in teflon bonded porous electrodes—III. Performance of teflon bonded Pt black electrodes for H2 evolution".

1242:

Ramanauskas, R.; Gudavičiūtė, L.; Ščit, O.; Bučinskienė, D.; Juškėnas, R. (2008). "Pulse plating effect on composition and corrosion properties of zinc alloy coatings".

1339:

Fang, YaHui; Liu, Zhi-Pan (2010). "Electrochemical reactions at the electrode/solution interface: Theory and applications to water electrolysis and oxygen reduction".

189:

ratio of 2.07 was observed, demonstrating, for the first time, that a pulsed current can double the production of hydrogen, in comparison to a steady state current.

363:

developed in order to optimise the process and gain the desired results, opposing the inability of traditional plating to be as freely tailored to a situation. The

853:

Nicoletti, Giovanni; Arcuri, Natale; Nicoletti, Gerardo; Bruno, Roberto (2015). "A technical and environmental comparison between hydrogen and some fossil fuels".

757:

Ehrenhaft, Felix (1944-05-01). "The

Decomposition of Water by the So-Called Permanent Magnet and the Measurement of the Intensity of the Magnetic Current".

158:

481:

Kireev, S. Yu. (2017-03-01). "Intensification of processes of electrodeposition of metals by use of various modes of pulse electrolysis".

28:

192:

Since hydrogen gas cannot be collected in its free form, and it can be used to provide a source of renewable and clean energy through

133:, and the frequency. Currently, there has been a focus on theoretical and experimental research into PDC electrolysis in terms of the

1109:

490:

292:

Their final decision was to use a homopolar generator as an external source of power. This follows

Faraday's method more closely.

359:', was only published in 1954 by Baeyens, this being the first area of research into the use of pulse electrolysis in industry.

261:

has the ability to do this, so in Bockris and Ghoroghchian's original experiment in 1985, they followed Faraday's idea. Using a

174:

promising results its ability to create smoother, denser deposits, and reducing the amount of metal required in electroplating.

450:

Morita, K.; Furuya, Etuo. (1994-07-01). "Pulse electrolysis within a solution boundary layer to minimize convective effects".

1196:

Hansal, Wolfgang; Roy, Sudipta (2008). "Pulse plating gaining importance – Review of the 3rdEuropean Pulse Plating Seminar".

1045:

Carmo, Marcelo; Fritz, David L.; Mergel, Jürgen; Stolten, Detlef (2013). "A comprehensive review on PEM water electrolysis".

230:

342:

that the effectiveness of non-pulsed dc current electrolysis increases by a factor of 2 when a pulsed current is applied.

679:

Bockris, J. O'M.; Potter, E. C. (1952). "The Mechanism of Hydrogen Evolution at Nickel Cathodes in Aqueous Solutions".

1388:

162:

142:

427:"Pulse electrolysis of alkaline solutions as highly efficient method of production of hydrogen/oxygen gas mixtures"

269:, they placed a stainless-steel disc in between. The disc needed a rotation speed of 2000 rpm to reach the correct

153:

and electrocrystallisation are also undergoing research due to the wider range of properties that can be achieved.

722:

Arouete, S.; Blurton, K. F.; Oswin, H. G. (1969). "Controlled Current Deposition of Zinc from Alkaline Solution".

1398:

459:

270:

157:

is on the properties of an electrical pulse has not been determined, hence, other forms of electrolysis such as

397:

According to Shabaan, during the pulse-off period, if the electrolytic cell is not constructed properly, the

205:

122:

1393:

242:

134:

815:

Ghoroghchian, J; Bockris, J (1985). "Use of a homopolar generator in hydrogen production from water".

965:

824:

766:

731:

688:

618:

544:

398:

258:

182:

138:

118:

1364:

1267:

1221:

997:

955:

568:

502:

208:

sources is a main cause of global environmental problems, hydrogen is being viewed as a possible

125:(PMW), multiple dependent variables can be altered, including the type of waveform, typically a

216:

1356:

1321:

1259:

1213:

1173:

1105:

989:

981:

782:

704:

560:

266:

149:

PDC electrolysis is not only confined to the electrolysis of water. Uses in industry such as

1348:

1311:

1301:

1251:

1205:

1165:

1097:

1092:

Pesco, Anthony M.; Cheh, Huk Y. (1989), "Theory and Applications of Periodic Electrolysis",

1054:

1027:

973:

927:

889:

862:

832:

774:

739:

696:

656:

647:

Ibl, N.; Puippe, J.Cl.; Angerer, H. (1978). "Electrocrystallization in pulse electrolysis".

