3681:, load life or useful life of electrolytic capacitors is a special characteristic of non-solid aluminum electrolytic capacitors, whose liquid electrolyte can evaporate over time. Lowering the electrolyte level influences the electrical parameters of the capacitors. The capacitance decreases and the impedance and ESR increase with decreasing amounts of electrolyte. This very slow electrolyte drying-out depends on the temperature, the applied ripple current load, and the applied voltage. The lower these parameters compared with their maximum values the longer the capacitor's “life”. The “end of life” point is defined by the appearance of wear-out failures or degradation failures when either capacitance, impedance, ESR or leakage current exceed their specified change limits.

624:

1584:

3246:

electrolytes. For non-solid aluminum electrolytic capacitors the leakage current includes all weakened imperfections of the dielectric caused by unwanted chemical processes taking place during the time without applied voltage (storage time) between operating cycles. These unwanted chemical processes depend on the kind of electrolyte. Electrolytes with water content or water based electrolytes are more aggressive to the aluminum oxide layer than are electrolytes based on organic liquids. This is why different electrolytic capacitor series specify different storage time without reforming instructions.

672:

1900:

Niobium as raw material is much more abundant in nature than tantalum and is less expensive. It was a question of the availability of the base metal in the late 1960s which led to development and implementation of niobium electrolytic capacitors in the former Soviet Union instead of tantalum capacitors as in the West. The materials and processes used to produce niobium-dielectric capacitors are essentially the same as for existing tantalum-dielectric capacitors. The characteristics of niobium electrolytic capacitors and tantalum electrolytic capacitors are roughly comparable.

4115:

stability of the electrolytic system and the protecting aluminum oxide layer because all chemical reactions are accelerated by high temperatures. Since decades nearly all today’s series of non-solid e-caps fulfill the 1000 hours shelf life test which comply with minimum fife years storage at room temperature. However, many e-cap series are specified only for a two years storage time. This is a standard storage time for electronic components for storing at room temperature caused by the oxidation of the terminals to ensure the solderability of the terminals.

4158:

2731:

1704:. He introduce a separated second foil to contact the electrolyte adjacent to the anode foil instead of using the electrolyte-filled container as the capacitor's cathode. The stacked second foil got its own terminal additional to the anode terminal and the container no longer had an electrical function. This type of electrolytic capacitor combined with an liquid or gel-like electrolyte of a non-aqueous nature, which is therefore dry in the sense of having a very low water content, became known as the “dry” type of electrolytic capacitor.

660:

1504:

4138:

2274:

1516:

684:

2719:

1492:

636:

1480:

612:

1798:

1559:

3665:

1677:

1721:

78:

2215:

2167:

4107:

aluminum electrolytic capacitors may occur after storage or unused times without voltage applied. During storage or unused times potentially chemical processes (corrosion) can weaken the oxide layer, which may lead to a higher leakage current. However, today’s most electrolytic systems are chemically inert and don’t generate any corrosion problems, even after storage times of two years or longer. Especially non-solid electrolytic capacitors using organic solvents like

1936:

1535:

3497:

1576:

1547:

3700:. It characterizes the change of thermic reaction speed. For every 10 °C lower temperature the evaporation is reduced by half. That means for every 10 °C lower temperature the lifetime of capacitors doubles. If a lifetime specification of an electrolytic capacitor is, for example, 2000 h/105 °C, the capacitor's lifetime at 45 °C can be ”calculated” as 128,000 hours—that is roughly 15 years—by using the 10-degrees-rule.

2880:

515:

1644:

1468:

3227:

212:

4098:

inverse of the individual capacitor’s leakage current. Since every capacitor differs a little bit in individual leakage current, the capacitors with a higher leakage current will get less voltage. The voltage balance over the series-connected capacitors is not symmetrical. Passive or active voltage balance has to be provided in order to stabilize the voltage over each individual capacitor .

268:

3648:. Tantalum capacitors with solid electrolyte have no wear-out mechanism so that the constant failure rate is least, up to the point when all capacitors fail. Electrolytic capacitors with non-solid electrolyte, however, have a limited time of constant random failures up to that point when the wear-out failures start. This time of the constant random failure rate corresponds with the

2086:

3597:. For other conditions of applied voltage, current load, temperature, capacitance value, circuit resistance (for tantalum capacitors), mechanical influences and humidity, the FIT figure can be recalculated with acceleration factors standardized for industrial or military contexts. The higher the temperature and applied voltage the higher the failure rate, for example.

3704:

conductivity decreases as a function of time, in agreement with a granular metal type structure, in which aging is due to the shrinking of the conductive polymer grains. The lifetime of polymer electrolytic capacitors is specified in terms similar to non-solid e-caps but its lifetime calculation follows other rules, leading to much longer operational lifetimes.

1457:

electrolytic capacitors and are used in devices with limited space or flat design such as laptops. They are also used in military technology, mostly in axial style, hermetically sealed. Niobium electrolytic chip capacitors are a new development in the market and are intended as a replacement for tantalum electrolytic chip capacitors.

32:

1781:, Sprague's Director of Research, is considered to be the actual inventor of tantalum capacitors in 1954. His invention was supported by R. J. Millard, who introduced the “reform” step in 1955, a significant improvement in which the dielectric of the capacitor was repaired after each dip-and-convert cycle of MnO

2206:

cycles, one of the oxides on the foil acts as a blocking dielectric, preventing reverse current from damaging the electrolyte of the other one. But these bipolar electrolytic capacitors are not adaptable for main AC applications instead of power capacitors with metallized polymer film or paper dielectric.

1713:, whose first patent for electrolytic capacitors was filed in 1928, industrialized the new ideas for electrolytic capacitors and started the first large commercial production in 1931 in the Cornell-Dubilier (CD) factory in Plainfield, New Jersey. At the same time in Berlin, Germany, the "Hydra-Werke", an

3257:

current in solid electrolyte capacitors cannot be reduced by “healing”, because under normal conditions solid electrolytes cannot provide oxygen for forming processes. This statement should not be confused with the self-healing process during field crystallization, see below, Reliability (Failure rate).

3668:

The electrical values of aluminum electrolytic capacitors with non-solid electrolyte change over time due to evaporation of electrolyte. Reaching the specified limits of the electrical parameters, the time of the constant failure rate ends and it is the end of the capacitor's lifetime. The graph show

3615:

It should be noted that industrially produced tantalum capacitors nowadays are very reliable components. Continuous improvement in tantalum powder and capacitor technologies have resulted in a significant reduction in the amount of impurities which formerly caused most field crystallization failures.

3213:

Aluminum electrolytic capacitors with non-solid electrolytes normally can be charged up to the rated voltage without any current surge, peak or pulse limitation. This property is a result of the limited ion movability in the liquid electrolyte, which slows down the voltage ramp across the dielectric,

2205:

Special bipolar aluminum electrolytic capacitors designed for bipolar operation are available, and usually referred to as "non-polarized" or "bipolar" types. In these, the capacitors have two anode foils with full-thickness oxide layers connected in reverse polarity. On the alternate halves of the AC

2178:

Nevertheless, electrolytic capacitors can withstand for short instants a reverse voltage for a limited number of cycles. In detail, aluminum electrolytic capacitors with non-solid electrolyte can withstand a reverse voltage of about 1 V to 1.5 V. This reverse voltage should never be used to

2149:

Aluminum electrolytic capacitors with non-solid electrolyte are relatively insensitive to high and short-term transient voltages higher than surge voltage, if the frequency and the energy content of the transients are low. This ability depends on rated voltage and component size. Low energy transient

1655:

electrolyte dissolved in water, in which a folded aluminum anode plate was inserted. Applying a DC voltage from outside, an oxide layer was formed on the surface of the anode. The advantage of these capacitors was that they were significantly smaller and cheaper than all other capacitors at this time

922:

The non-solid or so-called "wet" aluminum electrolytic capacitors were and are the cheapest among all other conventional capacitors. They not only provide the cheapest solutions for high capacitance or voltage values for decoupling and buffering purposes but are also insensitive to low ohmic charging

207:

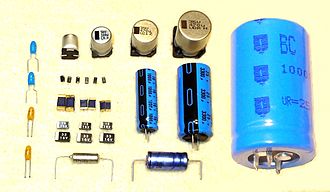

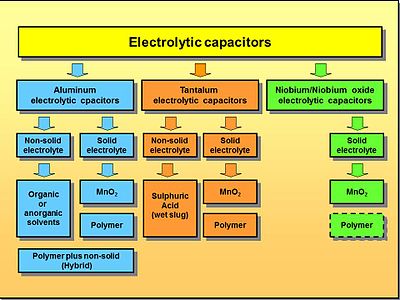

As to the basic construction principles of electrolytic capacitors, there are three different types: aluminum, tantalum, and niobium capacitors. Each of these three capacitor families uses non-solid and solid manganese dioxide or solid polymer electrolytes, so a great spread of different combinations

3692:

The lifetime of non-solid aluminum electrolytic capacitors is specified in terms of “hours per temperature", like “2,000h/105 °C”. With this specification the lifetime at operational conditions can be estimated by special formulas or graphs specified in the data sheets of serious manufacturers.

