1174:

389:

373:

in steels can decrease toughness dramatically. Phosphorus can segregate on grain boundary and lead to intergranular fracture. If the dephosphorization is improved during steelmaking, the steel will be toughened for a lower phosphorus content. After appropriate processing of steel, crystalline grains and second phases that are oriented along rolling direction can improve toughness of materials by delamination which can relax triaxial stress and blunt the crack tip.

2023:

780:

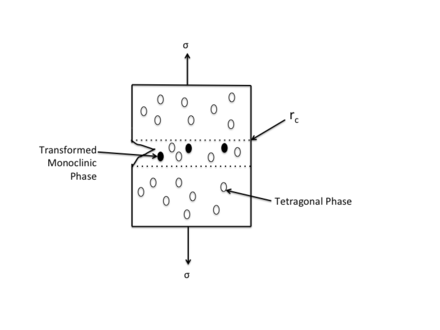

transformation is lower than room temperature. The stress field near the crack tip triggers the martensitic transformation at velocities hypothesized to approach that of sound in the material. The martensitic transformation causes volume expansion (volumetric/ dilatational strain) and shear strains of about 4% and 16% respectively. It applies compressive stress at the crack tip to prevent crack propagation as well as closure

772:

22:

361:

and can be transformed to martensite during deformation. The work associated to phase transformation contributes to the improvement of toughness. In a monolithic Pd–Ag–P–Si–Ge glass alloy, the properties of high bulk modulus and low shear modulus lead to proliferation of shear bands. These bands are self constrained and the toughness is improved.

2183:

microcracks form around elastomeric dispersion above or below the fracture plane. The HIPS is toughened by additional work associated with formation of microcracks. In epoxies, glass particles are used to improve toughness of materials. The toughening mechanism is similar with crack deflection. The addition of

352:

some safety-critical structural part such as pressure vessels and pipelines to aluminum alloy air frames are manufactured in relatively low strength version. Nonetheless, toughness should be improved without sacrificing its strength in metal. Designing a new alloy or improving its processing can achieve this goal.

2182:

Toughening mechanisms in polymers are similar with that have been discussed above. There are only several examples are used to explain the toughening in polymers. In high-impact polystyrene (HIPS), the elastomeric dispersion is used to improve crack propagation resistance. When main crack propagates,

360:

matrix and show an adverse effect on toughness. In 18%Ni-maraging steel, the carbon content is lower and martensite is strengthened by substitutional Ni atoms. In addition, transformation induced plasticity (TRIP) effects in steel can provide additional toughness. In TRIP steel, matrix is metastable

372:

particles lead to easy crack nucleation and fast crack propagation within the planar slip bands. Therefore, toughness of titanium alloy is decreased. Multiple vacuum arc melting (VAR) technique can be used to minimize the oxygen content and increase the toughness of the alloy. Similarly, phosphorus

1186:

In metal matrix composites (MMCs), the additions strengthen the metal and reduce the toughness of material. In ceramic matrix composites (CMCs), the additions can toughen materials but not strengthen them. at same time. In carbon fiber reinforced composites (CFRPs), graphite fibers can toughen and

973:

is the fraction of tetragonal grains that is related to microcracks in an affected volume. The tetragonal particle size should be controlled properly. It is due to that too large particle size leads to spontaneous transformation and too small particle size leads to a very small toughening effect.

754:

is the fraction of grains that is related to microcracks in an affected volume. In this equation, it has been assumed that residual stress is dominant in nucleating microcracks and formation of microcracks is caused by elastic work. In order to retard crack propagation, these microcracks must form

505:

Microcrack toughening means that the formation of microcracks before the main crack can toughen the ceramic. Additional microcracks will cause stress to concentrate in front of the main crack. This leads to additional irreversible work required for crack propagation. In addition, these microcracks

1169:

may also serve to toughen ceramics through crack deflection mechanisms. Formation of a textured internal structure within ceramics can be used as a toughening approach. silicon carbide materials have toughened by this approach. Because the interfacial surface area is increased due to the internal

409:

is the grain boundary energy. Though the irreversible work is decreased because of grain boundary energy, the fracture area is increased in intergranular crack propagation. Moreover, Mode II crack can be caused by deflection from normal fracture plane during intergranular crack propagation, which

351:

In a low yield strength material, the crack tip can be blunted easily and larger crack tip radius is formed. Thus, in a given metallic alloy, toughness in a low-strength condition is usually higher than for higher strength conditions because less plasticity is available for toughening. Therefore,

384:

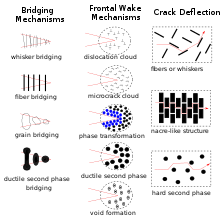

Ceramics are more brittle than most metals and plastics. The irreversible work associated with plastic deformation is not presented in ceramics. Hence, the methods that improve the toughness of ceramics are different from metals. There are several toughening mechanisms called crack deflection,

126:

refers to the process of making a material more resistant to the propagation of cracks. When a crack propagates, the associated irreversible work in different materials classes is different. Thus, the most effective toughening mechanisms differ among different materials classes. The crack tip

779:

The TRIP effect is found in partially stabilized zirconia. Partially stabilized zirconia is composed of tetragonal phase at high temperature and monoclinic phase and cubic phase at lower temperature in equilibrium. In some components, the onset temperature of tetragonal monoclinic martensite

982:

When a crack propagates in an irregular path, some grains of each side of main crack may protrude into other side. This leads to additional work for a complete fracture. This irreversible work is related to residual stress, which is about . The increment of toughness can be expressed by:

2018:

1421:

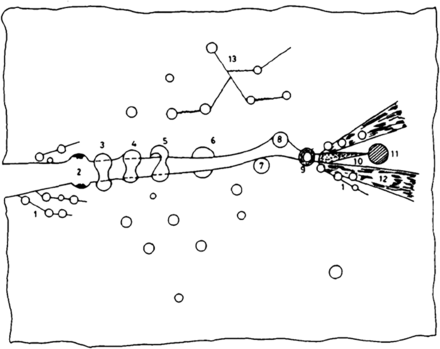

is the additional toughness caused by bridging toughening. After crack propagates across through fiber, the fiber is elongated and is pulled out from matrix. These processes correspond to plastic deformation and pull-out work and contribute to toughening of composite.