626:

552:

494:

463:

209:

368:

234:

186:

969:

828:

770:

735:

692:

622:

548:

1290:"Electroplating for Decorative Applications: Recent Trends in Research and Development"

352:

318:

284:

277:

262:

150:

1382:

1225:

1031:

836:

660:

426:

406:

178:

1368:

1271:

1001:

572:

506:

1169:

1058:

931:

866:

110:

893:

351:

successful application for a patent. A full review on using PDC electrolysis in

229:

When a voltage is applied to an electrolysis cell, immediately following this an

1101:

238:

535:

Poláčik, Ján; Pospíšil, Jiří (2016-10-01). "Some Aspects of PDC Electrolysis".

1352:

880:

Shinnar, Reuel (2003). "The hydrogen economy, fuel cells, and electric cars".

498:

364:

249:

fall to zero, and allow PDC electrolysis to achieve its highest efficiencies.

130:

126:

1360:

1325:

1263:

1255:

1217:

1209:

1177:

985:

786:

778:

708:

564:

1306:

1289:

193:

114:

993:

556:

1316:

915:

609:

Shaaban, Aly H. (1993). "Water Electrolysis and Pulsed Direct Current".

467:

356:

977:

743:

700:

630:

385:

voltage and the energy input required, increasing energy efficiency.

257:

Electrolysers require high currents produced by very low voltages. A

960:

283:

1156:

Baeyens, P. (1954). "Electroplating with Modulated Current".

215:

288:

Faraday disk generator the Magnetolysis design was based on

916:"Review of pulsed power for efficient hydrogen production"

213:

this experimental approach seems to remain consistent.

96:

88:

80:

72:

67:

59:

51:

43:

38:

21:

33:A Simplified Experimental Pulse Electrolysis Cell

376:mainly used as a sacrificial anode in industry.

237:, is theoretically formed. This can create a

204:With the perspective that the current use of

8:

355:, also known as electrodeposition or 'pulse

409:are needed that further converts to heat.

1315:

1305:

959:

1047:International Journal of Hydrogen Energy

920:International Journal of Hydrogen Energy

817:International Journal of Hydrogen Energy

418:

1283:

1281:

1237:

1235:

1191:

1189:

1187:

1151:

1149:

1147:

1122:

1120:

1087:

1085:

724:Journal of the Electrochemical Society

611:Journal of the Electrochemical Society

276:They encountered one large problem, a

18:

1013:

1011:

909:

907:

905:

903:

848:

846:

810:

808:

806:

804:

802:

800:

798:

796:

604:

602:

483:Inorganic Materials: Applied Research

7:

674:

672:

670:

642:

640:

600:

598:

596:

594:

592:

590:

588:

586:

584:

582:

530:

528:

526:

524:

522:

520:

518:

516:

914:Monk, Nigel; Watson, Simon (2016).

1094:Modern Aspects of Electrochemistry

119:non-spontaneous chemical reactions

14:

1096:, Springer US, pp. 251–293,

68:State-of-the-art Operating Ranges

855:Energy Conversion and Management

60:Catalyst material on the cathode

27:

681:The Journal of Chemical Physics

491:Springer Science+Business Media

394:repeated and used in industry.

181:, are used in conjunction with

1170:10.1080/00202967.1954.11869655

1059:10.1016/j.ijhydene.2013.01.151

932:10.1016/j.ijhydene.2015.12.086

867:10.1016/j.enconman.2014.09.057

143:electrical energy consumption.

52:Catalyst material on the anode

1:

894:10.1016/j.techsoc.2003.09.024

1032:10.1016/0013-4686(76)80026-6

837:10.1016/0360-3199(85)90042-4

661:10.1016/0376-4583(78)90044-4

165:are being used in industry.