3688:

But even after exceeding the specified limits and the capacitors having reached their “end of life” the electronic circuit is not in immediate danger; only the functionality of the capacitors is reduced. With today's high levels of purity in the manufacture of electrolytic capacitors it is not to be

3639:

as reference conditions. Also for aluminum electrolytic capacitors it should be noted that they are very reliable components. Published figures show for low voltage types (6.3…160 V) FIT rates in the range of 1 to 20 FIT and for high voltage types (>160 …550 V) FIT rates in the range of

3416:

Dielectric absorption occurs when a capacitor that has remained charged for a long time discharges only incompletely when briefly discharged. Although an ideal capacitor would reach zero volts after discharge, real capacitors develop a small voltage from time-delayed dipole discharging, a phenomenon

2018:

The standardized measuring condition for e-caps is an AC measuring method with 0.5 V at a frequency of 100/120 Hz and a temperature of 20 °C. For tantalum capacitors a DC bias voltage of 1.1 to 1.5 V for types with a rated voltage ≤2.5 V, or 2.1 to 2.5 V for types with

1769:

These first sintered tantalum capacitors used a non-solid electrolyte, which does not fit the concept of solid electronics. In 1952 a targeted search at Bell Labs by D. A. McLean and F. S. Power for a solid electrolyte led to the invention of manganese dioxide as a solid electrolyte for a sintered

1741:

One of the first tantalum electrolytic capacitors were developed in 1930 by

Tansitor Electronic Inc. USA, for military purposes. The basic construction of a wound cell was adopted and a tantalum anode foil was used together with a tantalum cathode foil, separated with a paper spacer impregnated with

1659:

The first more common application of wet aluminum electrolytic capacitors was in large telephone exchanges, to reduce relay hash (noise) on the 48 volt DC power supply. The development of AC-operated domestic radio receivers in the late 1920s created a demand for large-capacitance (for the time) and

591:

All etched or sintered anodes have a much higher surface compared to a smooth surface of the same area or the same volume. That increases the later capacitance value, depending on the rated voltage, by a factor of up to 200 for non-solid aluminum electrolytic capacitors as well as for solid tantalum

502:

Comparing the permittivities of the different oxide materials it is seen that tantalum pentoxide has a permittivity approximately three times higher than aluminum oxide. Tantalum electrolytic capacitors of a given CV value theoretically are therefore smaller than aluminum electrolytic capacitors. In

333:

All anode materials are either etched or sintered and have a rough surface structure with a much higher surface compared to a smooth surface of the same area or the same volume. By applying a positive voltage to the above mentioned anode material in an electrolytic bath an oxide barrier layer with a

4106:

All electrolytic capacitors with non-solid as well as with solid electrolyte are "aged" during manufacturing by applying rated voltage at high temperature for a sufficient time to repair all cracks and weaknesses that may have occurred during production. However, a particular problem with non-solid

3566:

Billions of tested capacitor unit-hours would be needed to establish failure rates in the very low level range which are required today to ensure the production of large quantities of components without failures. This requires about a million units over a long time period, which means a large staff

3217:

Solid tantalum electrolytic capacitors with manganese dioxide electrolyte or polymer electrolyte are damaged by peak or pulse currents. Solid

Tantalum capacitors which are exposed to surge, peak or pulse currents, for example, in in highly inductive circuits, should be used with a voltage derating.

2136:

The surge voltage indicates the maximum peak voltage value that may be applied to electrolytic capacitors during their application for a limited number of cycles. The surge voltage is standardized in IEC/EN 60384-1. For aluminum electrolytic capacitors with a rated voltage of up to 315 V, the

2112:

The voltage proof of electrolytic capacitors decreases with increasing temperature. For some applications it is important to use a higher temperature range. Lowering the voltage applied at a higher temperature maintains safety margins. For some capacitor types therefore the IEC standard specifies a

1999:

The electrical characteristics of electrolytic capacitors depend on the structure of the anode and the electrolyte used. This influences the capacitance value of electrolytic capacitors, which depends on measuring frequency and temperature. Electrolytic capacitors with non-solid electrolytes show a

1913:

was a leader in the development of new water-based electrolyte systems with enhanced conductivity in the late 1990s. The new series of non-solid e-caps with water-based electrolyte was described in the data sheets as having "Low-ESR", "Low-Impedance", "Ultra-Low-Impedance" or "High-Ripple

Current".

1732:

For aluminum electrolytic capacitors the decades from 1970 to 1990 were marked by the development of various new professional series specifically suited to certain industrial applications, for example with very low leakage currents or with long life characteristics, or for higher temperatures up to

926:

Tantalum electrolytic capacitors with solid electrolyte as surface-mountable chip capacitors are mainly used in electronic devices in which little space is available or a low profile is required. They operate reliably over a wide temperature range without large parameter deviations. In military and

474:

After forming a dielectric oxide on the rough anode structure, a counter electrode has to match the rough insulating oxide surface. This is accomplished by the electrolyte, which acts as the cathode electrode of an electrolytic capacitor. There are many different electrolytes in use. Generally they

4118:

Only for antique radio equipment or for very old e-caps built in the 1970s or earlier, "pre-conditioning" may be recommended. For this purpose, the rated voltage is applied to the capacitor via a series resistance of approximately 1 kΩ for a period of one hour. Applying a voltage via a safety

3703:

However, solid polymer electrolytic capacitors, aluminum as well as tantalum and niobium electrolytic capacitors also have a lifetime specification. The polymer electrolyte has a small deterioration of conductivity caused by a thermal degradation mechanism in the conductive polymer. The electrical

3471:

But especially for electrolytic capacitors with high rated voltage the voltage at the terminals generated by the dielectric absorption can be a safety risk to personnel or circuits. In order to prevent shocks most very large capacitors are shipped with shorting wires that need to be removed before

2127:

Applying a lower voltage may have a positive influence on electrolytic capacitors. For aluminum electrolytic capacitors a lower applied voltage can in some cases extend the lifetime.For tantalum electrolytic capacitors lowering the voltage applied increases the reliability and reduces the expected

1908:

With the goal of reducing ESR for inexpensive non-solid e-caps from the mid-1980s in Japan, new water-based electrolytes for aluminum electrolytic capacitors were developed. Water is inexpensive, an effective solvent for electrolytes, and significantly improves the conductivity of the electrolyte.

1805:

The first solid electrolyte of manganese dioxide developed 1952 for tantalum capacitors had a conductivity 10 times better than all other types of non-solid electrolytes. It also influenced the development of aluminum electrolytic capacitors. In 1964 the first aluminum electrolytic capacitors with

3707:

Tantalum electrolytic capacitors with solid manganese dioxide electrolyte do not have wear-out failures so they do not have a lifetime specification in the sense of non-solid aluminum electrolytic capacitors. Also, tantalum capacitors with non-solid electrolyte, the “wet tantalums”, do not have a

3562:

ime]. This is the number of failures that can be expected in one billion (10) component-hours of operation (e.g., 1000 components for 1 million hours, or 1 million components for 1000 hours which is 1 ppm/1000 hours) at fixed working conditions during the period of constant random

3256:

The main causes of DCL for solid tantalum capacitors include electrical breakdown of the dielectric, conductive paths due to impurities or poor anodization, bypassing of dielectric due to excess manganese dioxide, to moisture paths, or to cathode conductors (carbon, silver). This “normal” leakage

1899:

Another price explosion for tantalum in 2000/2001 forced the development of niobium electrolytic capacitors with manganese dioxide electrolyte, which have been available since 2002. Niobium is a sister metal to tantalum and serves as valve metal generating an oxide layer during anodic oxidation.

4080:

Smaller or low voltage electrolytic capacitors may be connected in parallel without any safety correction action. Large size capacitors, especially large sizes and high voltage types should be individually guarded against sudden energy charge of the whole capacitor bank due to a failed specimen.