1849:

is the debond length. From the equation, it can be found that higher flow stress and longer debond length can improve the toughening. However, longer debond length usually lead to a decrease of flow stress because of loss of constraint for plastic deformation.

755:

during crack propagation. The grain size should be smaller than a critical grain size to avoid spontaneous formation of microcracks. The distance between microcrack and fracture plane should be larger than grain size to have a toughening effect. As

1880:

by linear superposition of the matrix and crack bridging based on solutions by Tada. This model can predict behavior for small-scale bridging (bridge length << crack length) under monotonic loading conditions, but not large scale bridging.

1157:, or AGG, can be harnessed to impart a crack bridging microstructure within a single phase ceramic material. The presence of abnormally long grains serves to bridge crack-wakes and hinders their opening. This has been demonstrated in

496:

form materials that can be considered as “in-situ composites” or “self-reinforced materials. Crack deflections around second phase particles have also been used in fracture mechanics approaches to predict fracture toughness increases.

1515:

784:

at the crack wake. From another point of view, the work associated to this phase transformation contributes to the improvement of toughness. The increment of toughness caused by transformation toughening can be expressed by:

623:

355:

Designing a new alloy can be explained by different toughness in several ferrous alloy.18%Ni-maraging steel has a higher toughness than the martensitic steel AISI 4340. In an AISI 4340 alloy, interstitial carbon exist in a

2744:

Nagasawa, Toshio; Kohtoku, Yasuhiko; Hogami, Toshihiko; Matsunaga, Kenji; Kajii, Shinji; Ishikawa, Toshihiro (1998-11-13). "A Tough, Thermally

Conductive Silicon Carbide Composite with High Strength up to 1600°C in Air".

2796:

Johnson, William L.; Demetriou, Marios D.; Lind, Mary-Laura; Duan, Gang; Wiest, Aaron; Suh, Jin-Yoo; Hofmann, Douglas C. (2008). "Designing metallic glass matrix composites with high toughness and tensile ductility".

861:

1052:

211:

1717:

410:

furtherly improves the toughness of ceramics. As a result, the ceramics with intergranular fracture shows a higher toughness than that with transgranular fracture. In SiC, the fracture toughness is ~2-3

1886:

1279:

763:

in 1981, the toughening induced by the incorporation of second-phase particles subject to microcracking becomes appreciable for a narrow size distribution of particles of appropriate size.

143:

material such as a metal, this toughness is typically proportional to the fracture stress and strain as well as the gauge length of the crack. The plane strain toughness in a metal is given by:

1641:

When fiber is ductile, the work from plastic deformation mainly contributes to the improvement of toughens. The additional toughness contributed by plastic deformation can be expressed by:

2973:

Zeidi, Mahdi; Kim, Chun IL; Park, Chul B. (2021). "The role of interface on the toughening and failure mechanisms of thermoplastic nanocomposites reinforced with nanofibrillated rubbers".

1633:

is the interface friction stress. From the equation, it can be found that higher volume fraction, higher fiber strength and lower interfacial stress can get a better toughening effect.

376:

Metals can also be strengthened by the methods described below for ceramics, but these methods generally have a lesser impact on toughening than plasticity induced crack blunting.

2283:

Ritchie, Robert O.; Johnson, William L.; Hofmann, Douglas C.; Schramm, Joseph P.; Garrett, Glenn; Launey, Maximilien E.; Demetriou, Marios D. (2011). "A damage-tolerant glass".

246:

486:

447:

1425:

When fiber is brittle, the pull-out work dominates the irreversible work contributing to toughening. The increment of toughness caused by pull-out work can be expressed by:

702:

326:

1793:

944:

2085:

1419:

296:

2152:

1766:

1564:

1101:

917:

679:

725:

506:

can cause crack branches, and one crack can form multiple cracks. Because of the formation of these cracks, irreversible work is increased. The increment of toughness

2172:

1537:

364:

Metals can be toughened by improvement of processing. With a high affinity for oxygen, titanium alloy can absorb oxygen easily. Oxygen can promote the formation of α

2055:

1878:

1847:

1820:

1631:

1611:

1389:

1362:

1335:

1308:

1148:

971:

890:

752:

652:

531:

346:

1074:

2435:

Tsuzaki, Kaneaki; Yin, Fuxing; Inoue, Tadanobu; Kimura, Yuuji (2008-05-23). "Inverse

Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel".

2125:

2105:

1739:

1584:

1187:

strengthen polymer at same time. In bulk metallic glass composites(BMGs), dendrites are added to hind the movement of shear band and the toughness is improved.

1121:

266:

2494:

Gilbert, C. J.; Cao, J. J.; Jonghe, L. C. de; Ritchie, R. O. (1997). "Crack-Growth

Resistance-Curve Behavior in Silicon Carbide: Small versus Long Cracks".

1430:

538:

1190:

If fibers have larger fracture strain than matrix, the composite is toughened by crack bridging. The toughness of a composite can be expressed:

2630:

790:

988:

149:

1646:

2902:

2867:

2665:

401:

In polycrystalline ceramics, the crack can propagate in an intergranular way. The associated irreversible work per unit area is 2γ-γ

105:

2013:{\displaystyle K_{c}=K_{m}+\Delta K_{b}=K_{m}+{\sqrt {\frac {2}{\pi }}}\alpha V_{f}\int _{0}^{L}{\frac {\sigma _{y}}{\sqrt {x}}}dx}

1195:

43:

2528:

86:

58:

3030:

488:

when it fractures intergranularly. Crack deflection mechanisms bring about increased toughness in ceramics exhibiting

39:

2400:

Bandyopadhyay, N.; Briant, C. L. (1982). "The Effect of

Phosphorus on Intergranular Caustic Cracking of NiCr Steel".