159:polymer electrolyte membrane

1102:10.1007/978-1-4684-8667-4_4

163:alkaline water electrolysis

1415:

1353:10.1007/s11426-010-0047-6

537:Technological Engineering

499:10.1134/S2075113317020095

460:American Chemical Society

26:

1256:10.1179/174591908X272924

1210:10.1179/174591908x345897

779:10.1103/PhysRev.65.287.2

372:improve micro hardness.

1341:Science China Chemistry

1307:10.3390/coatings8080260

1244:Transactions of the IMF

1198:Transactions of the IMF

1158:Transactions of the IMF

113:method that utilises a

97:Cell voltage efficiency

1071:de la Rive, A (1837).

557:10.2478/teen-2016-0011

289:

243:thermo-neutral voltage

221:

127:rectangular pulse wave

123:pulse width modulation

882:Technology in Society

402:electrolysis method.

287:

265:of 0.86T produced by

231:Electric Double Layer

219:

210:renewable fuel source

200:Experimental research

135:electrolysis of water

115:pulsed direct current

44:Type of Electrolysis:

452:Analytical Chemistry

308:Conflicting research

271:electrical potential

183:homopolar propellers

1020:Electrochimica Acta

970:2013NanoL..13.3903C

829:1985IJHE...10..101G

771:1944PhRv...65..287E

736:1969JElS..116..166A

693:1952JChPh..20..614B

623:1993JElS..140.2863S

549:2016TeEng..13...33P

468:10.1021/ac00085a042

259:homopolar generator

253:Use in Magnetolisis

225:Theoretical Concept

1389:Chemical processes

649:Surface Technology

290:

222:

206:non-renewable fuel

107:Pulse electrolysis

22:Pulse Electrolysis

16:Pulse Electrolysis

1053:(12): 4901–4934.

978:10.1021/nl4019879

926:(19): 7782–7791.

765:(9–10): 287–289.

744:10.1149/1.2411787

701:10.1063/1.1700503

631:10.1149/1.2220923

617:(10): 2863–2867.

267:permanent magnets

104:

103:

39:Typical Materials

1406:

1399:Electrochemistry

1373:

1372:

1336:

1330:

1329:

1319:

1309:

1285:

1276:

1275:

1239:

1230:

1229:

1193:

1182:

1181:

1153:

1142:

1124:

1115:

1114:

1089:

1080:

1069:

1063:

1062:

1042:

1036:

1035:

1015:

1006:

1005:

963:

954:(8): 3903–3908.

942:

936:

935:

911:

898:

897:

877:

871:

870:

850:

841:

840:

812:

791:

790:

754:

748:

747:

719:

713:

712:

676:

665:

664:

644:

635:

634:

606:

577:

576:

532:

511:

510:

478:

472:

471:

447:

441:

440:

438:

437:

423:

399:current polarity

169:Research history

139:produce hydrogen

109:is an alternate

73:Cell temperature

47:PDC Electrolysis

31:

19:

1414:

1413:

1409:

1408:

1407:

1405:

1404:

1403:

1379:

1378:

1377:

1376:

1338:

1337:

1333:

1287:

1286:

1279:

1241:

1240:

1233:

1195:

1194:

1185:

1155:

1154:

1145:

1125:

1118:

1112:

1091:

1090:

1083:

1070:

1066:

1044:

1043:

1039:

1017:

1016:

1009:

944:

943:

939:

913:

912:

901:

879:

878:

874:

852:

851:

844:

814:

813:

794:

759:Physical Review

756:

755:

751:

721:

720:

716:

678:

677:

668:

646:

645:

638:

608:

607:

580:

534:

533:

514:

480:

479:

475:

449:

448:

444:

435:

433:

425:

424:

420:

415:

407:over potentials

391:

382:

369:crystallisation

348:

346:Industrial Uses

310:

255:

235:diffusion layer

227:

202:

187:current density

171:

81:Current density

34:

17:

12:

11:

5:

1412:

1410:

1402:

1401:

1396:

1391:

1381:

1380:

1375:

1374:

1347:(3): 543–552.