3719:

The many different types of electrolytic capacitors show differences in electrical long-term behavior, their inherent failure modes, and their self-healing mechanism. Application rules for types with an inherent failure mode are specified to ensure capacitors with high reliability and long life.

1788:

Although solid tantalum capacitors offered capacitors with lower ESR and leakage current values than the aluminum e-caps, 1980 a price shock for tantalum in the industry reduces the applications of Ta-e-caps especially in the entertainment industry dramatically. The industry switched back to use

1765:

in the early 1950s as a miniaturized, more reliable low-voltage support capacitor to complement their newly invented transistor. The solution found by R. L. Taylor and H. E. Haring of the Bell labs in early 1950 was based on experiences with ceramics. They ground tantalum to a powder, which they

4114:

The ability to reach longer storage times can be tested using an accelerated shelf-life testing, which requires the storage of capacitors without applied voltage at its upper category temperature for a certain period, usually 1000 hours. This shelf life test is a good indicator for the chemical

1728:

Already in his patent from 1896 Pollak wrote that the capacitance of the capacitor increase by roughening the surface of the anode foil. Today (2014), electrochemically etched low voltage foils can achieve an up to 200-fold increase in surface area compared to a smooth surface. Advances in the

941:

In order to compare the different characteristics of the different electrolytic capacitor types, capacitors with the same dimensions and of similar capacitance and voltage are compared in the following table. In such a comparison the values for ESR and ripple current load are the most important

595:

All electrolytic capacitors have one special advantage. Because the forming voltage defines the oxide layer thickness, the voltage proof of the later electrolytic capacitor can be produced very simply for the desired rated value. Therefore, the volume of a capacitor is defined by the product of

587:

per volt. On the other hand, the voltage strengths of these oxide layers are quite high. With this very thin dielectric oxide layer combined with a sufficient high dielectric strength the electrolytic capacitors can already achieve a high volumetric capacitance. This is one reason for the high

4097:

need the higher voltages aluminum electrolytic capacitors usually offer. For such applications electrolytic capacitors can be connected in series for increased voltage-withstanding capability. During charging, the voltage across each of the capacitors connected in series is proportional to the

4245:

Version 2: coding with year code/month code. The year codes are: "R" = 2003, "S"= 2004, "T" = 2005, "U" = 2006, "V" = 2007, "W" = 2008, "X" = 2009, "A" = 2010, "B" = 2011, "C" = 2012, "D" = 2013, “E” = 2014 etc. Month codes are: "1" to "9" = Jan. to Sept., "O" = October, "N" = November, "D" =

6221:

E. Vitoratos, S. Sakkopoulos, E. Dalas, N. Paliatsas, D. Karageorgopoulos, F. Petraki, S. Kennou, S.A. Choulis, Thermal degradation mechanisms of PEDOT:PSS, Organic

Electronics Volume 10, Issue 1, February 2009, Pages 61–66, Organic ElectronicsVolume 10, Issue 1, February 2009, Pages 61–66,

3600:

The most often cited source for recalculation of failure rate is the MIL-HDBK-217F, the “bible” of failure rate calculations for electronic components. SQC Online, the online statistical calculator for acceptance sampling and quality control, provides an online tool for short examination to

1943:

The electrical characteristics of capacitors are harmonized by the international generic specification IEC 60384-1. In this standard, the electrical characteristics of capacitors are described by an idealized series-equivalent circuit with electrical components which model all ohmic losses,

190:

voltage. Voltages with reverse polarity, or voltage or ripple current higher than specified, can destroy the dielectric and thus the capacitor. A possible ripple voltage must not cause reversal. The destruction of electrolytic capacitors can have catastrophic consequences (explosion, fire).

3245:

The reasons for leakage current are different between electrolytic capacitors with non-solid and with solid electrolyte or more common for “wet” aluminum and for “solid” tantalum electrolytic capacitors with manganese dioxide electrolyte as well as for electrolytic capacitors with polymer

1456:

Aluminum electrolytic capacitors form the bulk of the electrolytic capacitors used in electronics because of the large diversity of sizes and the inexpensive production. Tantalum electrolytic capacitors, usually used in the SMD version, have a higher specific capacitance than the aluminum

1656:

relative to the realized capacitance value. This construction with different styles of anode construction but with a case as cathode and container for the electrolyte was used up to the 1930s and was called a “wet” electrolytic capacitor, in the sense of its having a high water content.

3693:

They use different ways for specification, some give special formulas, others specify their e-caps lifetime calculation with graphs that consider the influence of applied voltage.. Basic principle for calculating the time under operational conditions is the so called “10-degree-rule”.

2293:; it describes the phase difference and the ratio of amplitudes between sinusoidally varying voltage and sinusoidally varying current at a given frequency. In this sense impedance is a measure of the ability of the capacitor to pass alternating currents and can be used like Ohm's law.

4219:

Smaller capacitors use a shorthand notation. The most commonly used format is: XYZ J/K/M “V”, where XYZ represents the capacitance (calculated as XY × 10 pF), the letters K or M indicate the tolerance (±10 % and ±20 % respectively) and “V” represents the working voltage.

3393:

623:

4182:

Electrolytic capacitors, like most other electronic components and if enough space is available, have imprinted markings to indicate manufacturer, type, electrical and thermal characteristics, and date of manufacture. If they are large enough the capacitor is marked with:

1631:), a producer of accumulators, found out that that the oxide layer on an aluminum anode remained stable in a neutral or alkaline electrolyte, even when the power was switched off. In 1896 he filed a patent for an "Electric liquid capacitor with aluminium electrodes" (de:

942:

parameters for the use of electrolytic capacitors in modern electronic equipment. The lower the ESR, the higher the ripple current per volume and better functionality of the capacitor in the circuit. However, better electrical parameters are combined with higher prices.

3200:

In solid tantalum electrolytic capacitors with manganese dioxide electrolyte the heat generated by the ripple current influences the reliability of the capacitors. Exceeding the limit tends to result in catastrophic failures with short circuits and burning components.

2157:

Electrolytic capacitors with solid manganese oxide or polymer electrolyte, and aluminum as well as tantalum electrolytic capacitors can not withstand transients or peak voltages higher than surge voltage. Transients for this type of e-caps may destroy the components.

1890:

A new conductive polymer for tantalum polymer capacitors was presented by Kemet at the "1999 Carts" conference. This capacitor used the newly developed organic conductive polymer PEDT Poly(3,4-ethylenedioxythiophene), also known as PEDOT (trade name

Baytron®)

6083:

3643:

The published figures show that both capacitor types, tantalum and aluminum, are reliable components, comparable with other electronic components and achieving safe operation for decades under normal conditions. But a great difference exists in the case of

705:

Combinations of anode materials for electrolytic capacitors and the electrolytes used have given rise to a wide variety of capacitor types with different properties. An outline of the main characteristics of the different types is shown in the table below.

3534:

and is divided into three areas: early failures or infant mortality failures, constant random failures and wear out failures. Failures totalized in a failure rate are short circuit, open circuit, and degradation failures (exceeding electrical parameters).

1886:

Tantalum electrolytic capacitors with PPy polymer electrolyte cathode followed three years later. In 1993 NEC introduced its SMD polymer tantalum electrolytic capacitors, called "NeoCap". In 1997 Sanyo followed with the "POSCAP" polymer tantalum chips.

3567:

and considerable financing. The tested failure rates are often complemented with figures resulting from feedback from the field from big users concerning failed components (field failure rate), which mostly results in a lower failure rate than tested.

3073:

The ripple current is specified as an effective (RMS) value at 100 or 120 Hz or at 10 kHz at upper category temperature. Non-sinusoidal ripple currents have to be analyzed and separated into their single sinusoidal frequencies by means of

1917:

A stolen recipe for such a water-based electrolyte, in which important stabilizing substances were absent,, led in the years 2000 to 2005 to the problem of mass-bursting capacitors in computers and power supplies, which became known under the term

671:

166:

The large capacitance of electrolytic capacitors makes them particularly suitable for passing or bypassing low-frequency signals up to some mega-hertz and storing large amounts of energy. They are widely used for decoupling or noise filtereng in

3252:

Although the leakage current of non-solid e-caps is higher than current flow over insulation resistance in ceramic or film capacitors, the self-discharge of modern non-solid electrolytic capacitors with organic electrolytes takes several weeks.

2387:

2775:

accounts for internal heat generation if a ripple current flows over the capacitor. This internal heat reduces the lifetime of non-solid aluminum electrolytic capacitors or influences the reliability of solid tantalum electrolytic capacitors.