2334:

Neuberger, B. W.; Oberson, P. G.; Ankem, S. (2011-05-01). "The Effect of

Yttrium on Ti-5111 Gas Tungsten Arc Welds".

65:

32:

1153:

There are some other approaches to improve the toughness of ceramics through crack bridging. The phenomenon of

1853:

The toughness in a composite with ductile phase toughening can also be shown using stress intensity factor,

72:

1173:

2581:

1166:

1154:

493:

489:

219:

54:

452:

413:

2939:

2806:

2754:

2444:

2343:

2292:

2241:

781:

357:

684:

301:

2022:

1771:

922:

2060:

1394:

388:

271:

3006:

2838:

2726:

2476:

2367:

2130:

1744:

1542:

1079:

895:

657:

2529:

Effect of Grain Growth of B-Silicon

Nitride on Strength, Weibull Modulus, and Fracture Toughness

2688:

2998:

2990:

2955:

2908:

2898:

2873:

2863:

2830:

2822:

2778:

2770:

2718:

2671:

2661:

2636:

2626:

2601:

2562:

2511:

2468:

2460:

2417:

2359:

2316:

2308:

2265:

2257:

756:

707:

119:

2222:

Courtney, T. H. (2005). Mechanical

Behavior of Materials. United States: Waveland Press, Inc.

2157:

2982:

2947:

2814:

2762:

2710:

2593:

2554:

2503:

2452:

2409:

2351:

2300:

2249:

1522:

2033:

1856:

1825:

1798:

1616:

1589:

1367:

1340:

1313:

1286:

1126:

949:

868:

771:

730:

630:

509:

331:

2928:"Small-scale crack bridging and the fracture toughness of particulate-reinforced ceramics"

1162:

1158:

1059:

760:

131:

have limited crack tip plasticity and primarily rely on different toughening mechanisms.

2943:

2810:

2758:

2448:

2347:

2296:

2245:

79:

2597:

2507:

2110:

2090:

1724:

1569:

1106:

251:

2951:

2542:

1510:{\displaystyle \Delta G_{C}={1 \over 32}{\beta ^{2}\sigma _{f}^{2}V_{f}d \over \tau }}

3024:

3010:

2842:

2730:

2558:

2371:

2927:

2480:

2184:

2766:

2714:

618:{\displaystyle \Delta G_{C}\cong 2r_{c}\sigma _{R}(\Delta \alpha )(\Delta T)V_{f}}

21:

2640:

2355:

2994:

2959:

2912:

2826:

2774:

2722:

2675:

2605:

2566:

2515:

2464:

2421:

2363:

2312:

2261:

704:

is the difference of thermal expansion coefficient between adjacent grains,

449:

if it fractures transgranularly and the fracture toughness is improved to 10

2877:

2456:

892:

is the distance between boundary of transformed region with fracture plane,

3002:

2834:

2620:

2472:

2320:

2269:

2232:

Ritchie, Robert O. (2011). "The conflicts between strength and toughness".

2782:

1170:

structure, the irreversible fracture work is increased in this material.

2857:

2188:

127:

plasticity is important in toughening of metals and long-chain polymers.

2818:

2986:

775:

Schematic of transformation toughening in partially stabilized zirconia

140:

128:

2413:

385:

microcrack toughening, transformation toughening, and crack bridging.

2892:

2655:

2304:

2253:

856:{\displaystyle \Delta G_{C}\cong 2r_{c}\sigma _{M}\epsilon _{M}V_{f}}

1047:{\displaystyle \Delta G_{C}\cong {1 \over 8}\mu \sigma _{R}V_{f}d}

387:

206:{\displaystyle G_{\mathrm {I} C}=B\sigma _{yf}\epsilon _{fr}\rho }

2926:

Budiansky, Bernard; Amazigo, John C.; Evans, Anthony G. (1988).

1712:{\displaystyle \Delta G_{C}=C\sigma _{y}\epsilon _{f}V_{f}l_{d}}

15:

2654:

Soboyejo, Wole O. (2003). "13.4 Transformation toughening".

2856:

Tada, Hiroshi; Paris, P. C.; Irwin, George Rankin (2000).

2691:

in

Journal of Crystal Growth 2012, Volume 359, Pages 83-91

1150:

is the fraction of grains associated with crack bridging.

727:

is the temperature difference causing thermal strain, and

2582:"Toughening of Ceramics by Circumferential Microcracking"

1539:

is the ratio between debond length and critical length,

2701:

Tredway, William K. (1998-11-13). "Toughened

Ceramics".

1274:{\displaystyle G_{C}=V_{m}G_{m}+V_{f}G_{f}+\Delta G_{C}}

654:

is the distance between microcracks and fracture plane,

2160:

2133:

2113:

2093:

2063:

2036:

1889:

1859:

1828:

1801:

1774:

1747:

1727:

1649:

1619:

1592:

1572:

1545:

1525:

1433:

1397:

1370:

1343:

1316:

1289:

1198:

1129:

1109:

1082:

1062:

991:

952:

925:

919:

is the stress triggering martensite transformation,

898:

871:

793:

733:

710:

687:

660:

633:

541:

512:

492:(AGG). The heterogeneous microstructures produced by

455:

416:

334:

304:

274:

254:

222:

152:

46:. Unsourced material may be challenged and removed.

2166:

2146:

2119:

2099:

2079:

2049:

2012:

1872:

1841:

1814:

1787:

1760:

1733:

1711:

1625:

1605:

1578:

1558:

1531:

1509:

1413:

1383:

1356:

1329:

1302:

1273:

1142:

1115:

1095:

1068:

1046:

965:

938:

911:

884:

855:

746:

719:

696:

673:

646:

617:

533:due to microcrack toughening can be expressed by:

525:

480:

441:

340:

320:

290:

268:is a constant that incorporates the stress state,

260:

240:

205:

2891:Soboyejo, Wole O. (2003). "13.5 Crack Bridging".

1337:are toughness of matrix and fibers respectively,

946:is the strain of martensite transformation, and

405:, where γ is the surface energy of material and γ

2932:Journal of the Mechanics and Physics of Solids

1391:are volume of matrix and fibers respectively,

2894:Mechanical properties of engineered materials

2657:Mechanical properties of engineered materials

2387:Engineering materials and processes: titanium

2191:is also a good way to improve its toughness.