1331:

1277:

1250:(2): 103–108.

1231:

1204:(5): 249–250.

1183:

1164:(1): 429–453.

1143:

1116:

1110:

1081:

1073:Comptes Rendus

1064:

1037:

1026:(4): 315–318.

1007:

937:

899:

888:(4): 455–476.

872:

842:

823:(2): 101–112.

792:

749:

714:

687:(4): 614–628.

666:

655:(4): 287–300.

636:

578:

512:

473:

442:

417:

416:

414:

411:

390:

387:

381:

378:

353:electroplating

347:

344:

319:weight percent

309:

306:

263:magnetic field

254:

251:

226:

223:

201:

198:

179:electromagnets

170:

167:

151:electroplating

146:electrolyser.

102:

101:

98:

94:

93:

90:

86:

85:

82:

78:

77:

74:

70:

69:

65:

64:

61:

57:

56:

53:

49:

48:

45:

41:

40:

36:

35:

32:

24:

23:

15:

13:

10:

9:

6:

4:

3:

2:

1411:

1400:

1397:

1395:

1392:

1390:

1387:

1386:

1384:

1370:

1366:

1362:

1358:

1354:

1350:

1346:

1342:

1335:

1332:

1327:

1323:

1318:

1317:11392/2436643

1313:

1308:

1303:

1299:

1295:

1291:

1284:

1282:

1278:

1273:

1269:

1265:

1261:

1257:

1253:

1249:

1245:

1238:

1236:

1232:

1227:

1223:

1219:

1215:

1211:

1207:

1203:

1199:

1192:

1190:

1188:

1184:

1179:

1175:

1171:

1167:

1163:

1159:

1152:

1150:

1148:

1144:

1140:

1136:

1132:

1131:German Patent

1128:

1123:

1121:

1117:

1113:

1111:9781468486698

1107:

1103:

1099:

1095:

1088:

1086:

1082:

1078:

1074:

1068:

1065:

1060:

1056:

1052:

1048:

1041:

1038:

1033:

1029:

1025:

1021:

1014:

1012:

1008:

1003:

999:

995:

991:

987:

983:

979:

975:

971:

967:

962:

957:

953:

949:

941:

938:

933:

929:

925:

921:

917:

910:

908:

906:

904:

900:

895:

891:

887:

883:

876:

873:

868:

864:

860:

856:

849:

847:

843:

838:

834:

830:

826:

822:

818:

811:

809:

807:

805:

803:

801:

799:

797:

793:

788:

784:

780:

776:

772:

768:

764:

760:

753:

750:

745:

741:

737:

733:

729:

725:

718:

715:

710:

706:

702:

698:

694:

690:

686:

682:

675:

673:

671:

667:

662:

658:

654:

650:

643:

641:

637:

632:

628:

624:

620:

616:

612:

605:

603:

601:

599:

597:

595:

593:

591:

589:

587:

585:

583:

579:

574:

570:

566:

562:

558:

554:

550:

546:

542:

538:

531:

529:

527:

525:

523:

521:

519:

517:

513:

508:

504:

500:

496:

492:

488:

484:

477:

474:

469:

465:

462:: 2197–2199.

461:

457:

453:

446:

443:

432:

428:

422:

419:

412:

410:

408:

403:

400:

395:

389:Disadvantages

388:

386:

379:

377:

373:

370:

366:

360:

358:

354:

345:

343:

341:

336:

332:

329:

323:

320:

314:

307:

305:

301:

297:

293:

286:

282:

279:

278:viscous force

274:

272:

268:

264:

260:

252:

250:

246:

244:

240:

236:

232:

224:

218:

214:

211:

207:

199:

197:

195:

190:

188:

184:

180:

175:

168:

166:

164:

160:

154:

152:

147:

144:

140:

136:

132:

128:

124:

120:

116:

112:

108:

99:

95:

91:

87:

83:

79:

75:

71:

66:

62:

58:

54:

50:

46:

42:

37:

30:

25:

20:

1394:Electrolysis

1344:

1340:

1334:

1297:

1293:

1247:

1243:

1201:

1197:

1161:

1157:

1138:

1134:

1130:

1126:

1093:

1076:

1072:

1067:

1050:

1046:

1040:

1023:

1019:

951:

948:Nano Letters

947:

940:

923:

919:

885:

881:

875:

858:

854:

820:

816:

762:

758:

752:

727:

723:

717:

684:

680:

652:

648:

614:

610:

543:(1): 33–34.