1817:

With the beginning of digitalization, Intel launched in 1971 its first microcomputer, MCS 4, and in 1972 Hewlett

Packard launched one of the first pocket calculators, HP 35. The requirements for capacitors increased in terms of lowering the

3684:

The lifetime is a specification of a collection of tested capacitors and delivers an expectation of the behavior of similar types. This lifetime definition corresponds with the time of the constant random failure rate in the bathtub curve.

4215:

Polarized capacitors have polarity markings, usually a "−" (minus) sign on the side of the negative electrode for electrolytic capacitors or a stripe or a "+" (plus) sign. Also, the negative lead for leaded "wet" e-caps is usually shorter.

3204:

The heat generated by the ripple current also influences the lifetime of aluminum and tantalum electrolytic capacitors with solid polymer electrolytes. Exceeding the limit tends to result in catastrophic failures with short components.

5807:

Y. K. ZHANG, J. LIN,Y. CHEN, Polymer

Aluminum Electrolytic Capacitors with Chemically-Polymerized Polypyrrole (PPy) as Cathode Materials Part I. Effect of Monomer Concentration and Oxidant on Electrical Properties of the Capacitors,

2034:

Measured with an AC measuring method with 100/120 Hz the capacitance value is the closest value to the electrical charge stored in the e-caps. The stored charge is measured with a special discharge method and is called the

6558:

E. Vitoratos, S. Sakkopoulos, E. Dalas, N. Paliatsas, D. Karageorgopoulos, F. Petraki, S. Kennou, S.A. Choulis, Thermal degradation mechanisms of PEDOT:PSS, Organic

Electronics, Volume 10, Issue 1, February 2009, Pages 61–66,

2046:

The percentage of allowed deviation of the measured capacitance from the rated value is called the capacitance tolerance. Electrolytic capacitors are available in different tolerance series, whose values are specified in the

2022:

The capacitance value measured at the frequency of 1 kHz is about 10% less than the 100/120 Hz value. Therefore the capacitance values of electrolytic capacitors are not directly comparable and differ from those of

2660:

3196:

In non-solid electrolytic capacitors the heat generated by the ripple current forces the evaporation of electrolytes, shortening the lifetime of the capacitors. Exceeding the limit tends to result in explosive failure.

3611:

as reference conditions and expressed as percent failed components per thousand hours (n %/1000 h). That is, “n” number of failed components per 10 hours, or in FIT the ten-thousand-fold value per 10 hours.

3191:

2140:

For tantalum electrolytic capacitors the surge voltage can be 1.3 times the rated voltage, rounded off to the nearest volt. The surge voltage applied to tantalum capacitors may influence the capacitor's failure rate.

4234:

Capacitance, tolerance and date of manufacture can be indicated with a short code specified in IEC/EN 60062. Examples of short-marking of the rated capacitance (microfarads): µ47 = 0,47 µF, 4µ7 = 4,7 µF, 47µ = 47 µF

2174:

Standard electrolytic capacitors, and aluminum as well as tantalum and niobium electrolytic capacitors are polarized and generally require the anode electrode voltage to be positive relative to the cathode voltage.

482:

caused by moving ions, non-solid electrolytes can easily fit the rough structures. Solid electrolytes which have electron conductivity can fit the rough structures with the help of special chemical processes like

2750:) summarizes all resistive losses of the capacitor. These are the terminal resistances, the contact resistance of the electrode contact, the line resistance of the electrodes, the electrolyte resistance, and the

334:

thickness corresponding to the applied voltage will be formed (formation). This oxide layer acts as dielectric in an electrolytic capacitor. The properties of this oxide layers are given in the following table:

5762:

Shinichi Niwa, Yutaka

Taketani, Development of new series of aluminium solid capacitors with organic Semiconductive electrolyte (OS-CON), Journal of Power Sources, Volume 60, Issue 2, June 1996, Pages 165–171,

3280:

2407:

Regarding the IEC/EN 60384-1 standard, the impedance values of electrolytic capacitors are measured and specified at 10 kHz or 100 kHz depending on the capacitance and voltage of the capacitor.

1922:". In these e-caps the water reacts quite aggressively and even violently with aluminum, accompanied by strong heat and gas development in the capacitor, and often led to the explosion of the capacitor.

2894:

value of a superimposed AC current of any frequency and any waveform of the current curve for continuous operation within the specified temperature range. It arises mainly in power supplies (including

1620:

etc. in an electrochemical process, which blocks an electric current from flowing in one direction but allow to flow in the other direction, was discovered in 1875 by the French researcher and founder

592:

electrolytic capacitors. The large surface compared to a smooth one is the second reason for the relatively high capacitance values of electrolytic capacitors compared with other capacitor families.

6548:

4137:

2858:

2202:

To minimize the likelihood of a polarized electrolytic being incorrectly inserted into a circuit, polarity has to be very clearly indicated on the case, see the section on "Polarity marking" below.

5916:

J.L. Stevens, T. R. Marshall, A.C. Geiculescu m, C.R. Feger, T.F. Strange, Carts USA 2006, The

Effects of Electrolyte Composition on the Deformation Characteristics of Wet Aluminum ICD Capacitors,

4157:

5928:

3503:

with times of “early failures”, “random failures”, and wear-out failures”. The time of random failures is the time of constant failure rate and corresponds with the lifetime of non-solid e-caps.

659:

3053:

578:

635:

5927:

Alfonso Berduque, Zongli Dou, Rong Xu, KEMET, Electrochemical Studies for Aluminium Electrolytic Capacitor Applications: Corrosion Analysis of Aluminium in Ethylene Glycol-Based Electrolytes

2553:

923:

and discharging as well as to low-energy transients. Non-solid electrolytic capacitors can be found in nearly all areas of electronic devices, with the exception of military applications.

683:

2486:

2982:

This internally generated heat, additional to the ambient temperature and possibly other external heat sources, leads to a capacitor body temperature having a temperature difference of

3249:

Applying a positive voltage to a "wet" capacitor causes a reforming (self-healing) process which repairs all weakened dielectric layers, and the leakage current remain at a low level.

2154:. An unambiguous and general specification of tolerable transients or peak voltages is not possible. In every case transients arise, the application has to be approved very carefully.

4119:

resistor repairs the oxide layer by self-healing. If the capacitors don’t meet the leakage current requirements after preconditioning, it may be an indication of a mechanical damage.

3616:

Commercially available industrially produced tantalum capacitors now have reached as standard products the high MIL standard “C” level, which is 0.01 %/1000h at 85 °C and U

2977:

930:

Niobium electrolytic capacitors are in direct competition with industrial tantalum electrolytic capacitors because niobium is more readily available. Their properties are comparable.

4297:

The tests and requirements to be met by aluminum and tantalum electrolytic capacitors for use in electronic equipment for approval as standardized types are set out in the following

3711:

Electrolytic capacitors with solid electrolyte do not have wear-out failures so they do not have a lifetime specification in the sense of non-solid aluminum electrolytic capacitors.

6701:

4111:

as electrolyte do not have problems with high leakage current after longer storage times. They can be specified with storage times up to 10 years without leakage current problems

1707:

With Rubens invention, together with the invention of wound foils separated with a paper spacer 1927 by A. Eckel of Hydra-Werke (Germany), the actual development of e-caps began.

2117:". The category voltage is the maximum DC voltage or peak pulse voltage that may be applied continuously to a capacitor at any temperature within the category temperature range T

5595:

Elektrolytischer Kondensator mit aufgerollten Metallbändern als Belegungen, Alfred Eckel Hydra-Werke, Berlin-Charlottenburg, DRP 498 794, filed 12.Mai 1927, granted 8.Mai 1930

3515:

and can be described qualitatively and quantitatively; it is not directly measurable. The reliability of electrolytic capacitors is empirically determined by identifying the

2299:

50:

2883:

The superimposed (DC biased) AC ripple current flow across the smoothing capacitor C1 of a power supply causes internal heat generation corresponding to the capacitor's

629:

Closeup cross-section of an aluminum electrolytic capacitor design, showing capacitor anode foil with oxide layer, paper spacer soaked with electrolyte, and cathode foil

2863:

The dissipation factor is used for capacitors with very low losses in frequency-determining circuits where the reciprocal value of the dissipation factor is called the

1773:

Although fundamental inventions came from Bell Labs, the inventions for manufacturing commercially viable tantalum electrolytic capacitors came from researchers at the

3070:. The temperature of the capacitor, which is the net balance between heat produced and distributed, must not exceed the capacitor's maximum specified temperature.

