227:

sub-component, of a (parent) component, it can in-turn have its own child components, and so on. The resulting top-level BOM (item number) would include children; a mix of finished sub-assemblies, various parts and raw materials. A multi-level structure can be illustrated by a tree with several levels. In contrast, a single-level structure only consists of one level of children in components, assemblies and material.

33:

226:

A multi-level bill of materials (BOM), referred to as an indented BOM, is a bill of materials that lists the assemblies, components, and parts required to make a product in a parent-child, top-down method. It provides a display of all items that are in parent-children relationships. When an item is a

202:

While most configurators utilize top-down hierarchical rules syntax to find appropriate modular BOMs, maintenance of very similar BOMs (i.e., only one component is different for various voltages) becomes highly excessive. A newer approach, (bottom-up/rules-based structuring) utilizing a proprietary

194:

The CBOM is used to dynamically create "end-items" that a company sells. The benefit of using CBOM structure is that it reduces the work-effort needed to maintain product structures. The configurable BOM is most frequently driven by "configurator" software, however it can be enabled manually (manual

217:

Parts which will not be assembled at all in one or more variants are typically marked as "DNP" (for "do not populate" or "do not place") in the affected variants. Other less frequently used designators for this include "NP" ("no placement", "not placed"), "NF" ("no fit", "not fitting"), "DNM" ("do

153:

Sometimes the term "pseudo-bill of materials" or "pseudo-BOM" is used to refer to a more flexible or simplified version. Often a place-holder part number is used to represent a group of related (usually standard) parts that have common attributes and are interchangeable in the context of this BOM.

569:

and attributes in addition to a more flexible system based on parentheses notation stored as prefixes to part values defining multi-level logical conditions and dependencies of assembly groups and possible alternative part values. Originally devised by the author as an easy-to-understand symbolic

79:

A BOM can also be visually represented by a product structure tree, although they are rarely used in the workplace. For example, one of them is Time-Phased

Product Structure where this diagram illustrates the time needed to build or acquire the needed components to assemble the final product. For

203:

search engine scheme transversing through selectable componentry at high speeds eliminates the planning modular BOM duplications. The search engine is also used for all combinatorial feature constraints and GUI representations to support specification selections.

75:

The first hierarchical databases were developed for automating bills of materials for manufacturing organizations in the early 1960s. At present, this BOM is used as a data base to identify the many parts and their codes in automobile manufacturing companies.

620:

607:

96:. An example of this is the NAAMS BOM that is used in the automotive industry to list all the components in an assembly line. The structure of the NAAMS BOM is System, Line, Tool, Unit and Detail.

161:

A single-level BOM (or unit list) that displays the assembly or sub-assembly with only one level of children. Thus it displays the components directly needed to make the assembly or sub-assembly.

130:

In electronics, the BOM represents the list of components used on the printed wiring board or printed circuit board. Once the design of the circuit is completed, the BOM list is passed on to the

218:

not mount"), "NM" ("not mounted"), "NU" ("not used"), "DNI" ("do not install", "do not insert"), "DNE" ("do not equip"), "DNA" ("do not assemble"), "DNS" ("do not stuff"), "NOFIT" etc.

195:

maintenance is infrequent because it is unwieldy to manage the number of permutations and combinations of possible configurations). The development of the CBOM is dependent on having a

171:

A single-level BOM resolved to list the effectively needed quantities of components to produce a product (rather than to list each individual part by its logical name) is also called

99:

A bill of materials "implosion" links component pieces to a major assembly, while a bill of materials "explosion" breaks apart each assembly or sub-assembly into its component parts.

584:

Frischen, Christian; Marbach, Anastasia; Tichla, Florian; Mantwill, Frank (2019-09-18). Written at

Hamburg, Germany. Krause, Dieter; Paetzold, Kristin; Wartzack, Sandro (eds.).

420:

695:

585:

164:

An indented BOM (or structural parts list) that displays the highest-level item closest to the left margin and the components used in that item indented more to the right.

127:

to refer not to the literal bill, but to the current production configuration of a product, to distinguish it from modified or improved versions under study or in test.

206:

To decide which assembly variant of the parts or components is to be chosen, they are attributed by the product options which are the characteristic features of the

538:"Eine durch den Nutzer erweiterbare Klammer-Präfix-Notation zur flexiblen Definition und Verwaltung von Bestückungsvarianten durch Auflösung logischer Bedingungen"

92:, with the top level representing the finished product which may be a sub-assembly or a completed item. BOMs that describe the sub-assemblies are referred to as

214:, it is possible to describe the connection between parts and product variants with a Boolean expression, which refers to a subset of the set of products.

72:

whose issuance may generate reservations for components in the bill of materials that are in stock and requisitions for components that are not in stock.

68:. A BOM may be used for communication between manufacturing partners or confined to a single manufacturing plant. A bill of materials is often tied to a

353:

150:), or as they are maintained (service bill of materials). The different types depend on the business need and use for which they are intended.