540:

536:

486:

482:

476:

458:(13). U.S.:

455:

451:

445:

434:. Retrieved

431:ResearchGate

430:

421:

404:

396:

392:

383:

374:

361:

349:

339:

337:

333:

327:

324:

315:

311:

302:

298:

294:

291:

275:

256:

247:

233:(EDL), or a

228:

220:Double Layer

203:

191:

176:

172:

155:

148:

117:to initiate

111:electrolysis

106:

105:

89:Cell voltage

861:: 205–213.

493:: 203–210.

239:capacitance

1383:Categories

1300:(8): 260.

1079:: 835–840.

730:(2): 166.

436:2019-05-31

413:References

380:Advantages

365:nucleation

300:achieved.

194:fuel cells

131:duty cycle

1361:1674-7291

1326:2079-6412

1264:0020-2967

1226:109143443

1218:0020-2967

1178:0020-2967

986:1530-6984

961:1307.6723

787:0031-899X

709:0021-9606

565:2451-3156

63:Aluminium

55:Aluminium

1369:96201556

1294:Coatings

1272:96146510

1127:A. Coehn

1002:20925098

994:23879333

573:99125043

507:99479894

92:+18 V DC

76:25 ± 2°C

966:Bibcode

825:Bibcode

767:Bibcode

732:Bibcode

689:Bibcode

619:Bibcode

545:Bibcode

357:plating

1367:

1359:

1324:

1270:

1262:

1224:

1216:

1176:

1108:

1000:

992:

984:

785:

707:

571:

563:

505:

340:et al.

328:et al.

129:, the

100:60-70%

84:400 mA

1365:S2CID

1268:S2CID

1222:S2CID

1135:75482

998:S2CID

956:arXiv

569:S2CID

503:S2CID

489:(2).

1357:ISSN

1322:ISSN

1260:ISSN

1214:ISSN

1174:ISSN

1139:1893

1106:ISBN

990:PMID

982:ISSN

783:ISSN

705:ISSN

561:ISSN

367:and

161:and

1349:doi

1312:hdl

1302:doi

1252:doi

1206:doi

1166:doi

1098:doi

1055:doi

1028:doi

974:doi

928:doi

890:doi

863:doi

833:doi

775:doi

740:doi

728:116

697:doi

657:doi

627:doi

615:140

553:doi

495:doi

464:doi

137:to

1385::

1363:.

1355:.

1345:53

1343:.

1320:.

1310:.

1296:.

1292:.

1280:^

1266:.

1258:.

1248:86

1246:.

1234:^

1220:.

1212:.

1202:86

1200:.

1186:^

1172:.

1162:31

1160:.

1146:^

1133:,

1129:,

1119:^

1104:,

1084:^

1075:.

1051:38

1049:.

1024:21

1022:.

1010:^

996:.

988:.

980:.

972:.

964:.

952:13

950:.

924:41

922:.

918:.

902:^

886:25

884:.

859:89

857:.

845:^

831:.

821:10

819:.

795:^

781:.

773:.

763:65

761:.

738:.

726:.

703:.

695:.

685:20

683:.

669:^

651:.

639:^

625:.

613:.

581:^

567:.

559:.

551:.

541:13

539:.

515:^

501:.

485:.

456:66

454:.

429:.

1371:.

1351::

1328:.

1314::

1304::

1298:8

1274:.

1254::

1228:.

1208::

1180:.

1168::

1141:)

1137:(

1100::

1077:4

1061:.

1057::

1034:.

1030::

1004:.

976::

968::

958::

934:.

930::

896:.

892::

869:.

865::

839:.

835::

827::

789:.

777::

769::

746:.

742::

734::

711:.

699::

691::

663:.

659::

653:6

633:.

629::

621::

575:.

555::

547::

509:.

497::

487:8

470:.

466::

439:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.