411:

61:

This petroleum coke can either be fuel grade (high in sulphur and metals) or anode grade (low in sulphur and metals). The raw coke from the coker is often referred to as

77:

can be further processed in an anode baking oven in order to produce anode coke of the desired shape and physical properties. The anodes are mainly used in the

273:

58:

the long chain hydrocarbon molecules in the residual oil feed into shorter chain molecules leaving behind the excess carbon in the form of petroleum coke.

327:

118:

191:

446:

246:

415:

441:

266:

259:

367:

136:

436:

74:

298:

357:

362:

352:

377:

55:

342:

332:

32:

392:

337:

282:

104:

108:

220:

197:

187:

347:

65:. In this context, "green" means unprocessed. The further processing of green coke by

241:

146:

141:

51:

430:

372:

131:

100:

94:

28:

382:

70:

66:

36:

62:

224:

293:

201:

78:

117:

322:

165:

47:

43:

215:

Hydrocarbon

Refining staff (November 1998). "Refining Processes '98".

111:. The one that is by far the most commonly used is the delayed coker.

251:

169:

116:

114:

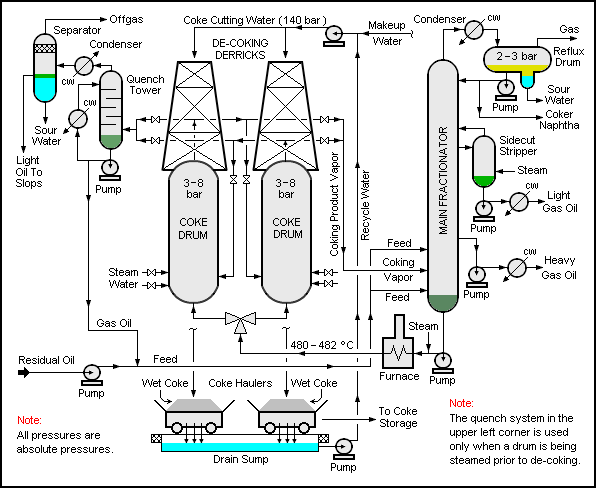

The schematic flow diagram below depicts a typical delayed coker:

82:

311:

255:

39:

73:

removes residual volatile hydrocarbons from the coke. The

121:

A typical schematic flow diagram of a delayed coking unit

99:

There are three types of cokers used in oil refineries:

31:

processing unit that converts the residual oil from the

242:Detailed description of cokers and related topics

267:

8:

184:Petroleum Refining Technology and Economics

308:

274:

260:

252:

247:Quality specifications for petroleum cokes

158:

7:

410:

186:(2nd ed.). Marcel Dekker, Inc.

182:Gary, J.H.; Handwerk, G.E. (1984).

172:Compendium of Chemical Terminology

14:

409:

1:

16:Oil refinery processing unit

463:

92:

35:into low molecular weight

33:vacuum distillation column

405:

318:

307:

289:

328:Atmospheric distillation

137:Shukhov cracking process

54:. The process thermally

75:calcined petroleum coke

299:List of oil refineries

217:Hydrocarbon Processing

168:on the website of the

122:

363:Hydrodesulphurisation

120:

447:Petroleum production

378:Solvent deasphalting

343:Catalytic reforming

333:Vacuum distillation

442:Chemical equipment

393:Amine gas treating

338:Catalytic cracking

283:Petroleum refining

123:

46:, light and heavy

424:

423:

401:

400:

454:

413:

412:

309:

276:

269:

262:

253:

229:

228:

212:

206:

205:

179:

173:

163:

462:

461:

457:

456:

455:

453:

452:

451:

427:

426:

425:

420:

397:

314:

303:

285:

280:

238:

233:

232:

214:

213:

209:

194:

181:

180:

176:

164:

160:

155:

128:

97:

91:

17:

12:

11:

5:

460:

458:

450:

449:

444:

439:

437:Oil refineries

429:

428:

422:

421:

419:

418:

406:

403:

402:

399:

398:

396:

395:

390:

385:

380:

375:

370:

365:

360:

358:Polymerisation

355:

350:

345:

340:

335:

330:

325:

319:

316:

315:

312:

305:

304:

302:

301:

296:

290:

287:

286:

281:

279:

278:

271:

264:

256:

250:

249:

244:

237:

236:External links

234:

231:

230:

207:

192:

174:

166:Petroleum coke

157:

156:

154:

151:

150:

149:

147:Petroleum coke

144:

142:Burton process

139:

134:

127:

124:

93:Main article:

90:

87:

52:petroleum coke

15:

13:

10:

9:

6:

4:

3:

2:

459:

448:

445:

443:

440:

438:

435:

434:

432:

417:

408:

407:

404:

394:

391:

389:

386:

384:

381:

379:

376:

374:

373:Hydrocracking

371:

369:

366:

364:

361:

359:

356:

354:

353:Isomerisation

351:

349:

346:

344:

341:

339:

336:

334:

331:

329:

326:

324:

321:

320:

317:

310:

306:

300:

297:

295:

292:

291:

288:

284:

277:

272:

270:

265:

263:

258:

257:

254:

248:

245:

243:

240:

239:

235:

226:

222:

218:

211:

208:

203:

199:

195:

193:0-8247-7150-8

189:

185:

178:

175:

171:

167:

162:

159:

152:

148:

145:

143:

140:

138:

135:

133:

132:Delayed coker

130:

129:

125:

119:

115:

112:

110:

106:

102:

101:delayed coker

96:

95:Delayed coker

88:

86:

84:

80:

76:

72:

68:

64:

59:

57:

53:

49:

45:

41:

38:

34:

30:

26:

22:

387:

216:

210:

183:

177:

161:

113:

98:

60:

29:oil refinery

24:

20:

18:

383:Visbreaking

105:fluid coker

71:rotary kiln

37:hydrocarbon

431:Categories

368:Sweetening

348:Alkylation

153:References

109:flexicoker

85:industry.

63:green coke

25:coker unit

323:Desalting

313:Processes

294:Petroleum

225:0887-0284

219:: 62–64.

79:aluminium

67:calcining

202:10323572

126:See also

48:gas oils

416:Commons

44:naphtha

414:

388:Coking

223:

200:

190:

56:cracks

50:, and

27:is an

170:IUPAC

89:Types

83:steel

69:in a

40:gases

21:coker

221:ISSN

198:OCLC

188:ISBN

107:and

81:and

23:or

433::

196:.

103:,

42:,

19:A

275:e

268:t

261:v

227:.

204:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.