6070:

P. Vasina, T. Zednicek, Z. Sita, J. Sikula, J. Pavelka, AVX, Thermal and Electrical Breakdown Versus Reliability of Ta2O5 Under Both – Bipolar Biasing Conditions

1503:

5641:

2137:

surge voltage is 1.15 times the rated voltage, and for capacitors with a rated voltage exceeding 315 V, the surge voltage is 1.10 times the rated voltage.

1515:

2039:

capacitance. The DC capacitance is about 10% higher than the 100/120 Hz AC capacitance. The DC capacitance is of interest for discharge applications like

1491:

611:

2730:

2196:

These guidelines apply for short excursion and should never be used to determine the maximum reverse voltage under which a capacitor can be used permanently.

6248:

2718:

2411:

Besides measuring, the impedance can be calculated using the idealized components of a capacitor's series-equivalent circuit, including an ideal capacitor

3563:

failures. This failure rate model implicitly assumes the idea of "random failure". Individual components fail at random times but at a predictable rate.

247:

in principle is the cathode, which thus forms the second electrode of the capacitor. This and the storage principle distinguish them from electrochemical

5894:

Shigeru Uzawa, Akihiko Komat-u, Tetsushi Ogawara, Rubycon Corporation, Ultra Low Impedance Aluminum Electrolytic Capacitor with Water based Electrolyte

2199:

But in no case, for aluminum as well as for tantalum and niobium electrolytic capacitors, may a reverse voltage be used for a permanent AC application.

1766:

pressed into a cylindrical form and then sintered at high a temperature between 1500 and 2000°C under vacuum conditions to produce a pellet (“slug”).

5833:

4267:

2568:

6008:

Imam, A.M., Condition Monitoring of Electrolytic Capacitors for Power Electronics Applications, Dissertation, Georgia Institute of Technology (2007)

1479:

282:(forming) an insulating oxide layer originates and serves as dielectric. There are three different anode metals in use for electrolytic capacitors:

6479:

5622:

D. F. Tailor, Tantalum and Tantalum Compounds, Fansteel Inc., Encyclopedia of Chemical Technology, Vol. 19, 2nd ed. 1969 John Wiley & sons, Inc.

3628:

is the failure rate. For a 100 µF/25 V tantalum chip capacitor used with a series resistance of 0.1 Ω the failure rate is 0.02 FIT.

2247:

In general, a capacitor is seen as a storage component for electric energy. But this is only one capacitor function. A capacitor can also act as an

6547:

Gregory Mirsky, Determining end-of-life, ESR, and lifetime calculations for electrolytic capacitors at higher temperatures, EDN, August 20, 2008,

5741:

4043:

4036:

4029:

1558:

5844:

3398:

The leakage current value depends on the voltage applied, on the temperature of the capacitor, and on measuring time. Leakage current in solid MnO

271:

Basic principle of anodic oxidation (forming), in which, by applying a voltage with a current source, an oxide layer is formed on a metallic anode

4022:

3084:

677:

Schematic representation of the structure of a sintered tantalum electrolytic capacitor with solid electrolyte and the cathode contacting layers

5533:

I.Horacek, T.Zednicek, S.Zednicek, T.Karnik, J.Petrzilek, P.Jacisko, P.Gregorova, AVX, High CV Tantalum Capacitors - Challenges and Limitations

5884:

194:

Bipolar electrolytic capacitors which may be operated with AC voltage are special constructions with two anodes connected in reverse polarity.

3724:

Long-term electrical behavior, failure modes, self-healing mechanism, and application rules of the different types of electrolytic capacitors

3402:

tantalum electrolytic capacitors generally drops very much faster than for non-solid electrolytic capacitors but remain at the level reached.

2182:

Solid tantalum capacitors can also withstand reverse voltages for short periods. The most common guidelines for tantalum reverse voltage are:

3457:

Dielectric absorption may be a problem in circuits where very small currents are used in the function of an electronic circuit, such as long-

6270:

5786:

4250:

For very small capacitors no marking is possible. Here only the traceability of the manufacturers can ensure the identification of a type.

3388:{\displaystyle I_{\mathrm {Leak} }=0{,}01\,\mathrm {{A} \over {V\cdot F}} \cdot U_{\mathrm {R} }\cdot C_{\mathrm {R} }+3\,\mathrm {\mu A} }

1647:

Various forms of historical anode structures for wet capacitors. For all of these anodes the outer metallic container served as the cathode

933:

The electrical properties of aluminum, tantalum and niobium electrolytic capacitors have been greatly improved by the polymer electrolyte.

1467:

534:

Every electrolytic capacitor forms on principle a "plate capacitor" whose capacitance is greater, the larger the electrode area A and the

5508:

2105:

is the maximum DC voltage or peak pulse voltage that may be applied continuously at any temperature within the rated temperature range T

143:

Due to their very thin dielectric oxide layer and enlarged anode surface electrolytic capacitors have—based on the volume—a much higher

6430:

5775:

2277:

Typical impedance curves for different capacitance values over frequency. The higher the capacitance the lower the resonance frequency.

1635:) based on his idea of using the oxide layer in a polarized capacitor in combination with a neutral or slightly alkaline electrolyte.

1546:

5863:

Ch. Schnitter, A. Michaelis, U. Merker, H.C. Starck, Bayer, New Niobium Based Materials for Solid Electrolyte Capacitors, Carts 2002

2007:(μF, or less correctly, uF). The capacitance value specified in the data sheets of the manufacturers is called the rated capacitance C

3511:

of a component is a property that indicates how reliably this component performs its function in a time interval. It is subject to a

1583:

59:

3214:

and of the capacitor's ESR. Only the frequency of peaks integrated over time must not exceed the maximal specified ripple current.

5883:

Y. Pozdeev-Freeman, P. Maden, Vishay, Solid-Electrolyte Niobium Capacitors Exhibit Similar Performance to Tantalum, Feb 1, 2002,

5797:

2093:

Referring to the IEC/EN 60384-1 standard, the allowed operating voltage for electrolytic capacitors is called the "rated voltage U

2065:

The required capacitance tolerance is determined by the particular application. Electrolytic capacitors, which are often used for

6211:

6095:

3689:

expected that short circuits occur after the end-of-life-point with progressive evaporation combined with parameter degradation.

3607:

It is good to know that for tantalum capacitors the failure rate is often specified in essence at 85 °C and rated voltage U

251:, in which the electrolyte generally is the conductive connection between two electrodes and the storage occurs with statically

5996:

A. Teverovsky, Perot Systems Code 562, NASA GSFCE, Effect of Surge Current Testing on Reliability of Solid Tantalum Capacitors

5433:

3468:

circuits. In most electrolytic capacitor applications supporting power supply lines, dielectric absorption is not a problem.

3238:(DCL) is a special characteristic that other conventional capacitors do not have. This current is represented by the resistor R

286:

92:

2218:

Simplified series-equivalent circuit of a capacitor for higher frequencies (above); vector diagram with electrical reactances

1651:

The first industrially realized electrolytic capacitors consisted of a metallic box used as the cathode. It was filled with a

1534:

6454:

2818:

2051:

specified in IEC 60063. For abbreviated marking in tight spaces, a letter code for each tolerance is specified in IEC 60062.

5299:

215:

Depending on the nature of the anode metal used and the electrolyte used, there is a wide variety of electrolytic capacitors

42:

5820:

U. Merker, K. Wussow, W. Lövenich, H. C. Starck GmbH, New Conducting Polymer Dispersions for Solid Electrolyte Capacitors,

5809:

5640:

E. K. Reed, Jet Propulsion Laboratory, Characterization of Tantalum Polymer Capacitors, NEPP Task 1.21.5, Phase 1, FY05]

5113:

2898:) after rectifying an AC voltage and flows as charge and discharge current through the decoupling or smoothing capacitor.

5631:

R. L. Taylor and H. E. Haring, “A metal semi-conductor capacitor,” J. Electrochem. Soc., vol. 103, p. 611, November, 1956.

2868:

2073:, do not have the need for narrow tolerances because they are mostly not used for accurate frequency applications like in

6442:

4372:

In number of pieces, these capacitors cover about 10% of the total capacitor market, or about 100 to 120 billion pieces.

3218:

If possible the voltage profile should be a ramp turn-on, as this reduces the peak current experienced by the capacitor.

3260:

The specification of the leakage current in data sheets is often given by multiplication of the rated capacitance value

3007:

2743:

1974:

1961:

1833:" aluminum electrolytic capacitors. These capacitors used a solid organic conductor, the charge transfer salt TTF-TCNQ (

1819:

544:

6326:

IEC/EN 61709, Electric components. Reliability. Reference conditions for failure rates and stress models for conversion

5545:

1668:

were available, but devices with that order of capacitance and voltage rating were bulky and prohibitively expensive.