537:

515:

470:

337:

681:

397:

64:

of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an

574:

added support for variants and attributes to EAGLE, it was later integrated into the author's BOM tool for automatic variant management.)

505:

308:

199:

structure in place. The modular BOM structure provides the assemblies/sub-systems that can be selected to "configure" an end-item.

729:

432:

636:

147:

724:

593:

143:

558:

592:. DfX (in German and English). Jesteburg, Germany: Mechanical Engineering & Computer-assisted Product Development,

236:

496:]. Fortschritt-Berichte VDI, Reihe 16: Technik und Wirtschaft (in German). Vol. 52. Düsseldorf, Germany:

361:

134:

layout engineer as well as the component engineer who will procure the components required for the design.

89:

554:

188:

131:

562:

389:

329:

300:

246:

80:

each product, the time-phased product structure shows the sequence and duration of each operation.

459:

PPS in automobile engineering – Production program planning and control of vehicles and assemblies

661:

462:

207:

108:

65:

687:

677:

511:

501:

466:

393:

383:

333:

304:

455:

PPS im

Automobilbau – Produktionsprogrammplanung und -steuerung von Fahrzeugen und Aggregaten

669:

653:

597:

566:

69:

385:

Das kleine QM-Lexikon: Begriffe des Qualitätsmanagements aus GLP, GCP, GMP und EN ISO 9000

211:

718:

487:

489:

Zur

Problematik der Abbildung variantenreicher Erzeugnisse in der Automobilindustrie

124:

710:

187:(CBOM) is a form of BOM used by industries that have multiple options and highly

157:

A modular BOM (or variant parts list) can be displayed in the following formats:

586:"Durchgängige Variantensteuerung mit Hilfe der regelbasierten Komplexstückliste"

196:

32:

673:

191:(e.g. telecom systems, data-center hardware (SANS, servers, etc.), PCs, cars).

649:

497:

691:

665:

657:

494:

On the problems of mapping high-variation products in the automobile industry

123:. The phrase "bill of material" (or "BOM") is frequently used by engineers

17:

241:

602:

571:

544:(Program documentation). 1.06 (also 1.09 as of 2013-03-04) (in German)

428:

146:), as they are ordered (sales bill of materials), as they are built (

638:

Variant

Management of Modular Product Families in the Market Phase

570:

notation assisting a user manually processing variant BOMs before

31:

648:(Thesis). Reihe 16: Technik und Wirtschaft. Düsseldorf, Germany:

590:

DS 98: Proceedings of the 30th

Symposium Design for X (DFX 2019)

61:

326:

Operations and

Production Systems with Multiple Objectives

36:

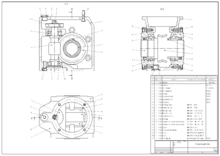

An example of a BOM for a mechanical assembly (in German)

635:

Avak, Björn (2007) . Written at Zürich, Switzerland.

565:5 to 7 with support for part databases and EAGLE's

271:) is commonly used in German-speaking countries.

142:A BOM can define products as they are designed (

210:. If the options of the product build an ideal

8:

266:

486:Herlyn, Wilmjakob Johannes (January 1990).

601:

295:Reid, R. Dan; Sanders, Nada R. (2002).

284:

258:

290:

288:

265:The abbreviation "NB" or "n.b." (for

7:

461:] (in German). Munich, Germany:

557:-based BOM management tool for the

453:Herlyn, Wilmjakob Johannes (2012).

25:

536:Paul, Matthias R. (2012-01-20) .

701:from the original on 2018-04-22

610:from the original on 2021-03-27

148:manufacturing bill of materials

111:, the BOM is also known as the

185:configurable bill of materials

1:

144:engineering bill of materials

382:Hochheimer, Norbert (2011).

173:quantity synopsis parts list

746:

594:Helmut-Schmidt-Universität

324:Malakooti, Behnam (2013).

237:Software bill of materials

27:List used in manufacturing

354:"pseudo bill of material"

658:10.3929/ethz-a-005320674

646:Fortschritt-Berichte VDI

730:Supply chain management

431:. 2012. Archived from

358:BusinessDictionary.com

267:

167:Modular (planning) BOM

37:

390:John Wiley & Sons

330:John Wiley & Sons

301:John Wiley & Sons

297:Operations Management

189:configurable products

35:

725:Production economics

303:. pp. 457–458.

674:20.500.11850/149674

247:Component placement

90:hierarchical nature

603:10.35199/dfx2019.2

463:Carl Hanser Verlag

109:process industries

38:

694:. ETH No. 16885.