8:

2385:Lütjering, Gerd; Williams, James C (2007).

2336:Metallurgical and Materials Transactions A

2541:Faber, K. T.; Evans, A. G. (1983-04-01).

2159:

2138:

2132:

2112:

2092:

2087:is the toughening due to crack bridging,

2071:

2062:

2057:is the fracture toughness of the matrix,

2041:

2035:

1991:

1985:

1979:

1974:

1964:

1945:

1936:

1923:

1907:

1894:

1888:

1864:

1858:

1833:

1827:

1806:

1800:

1779:

1773:

1752:

1746:

1726:

1703:

1693:

1683:

1673:

1657:

1648:

1618:

1597:

1591:

1571:

1550:

1544:

1524:

1492:

1482:

1477:

1467:

1460:

1450:

1441:

1432:

1405:

1396:

1375:

1369:

1348:

1342:

1321:

1315:

1294:

1288:

1265:

1249:

1239:

1226:

1216:

1203:

1197:

1134:

1128:

1108:

1087:

1081:

1061:

1035:

1025:

1008:

999:

990:

957:

951:

930:

924:

903:

897:

876:

870:

847:

837:

827:

817:

801:

792:

738:

732:

709:

686:

665:

659:

638:

632:

609:

575:

565:

549:

540:

517:

511:

472:

454:

433:

415:

333:

309:

303:

279:

273:

253:

228:

227:

221:

191:

178:

158:

157:

151:

106:Learn how and when to remove this message

2531:Journal of the American Ceramic Society

2021:

1172:

770:

298:is the tensile flow stress at fracture,

2586:Journal of the American Ceramic Society

2496:Journal of the American Ceramic Society

2200:

2026:Several toughening mechanism in epoxies

2862:(3rd ed.). New York: ASME Press.

2859:The stress analysis of cracks handbook

2543:"Crack deflection processes—I. Theory"

2127:is the distance behind the crack tip,

2622:Transformation Toughening Of Ceramics

2174:is a constraint/ triaxiality factor.

1177:Schematic fiber-reinforced composites

7:

2218:

2216:

2214:

2212:

2210:

2208:

2206:

2204:

328:is the tensile fracture strain, and

44:adding citations to reliable sources

2580:Evans, A. G.; Faber, K. T. (1981).

2598:10.1111/j.1151-2916.1981.tb09877.x

2508:10.1111/j.1151-2916.1997.tb03115.x

2389:. New York: Springer. p. 221.

2154:is the uniaxial yield stress, and

2064:

1916:

1795:is the fracture strain of fibers,

1650:

1434:

1398:

1258:

992:

794:

711:

688:

596:

584:

542:

229:

159:

14:

2625:. Milton: CRC Press. p. 14.

1123:is the edge length of grain, and

241:{\displaystyle G_{\mathrm {I} C}}

1076:is the coefficient of friction,

481:{\displaystyle MPa\cdot m^{0.5}}

442:{\displaystyle MPa\cdot m^{0.5}}

20:

1822:is the fraction of fibers, and

1768:is the flow stress of fibers,

248:is the plane strain toughness,

31:needs additional citations for

1741:is a constant between 1.5-6,

1613:is the fraction of fibers and

697:{\displaystyle \Delta \alpha }

602:

593:

590:

581:

321:{\displaystyle \epsilon _{fr}}

1:

2952:10.1016/s0022-5096(98)90003-5

2767:10.1126/science.282.5392.1295

2715:10.1126/science.282.5392.1275

1788:{\displaystyle \epsilon _{y}}

939:{\displaystyle \epsilon _{M}}

2559:10.1016/0001-6160(83)90046-9

2080:{\displaystyle \Delta K_{b}}

1637:Ductile phase crack bridging

1414:{\displaystyle \Delta G_{C}}

392:Common toughening mechanisms

348:is the radius of crack tip.

291:{\displaystyle \sigma _{yf}}

2147:{\displaystyle \sigma _{y}}

1761:{\displaystyle \sigma _{y}}

1566:is the strength of fibers,

1559:{\displaystyle \sigma _{f}}

1096:{\displaystyle \sigma _{R}}

912:{\displaystyle \sigma _{M}}

674:{\displaystyle \sigma _{R}}

3047:

2356:10.1007/s11661-010-0532-8

767:Transformation toughening

358:bcc (body centered cubic)

2619:Green, David J. (2018).

1182:Toughening in composites

720:{\displaystyle \Delta T}

2457:10.1126/science.1156084

2167:{\displaystyle \alpha }

1586:is the width of fiber,

1167:Abnormally large grains

368:phase. These coherent α

2178:Toughening in polymers

2168:

2148:

2121:

2107:is the bridge length,

2101:

2081:

2051:

2027:

2014:

1874:

1843:

1816:

1789:

1762:

1735:

1713:

1627:

1607:

1580:

1560:

1533:

1532:{\displaystyle \beta }

1511:

1415:

1385:

1358:

1331:

1304:

1275:

1178:

1144:

1117:

1097:

1070:

1048:

967:

940:

913:

886:

857:

776:

748:

721:

698:

675:

648:

619:

527:

482:

443:

393:

380:Toughening in ceramics

342:

322:

292:

262:

242:

207:

2689:Abnormal Grain Growth

2169:

2149:

2122:

2102:

2082:

2052:

2050:{\displaystyle K_{m}}

2025:

2015:

1875:

1873:{\displaystyle K_{c}}

1844:

1842:{\displaystyle l_{d}}

1817:

1815:{\displaystyle V_{f}}

1790:

1763:

1736:

1714:

1628:

1626:{\displaystyle \tau }

1608:

1606:{\displaystyle V_{f}}

1581:

1561:

1534:

1512:

1416:

1386:

1384:{\displaystyle V_{f}}

1359:

1357:{\displaystyle V_{m}}

1332:

1330:{\displaystyle G_{f}}

1305:

1303:{\displaystyle G_{m}}

1276:

1176:

1155:abnormal grain growth

1145:

1143:{\displaystyle V_{f}}

1118:

1103:is residual stress,

1098:

1071:

1049:

968:

966:{\displaystyle V_{f}}

941:

914:

887:

885:{\displaystyle r_{c}}

858:

774:

749:

747:{\displaystyle V_{f}}

722:

699:

676:

649:

647:{\displaystyle r_{c}}

620:

528:

526:{\displaystyle G_{C}}

501:Microcrack toughening

490:abnormal grain growth

483:

444:

391:

343:

341:{\displaystyle \rho }

323:

293:

263:

243:

208:

2158:

2131:

2111:

2091:

2061:

2034:

1887:

1857:

1826:

1799:

1772:

1745:

1725:

1647:

1617:

1590:

1570:

1543:

1523:

1431:

1395:

1368:

1341:

1314:

1287:

1196:

1127:

1107:

1080:

1069:{\displaystyle \mu }

1060:

989:

950:

923:

896:

869:

791:

759:most prominently by

731:

708:

685:

681:is residual stress,

658:

631:

539:

510:

453:

414:

332:

302:

272:

252:

220:

150:

135:Toughening in metals

40:improve this article

2981:(47): 20248–20280.

2944:1988JMPSo..36..167B

2819:10.1038/nature06598

2811:2008Natur.451.1085H

2805:(7182): 1085–1089.

2759:1998Sci...282.1295I

2753:(5392): 1295–1297.

2449:2008Sci...320.1057K

2443:(5879): 1057–1060.

2348:2011MMTA...42.1296N

2297:2011NatMa..10..123D

2246:2011NatMa..10..817R

1984:

1487:

3031:Fracture mechanics

2987:10.1039/D1NR07363J

2164:

2144:

2117:

2097:

2077:

2047:

2028:

2010:

1970:

1870:

1839:

1812:

1785:

1758:

1731:

1709:

1623:

1603:

1576:

1556:

1529:

1507:

1473:

1411:

1381:

1354:

1327:

1300:

1271:

1179:

1140:

1113:

1093:

1066:

1044:

963:

936:

909:

882:

853:

777:

744:

717:

694:

671:

644:

615:

523:

478:

439:

394:

338:

318:

288:

258:

238:

203:

139:For the case of a

2897:. Marcel Dekker.

2660:. Marcel Dekker.

2632:978-1-351-08585-4

2547:Acta Metallurgica

2414:10.5006/1.3579264

2120:{\displaystyle x}

2100:{\displaystyle L}

2002:

2001:

1955:

1954:

1734:{\displaystyle C}

1579:{\displaystyle d}

1505:

1458:

1116:{\displaystyle d}

1016:

261:{\displaystyle B}

120:materials science

116:

115:

108:

90:

3038:

3015:

3014:

2970:

2964:

2963:

2923:

2917:

2916:

2888:

2882:

2881:

2853:

2847:

2846:

2793:

2787:

2786:

2741:

2735:

2734:

2698:

2692:

2686:

2680:

2679:

2651:

2645:

2644:

2616:

2610:

2609:

2577:

2571:

2570:

2538:

2532:

2526:

2520:

2519:

2502:(9): 2253–2261.

2491:

2485:

2484:

2432:

2426:

2425:

2397:

2391:

2390:

2382:

2376:

2375:

2342:(5): 1296–1309.

2331:

2325:

2324:

2305:10.1038/nmat2930

2285:Nature Materials

2280:

2274:

2273:

2254:10.1038/nmat3115

2234:Nature Materials

2229:

2223:

2220:

2173:

2171:

2170:

2165:

2153:

2151:

2150:

2145:

2143:

2142:

2126:

2124:

2123:

2118:

2106:

2104:

2103:

2098:

2086:

2084:

2083:

2078:

2076:

2075:

2056:

2054:

2053:

2048:

2046:

2045:

2019:

2017:

2016:

2011:

2003:

1997:

1996:

1995:

1986:

1983:

1978:

1969:

1968:

1956:

1947:

1946:

1941:

1940:

1928:

1927:

1912:

1911:

1899:

1898:

1879:

1877:

1876:

1871:

1869:

1868:

1848:

1846:

1845:

1840:

1838:

1837:

1821:

1819:

1818:

1813:

1811:

1810:

1794:

1792:

1791:

1786:

1784:

1783:

1767:

1765:

1764:

1759:

1757:

1756:

1740:

1738:

1737:

1732:

1718:

1716:

1715:

1710:

1708:

1707:

1698:

1697:

1688:

1687:

1678:

1677:

1662:

1661:

1632:

1630:

1629:

1624:

1612:

1610:

1609:

1604:

1602:

1601:

1585:

1583:

1582:

1577:

1565:

1563:

1562:

1557:

1555:

1554:

1538:

1536:

1535:

1530:

1516:

1514:

1513:

1508:

1506:

1501:

1497:

1496:

1486:

1481:

1472:

1471:

1461:

1459:

1451:

1446:

1445:

1420:

1418:

1417:

1412:

1410:

1409:

1390:

1388:

1387:

1382:

1380:

1379:

1363:

1361:

1360:

1355:

1353:

1352:

1336:

1334:

1333:

1328:

1326:

1325:

1309:

1307:

1306:

1301:

1299:

1298:

1280:

1278:

1277:

1272:

1270:

1269:

1254:

1253:

1244:

1243:

1231:

1230:

1221:

1220:

1208:

1207:

1149:

1147:

1146:

1141:

1139:

1138:

1122:

1120:

1119:

1114:

1102:

1100:

1099:

1094:

1092:

1091:

1075:

1073:

1072:

1067:

1053:

1051:

1050:

1045:

1040:

1039:

1030:

1029:

1017:

1009:

1004:

1003:

972:

970:

969:

964:

962:

961:

945:

943:

942:

937:

935:

934:

918:

916:

915:

910:

908:

907:

891:

889:

888:

883:

881:

880:

862:

860:

859:

854:

852:

851:

842:

841:

832:

831:

822:

821:

806:

805:

753:

751:

750:

745:

743:

742:

726:

724:

723:

718:

703:

701:

700:

695:

680:

678:

677:

672:

670:

669:

653:

651:

650:

645:

643:

642:

624:

622:

621:

616:

614:

613:

580:

579:

570:

569:

554:

553:

532:

530:

529:

524:

522:

521:

487:

485:

484:

479:

477:

476:

448:

446:

445:

440:

438:

437:

397:Crack deflection

347:

345:

344:

339:

327:

325:

324:

319:

317:

316:

297:

295:

294:

289:

287:

286:

267:

265:

264:

259:

247:

245:

244:

239:

237:

236:

232:

212:

210:

209:

204:

199:

198:

186:

185:

167:

166:

162:

111:

104:

100:

97:

91:

89:

48:

24:

16:

3046:

3045:

3041:

3040:

3039:

3037:

3036:

3035:

3021:

3020:

3019:

3018:

2972:

2971:

2967:

2925:

2924:

2920:

2905:

2890:

2889:

2885:

2870:

2855:

2854:

2850:

2795:

2794:

2790:

2743:

2742:

2738:

2700:

2699:

2695:

2687:

2683:

2668:

2653:

2652:

2648:

2633:

2618:

2617:

2613:

2579:

2578:

2574:

2540:

2539:

2535:

2527:

2523:

2493:

2492:

2488:

2434:

2433:

2429:

2399:

2398:

2394:

2384:

2383:

2379:

2333:

2332:

2328:

2282:

2281:

2277:

2240:(11): 817–822.

2231:

2230:

2226:

2221:

2202:

2197:

2180:

2156:

2155:

2134:

2129:

2128:

2109:

2108:

2089:

2088:

2067:

2059:

2058:

2037:

2032:

2031:

1987:

1960:

1932:

1919:

1903:

1890:

1885:

1884:

1860:

1855:

1854:

1829:

1824:

1823:

1802:

1797:

1796:

1775:

1770:

1769:

1748:

1743:

1742:

1723:

1722:

1699:

1689:

1679:

1669:

1653:

1645:

1644:

1639:

1615:

1614:

1593:

1588:

1587:

1568:

1567:

1546:

1541:

1540:

1521:

1520:

1488:

1463:

1462:

1437:

1429:

1428:

1401:

1393:

1392:

1371:

1366:

1365:

1344:

1339:

1338:

1317:

1312:

1311:

1290:

1285:

1284:

1261:

1245:

1235:

1222:

1212:

1199:

1194:

1193:

1184:

1163:silicon nitride

1159:silicon carbide

1130:

1125:

1124:

1105:

1104:

1083:

1078:

1077:

1058:

1057:

1031:

1021:

995:

987:

986:

980:

953:

948:

947:

926:

921:

920:

899:

894:

893:

872:

867:

866:

843:

833:

823:

813:

797:

789:

788:

769:

761:Katherine Faber

734:

729:

728:

706:

705:

683:

682:

661:

656:

655:

634:

629:

628:

605:

571:

561:

545:

537:

536:

513:

508:

507:

503:

468:

451:

450:

429:

412:

411:

408:

404:

399:

382:

371:

367:

330:

329:

305:

300:

299:

275:

270:

269:

250:

249:

223:

218:

217:

187:

174:

153:

148:

147:

137:

112:

101:

95:

92:

49:

47:

37:

25:

12:

11:

5:

3044:

3042:

3034:

3033:

3023:

3022:

3017:

3016:

2965:

2938:(2): 167–187.

2918:

2903:

2883:

2868:

2848:

2788:

2736:

2709:(5392): 1275.

2693:

2681:

2666:

2646:

2631:

2611:

2592:(7): 394–398.

2572:

2553:(4): 565–576.

2533:

2521:

2486:

2427:

2408:(3): 125–129.

2392:

2377:

2326:

2291:(2): 123–128.

2275:

2224:

2199:

2198:

2196:

2193:

2179:

2176:

2163:

2141:

2137:

2116:

2096:

2074:

2070:

2066:

2044:

2040:

2009:

2006:

2000:

1994:

1990:

1982:

1977:

1973:

1967:

1963:

1959:

1953:

1950:

1944:

1939:

1935:

1931:

1926:

1922:

1918:

1915:

1910:

1906:

1902:

1897:

1893:

1867:

1863:

1836:

1832:

1809:

1805:

1782:

1778:

1755:

1751:

1730:

1706:

1702:

1696:

1692:

1686:

1682:

1676:

1672:

1668:

1665:

1660:

1656:

1652:

1638:

1635:

1622:

1600:

1596:

1575:

1553:

1549:

1528:

1504:

1500:

1495:

1491:

1485:

1480:

1476:

1470:

1466:

1457:

1454:

1449:

1444:

1440:

1436:

1408:

1404:

1400:

1378:

1374:

1351:

1347:

1324:

1320:

1297:

1293:

1268:

1264:

1260:

1257:

1252:

1248:

1242:

1238:

1234:

1229:

1225:

1219:

1215:

1211:

1206:

1202:

1183:

1180:

1137:

1133:

1112:

1090:

1086:

1065:

1043:

1038:

1034:

1028:

1024:

1020:

1015:

1012:

1007:

1002:

998:

994:

979:

978:Crack bridging

976:

960:

956:

933:

929:

906:

902:

879:

875:

850:

846:

840:

836:

830:

826:

820:

816:

812:

809:

804:

800:

796:

768:

765:

741:

737:

716:

713:

693:

690:

668:

664:

641:

637:

612:

608:

604:

601:

598:

595:

592:

589:

586:

583:

578:

574:

568:

564:

560:

557:

552:

548:

544:

520:

516:

502:

499:

475:

471:

467:

464:

461:

458:

436:

432:

428:

425:

422:

419:

406:

402:

398:

395:

381:

378:

369:

365:

337:

315:

312:

308:

285:

282:

278:

257:

235:

231:

226:

214:

213:

202:

197:

194:

190:

184:

181:

177:

173:

170:

165:

161:

156:

136:

133:

114:

113:

28:

26:

19:

13:

10:

9:

6:

4:

3:

2:

3043:

3032:

3029:

3028:

3026:

3012:

3008:

3004:

3000:

2996:

2992:

2988:

2984:

2980:

2976:

2969:

2966:

2961:

2957:

2953:

2949:

2945:

2941:

2937:

2933:

2929:

2922:

2919:

2914:

2910:

2906:

2904:0-8247-8900-8

2900:

2896:

2895:

2887:

2884:

2879:

2875:

2871:

2869:0-7918-0153-5

2865:

2861:

2860:

2852:

2849:

2844:

2840:

2836:

2832:

2828:

2824:

2820:

2816:

2812:

2808:

2804:

2800:

2792:

2789:

2784:

2780:

2776:

2772:

2768:

2764:

2760:

2756:

2752:

2748:

2740:

2737:

2732:

2728:

2724:

2720:

2716:

2712:

2708:

2704:

2697:

2694:

2690:

2685:

2682:

2677:

2673:

2669:

2667:0-8247-8900-8

2663:

2659:

2658:

2650:

2647:

2642:

2638:

2634:

2628:

2624:

2623:

2615:

2612:

2607:

2603:

2599:

2595:

2591:

2587:

2583:

2576:

2573:

2568:

2564:

2560:

2556:

2552:

2548:

2544:

2537:

2534:

2530:

2525:

2522:

2517:

2513:

2509:

2505:

2501:

2497:

2490:

2487:

2482:

2478:

2474:

2470:

2466:

2462:

2458:

2454:

2450:

2446:

2442:

2438:

2431:

2428:

2423:

2419:

2415:

2411:

2407:

2403:

2396:

2393:

2388:

2381:

2378:

2373:

2369:

2365:

2361:

2357:

2353:

2349:

2345:

2341:

2337:

2330:

2327:

2322:

2318:

2314:

2310:

2306:

2302:

2298:

2294:

2290:

2286:

2279:

2276:

2271:

2267:

2263:

2259:

2255:

2251:

2247:

2243:

2239:

2235:

2228:

2225:

2219:

2217:

2215:

2213:

2211:

2209:

2207:

2205:

2201:

2194:

2192:

2190:

2186:

2177:

2175:

2161:

2139:

2135:

2114:

2094:

2072:

2068:

2042:

2038:

2024:

2020:

2007:

2004:

1998:

1992:

1988:

1980:

1975:

1971:

1965:

1961:

1957:

1951:

1948:

1942:

1937:

1933:

1929:

1924:

1920:

1913:

1908:

1904:

1900:

1895:

1891:

1882:

1865:

1861:

1851:

1834:

1830:

1807:

1803:

1780:

1776:

1753:

1749:

1728:

1719:

1704:

1700:

1694:

1690:

1684:

1680:

1674:

1670:

1666:

1663:

1658:

1654:

1642:

1636:

1634:

1620:

1598:

1594:

1573:

1551:

1547:

1526:

1517:

1502:

1498:

1493:

1489:

1483:

1478:

1474:

1468:

1464:

1455:

1452:

1447:

1442:

1438:

1426:

1423:

1406:

1402:

1376:

1372:

1349:

1345:

1322:

1318:

1295:

1291:

1281:

1266:

1262:

1255:

1250:

1246:

1240:

1236:

1232:

1227:

1223:

1217:

1213:

1209:

1204:

1200:

1191:

1188:

1181:

1175:

1171:

1168:

1164:

1160:

1156:

1151:

1135:

1131:

1110:

1088:

1084:

1063:

1054:

1041:

1036:

1032:

1026:

1022:

1018:

1013:

1010:

1005:

1000:

996:

984:

977:

975:

958:

954:

931:

927:

904:

900:

877:

873:

863:

848:

844:

838:

834:

828:

824:

818:

814:

810:

807:

802:

798:

786:

783:

773:

766:

764:

762:

758:

739:

735:

714:

691:

666:

662:

639:

635:

625:

610:

606:

599:

587:

576:

572:

566:

562:

558:

555:

550:

546:

534:

518:

514:

500:

498:

495:

491:

473:

469:

465:

462:

459:

456:

434:

430:

426:

423:

420:

417:

396:

390:

386:

379:

377:

374:

362:

359:

353:

349:

335:

313:

310:

306:

283:

280:

276:

255:

233:

224:

200:

195:

192:

188:

182:

179:

175:

171:

168:

163:

154:

146:

145:

144:

142:

134:

132:

130:

125:

121:

110:

107:

99:

88:

85:

81:

78:

74:

71:

67:

64:

60:

57: –

56:

52:

51:Find sources:

45:

41:

35:

34:

29:This article

27:

23:

18:

17:

2978:

2974:

2968:

2935:

2931:

2921:

2893:

2886:

2858:

2851:

2802:

2798:

2791:

2750:

2746:

2739:

2706:

2702:

2696:

2684:

2656:

2649:

2621:

2614:

2589:

2585:

2575:

2550:

2546:

2536:

2524:

2499:

2495:

2489:

2440:

2436:

2430:

2405:

2401:

2395:

2386:

2380:

2339:

2335:

2329:

2288:

2284:

2278:

2237:

2233:

2227:

2185:plasticizers

2181:

2029:

1883:

1852:

1720:

1643:

1640:

1518:

1427:

1424:

1282:

1192:

1189:

1185:

1152:

1055:

985:

981:

864:

787:

778:

757:demonstrated

626:

535:

504:

400:

383:

375:

363:

354:

350:

215:

138:

123:

117:

102:

93:

83:

76:

69:

62:

55:"Toughening"

50:

38:Please help

33:verification

30:

2641:1023540708

2195:References

124:toughening

66:newspapers

3011:244288401

2995:2040-3372

2975:Nanoscale

2960:0022-5096

2913:300921090

2843:205212209

2827:1476-4687

2775:0036-8075

2731:135692500

2723:0036-8075

2676:300921090

2606:0002-7820

2567:0001-6160

2516:1551-2916

2465:0036-8075

2422:0010-9312

2402:Corrosion

2372:137276443

2364:1543-1940

2313:1476-4660

2262:1476-4660

2162:α

2136:σ

2065:Δ

1989:σ

1972:∫

1958:α

1952:π

1917:Δ

1777:ϵ

1750:σ

1681:ϵ

1671:σ

1651:Δ

1621:τ

1548:σ

1527:β

1503:τ

1475:σ

1465:β

1435:Δ

1399:Δ

1259:Δ

1085:σ

1064:μ

1023:σ

1019:μ

1006:≅

993:Δ

928:ϵ

901:σ

835:ϵ

825:σ

808:≅

795:Δ

782:tractions

712:Δ

692:α

689:Δ

663:σ

597:Δ

588:α

585:Δ

573:σ

556:≅

543:Δ

466:⋅

427:⋅

336:ρ

307:ϵ

277:σ

201:ρ

189:ϵ

176:σ

3025:Category

3003:34851346

2878:43287080

2835:18305540

2473:18497294

2321:21217693

2270:22020005

2189:polymers

129:Ceramics

96:May 2017

2940:Bibcode

2807:Bibcode

2783:9812889

2755:Bibcode

2747:Science

2703:Science

2481:7119752

2445:Bibcode

2437:Science

2344:Bibcode

2293:Bibcode

2242:Bibcode

141:ductile

80:scholar

3009:

3001:

2993:

2958:

2911:

2901:

2876:

2866:

2841:

2833:

2825:

2799:Nature

2781:

2773:

2729:

2721:

2674:

2664:

2639:

2629:

2604:

2565:

2514:

2479:

2471:

2463:

2420:

2370:

2362:

2319:

2311:

2268:

2260:

2030:where

1721:where

1519:where

1283:where

1056:where

865:where

627:where

216:where

82:

75:

68:

61:

53:

3007:S2CID

2839:S2CID

2727:S2CID

2477:S2CID

2368:S2CID

87:JSTOR

73:books

2999:PMID

2991:ISSN

2956:ISSN

2909:OCLC

2899:ISBN

2874:OCLC

2864:ISBN

2831:PMID

2823:ISSN

2779:PMID

2771:ISSN

2719:ISSN

2672:OCLC

2662:ISBN

2637:OCLC

2627:ISBN

2602:ISSN

2563:ISSN

2512:ISSN

2469:PMID

2461:ISSN

2418:ISSN

2360:ISSN

2317:PMID

2309:ISSN

2266:PMID

2258:ISSN

2187:in

1364:and

1310:and

1161:and

59:news

2983:doi

2948:doi

2815:doi

2803:451

2763:doi

2751:282

2711:doi

2707:282

2594:doi

2555:doi

2504:doi

2453:doi

2441:320

2410:doi

2352:doi

2301:doi

2250:doi

494:AGG

474:0.5

435:0.5

118:In

42:by

3027::

3005:.

2997:.

2989:.

2979:13

2977:.

2954:.

2946:.

2936:36

2934:.

2930:.

2907:.

2872:.

2837:.

2829:.

2821:.

2813:.

2801:.

2777:.

2769:.

2761:.

2749:.

2725:.

2717:.

2705:.

2670:.

2635:.

2600:.

2590:64

2588:.

2584:.

2561:.

2551:31

2549:.

2545:.

2510:.

2500:80

2498:.

2475:.

2467:.

2459:.

2451:.

2439:.

2416:.

2406:38

2404:.

2366:.

2358:.

2350:.

2340:42

2338:.

2315:.

2307:.

2299:.

2289:10

2287:.

2264:.

2256:.

2248:.

2238:10

2236:.

2203:^

1456:32

1165:.

407:gb

403:gb

122:,

3013:.

2985::

2962:.

2950::

2942::

2915:.

2880:.

2845:.

2817::

2809::

2785:.

2765::

2757::

2733:.

2713::

2678:.

2643:.

2608:.

2596::

2569:.

2557::

2518:.

2506::

2483:.

2455::

2447::

2424:.

2412::

2374:.

2354::

2346::

2323:.

2303::

2295::

2272:.

2252::

2244::

2140:y

2115:x

2095:L

2073:b

2069:K

2043:m

2039:K

2008:x

2005:d

1999:x

1993:y

1981:L

1976:0

1966:f

1962:V

1949:2

1943:+

1938:m

1934:K

1930:=

1925:b

1921:K

1914:+

1909:m

1905:K

1901:=

1896:c

1892:K

1866:c

1862:K

1835:d

1831:l

1808:f

1804:V

1781:y

1754:y

1729:C

1705:d

1701:l

1695:f

1691:V

1685:f

1675:y

1667:C

1664:=

1659:C

1655:G

1599:f

1595:V

1574:d

1552:f

1499:d

1494:f

1490:V

1484:2

1479:f

1469:2

1453:1

1448:=

1443:C

1439:G

1407:C

1403:G

1377:f

1373:V

1350:m

1346:V

1323:f

1319:G

1296:m

1292:G

1267:C

1263:G

1256:+

1251:f

1247:G

1241:f

1237:V

1233:+

1228:m

1224:G

1218:m

1214:V

1210:=

1205:C

1201:G

1136:f

1132:V

1111:d

1089:R

1042:d

1037:f

1033:V

1027:R

1014:8

1011:1

1001:C

997:G

959:f

955:V

932:M

905:M

878:c

874:r

849:f

845:V

839:M

829:M

819:c

815:r

811:2

803:C

799:G

740:f

736:V

715:T

667:R

640:c

636:r

611:f

607:V

603:)

600:T

594:(

591:)

582:(

577:R

567:c

563:r

559:2

551:C

547:G

519:C

515:G

470:m

463:a

460:P

457:M

431:m

424:a

421:P

418:M

370:2

366:2

314:r

311:f

284:f

281:y

256:B

234:C

230:I

225:G

196:r

193:f

183:f

180:y

172:B

169:=

164:C

160:I

155:G

109:)

103:(

98:)

94:(

84:·

77:·

70:·

63:·

36:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.