6009:

1871:. These aluminum electrolytic capacitors with polymer electrolytes reached very low ESR values directly comparable to

6336:

5680:

A. Fraioli, Recent Advances in the Solid-State Electrolytic Capacitor, IRE Transactions on Component Parts, June 1958

2507:

1729:

etching process are the reason for the dimension reductions in aluminum electrolytic capacitors over recent decades.

6347:

1837:), which provided an improvement in conductivity by a factor of 10 compared with the manganese dioxide electrolyte.

5710:

5699:

5448:

4094:

3571:

2895:

1807:

6260:

6233:

Vishay, Aluminium capacitors, Introduction, Revision: 10-Sep-13 1 Document Number: 28356, Chapter Storage, page 7

3604:

Some manufacturers may have their own FIT calculation tables for tantalum capacitors. or for aluminum capacitors

2443:

275:

Electrolytic capacitors use a chemical feature of some special metals, earlier called “valve metals”, on which by

6510:

5476:

J.L. Stevens, A.C. Geiculescu, T.F. Strange, Dielectric Aluminum Oxides: Nano-Structural Features and Composites

6690:

6413:

T.Zednicek, AVX, A Study of Field Crystallization in Tantalum Capacitors and its effect on DCL and Reliability,

2273:

1834:

1774:

252:

172:

5872:

T. Zednicek, S. Sita, C. McCracken, W. A. Millman, J. Gill, AVX, Niobium Oxide Technology Roadmap, CARTS 2002

5586:

P. McK. Deeley, Electrolytic Capacitors, The Cornell-Dubilier Electric Corp. South Plainfield New Jersey, 1938

2925:

186:

Electrolytic capacitors are polarized components by the manufacturing principle and may only be operated with

5943:

Identification of Missing or Insufficient Electrolyte Constituents in Failed Aluminum Electrolytic Capacitors

506:

The anodically generated insulating oxide layer is destroyed if the polarity of the applied voltage changes.

5175:

4271:

3624:. Recalculated in FIT with the acceleration factors coming from MIL HDKB 217F at 40 °C and 0.5 , U

3539:

3524:

3508:

5489:

6571:

6522:

5751:

Larry E. Mosley, Intel Corporation, Capacitor Impedance Needs For Future Microprocessors, CARTS USA 2006,

5720:

J.Both, Valvo, SAL contra Tantal, Zuverlässige Technologien im Wettstreit, nachrichten elektronik 35, 1981

4275:

3631:

Aluminum electrolytic capacitors do not use a specification in "% per 1000 h at 85 °C and U

2790:. The dissipation factor is determined by the tangent of the phase angle between the capacitive reactance

1822:(ESR) for bypass and decoupling capacitors. The manganese dioxide type of electrolyte should be better.

1797:

1754:

6358:

6167:

3708:

lifetime specification because they are hermetically sealed and evaporation of electrolyte is minimized.

1664:

technique, typically at least 4 microfarads and rated at around 500 volts DC. Waxed paper and oiled silk

5941:

5907:

3418:

3411:

3235:

2290:

2263:

1987:

1724:

Miniaturisation of aluminum electrolytic capacitors driven by progress in the anode foil etching process

1701:

339:

Characteristics of the different oxide layers in aluminum, tantalum and niobium electrolytic capacitors

6082:

A. Berduque, Kemet, Low ESR Aluminium Electrolytic Capacitors for Medium to High Voltage Applications,

5898:

5670:

4989:

3664:

475:

are distinguished into two species, “non-solid” and “solid” electrolytes. As a liquid medium which has

6134:

5570:

2392:

In other words, the impedance is a frequency-dependent AC resistance and possesses both magnitude and

2382:{\displaystyle Z={\frac {\hat {u}}{\hat {\imath }}}={\frac {U_{\mathrm {eff} }}{I_{\mathrm {eff} }}}.}

2000:

broader aberration over frequency and temperature ranges than do capacitors with solid electrolytes.

1778:

1720:

6560:

6223:

6110:

Vishay BCcomponents, Introduction Aluminum Capacitors, Revision: 10-Sep-13 1 Document Number: 28356,

5764:

4927:

4648:

3274:

together with an addendum figure, measured after a measuring time of 2 or 5 minutes, for example:

2286:

2267:

2255:

2070:

6689:

Electronic Capacitors, SIC 3675, NAICS 334414: Electronic Capacitor Manufacturing, Industry report:

5997:

5821:

2262:

of audio AC signals. Than the dielectric is used only for blocking DC. For such applications the AC

2019:

a rated voltage of >2.5 V, may be applied during the measurement to avoid reverse voltage.

1676:

77:

6698:

5523:

4108:

2768:

2259:

2248:

2166:

1910:

756:

6535:

6491:

5740:

K. Lischka, Spiegel 27.09.2007, 40 Jahre Elektro-Addierer: Der erste Taschenrechner wog 1,5 Kilo,

3230:

The general leakage current behavior of electrolytic capacitors depends on the kind of electrolyte

5698:

W. Serjak, H. Seyeda, Ch. Cymorek, Tantalum Availability: 2000 and Beyond, PCI,March/April 2002,

5458:

5453:

4230:

476M 100V implies a capacitance of 47 × 10 pF = 47 µF (M = ±20%) with a working voltage of 100 V.

3697:

3512:

3067:

2780:

1864:

is better than that of TCNQ by a factor of 100 to 500, and close to the conductivity of metals.

1841:

641:

Construction of a typical single-ended aluminum electrolytic capacitor with non-solid electrolyte

308:

300:

228:

96:

4227:

105K 330V implies a capacitance of 10 × 10 pF = 1 µF (K = ±10%) with a working voltage of 330 V.

2214:

1875:(MLCCs). They were still less expensive than tantalum capacitors and with their flat design for

1621:

6156:

6021:

4345:

Surface mount fixed aluminium electrolytic capacitors with conductive polymer solid electrolyte

4042:

4035:

4028:

3496:

1935:

1575:

946:

Comparison of the most important characteristics of different types of electrolytic capacitors

665:

The capacitor cell of a tantalum electrolytic capacitor consist out of sintered tantalum powder

503:

praxis different safety margins to reach reliable components makes a comparization difficult.

6645:

R. Faltus, AVX, Advanced capacitors ensure long-term control-circuit stability, 7/2/2012, EDT

6369:

5507:

A. Albertsen, Jianghai Europe, Keep your distance – Voltage Proof of Electrolytic Capacitors,

5443:

5438:

4339:

Surface mount fixed tantalum electrolytic capacitors with conductive polymer solid electrolyte

3640:

20 to 200 FIT.Field failure rates for aluminum e-caps are in the range of 0.5 to 20 FIT.

3059:

2751:

2066:

2028:

1872:

1868:

1762:

764:

760:

488:

326:

314:

256:

152:

100:

4741:

4361:

The market for electrolytic capacitors in 2008 was roughly 30% of the total market in value

4307:

Surface mount fixed tantalum electrolytic capacitors with manganese dioxide solid electrolyte

3242:

in parallel with the capacitor in the series-equivalent circuit of electrolytic capacitors.

6627:

J.Gill, T. Zednicek, AVX, VOLTAGE DERATING RULES FOR SOLID TANTALUM AND NIOBIUM CAPACITORS,

6414:

6293:

4021:

3075:

2891:

2879:

2048:

1919:

1853:

1746:

1710:

6346:

SQC online table calculator, Capacitor Failure Rate Model, MIL-HDBK-217, Rev. F - Notice 2

6234:

6111:

5488:

T. Kárník, AVX, NIOBIUM OXIDE FOR CAPACITOR MANUFACTURING , METAL 2008, 13. –15. 5. 2008,

5392:

1579:

Early small electrolytic capacitor from 1914. It had a capacitance of around 2 microfarads.

6466:

5854:

F. Jonas, H.C.Starck, Baytron, Basic chemical and physical properties, Präsentation 2003,

5206:

4122:

Electrolytic capacitors with solid electrolytes don’t have any precondition instructions.

4090:

3465:

2121:. The relation between both voltages and temperatures is given in the picture at right.