567:assembly variants

516:978-3-18-145216-5

472:978-3-446-41370-2

339:978-1-118-58537-5

46:product structure

42:bill of materials

16:(Redirected from

737:

709:

707:

706:

700:

683:978-3-18318016-5

643:

622:

618:

616:

615:

605:

581:

575:

552:

550:

549:

533:

527:

525:

523:

522:

483:

477:

476:

450:

444:

443:

441:

440:

417:

411:

409:

407:

406:

399:978-3-52733076-8

379:

373:

372:

370:

369:

360:. Archived from

350:

344:

343:

321:

315:

314:

292:

272:

270:

263:

179:Configurable BOM

121:ingredients list

70:production order

50:bill of material

21:

745:

744:

740:

739:

738:

736:

735:

734:

715:

714:

704:

702:

698:

684:

641:

634:

631:

629:Further reading

626:

625:

613:

611:

583:

582:

578:

547:

545:

535:

534:

530:

520:

518:

508:

485:

484:

480:

473:

452:

451:

447:

438:

436:

419:

418:

414:

404:

402:

400:

392:. p. 277.

381:

380:

376:

367:

365:

352:

351:

347:

340:

323:

322:

318:

311:

294:

293:

286:

281:

276:

275:

268:nicht bestücken

264:

260:

255:

233:

224:

222:Multi-level BOM

212:Boolean algebra

181:

140:

105:

86:

58:associated list

28:

23:

22:

15:

12:

11:

5:

743:

741:

733:

732:

727:

717:

716:

713:

712:

682:

630:

627:

624:

623:

576:

528:

506:

478:

471:

445:

412:

398:

374:

345:

338:

316:

309:

283:

282:

280:

277:

274:

273:

257:

256:

254:

251:

250:

249:

244:

239:

232:

229:

223:

220:

180:

177:

169:

168:

165:

162:

139:

136:

104:

101:

85:

82:

26:

24:

14:

13:

10:

9:

6:

4:

3:

2:

742:

731:

728:

726:

723:

722:

720:

711:

697:

693:

689:

685:

679:

675:

671:

667:

663:

659:

655:

651:

647:

640:

639:

633:

632:

628:

621:

609:

604:

599:

595:

591:

587:

580:

577:

573:

568:

564:

560:

556:

543:

539:

532:

529:

517:

513:

509:

507:3-18-145216-5

503:

499:

495:

491:

490:

482:

479:

474:

468:

464:

460:

456:

449:

446:

435:on 2013-02-17

434:

430:

426:

422:

416:

413:

401:

395:

391:

388:(in German).

387:

386:

378:

375:

364:on 2020-08-05

363:

359:

355:

349:

346:

341:

335:

331:

327:

320:

317:

312:

310:0-471-32011-0

306:

302:

298:

291:

289:

285:

278:

269:

262:

259:

252:

248:

245:

243:

240:

238:

235:

234:

230:

228:

221:

219:

215:

213:

209:

204:

200:

198:

192:

190:

186:

178:

176:

174:

166:

163:

160:

159:

158:

155:

151:

149:

145:

137:

135:

133:

128:

126:

125:attributively

122:

118:

114:

110:

102:

100:

97:

95:

91:

83:

81:

77:

73:

71:

67:

63:

59:

55:

51:

47:

43:

34:

30:

19:

703:. Retrieved

645:

637:

612:. Retrieved

589:

579:

546:. Retrieved

541:

531:

519:. Retrieved

493:

488:

481:

458:

454:

448:

437:. Retrieved

433:the original

424:

415:

403:. Retrieved

384:

377:

366:. Retrieved

362:the original

357:

348:

325:

319:

296:

261:

225:

216:

205:

201:

193:

184:

182:

172:

170:

156:

152:

141:

129:

120:

116:

112:

106:

98:

94:modular BOMs

93:

88:BOMs are of

87:

78:

74:

57:

53:

49:

45:

41:

39:

29:

619:(12 pages)

526:(127 pages)

425:SAP ERP 6.0

421:"Super BOM"

410:(334 pages)

197:modular BOM

66:end product

48:(sometimes

18:Modular BOM

719:Categories

705:2018-04-22

650:VDI Verlag

614:2021-03-28

548:2012-02-05

521:2021-01-29

498:VDI Verlag

439:2012-07-17

405:2022-04-04

368:2018-04-17

279:References

692:0178-9597

666:0507-617X

596:: 13–24.

84:Structure

696:Archived

608:Archived

242:RKM code

231:See also

572:CadSoft

553:(NB. A

542:BOM-MPL

208:product

113:formula

60:) is a

690:

680:

664:

514:

504:

469:

396:

336:

307:

117:recipe

699:(PDF)

662:eISSN

642:(PDF)

563:EAGLE

561:tool

492:[

457:[

253:Notes

138:Types

119:, or

103:Usage

688:ISSN

678:ISBN

512:ISBN

502:ISBN

467:ISBN

394:ISBN

334:ISBN

305:ISBN

62:list

670:hdl

654:doi

598:doi

559:EDA

555:ULP

429:SAP

132:PCB

107:In

56:or

54:BOM

44:or

721::

686:.

676:.

668:.

660:.

652:.

644:.

606:.

588:.

540:.

510:.

500:.

465:.

427:.

423:.

356:.

332:.

328:.

299:.

287:^

183:A

175:.

115:,

52:,

40:A

708:.

672::

656::

617:.

600::

551:.

524:.

475:.

442:.

408:.

371:.

342:.

313:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.