1849:

1661:

1643:

514:

232:

225:

160:

6316:

5963:

Ch. Reynolds, AVX, Technical Information, Reliability Management of Tantalum Capacitors,

5477:

5082:

1745:

The relevant development of solid electrolyte tantalum capacitors began some years after

689:

Construction of a typical SMD tantalum electrolytic chip capacitor with solid electrolyte

518:

A dielectric material is placed between two conducting plates (electrodes), each of area

136:

which covers the surface of the oxide layer in principle serves as the second electrode (

6583:

6368:

Hitachi, Precautions in using Tantalum Capacitors, 4.2 Failure Rate Calculation Formula

5330:

3593:

The standard operating conditions for the failure rate FIT are 40 °C and 0.5 U

2771:

behind smoothing and may influence the circuit functionality. Related to the capacitorm

1785:

deposition, which dramatically reduced the leakage current of the finished capacitors.

1587:

View of the anode of a „wet“ aluminum electrolytic capacitor, Bell System Technique 1929

5268:

3520:

3226:

2179:

determine the maximum reverse voltage under which a capacitor can be used permanently.

2036:

2024:

1845:

1693:

1665:

927:

space applications only tantalum electrolytic capacitors have the necessary approvals.

492:

294:

248:

236:

156:

6395:

Sam G. Parler, Cornell Dubilier, Reliability of CDE Aluminum Electrolytic Capacitors (

6034:

5917:

5752:

2901:

Ripple currents generates heat inside the capacitor body. This dissipation power loss

1977:

which is the effective self-inductance of the capacitor, usually abbreviated as "ESL".

211:

6646:

6199:

Vishay, Application Notes, AC Ripple Current, Calculations Solid Tantalum Capacitors

4555:

4462:

4238:

The date of manufacture is often printed in accordance with international standards.

3645:

3531:

3500:

3458:

1652:

322:

6123:

6058:

I. Bishop, J. Gill, AVX Ltd., Reverse Voltage Behavior of Solid Tantalum Capacitors

588:

capacitance values of electrolytic capacitors compared to conventional capacitors.

583:

The dielectric thickness of electrolytic capacitors is very slight, in the range of

4211:

certification marks of safety standards (for safety EMI/RFI suppression capacitors)

3678:

3674:

3653:

3649:

3543:

3516:

1750:

1689:

1628:

535:

479:

168:

6247:

Ch. Baur, N. Will, Epcos, Long-term stability of aluminum electrolytic capacitors

5534:

5020:

4382:

Worldwide operating manufacturers and their electrolytic capacitor product program

654:

Construction of a solid tantalum chip capacitor with manganese dioxide electrolyte

6304:

5669:

Sprague, Dr. Preston Robinson Granted 103rd Patent Since Joining Company In 1929

4351:

Fixed aluminium electrolytic capacitors with conductive polymer solid electrolyte

121:(+) are made of a special metal on which an insulating oxide layer originates by

6628:

6200:

6189:

6178:

6071:

5873:

5796:

About the Nobel Prize in Chemistry 2000, Advanced Information, October 10, 2000,

4617:

4281:

The definition of the characteristics and the procedure of the test methods for

4263:

2699:. With frequencies above the resonance the impedance increases again due to the

2655:{\displaystyle Z={\sqrt {{ESR}^{2}+(X_{\mathrm {C} }+(-X_{\mathrm {L} }))^{2}}}}

2151:

1964:

which summarizes all ohmic losses of the capacitor, usually abbreviated as "ESR"

1857:

1742:

a liquid electrolyte, mostly sulfuric acid, and encapsulated in a silver case.

244:

144:

133:

122:

6281:

6059:

4896:

4242:

Version 1: coding with year/week numeral code, "1208" is "2012, week number 8".

2254:. Especially aluminum electrolytic capacitors in many applications are used as

2113:"temperature derated voltage" for a higher temperature, the "category voltage U

267:

6609:

5981:

5964:

4834:

4803:

4259:

3461:

3063:

2499:

2124:

Applying a higher voltage than specified may destroy electrolytic capacitors.

2089:

Relation between rated and category voltage and rated and category temperature

2074:

2040:

1880:

1758:

1596:

The phenomenon that can form an oxide layer on aluminum and other metals like

710:

Overview of the key features of the different types of electrolytic capacitor

129:

17:

6177:

I. Salisbury, AVX, Thermal Management of Surface Mounted Tantalum Capacitors

6145:

6046:

5689:

R. J. Millard, Sprague, US Patent 2936514, October 24, 1955 - May 17, 1960

6292:"Understand Capacitor Soakage to Optimize Analog Systems" by Bob Pease 1982

5660:

Preston Robinson, Sprague, US Patent 3066247, 25. Aug. 1954 - 27. Nov. 1962

4493:

4282:

2667:

2085:

1605:

484:

279:

276:

240:

180:

176:

125:

118:

111:

5544:

Charles Pollack: D.R.P. 92564, filed 14. Januar 1896, granted 19. Mai 1897

4524:

3186:{\displaystyle Z={\sqrt {{i_{1}}^{2}+{i_{2}}^{2}+{i_{3}}^{2}+{i_{n}}^{2}}}}

2713:

Typical impedance and ESR curves as a function of frequency and temperature

6396:

4132:

Polarity marking for non-solid and solid aluminum electrolytic capacitors

2864:

2258:

to filter or bypass undesired biased AC frequencies to the ground or for

2251:

1697:

1685:

1609:

1597:

304:

290:

6509:

Epcos, Aluminum electrolytic capacitors, General technical informations

5613:

Philips Data Handbook PA01, 1986, the first 125 °C series “118 AHT”

2786:

will sometimes be specified in the relevant data sheets, instead of the

1825:

It was not until 1983 when a new step toward ESR reduction was taken by

6595:

6429:

A. Albertsen, Jianghai Europe, Reliability of Electrolytic Capacitors,

6122:

Vishay, Engineering Solutions, Aluminum Capacitors in Power Supplies

5709:

The Tantalum Supply Chain: A Detailed Analysis, PCI, March/April 2002,

3601:

calculate given failure rate values for given application conditions.

2986:

against the ambient. This heat has to be distributed as thermal losses

2399:

In data sheets of electrolytic capacitors only the impedance magnitude

1811:

1617:

1601:

496:

318:

148:

137:

6453:

NCC, Technical Note Judicious Use of Aluminum Electrolytic Capacitors

5569:

Samuel Ruben: Inventor, Scholar, and Benefactor by Kathryn R. Bullock

4586:

3058:

The internally generated heat has to be distributed to the ambient by

224:

Like other conventional capacitors, electrolytic capacitors store the

6155:

Nichicon, Application Guidelines for Aluminum Electolytic Capacitors

4329:

Fixed aluminium electrolytic surface mount capacitors with solid (MnO

2393:

1876:

1830:

6478:

A. Albertsen, Jianghai, Electrolytic Capacitor Lifetime Estimation

6020:

Nichicon. "General Description of Aluminum Electrolytic Capacitors"

5361:

5237:

2192:

1 % of rated voltage to a maximum of 0.1 V at 125 °C.

208:

of anode material and solid or non-solid electrolytes is available.

88:

is the generic term for three different capacitor family members:

6668:

4266:

components and related technologies follows the rules given by the

2189:

3 % of rated voltage to a maximum of 0.5 V at 85 °C,

81:

Most common styles of aluminum and tantalum electrolytic capacitors

6094:

Joelle Arnold, Uprating of Electrolytic Capacitors, DfR Solutions

4865:

3495:

3225:

2272:

2213:

2186:

10 % of rated voltage to a maximum of 1 V at 25 °C,

2165:

2084:

2004:

1944:

capacitive and inductive parameters of an electrolytic capacitor:

1934:

1861:

1826:

1796:

1719:

1675:

1642:

1582:

1574:

584:

513:

266:

210:

115:

76:

6534:

NIC Life expectancy of aluminum electrolytic capacitors (rev.1) (

5651:

D. A. McLean, F. S. Power, Proc. Inst. Radio Engrs. 44 (1956) 872

4293:

IEC/EN 60384-1 - Fixed capacitors for use in electronic equipment

2003:

The basic unit of an electrolytic capacitor's capacitance is the

606:

Basic construction of a non-solid aluminum electrolytic capacitor

6188:

R.W. Franklin, AVX , Ripple Rating of Tantalum Chip Capacitors,

5895:

3635:". They use the FIT specification with 40 °C and 0.5 U

1613:

600:

Basic construction of non-solid aluminum electrolytic capacitors

5730:

3426:

Values of dielectric absorption for some often used capacitors

2912:

and is the squared value of the effective (RMS) ripple current

1867:

In 1991 Panasonic came on the market with its "SP-Cap", called

1717:

company, started the production of e-caps in large quantities.

6305:"Modeling Dielectric Absorption in Capacitors", by Ken Kundert

5948:

4323:

Fixed tantalum capacitors with non-solid and solid electrolyte

2061:

rated capacitance, series E12, tolerance ±10%, letter code "K“

1714:

1680:

A “dry” electrolytic capacitor with 100 µF and 150 V

476:

25:

6335:

MIL-HDBK-217F Reliability Prediction of Electronic Equipment

6133:

Panasonic, Use technique of Aluminum Electrolytic Capacitors

5843:

John Prymak, Kemet, Replacing MnO2 with Polymers, 1999 CARTS

3669:

this behavior in a 2000 h endurance test at 105 °C.

2058:

rated capacitance, series E6, tolerance ±20%, letter code "M“

2055:

rated capacitance, series E3, tolerance ±20%, letter code "M“

2015:

and is the value for which the capacitor has been designed.

159:, but an articulately smaller C/V value than electrochemical

6570:

Nichicon, Technical Guide, Calculation Formula of Lifetime

5774:

Kuch, Investigation of charge transfer complexes:TCNQ-TTF,

4710:

1939:

Series-equivalent circuit model of an electrolytic capacitor

1633:

Elektrischer Flüssigkeitskondensator mit Aluminiumelektroden

648:

Basic construction of solid tantalum electrolytic capacitors

6380:

6210:

KEMET, Ripple Current Capabilities, Technical Update 2004

5522:

KDK, Specifications for Etched Foil for Anode, Low Voltage

3715:

Failure modes, self-healing mechanism and application rules

3447:

Aluminium electrolytic capacitor with non solid electrolyte

187:

6678:

5051:

4772:

1856:

in 1975. The conductivity of conductive polymers such as

1696:, the founder of the battery company that is now known as

6465:

Rubycon, LIFE OF ALUMINUM ELECTROLYTIC CAPACITORS, S. 9 (

6282:

AVX, ANALYSIS OF SOLID TANTALUM CAPACITOR LEAKAGE CURRENT

4958:

3078:

and summarized by squared addition the single currents.

2812:

is small, the dissipation factor can be approximated as:

5144:

4679:

2779:

For electrolytic capacitors, for historical reasons the

1509:

Aluminum electrolytic capacitor with “snap-in” terminals

1497:

Radial or single-ended aluminum electrolytic capacitors

617:

Opened winding of an e-cap with multiple connected foils

6144:

CDE, Aluminum Electrolytic Capacitor Application Guide

4368:

Tantalum electrolytic capacitors—US$ 2.2 billion (12%);

4365:

Aluminum electrolytic capacitors—US$ 3.9 billion (22%);

4193:

polarity of the terminations (for polarized capacitors)

3439:

Tantalum electrolytic capacitors with solid electrolyte

2853:{\displaystyle \tan \delta ={\mbox{ESR}}\cdot \omega C}

2703:

of the capacitor. The capacitor becomes an inductance.

1473:

Aluminum electrolytic SMD “V (vertical) chip capacitors

1452:

Styles of aluminum and tantalum electrolytic capacitors

6702:

Category:Electronics articles needing expert attention

6259:

R.W. Franklin, AVX, AN EXPLORATION OF LEAKAGE CURRENT

6166:

Evox Rifa,Electrolytic Capacitors Application Guide

5604:

William Dubilier, Electric Condenser, US Patent 468787

2835:

2423:. In this case the impedance at the angular frequency

1840:

The next step in ESR reduction was the development of

6657:

6594:

NIC Technical Guide, Calculation Formula of Lifetime

6582:

Estimating of Lifetime FUJITSU MEDIA DEVICES LIMITED

6441:

Hitachi aic-europe, Explanations to the useful life,

3283:

3087:

3010:

2928:

2821:

2761:

decreases with increasing frequency and temperature.

2571:

2510:

2446:

2302:

1688:

of the modern electrolytic capacitor was patented by

1521:

Aluminum electrolytic capacitors with screw terminals

1445:) calculated for a capacitor 100 µF/10 V,

596:

capacitance and voltage, the so-called "CV product".

547:

4147:

electrolyte have a polarity marking at the cathode (

2724:

Typical impedance and ESR as a function of frequency

2170:

An exploded aluminum electrolytic capacitor on a PCB

2031:, whose capacitance is measured at 1 kHz or higher.

1700:. Rubens idea adopted the stacked construction of a

1624:. He coined the term "valve metal" for such metals.

1529:

Different styles of tantalum electrolytic capacitors

1462:

Different styles of aluminum electrolytic capacitors

132:

of the electrolytic capacitor. A non-solid or solid

6047:"Aluminum Electrolytic Capacitor Application Guide"

4285:for use in electronic equipment are set out in the

2150:voltages lead to a voltage limitation similar to a

5980:J. Gill, AVX, Surge in Solid Tantalum Capacitors,

4167:electrolyte have a polarity marking at the anode (

3387:

3185:

3048:{\displaystyle P_{th}=\Delta T\cdot A\cdot \beta }

3047:

2971:

2852:

2654:

2547:

2480:

2381:

1442:) Manufacturer, series name, capacitance/voltage

573:{\displaystyle C=\varepsilon \cdot {\frac {A}{d}}}

572:

6425:

6423:

6421:

5560:, filed October 19,1925, granted August 26, 1930

4313:Aluminium electrolytic capacitors with solid (MnO

2695:), then the impedance will only be determined by

2427:is given by the geometric (complex) addition of

1883:competed with tantalum chip capacitors as well.

1801:Conductivity of non-solid and solid electrolytes

6623:

6621:

6619:

6617:

2548:{\displaystyle X_{L}=\omega L_{\mathrm {ESL} }}

45:for grammar, style, cohesion, tone, or spelling

3875:in the dielectric by oxidation or evaporation

2736:Typical impedance as a function of temperature

303:use a sintered pellet (“slug”) of high-purity

5992:

5990:

5988:

4202:rated voltage and nature of supply (AC or DC)

3620:or 1 failure per 10 hours at 85 °C and U

696:Types and features of electrolytic capacitors

8:

6106:

6104:

6102:

5785:Sanyo, OS-CON, Technical Book Ver. 15, 2007

2481:{\displaystyle X_{C}=-{\frac {1}{\omega C}}}

2270:, is as important as the capacitance value.

1564:Axial style tantalum electrolytic capacitors

1485:Axial style aluminum electrolytic capacitors

6505:

6503:

6501:

6409:

6407:

6405:

3656:of “wet” aluminum electrolytic capacitors.

1995:Capacitance, standard values and tolerances

1552:Dipped laquered tantalum “pearl” capacitors

3722:

3424:

2757:For electrolytic capacitors generally the

708:

701:Comparison of electrolytic capacitor types

239:in the dielectric oxide layer between two

6641:

6639:

6637:

6635:

6604:

6602:

6391:

6389:

6387:

5503:

5501:

5499:

5497:

4268:International Electrotechnical Commission

3970:Hybrid aluminum electrolytic capacitors,

3377:

3376:

3363:

3362:

3348:

3347:

3327:

3322:

3320:

3319:

3311:

3289:

3288:

3282:

3175:

3168:

3163:

3153:

3146:

3141:

3131:

3124:

3119:

3109:

3102:

3097:

3094:

3086:

3015:

3009:

2951:

2946:

2933:

2927:

2834:

2820:

2767:influences the remaining superimposed AC

2670:, in which the both reactive resistances

2644:

2630:

2629:

2609:

2608:

2592:

2581:

2578:

2570:

2532:

2531:

2515:

2509:

2463:

2451:

2445:

2361:

2360:

2343:

2342:

2336:

2321:

2311:

2309:

2301:

560:

546:

60:Learn how and when to remove this message

5976:

5974:

5972:

5582:

5580:

5578:

4379:

4208:year and month (or week) of manufacture;

3663:

2972:{\displaystyle P_{L}=I_{R}^{2}\cdot ESR}

2878:

1869:polymer aluminum electrolytic capacitors

944:

337:

6271:Kemet, Polymer Tantalum Chip Capacitors

6243:

6241:

5469:

4408:

4386:

4205:climatic category or rated temperature;

4130:

4093:with DC-link for frequency controls in

3903:Thermally induced insulation of faults

3727:

3542:prediction is generally expressed in a

2711:

1527:

1460:

1281:Solid niobium electrolytic capacitors,

1253:Solid niobium electrolytic capacitors,

1225:Solid tantalum electrolytic capacitors

989:"wet" Al-electrolytic capacitors 1976 )

713:

652:

604:

538:ε, and the thinner the dielectric (d).

6035:"Aluminum Electrolytic Capacitors FAQ"

1309:Solid niobium electrolytic capacitors